Professional Documents

Culture Documents

Model 4WI 100 - 800 HP Boilers: 1.4 Submittals

Uploaded by

sebaversaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Model 4WI 100 - 800 HP Boilers: 1.4 Submittals

Uploaded by

sebaversaCopyright:

Available Formats

Model 4WI 100 800 HP Boilers

1.4 SUBMITTALS

A. The contractor shall submit, in a timely manner, all submittals for approval by the

engineer. Under no circumstances shall the contractor install any materials until the

engineer has made final approval on the submittals.

B. The engineer shall review and stamp submittals. Work may proceed and equipment

released for fabrication after contractor receives returned submittals stamped with

NO EXCEPTIONS TAKEN or MAKE CORRECTIONS NOTED.

C. The bidder must submit in writing to the engineer any request for a proposed

deviation, omission, modification, or substitution to this specification for evaluation no

later than ten (10) days prior to the bid date. A request for any substitution shall be

accompanied by technical data, drawings, product samples, and complete data

substantiating compliance of proposed substitution with these specifications. No

materials shall be deemed acceptable if not in strict and full compliance with these

specifications. All bidders must bid solely on the specified materials unless

acceptance by the engineer of a deviation, omission, modification, or substitution is

granted in writing to all bidders prior to the bid date.

D. Shop Drawings - Shop drawings shall be submitted to the engineer for approval and

shall consist of:

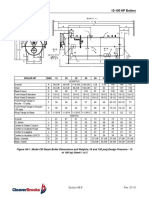

1. General assembly drawing of the boiler including product description, model

number, dimensions, clearances, weights, service sizes, etc.

2. Schematic flow diagram of gas valve trains.

3. Schematic wiring diagram of boiler control system of the ladder-type showing all

components, all interlocks, etc. Schematic wiring diagram shall clearly identify

factory wiring and field wiring.

E. Manufacturers Warranties: Manufacturers printed warranties, as specified

hereinafter, shall be submitted prior to final acceptance by the engineer.

F. Manufacturers Field Service: Manufacturers printed field service procedures and

reports, as specified hereinafter, shall be submitted prior to final acceptance by the

engineer. Report forms shall contain all information as required to do start-up and

testing as specified in the products section.

1.5 CERTIFICATIONS

A. Manufacturers Certification: The boiler manufacturer shall certify the following:

1. The products and systems furnished are in compliance with the specifications,

except as clarified in the bid package.

2. The boiler and burner have all been properly coordinated and integrated to

provide a complete and operable boiler.

3. ASME certification.

4. UL and CSD-1 (if applicable) certification.

5. The equipment furnished has been installed in accordance with the

manufacturers installation instructions.

6. The specified factory tests have been satisfactorily performed.

7. The specified field tests have been satisfactorily performed.

B. Contractors Certification: The contractor shall certify the following:

1. The products and systems installed are in strict compliance with the

specifications.

Section A2-44 Rev. 09-09

Model 4WI 100 800 HP Boilers

2. The specified field tests have been satisfactorily performed.

C. Boiler Inspectors' Certification: All boiler inspections during hydrostatic testing shall

be performed by an authorized boiler inspector who is certified by the National Board

of Boiler and Pressure Vessel Inspectors and shall be submitted in writing prior to

final acceptance by the engineer.

D. Test Reports: Factory and field test reports as described above and as specified

hereinafter, shall be submitted prior to final acceptance by the engineer.

E. Operation and Maintenance Manuals: Manufacturers printed operation and

maintenance manuals shall be submitted prior to final acceptance by the engineer.

Operation and maintenance manuals shall contain, product data, operating

instructions, cleaning procedures, replacement parts list, maintenance and repair

data, etc.

1.6 SHIPMENT, STORAGE, AND HANDLING

A. The contractor shall be responsible for the timely shipment of the equipment to the

job site. The contractor shall be responsible for unloading and rigging of the

equipment. The contractor shall be responsible for protecting the equipment from the

weather, humidity and temperature conditions, dirt, dust, other contaminants, as well

as job site conditions during construction.

B. Equipment shall be unloaded, handled, and stored in accordance with the

manufacturers handling and storage instructions.

C. The work to be performed consists of providing all labor, equipment, materials, etc. to

furnish and new factory assembled, low pressure hot water boilers as described in

the specifications herein.

PART 2 PRODUCTS

2.1 MANUFACTURERS

A. Contractor shall furnish and install Cleaver Brooks Model 4WI _____ natural gas

(combination Gas/Oil fired) hot water boiler(s) with design pressure as scheduled on

the drawings.

