Professional Documents

Culture Documents

BTL Detection PDF

BTL Detection PDF

Uploaded by

Mohsin ImamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BTL Detection PDF

BTL Detection PDF

Uploaded by

Mohsin ImamCopyright:

Available Formats

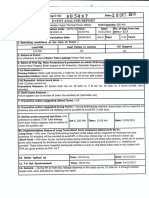

Early BTL detected and Immediate Unit Shut down.

Load-500Mw Coal Flow-300T/Hr

DETAILS OF THE INCIDENT:-

Primary Observation:

At 2:17hrs:

1) Sudden increase (-10 t to 7mmwc) in Furnace Pressure was noted and Drum level dipped to -

75 mm.

2) Feed water suddenly increased by 150T/Hr. Difference in BLI and Feed –Water noted, as was

reflected in their trends.

3) DM make up increased to maintain hot well level.

4) ALSD graph running in alarm (red color) zone for some locations.

Secondary Observations:

1) ID-Fans loading were increased.(270 A-300 A)

2) Flue gas temperature at Platen I/L-Left stated to decrease from 905 C and came down to 711

C.in 12m.

Actions taken:

1) Boiler round taken immediately and abnormal sound, suspected to be due to BTL, located to

goose neck area.

2) BMD was informed for conformation of BTL

3) At 03:23 hrs. Unit shut down taken after reducing Unit load to minimum and following

necessary protocols after BTL confirmation.

The alertness and timely action shown resulted in immediate detection of BTL and shut down

of Unit, and prevented from any secondary damage to boiler.

Suggestion: Provide alarm in LVS for any spike in ASLD value.

You might also like

- Level RR /: 5.Observations:-Coalmillcd&Efwereinservice ItDocument1 pageLevel RR /: 5.Observations:-Coalmillcd&Efwereinservice ItSE ESTNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Abnormality Prediction During Furnace Operation (C) Rev1Document35 pagesAbnormality Prediction During Furnace Operation (C) Rev1Shauvik Roy100% (1)

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Paras-3 18.12.2013Document1 pageParas-3 18.12.2013SE ESTNo ratings yet

- Analysis: cHN/poc/rrippins/c-42t EventDocument3 pagesAnalysis: cHN/poc/rrippins/c-42t EventSE ESTNo ratings yet

- Visvesvaraya National Institute of TechnologyDocument5 pagesVisvesvaraya National Institute of TechnologyAbhishekRajeshDhobeNo ratings yet

- Thermal and Electrical Conductivity of MetalsDocument4 pagesThermal and Electrical Conductivity of MetalsNani Neijie50% (2)

- GPIL - SOP For OperationDocument5 pagesGPIL - SOP For OperationMurali Krishnan NairNo ratings yet

- GE Water PoliaminesDocument5 pagesGE Water PoliaminesVitor MarquesNo ratings yet

- Tube Swelling and Broken Hole in The Auxiliary Boiler Water Tube (Riser Tube)Document2 pagesTube Swelling and Broken Hole in The Auxiliary Boiler Water Tube (Riser Tube)Rani NoumanNo ratings yet

- Report On Potable Water High Temperature Issue Rev-1Document3 pagesReport On Potable Water High Temperature Issue Rev-1tere_naam8812142No ratings yet

- 78.89C (Under Survey) : April 6th)Document38 pages78.89C (Under Survey) : April 6th)EnformableNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument2 pagesEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- ANDAL Lampiran4 Coal Stockpile Management SelfCombustion Control ProcedureDocument4 pagesANDAL Lampiran4 Coal Stockpile Management SelfCombustion Control Procedurefranco_2010100% (1)

- Event Ana U#7,2006 - CompletedDocument31 pagesEvent Ana U#7,2006 - CompletedGajanan JagtapNo ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- HTL-04 Thermal Conductivity of LiquidDocument2 pagesHTL-04 Thermal Conductivity of Liquidvindiesel9222No ratings yet

- Event Analysis Report: 4 X 210 MW Cstps ChandrapurDocument1 pageEvent Analysis Report: 4 X 210 MW Cstps ChandrapurGajanan JagtapNo ratings yet

- Ti Sputter Ion Pump ..Contd &: Introduction To CryogenicsDocument15 pagesTi Sputter Ion Pump ..Contd &: Introduction To CryogenicsRakesh KumarNo ratings yet

- HT Lab Manual FinalDocument58 pagesHT Lab Manual Finalsharadesh sarnaikNo ratings yet

- Unit-1 Tripping 28-3-2009Document1 pageUnit-1 Tripping 28-3-2009Gajanan JagtapNo ratings yet

- Critical Heat FluxDocument4 pagesCritical Heat FluxAshish VermaNo ratings yet

- Reformer Component Management After An Overheating Incident That Resulted in Tube FailuresDocument12 pagesReformer Component Management After An Overheating Incident That Resulted in Tube FailuresGrootNo ratings yet

- CO2 Data Density (Kennedy, G.C.) - 422 - OCR PDFDocument18 pagesCO2 Data Density (Kennedy, G.C.) - 422 - OCR PDFshaonaaNo ratings yet

