Professional Documents

Culture Documents

Ceiling-M Panel 300

Uploaded by

Sujeevan TharmakulasingamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ceiling-M Panel 300

Uploaded by

Sujeevan TharmakulasingamCopyright:

Available Formats

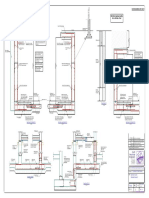

Material Specification Fixing

M Metal is a Singapore-based manufacturer of high quality Our sense of responsibility extends to workplace safety. M-Panel 300 is manufactured from steel grade G300 with a Fasteners

minimum yield stress of 300MPa and paint coating of It is important that the correct fasteners are used so that

M Metal - a

TIMBER SUPPORT

steel and non-steel roofing and walling products. We strongly believe that good safety equates good

ColorLume® VF-20L PVDF 70/30 (Fluorocarbon), which offers it is compatible with the cladding material selected, and

business. Through regular training sessions, we make Grade Hardwood Softwood

superior gloss and colour retention.

game changer We started the company in 2007 in response to what we

saw was a growing industry need for a responsible supplier,

sure that our workers, and also those of our contractors,

are able to do a good job safely. Optional paint system in ColorLume® SMP (Silicone Modified

matches with the cladding’s life expectancy.

Directly to

support

No. 10 - 12 x 25mm

wafer-head type 17

No. 10 - 12 x 46mm

wafer-head type 17

which believes in the value of forging partnerships with Polyester) is also available. The fasteners used for installation of M-Panel 300 sheeting self drilling wood screw; self drilling wood screw

3.75mm x 50mm flat-head

stakeholders in order to deliver innovative, reliable and Staffed by experienced professionals with an in-depth to the structural support shall conform to AS3566 – Class 3

ColorLume® VF-20L top-coat is derived from a reliable 2-coat/ spiral threaded nail

customized solutions. It is our breadth and depth of knowledge of the industry and who are motivated by the or Class 4, and should be self-drilling with a wafer head. (on special orders).

2-bake Fluorocarbon (PVDF) process with over 70% of KYNAR

specialized knowledge, combined with our stakeholders’ company’s vision - to be the industry’s preferred building

500® or HYLAR 5000® paint system, and AZ 200 (200g/m2)

awareness of their client needs, which results in a win-win solutions provider from concept to completion - we aim STEEL SUPPORT

coating mass of zinc/aluminium alloy substrate complying with

collaboration. to be a game-changer in Singapore’s building industry. FEATURES OF FASTENER

ASTM A792M. AZ 200 comprises 55% aluminium, 43.5% zinc Thickness Up to 4.5mm Exceeds 4.5mm

and 1.5% silicon, and is widely known as Galvalume* for

Directly to No. 10 - 24 x 16mm Teks 5 • Forged drill point

long-term performance against corrosion as determined by support wafer-head self drilling No. 12 - 24 x 32mm • Strip out resistant

Australian Standard AS1397-2011. and tapping screw and tapping screw • Higher pullout load

M-PANEL 300 Benefits of Thickness & Weight

• Zinc alloy proven corrosion protection

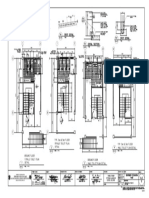

Lightweight, easy and fast M-PANEL 300 Standard

to install with concealed • It is extremely versatile – it can be laid vertically or

Base Metal Thickness

Total Coated Thickness

0.55mm

0.61mm

Hoarding Application

fixing method

horizontally depending on the architect’s design - and Weight 6.10 kg/m 2 It is perfect for hoarding and totally transforming the

can be used in ceilings, soffit, fascia, wall and hoarding appearance of a building site.

* Galvalume® is a registered trademark of BIEC International Inc (USA) licensed to

applications. YP Enterprise Co., Ltd.

* For colour selection, please refer to our colour chart or the actual colour plate sample.

M-Panel 300 laid

Specular gloss to finish is 25~30 G.U. (Gloss Unit is measured at 60˚ reflection angle

• It is extremely strong and can be used for exterior and in accordance to ASTM D 523 : 2008 / SS 5 Part E1 : 2003 Performance Standards). in horizontal direction

interior walls.