B. Alternate manufacturers complying with plans and specifications must be submitted

and approved by the consulting engineer within 10 days prior to bid date.

2.2 GENERAL DESCRIPTION

A. Factory packaged unit shall include boiler, burner, heavy duty skids, painted steel

jacket with two inches of fiberglass insulation, controls and accessories all piped and

wired for single point field connections. Units shall carry packaged label of

Underwriters Laboratory (UL) and be in accordance with ASME, all codes required by

the local governing authorities and as indicated on the design performance data

sheet. A certified factory fire-test shall be provided on all fuels with data sheets

furnished to Engineer and Owner. ASME certified, labeled, stamped and designed for

_____PSIG water in accordance with Section IV of ASME Code. Unit shall be

designed to Seismic Zone requirements applicable to boiler location. Manufacturers

Representative to provide services for field testing and adjusting of boiler and

controls to meet design requirements.

2.3 PERFORMANCE: BOILER SIZE AND RATINGS

A. The capacity of each unit shall be indicated on the drawing schedule.

B. Performance Criteria:

Section A2-45 Rev. 09-09

Model 4WI 100 800 HP Boilers

Performance Criteria

Manufacturer: CLEAVER-BROOKS

Model: Promethean Line

Horsepower: _____ HP

Output: _____ #/hr (from and at 212F)

Gas Input: _____ MBH

Oil Input: _____ GPH

Design Pressure: _____ PSIG

Operating Pressure _____ PSIG

Operating Temperature _____ degrees F

Heating Surface (minimum): _____ Sq. Ft. Fireside

Burner Turndown Ratio Natural Gas:

Overall Efficiency

Natural Gas (%): _____ % at High Fire

No. 2 Oil (%): _____ % at High Fire

NOX Emission (maximum)

Gas (Natural): _____ PPM (corrected to 3%O2)

Oil (No. 2): _____ PPM (corrected to 3%O2)

CO Emissions (maximum)

Gas (Natural): _____ PPM (corrected to 3%O2)

Oil (No. 2): _____ PPM (corrected to 3%O2)

Electrical: _____ V / _____H / _____P

Fan Motor: _____ HP

Air Compressor Motor: _____ HP

Oil Pump Motor: _____ HP

Noise Level (3' from burner): _____ dBA

Available Gas Supply Pressure: _____ PSIG

Weight

Dry: _____

Flooded: _____

Seismic Zone: _____

Altitude: _____ ASL

Code Requirements: ASME / NATIONAL BOARD

CSD-1 NFPA 85 (optional)

Underwriters Lab (UL)

State Of _____

Factory Mutual (FM) (optional)

GE-GAP (optional)

Section A2-46 Rev. 09-09

Model 4WI 100 800 HP Boilers

C. Noise Sound Levels: Based on ABMA test code for packaged boilers measured 4-1/2

feet vertically above the bottom of the base rail and 3'0" horizontally in front of the

end of the blower motor or front surface of control cabinet. Sound levels dBA on the

scale in reference to 0.0002 microbars.

High Fire #2 oil dBA

Low Fire #2 oil dBA

High Fire Nat Gas dBA

Low Fire Nat Gas dBA

2.4 EFFICIENCY GUARANTEE

The boiler manufacturer shall guarantee that, at the time of startup, the boiler will achieve

_____ fuel-to-steam efficiency at 100% firing rate when burning natural gas and _____

fuel-to-steam efficiency at 100% firing rate when burning oil (add efficiency guarantees at

25%, 50%, and 75% of rating, if required). If the boiler(s) fail to achieve the

corresponding guaranteed efficiency as published, the boiler manufacturer will rebate, to

the ultimate boiler owner, ten thousand dollars ($10,000) for every full efficiency point

(1.0%) that the actual efficiency is below the guaranteed level.

The specified boiler efficiency is based on the following conditions.

Natural Gas

Carbon, % (wt) = 69.98

Hydrogen, % (wt) = 22.31

Sulfur, % (wt) = 0.0

Heating value, Btu/lb. = 21,830

No. 2 Oil

Carbon, % (wt) = 85.8

Hydrogen, % (wt) = 12.7

Sulfur, % (wt) = 0.2

Heating value, Btu/lb. = 19,420

No. 6 Oil

Carbon, % (wt) = 86.6

Hydrogen, % (wt) = 10.9

Sulfur, % (wt) = 2.09

Heating value, Btu/lb. = 18,830

Efficiencies are based on ambient air temperature of 80 F, relative humidity of 30%, and

15% excess air in the exhaust flue gas.