- Lot 6 - Calorimeter - Manual 2Document2 pagesLot 6 - Calorimeter - Manual 2MichaelNo ratings yet

- Pump Explosions AmplatsDocument85 pagesPump Explosions AmplatsArun KumarNo ratings yet

- Operated.: Event Analysis ReportDocument1 pageOperated.: Event Analysis ReportSE ESTNo ratings yet

- Kiln Heat-Up, Optimun Kiln OperationDocument42 pagesKiln Heat-Up, Optimun Kiln OperationJoko Dewoto100% (11)

- Ffis:Chandrapursuperthermalpowerstutioffi:500Mw: Zuij Event Analysis ReportDocument2 pagesFfis:Chandrapursuperthermalpowerstutioffi:500Mw: Zuij Event Analysis ReportSE ESTNo ratings yet

- Thermometry: T/s T/KDocument9 pagesThermometry: T/s T/KJing Yu VoonNo ratings yet

- ZEMATRA - Density With HeatingDocument2 pagesZEMATRA - Density With Heatingadit interlabNo ratings yet

- DH02 FL - Site Survey NNB - EquipmentDocument12 pagesDH02 FL - Site Survey NNB - Equipmentnhutbang21891No ratings yet

- E X T e N S I V e F U R N A C e Q U e N C H E X C H A N G e R D A M A G e S D U e T o P o o R B o I L e R F e e D W A T e R Q U A L I T yDocument26 pagesE X T e N S I V e F U R N A C e Q U e N C H E X C H A N G e R D A M A G e S D U e T o P o o R B o I L e R F e e D W A T e R Q U A L I T yAdriano Dorneles de OliveiraNo ratings yet

- Thermal Conductivity of Metal RodDocument6 pagesThermal Conductivity of Metal Rodanil chejara100% (7)

- Reduction in Boiler Cooling TimeDocument16 pagesReduction in Boiler Cooling Timejp mishraNo ratings yet

- A1 Batch NKC Sir Heat Thermodynamics KTG 1637843224143Document57 pagesA1 Batch NKC Sir Heat Thermodynamics KTG 1637843224143Harsh SinghNo ratings yet

- Conditions of Fukush'Iima Dai-Ichi Nuclear Power Station Unit 1 (As O6f 7 00 April 22nd, 2011) - Pages From ML12122A221-6Document14 pagesConditions of Fukush'Iima Dai-Ichi Nuclear Power Station Unit 1 (As O6f 7 00 April 22nd, 2011) - Pages From ML12122A221-6EnformableNo ratings yet

- Handling Power and Steam Outage in DCU Vinothkanna Pai MRPL DCU Mumbai 2016 PDFDocument22 pagesHandling Power and Steam Outage in DCU Vinothkanna Pai MRPL DCU Mumbai 2016 PDFFayaz MohammedNo ratings yet

- ARU Re-Boiling Issue TroubleshootingDocument7 pagesARU Re-Boiling Issue TroubleshootingXevierNo ratings yet

- Case Study Unit-4 10.06.2017 Condenser Vacuum DeteriorationDocument1 pageCase Study Unit-4 10.06.2017 Condenser Vacuum Deteriorationjp mishraNo ratings yet

- Critical Heat Flux ApparatusDocument6 pagesCritical Heat Flux Apparatusأشرف عليNo ratings yet

- Latent Heat VaporizationDocument3 pagesLatent Heat VaporizationerorkinNo ratings yet

- Exercises Ch2 2Document3 pagesExercises Ch2 2rawan falatahNo ratings yet

- Experiment No.: 1: Aim: Thermal Conductivity of Metal RodDocument4 pagesExperiment No.: 1: Aim: Thermal Conductivity of Metal RodHardik Kumar MendparaNo ratings yet

- Event Analysis Report: DaieDocument2 pagesEvent Analysis Report: DaieSE ESTNo ratings yet

- 8 - ORT - April-2016 PDFDocument62 pages8 - ORT - April-2016 PDFVikranth ChintaparthiNo ratings yet

- 7 Station: Date: Evei (T AnalysisDocument2 pages7 Station: Date: Evei (T AnalysisSE ESTNo ratings yet

- CDU IV Highlights 21-Feb'2024Document2 pagesCDU IV Highlights 21-Feb'2024Manjunath GangaramNo ratings yet

- Control System Response During TripDocument5 pagesControl System Response During TripVPORWALNo ratings yet

- Echo Yodel Heat Radiation-Report 3035780 01Document29 pagesEcho Yodel Heat Radiation-Report 3035780 01Mortadha Al-YahyaNo ratings yet

- Thermoanalytical and X-Ray Studies Rapidly Solidified K&03: G. VassilevDocument11 pagesThermoanalytical and X-Ray Studies Rapidly Solidified K&03: G. VassilevEngineering Office ShahrakNo ratings yet

- Unit 5 Student Version - EngDocument16 pagesUnit 5 Student Version - EngMoonLove月戀No ratings yet

- BOF Plant Write UpDocument20 pagesBOF Plant Write UpKalyan HalderNo ratings yet

- Boiler-Water ChemistryDocument94 pagesBoiler-Water ChemistryPRAG100% (3)

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningFrom EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningRating: 5 out of 5 stars5/5 (2)