• It is fast and easy to install, using the concealed fixing

method, which is also aesthetically pleasing as the

Material

fasteners are invisible. Performance Test

M-Panel 300 laid

Typical Test Standard Correspond to Singapore in vertical direction

• It is rigorously made with machines built on German Properties (Method) Standard SS370:1994*

technology so that its profile, at 25mm height and

T-Bend Test ASTM D 4145-10 AS 2728

300mm width, is accurately manufactured. Installation of panels for hoarding application is not recommended to be

Pencil Hardness ASTM D 3363-09e2 ASTM D 3363 laid in direct contact with ground level.

Colour ASTM D 2244-11 SS Part E3

• There is flexibility in paint choices. M-Panel 300 can be

Specular Gloss ASTM D 523-08 SS 5 Part E1

M-Panel 300 is a rigorously manufactured, light-weight coated in superior long-lasting ColorLume® VF-20L

and aesthetically-pleasing flat steel panel which is extremely PVDF (Fluorocarbon) paint for internal and external Dry Film Thickness ASTM D 7091-05 SS 5 Part B1 Compatibility Length

Impact Resistance JIS K5600-5-3 ISO 6272 All products should be checked for compatibility with adjacent M-Panel 300 claddings are supplied to your custom cut-to-length

versatile in its range of uses. applications requiring high gloss and colour

materials before installation. It is important to check the implications requirements. Recommended length not exceeding 6 metres.

retention, ColorLume ® SMP (Silicone Modified Humidity Resistance JIS K5600-7-2 SS 5 Part G6

of direct contact between materials, and water runs from one Maximum sheet length shall be subject to regulatory limits for

Polyester) or PE (Polyester) for hoardings, showflats Cross Cut Adhesion JIS K5600-5-6 ISO 2409 material to another. transportation, practical handling, site constraints, design, etc.

The manufacturing tolerence on the length of product supplied is

and temporary buildings. Galvalume®/ColorLume® SMP/ColorLume® PVDF and Polyester ±10mm.

Corrosion & Test Standard Correspond to Singapore prepainted steel sheets should not be in direct contact with

Weathering (Method) Standard SS370:1994* copper, lead, green or treated timber, stainless steel and mortar

Other choices of non-ferrous materials are also available on request. Please

contact M Metal Pte Ltd for more information. Salt Spray Test ASTM B 117-09 SS 5 Part G1

or concrete. Oil Canning

Oil canning describes how flat surfaces tend to show variations

Weathering Test ASTM G 154-06 SS 5 Part G4

Handling / Storage in reflectivity (waviness). The level of oil canning depends on the

ability of the metal sheet to distribute stresses caused by

Acid Resistance (10%v/v HCL) JIS K5600-6-1 ISO 2812

M-Panel 300 should be handled with care at all times to preserve temperature change across the surface. Oil canning is inherent

* Material performance for the manufacture of profiled roof and wall cladding conforms the quality of its finish and product capabilities. Packs should in flat sheets; it is a characteristic, not a defect, and it should

to Singapore Standard 370 : 1994 Specification for Metal Roofing. be stored above ground level while on site, and kept dry. not be used as the basis for panel rejection.

You might also like

- FLOOR 2AACAsdcfdfefwaswe2dcdcedDocument1 pageFLOOR 2AACAsdcfdfefwaswe2dcdcedKanak YadavNo ratings yet

- Chi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsDocument1 pageChi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsPhanLạcKhanhNo ratings yet

- Gaskets PDFDocument58 pagesGaskets PDFAmit SharmaNo ratings yet

- Ridge Installation GuideDocument1 pageRidge Installation GuideGeorgios PNo ratings yet

- EagleBurgmann Catalog Compression Packings en 26.11.2015Document30 pagesEagleBurgmann Catalog Compression Packings en 26.11.2015Anh Võ ĐứcNo ratings yet

- Technical Data Reynobond and Reynolux .: Aluminium Composite Panels and SheetsDocument2 pagesTechnical Data Reynobond and Reynolux .: Aluminium Composite Panels and Sheetsfarah rosaNo ratings yet

- WEDDING AREA REVISED-s1Document1 pageWEDDING AREA REVISED-s1benjie baunNo ratings yet

- FischerPANEEL 06 2012 Engl IDocument12 pagesFischerPANEEL 06 2012 Engl IviviNo ratings yet