Efficiencies are based on manufacturers published radiation and convection losses. (For

Cleaver-Brooks radiation and convection losses, see Boiler Efficiency Facts Guide,

publication number CB-7767).

Any efficiency verification testing will be based on the stack loss method.

Section A2-47 Rev. 09-09

You might also like

- Model 4WI 100 - 800 HP Boilers: 1.4 SubmittalsDocument4 pagesModel 4WI 100 - 800 HP Boilers: 1.4 SubmittalssebaversaNo ratings yet

- Industrial Process Plant Construction Estimating and Man-Hour AnalysisFrom EverandIndustrial Process Plant Construction Estimating and Man-Hour AnalysisRating: 5 out of 5 stars5/5 (1)

- Attachment 1 - Section 15620 Centrifugal ChillersDocument21 pagesAttachment 1 - Section 15620 Centrifugal ChillersMohammad Ali DiabNo ratings yet

- Request For Hot-Water-Boiler-For-AirportDocument23 pagesRequest For Hot-Water-Boiler-For-AirportHatem HadiaNo ratings yet

- 15785-Pca Air Handling UnitsDocument10 pages15785-Pca Air Handling Unitsadel rihanaNo ratings yet

- Air Conditioning System SpecificationDocument16 pagesAir Conditioning System Specification123agattarNo ratings yet

- Section 23 72 00Document7 pagesSection 23 72 00Ismail MohammadNo ratings yet

- Section 02815 FountainsDocument8 pagesSection 02815 FountainsMØhãmmed ØwięsNo ratings yet

- Foam-Water SystemsDocument10 pagesFoam-Water SystemsAlaa FouaniNo ratings yet

- SECTION 26 3213 Engine Generators Part 1 General 1.01 Section IncludesDocument31 pagesSECTION 26 3213 Engine Generators Part 1 General 1.01 Section IncludesMarcos FernandezNo ratings yet

- Kidde Spec - HPCO2 Marine - 2016-12Document4 pagesKidde Spec - HPCO2 Marine - 2016-1299No ratings yet

- Project Standard Specification: Rotary-Screw Chillers 15684 - Page 1/11Document11 pagesProject Standard Specification: Rotary-Screw Chillers 15684 - Page 1/11adel rihanaNo ratings yet

- Chlorination Equipment - MSTDocument20 pagesChlorination Equipment - MSTwafikmh4No ratings yet

- 23 6418 Oil Free Centrifugal Water Chillers 111001Document11 pages23 6418 Oil Free Centrifugal Water Chillers 111001Mohd RizalNo ratings yet

- Model 4WI 100 - 800 HP BoilersDocument4 pagesModel 4WI 100 - 800 HP BoilerssebaversaNo ratings yet

- 1-Any Item Mentioned in The Manufacturer Reply As by CONTRACTOR, Should Be Replied Again by Contractor and Included in His Scope of WorkDocument5 pages1-Any Item Mentioned in The Manufacturer Reply As by CONTRACTOR, Should Be Replied Again by Contractor and Included in His Scope of WorkLi LiuNo ratings yet

- Technical Requirements, Specifications and Bidding Documents: Dated: 11-14-2016Document20 pagesTechnical Requirements, Specifications and Bidding Documents: Dated: 11-14-2016Savy PhanethNo ratings yet

- P KG Waste Water TreatmentDocument28 pagesP KG Waste Water TreatmentsoetrisnoNo ratings yet

- Part 1 - General: SpecificationsDocument6 pagesPart 1 - General: SpecificationsDiego Plata VasquezNo ratings yet

- Technical Specification Section - Viii: 1. General Information and Scope 1.1 ScopeDocument19 pagesTechnical Specification Section - Viii: 1. General Information and Scope 1.1 ScopeMl JainNo ratings yet

- Computer-Room Air ConditionersDocument19 pagesComputer-Room Air ConditionersAbdullah.N FAAliNo ratings yet

- 43 00 00 - LPG InstallationDocument13 pages43 00 00 - LPG InstallationNiong David100% (1)

- Chapter 2 - ChillersDocument33 pagesChapter 2 - ChillersRajesh VenkiteswaranNo ratings yet

- Chlorination Equipment - MSTDocument24 pagesChlorination Equipment - MSTwafikmh4No ratings yet

- Hvac - Tech SpecificationsDocument181 pagesHvac - Tech Specificationsganesha raoNo ratings yet