- Off R1Document1 pageOff R1Josphat benzNo ratings yet

- MAG'Impact: The High-Performance Impactor: Cubicity and SimplicityDocument5 pagesMAG'Impact: The High-Performance Impactor: Cubicity and SimplicityPrekelNo ratings yet

- Wa0000.Document3 pagesWa0000.nmarozhe_225151671No ratings yet

- C.H. - 0+465.5 Section No5Document1 pageC.H. - 0+465.5 Section No5Fran LuqueNo ratings yet

- Ydr DMSF LDocument2 pagesYdr DMSF Lsf wNo ratings yet

- 06020101_DTF Structural drawingsDocument35 pages06020101_DTF Structural drawings宋海波No ratings yet

- Calf Pen Design and DimensionsDocument1 pageCalf Pen Design and DimensionsfwaksNo ratings yet

- 30° roof galvanized IBR sheetsDocument1 page30° roof galvanized IBR sheetsanzaniNo ratings yet

- A (44) SeriesDocument4 pagesA (44) SeriesSsenyonjo EricNo ratings yet

- 3M Quick Reference Guide Jun17Document10 pages3M Quick Reference Guide Jun17Faith_No_MoreNo ratings yet

- Compression Packings: Rely On ExcellenceDocument30 pagesCompression Packings: Rely On ExcellenceAnonymous s6WwRJVSxmNo ratings yet

- Li.05-DR-2500 Typical Landscape DetailsDocument1 pageLi.05-DR-2500 Typical Landscape Detailsstupido3337No ratings yet

- Maritime Progress BookDocument64 pagesMaritime Progress Bookfle92No ratings yet

- CV Flexible Body Filler, Light Grey: Technical InformationDocument2 pagesCV Flexible Body Filler, Light Grey: Technical InformationGoodBoi EsberNo ratings yet

- Universityofst - Louis Freiya - Jane Unday Activity 1 Ar. Jorge BaccayDocument1 pageUniversityofst - Louis Freiya - Jane Unday Activity 1 Ar. Jorge BaccayFreiya - Jane UndayNo ratings yet

- General steel and concrete notesDocument1 pageGeneral steel and concrete notesLeonard MwangokaNo ratings yet

- 200mm thick masonry wall tile flooringDocument1 page200mm thick masonry wall tile flooringmaxNo ratings yet

- Details of external facade glass wall systemDocument1 pageDetails of external facade glass wall systemEng.Hesham AL-HelaleeNo ratings yet

- S1-521 Ticket Counter Details 02Document1 pageS1-521 Ticket Counter Details 02Milan PuzigaćaNo ratings yet

- Toll Plaza PCC Bar-1Document1 pageToll Plaza PCC Bar-1Praveen KumarNo ratings yet

- 72M - 151KMPH (18Sqm) - ISO FDN - 150KPADocument2 pages72M - 151KMPH (18Sqm) - ISO FDN - 150KPAZili Avebe SergesNo ratings yet

- TGS Sukhoi Su-35sDocument1 pageTGS Sukhoi Su-35sairsoft doença100% (1)

- Power Tap SwitchesDocument2 pagesPower Tap Switchesmikepower007No ratings yet

- Sainte Lizaigne e Cub sl003 enDocument4 pagesSainte Lizaigne e Cub sl003 enPartene PaulaNo ratings yet

- Transformers - App Guide 2015Document6 pagesTransformers - App Guide 2015Florin AdrianNo ratings yet

- Section Aa': Plan-Ground FloorDocument1 pageSection Aa': Plan-Ground FloorSardar DwivediNo ratings yet

- 0120 CSS Subsea Diver Installed ConnectorsDocument2 pages0120 CSS Subsea Diver Installed ConnectorsThamer KhatibNo ratings yet

- Drawing - BasementDocument1 pageDrawing - BasementCanny EngineerNo ratings yet

- High pressure laminate wall cladding documentDocument1 pageHigh pressure laminate wall cladding documentAngelyka Ablog AsadaNo ratings yet

- SKF Double Direction Angular Contact Thrust Ball Bearings For Screw DrivesDocument12 pagesSKF Double Direction Angular Contact Thrust Ball Bearings For Screw DrivesSusmit patelNo ratings yet

- 5 - Sections PDFDocument1 page5 - Sections PDFforbeskaNo ratings yet

- Acuv Stage 5-PlansDocument1 pageAcuv Stage 5-PlansMonde Tidimalo Lunathi MbaluNo ratings yet

- KENT Year 2 Sustainable-Housing A3Document1 pageKENT Year 2 Sustainable-Housing A3Ralph KentNo ratings yet

- Redkite ExamplesDocument2 pagesRedkite ExamplesIan LeaperNo ratings yet

- C2 Columns ReinforcementDocument1 pageC2 Columns ReinforcementMilad Ahmad MSTNo ratings yet

- 202 Sections EE & FFDocument1 page202 Sections EE & FFD HOLNo ratings yet

- OPB - GWPC - Letter - en - Abril2020Document2 pagesOPB - GWPC - Letter - en - Abril2020rafaelberaldiNo ratings yet

- Shop Materials and Pipe Supports ListDocument1 pageShop Materials and Pipe Supports ListABDERRAZZAKNo ratings yet

- Detail 2Document1 pageDetail 2KangBaharNo ratings yet

- Castillejos WELL DataDocument3 pagesCastillejos WELL DataJohn Christopher BaquingNo ratings yet

- C&T Store. FRP Traditional Cornices, Dingri and Lungzey.: TH TH THDocument3 pagesC&T Store. FRP Traditional Cornices, Dingri and Lungzey.: TH TH THkassovNo ratings yet

- Jotun Light Industry SolutionDocument4 pagesJotun Light Industry SolutionPt sun jaya nusantaraNo ratings yet

- Executive - Parking REV.2 Layout1Document1 pageExecutive - Parking REV.2 Layout1Fadhlan Husnul YaqinNo ratings yet

- 10ENA01BR003 Sheet3-ModelDocument1 page10ENA01BR003 Sheet3-ModelValesh MonisNo ratings yet

- Advance Direction Sign PDFDocument1 pageAdvance Direction Sign PDFVignesh ChettiyarNo ratings yet

- Section-1 Section-2 Section-3: Bureau of DesignDocument1 pageSection-1 Section-2 Section-3: Bureau of DesignGarry WaveNo ratings yet

- Spot Detail Det. Elevation of Ramp Spot Detail: A-6 5a A-6 5b 5b1Document1 pageSpot Detail Det. Elevation of Ramp Spot Detail: A-6 5a A-6 5b 5b1Jhn Cbllr BqngNo ratings yet

- Concrete Column ScheduleDocument1 pageConcrete Column ScheduleShariah MelonNo ratings yet

- 06 Ground Floor PlanDocument1 page06 Ground Floor PlanCiobanu BogdanNo ratings yet

- Muloho A3 Page SizeDocument1 pageMuloho A3 Page SizeanzaniNo ratings yet

- 1st FLOOR 2 PDFDocument1 page1st FLOOR 2 PDFci_balaNo ratings yet

- Professional Exams in Engineering OverviewDocument62 pagesProfessional Exams in Engineering OverviewSujeevan TharmakulasingamNo ratings yet

- EOTA TR29 Design of Bonded AnchorsDocument36 pagesEOTA TR29 Design of Bonded Anchorsl282No ratings yet

- Euro Truss PDFDocument92 pagesEuro Truss PDFSujeevan TharmakulasingamNo ratings yet

- Steel To Concrete Joints Design-Manual II enDocument292 pagesSteel To Concrete Joints Design-Manual II enSujeevan Tharmakulasingam100% (2)

- GTL S13 Undrained AnalysisDocument14 pagesGTL S13 Undrained AnalysisSujeevan TharmakulasingamNo ratings yet

- Glass in BuildingsDocument176 pagesGlass in BuildingsPranay Varma100% (10)

- A Teaching Guide For Structural Steel ConnectionsDocument85 pagesA Teaching Guide For Structural Steel Connectionsv97% (65)

- Cec5 5Document0 pagesCec5 5denis1808scribdNo ratings yet

- Cec5 5Document0 pagesCec5 5denis1808scribdNo ratings yet

- BS 812-103.2 PDFDocument13 pagesBS 812-103.2 PDFUpali KarunarathneNo ratings yet

- BS En160947-4-1-1992Document117 pagesBS En160947-4-1-1992Sujeevan TharmakulasingamNo ratings yet