- CITY WALK (RESI 1 & 2) - Project Specific Details - REV 3 (17-12-2019)Document4 pagesCITY WALK (RESI 1 & 2) - Project Specific Details - REV 3 (17-12-2019)FarisNo ratings yet

- Series e 80 SpecificationsDocument7 pagesSeries e 80 SpecificationsJavier CastilloNo ratings yet

- HVAC Mechanical Specification M2 1Document4 pagesHVAC Mechanical Specification M2 1Bernadas PabloNo ratings yet

- Air Cooled Screw Liquid Free Cooling Chiller - YORK YVFA R134a 50Hz & 60HzDocument6 pagesAir Cooled Screw Liquid Free Cooling Chiller - YORK YVFA R134a 50Hz & 60Hzalf_haroNo ratings yet

- HVAC TescomDocument14 pagesHVAC Tescomamsal kotoNo ratings yet

- Multi Indoor Unit VRFDocument18 pagesMulti Indoor Unit VRFVu SonNo ratings yet

- SECTION 23 65 00 Cooling TowersDocument28 pagesSECTION 23 65 00 Cooling TowersDivyansh Singh ChauhanNo ratings yet

- Specification PipaDocument103 pagesSpecification Pipamechanical 1No ratings yet

- Oil Immersed TransformerDocument8 pagesOil Immersed TransformerAbdul JabbarNo ratings yet

- Automatic Fire Sprinkler SystemDocument16 pagesAutomatic Fire Sprinkler SystemArnel ArnaoNo ratings yet

- SOW - Repair of Ex Unit 1 Turbine CasingR1Document5 pagesSOW - Repair of Ex Unit 1 Turbine CasingR1neiltaneo96No ratings yet

- 300 KW EB Melting Furnace: Scope of Work 1.0 General Scope of WorkDocument14 pages300 KW EB Melting Furnace: Scope of Work 1.0 General Scope of Workjkhgvdj mnhsnjkhgNo ratings yet

- Spec-K102 ADS N1230 2016 PDFDocument7 pagesSpec-K102 ADS N1230 2016 PDFshayan351No ratings yet

- AES Vol 2 P15007 Split AC UnitsDocument5 pagesAES Vol 2 P15007 Split AC UnitsShreejith PanickerNo ratings yet

- DD Electric Driven Fire Pump SpecificationDocument16 pagesDD Electric Driven Fire Pump SpecificationNurcahyo Djati WNo ratings yet

- GeneratorDocument19 pagesGeneratoruddinnadeemNo ratings yet

- Wet Pipe Sprinkler SystemDocument12 pagesWet Pipe Sprinkler SystemrockykrishNo ratings yet

- Modifications/Changes in This UpdateDocument20 pagesModifications/Changes in This UpdateMary Joy PaunilNo ratings yet

- 211313P Fire Protection Sprinkler and Standpipe Systems 05-17-2023Document23 pages211313P Fire Protection Sprinkler and Standpipe Systems 05-17-2023fazil yoosufNo ratings yet

- Generator SET Specification: Caterpillar Diesel Generator SetsDocument24 pagesGenerator SET Specification: Caterpillar Diesel Generator SetsRaed Al-HajNo ratings yet

- Ahu CRSDocument4 pagesAhu CRSMaqbool FatimaNo ratings yet

- 14 21 00 MRL and MRA Electric Traction Passenger Elevators (Schindler Elevator Corporation)Document10 pages14 21 00 MRL and MRA Electric Traction Passenger Elevators (Schindler Elevator Corporation)Bahaa RaslanNo ratings yet

- Kidde Clean Agent Fire Extinguishing SystemDocument6 pagesKidde Clean Agent Fire Extinguishing SystemAhmed AhmedabdelrazekNo ratings yet

- Modifications/Changes in This UpdateDocument19 pagesModifications/Changes in This UpdateAdea CarolNo ratings yet

- SpecsDocument6 pagesSpecsTAHANINo ratings yet

- Tender Specifications HVACDocument100 pagesTender Specifications HVACCau Vo100% (1)

- Fire Fighting Pumping SystemDocument23 pagesFire Fighting Pumping Systemvirtech100% (1)

- Air Cooled Water Chiller-SpecsDocument9 pagesAir Cooled Water Chiller-SpecsShrikant SomvanshiNo ratings yet

- Diesel Engine GeneratorDocument35 pagesDiesel Engine GeneratorIatan AlexandruNo ratings yet

- Packaged Outdoor Central StationDocument14 pagesPackaged Outdoor Central StationAbdullah.N FAAliNo ratings yet