- Gee 2017Document10 pagesGee 2017Sujeevan TharmakulasingamNo ratings yet

- Deep Excavations FoundationsDocument182 pagesDeep Excavations Foundationsbannasengineer94% (18)

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- Review of English Tenses: Affirmative Negative Interrogative FormDocument4 pagesReview of English Tenses: Affirmative Negative Interrogative FormSujeevan TharmakulasingamNo ratings yet

- ProLock Luxury Collection 160320Document28 pagesProLock Luxury Collection 160320jaganrajNo ratings yet

- ISO 17746-2016 Steel Wire Rope Net Panels and RollsDocument24 pagesISO 17746-2016 Steel Wire Rope Net Panels and RollsOctavian Miclescu100% (1)

- Nasa Passivation TestDocument134 pagesNasa Passivation Testlmayhew100% (1)

- Technolgy Information Surface Protection Retaining RingDocument1 pageTechnolgy Information Surface Protection Retaining Ringm4ri01981No ratings yet

- Astm B633Document6 pagesAstm B633Shawn Deol100% (1)

- Thalachrome Se 500: High Corrosion ResistanceDocument1 pageThalachrome Se 500: High Corrosion ResistancethyskieNo ratings yet

- Alpha Series - Front End Cylinder With Single EyeDocument2 pagesAlpha Series - Front End Cylinder With Single EyeAji Aryandie100% (1)

- Ficha Técnica Bisagras Certf. UlDocument3 pagesFicha Técnica Bisagras Certf. UlQuiroa, Antonio JNo ratings yet

- Actuadores Neumaticos TS - AdasDocument25 pagesActuadores Neumaticos TS - AdasDaniel SanNo ratings yet

- Dovetail Deck Coating SolutionsDocument2 pagesDovetail Deck Coating SolutionsDan SmithNo ratings yet

- BS 362 ConnectorDocument20 pagesBS 362 ConnectorAndreas SchlagerNo ratings yet

- Fixtures & Solutions For Electronics Stores & Mobile Stores-1Document30 pagesFixtures & Solutions For Electronics Stores & Mobile Stores-1Vinay SawarkarNo ratings yet

- 21TR1 E1a2-20200401Document6 pages21TR1 E1a2-20200401toddflyNo ratings yet

- Axalta PaintDocument8 pagesAxalta PaintElliza IshakNo ratings yet

- Ascott Manual S Ip RangeDocument80 pagesAscott Manual S Ip Rangejeremias100% (1)

- Chennai Mettex Lab Testing FacilitiesDocument14 pagesChennai Mettex Lab Testing Facilitiesmetallurgy mettexNo ratings yet

- GMR Nottingham K Ficha TecnicaDocument7 pagesGMR Nottingham K Ficha TecnicaVictor Manuel Bocanegra GarciaNo ratings yet

- STAUFF Catalogue 1 STAUFF Clamps EnglishDocument172 pagesSTAUFF Catalogue 1 STAUFF Clamps EnglishСергейNo ratings yet

- DP B58W00610Document4 pagesDP B58W00610tangouzeNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataJamal Mohamed RahamathullahNo ratings yet

- En 50979Document14 pagesEn 50979rajeskumarNo ratings yet

- METAL PAINTING SPECIFICATIONSDocument14 pagesMETAL PAINTING SPECIFICATIONSIm ChinithNo ratings yet

- GMW 3044 Zinc Plating TrivalentDocument5 pagesGMW 3044 Zinc Plating TrivalentRaymond100% (1)

- BS en 10223-7-2002Document17 pagesBS en 10223-7-2002Eidrish Shaikh100% (1)

- Hadzich2018 PeruDocument12 pagesHadzich2018 PeruJose CornejoNo ratings yet

- 4628 8 PDFDocument16 pages4628 8 PDFTomasPavlovicNo ratings yet

- METALUBE OCG5000 Statement of ConformityDocument3 pagesMETALUBE OCG5000 Statement of ConformityMohammedNo ratings yet

- BS en 12330Document19 pagesBS en 12330OmerfAtaNo ratings yet

- AnodizingDocument14 pagesAnodizingvikeshmNo ratings yet

- 09-Samss-069 Qualification Requirements For Epoxy Coatings For Atmospheric ServiceDocument10 pages09-Samss-069 Qualification Requirements For Epoxy Coatings For Atmospheric ServicealiabdulhamidNo ratings yet