- Fiberglass Density Current Baffles - MSTDocument10 pagesFiberglass Density Current Baffles - MSTwafikmh4No ratings yet

- Fire Protection SpecDocument70 pagesFire Protection SpecZezo Abdallah100% (1)

- Kidde - Spec - ECS - Novec 1230 - 8-14 PDFDocument7 pagesKidde - Spec - ECS - Novec 1230 - 8-14 PDFMarcio BritoNo ratings yet

- Afss Specs Homeaid Aug 20,2016Document16 pagesAfss Specs Homeaid Aug 20,2016jhecyNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-14. No. 2 Oil Piping, Multiple Boiler InstallationsebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: 1.04 Burner and ControlsDocument5 pagesModel CB 15-100 HP Boilers: 1.04 Burner and ControlssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: LightsDocument5 pagesModel CB 15-100 HP Boilers: LightssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementDocument5 pagesModel CB 15-100 HP Boilers: Figure A6-19. Breeching ArrangementsebaversaNo ratings yet

- Model CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)Document5 pagesModel CB Hot Water Boiler (15-100 HP, 30 PSIG, 125 PSIG)sebaversaNo ratings yet

- Section A5: Model CBL 900-1800 HP BoilersDocument5 pagesSection A5: Model CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EDocument5 pagesModel CB 15-100 HP Boilers: Boiler HP View All Dimensions in Inches A B C D EsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporDocument5 pagesModel CB 15-100 HP Boilers: Table A6-22. Maximum Gas Consumption (CFH) For Natural Gas and Propane VaporsebaversaNo ratings yet

- Features and Benefits: Model CB 15-100 HP BoilersDocument5 pagesFeatures and Benefits: Model CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CB 15-100 HP BoilersDocument5 pagesModel CB 15-100 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNo ratings yet

- Model CB 15-100 HP Boilers: Sound LevelDocument5 pagesModel CB 15-100 HP Boilers: Sound LevelsebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Front Feedwater TankDocument5 pagesModel CBR 125-800 HP Boilers: Front Feedwater TanksebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Engineering DataDocument5 pagesModel CBL 900-1800 HP Boilers: Engineering DatasebaversaNo ratings yet

- Model CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizeDocument5 pagesModel CBL 900-1800 HP Boilers: Table A5-11. CBL Recommended Steam Nozzle SizesebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteeDocument5 pagesModel CBR 125-800 HP Boilers: 2.05 Efficiency GuaranteesebaversaNo ratings yet

- Model CBR 125-800 HP BoilersDocument5 pagesModel CBR 125-800 HP BoilerssebaversaNo ratings yet

- Model CBL: 900 - 1800 HP Steam Wet-Back Package BurnerDocument5 pagesModel CBL: 900 - 1800 HP Steam Wet-Back Package BurnersebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutDocument5 pagesModel CBR 125-800 HP Boilers: Figure A10-10. Typical Gas Piping LayoutsebaversaNo ratings yet

- 78Document5 pages78sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EDocument5 pagesModel CBR 125-800 HP Boilers: Boiler H.P. Dimensions (Inches) A B C D EsebaversaNo ratings yet

- Model CBL 900-1800 HP BoilersDocument5 pagesModel CBL 900-1800 HP BoilerssebaversaNo ratings yet

- 81Document5 pages81sebaversaNo ratings yet

- 75Document5 pages75sebaversaNo ratings yet

- Model CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2Document6 pagesModel CBR 125-800 HP Boilers: Figure A10-2. Model CBR Hot Water Boiler Dimensions - Sheet 1 of 2sebaversaNo ratings yet

- General: Model ICB 100-800 HP BoilersDocument4 pagesGeneral: Model ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP BoilersDocument4 pagesModel ICB 100-800 HP BoilerssebaversaNo ratings yet

- Model ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimDocument4 pagesModel ICB 100-800 HP Boilers: 2.2 Hot Water Boiler TrimsebaversaNo ratings yet

- Manual XLDocument45 pagesManual XLdan popNo ratings yet

- Material and Energy Balance-GeneralDocument30 pagesMaterial and Energy Balance-GeneralOmesh Borole100% (2)

- Boiler Feed PumpDocument12 pagesBoiler Feed PumpFirdaus Syifaan PratamaNo ratings yet

- Detailed CV P Basu June 24Document4 pagesDetailed CV P Basu June 24Pravin ShindeNo ratings yet

- Selected SELO AnnouncementsDocument7 pagesSelected SELO AnnouncementsSalvatore CannataNo ratings yet

- Meo Class IV Steam BitsDocument26 pagesMeo Class IV Steam BitsVijay Prakash100% (3)

- 1 Question Function 6 4bDocument29 pages1 Question Function 6 4bArun GouthamNo ratings yet

- Proper Steam Turbine OperationDocument32 pagesProper Steam Turbine OperationBalasubramanian C100% (1)

- 02 PDFDocument6 pages02 PDFSerban LucianNo ratings yet

- Ariston Clas24 30Document76 pagesAriston Clas24 30anca_dovleacNo ratings yet

- Form H-3 Manufacturer'S Data Report For Watertube Boilers As Required by The Provisions of The ASME Code Rules, Section IVDocument2 pagesForm H-3 Manufacturer'S Data Report For Watertube Boilers As Required by The Provisions of The ASME Code Rules, Section IVmohdfirdausNo ratings yet

- Boiler SafetyDocument40 pagesBoiler SafetyCarl Stien0% (1)

- Drawings of Heat and Power Plant & Coal Gas Station: Technical DesignDocument39 pagesDrawings of Heat and Power Plant & Coal Gas Station: Technical Designtieu quyNo ratings yet

- Boiler Safety ValveDocument12 pagesBoiler Safety ValveJaroslav Kuruc100% (2)

- ALDE Comfort - 29232928 Service ManualDocument28 pagesALDE Comfort - 29232928 Service ManualAnders TärnbrantNo ratings yet

- Syllabus Btech CeDocument15 pagesSyllabus Btech CePrasanna MuleyNo ratings yet

- Miura EGE BoilerDocument3 pagesMiura EGE BoilerHenry Roa MalubayNo ratings yet

- Case StudyDocument60 pagesCase Studyj4leschelNo ratings yet

- Guidelines For The Registration of Boilers and Pressure VesselsDocument4 pagesGuidelines For The Registration of Boilers and Pressure Vesselsprabhu74No ratings yet

- Boilar Mounting and AccessoriesDocument44 pagesBoilar Mounting and AccessoriesSyam RajuNo ratings yet

- Westinghouse 9.5 in Air Compressor Manual From 1917Document37 pagesWestinghouse 9.5 in Air Compressor Manual From 1917John Galt Fan75% (4)

- Lalit Gujral - Macawber Beekay PDFDocument50 pagesLalit Gujral - Macawber Beekay PDFkalai100% (1)

- Eolo Mini User Manual PDFDocument27 pagesEolo Mini User Manual PDFFlorian Leordeanu0% (1)

- Control Systems TimelineDocument34 pagesControl Systems Timelinepedrohcg100% (1)

- Calculating The True Cost of SteamDocument2 pagesCalculating The True Cost of Steamisquare77No ratings yet

- Marine Engineering KnowledgeDocument1,055 pagesMarine Engineering KnowledgebalajimeieNo ratings yet

- Opi-Overhauling & Maint. MGMTDocument183 pagesOpi-Overhauling & Maint. MGMTVIBHAV100% (1)

- Steam Engineering TutorialsDocument208 pagesSteam Engineering Tutorialsaecsuresh35No ratings yet

- EcoMAX 800 D1 DTR Wydanie 1.2 enDocument40 pagesEcoMAX 800 D1 DTR Wydanie 1.2 enAlin Beșa100% (1)

- Boiler Statutes RulesDocument24 pagesBoiler Statutes RulesSubburajMechNo ratings yet

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsFrom EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsRating: 4 out of 5 stars4/5 (4)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Heavy and Extra-heavy Oil Upgrading TechnologiesFrom EverandHeavy and Extra-heavy Oil Upgrading TechnologiesRating: 4 out of 5 stars4/5 (2)

- Essentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesFrom EverandEssentials of Coating, Painting, and Lining for the Oil, Gas and Petrochemical IndustriesRating: 5 out of 5 stars5/5 (5)

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityFrom EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityRating: 3 out of 5 stars3/5 (2)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Advanced Production Decline Analysis and ApplicationFrom EverandAdvanced Production Decline Analysis and ApplicationRating: 3.5 out of 5 stars3.5/5 (4)

- Gas and Oil Reliability Engineering: Modeling and AnalysisFrom EverandGas and Oil Reliability Engineering: Modeling and AnalysisRating: 4.5 out of 5 stars4.5/5 (6)

- Hydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&AFrom EverandHydro Testing Handbook: Principles, Practices, Applications, Formulas, and Common Q&ANo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)