Professional Documents

Culture Documents

Optimization of Shell and Tube Heat Exchanger 1 PDF

Uploaded by

SynesiusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Optimization of Shell and Tube Heat Exchanger 1 PDF

Uploaded by

SynesiusCopyright:

Available Formats

Optimization of shell and tube heat exchanger

SCHOOL OF ENGINEERING AND TECHNOLOGY

Student name: Salah Hewidi

MSc Mechanical Engineering

Msc project (interim report)

Course: EN 541

Project title: Optimization of shell and tube heat exchanger

Supervisor: Dr. Ken Leung

Year of submission: 2004

School of Engineering and Technology 1

Optimization of shell and tube heat exchanger

Abstract:

Shell and tube type heat exchangers are widely used in process industries, for economic reasons;

there is a need for a new optimization approach for shell and tube type heat exchanger design

and operation.

The objective function is to achieve a minimal total annual cost of heat exchangers, Pressure

drop and heat transfer are interdependent, and both of them strongly influence capital and

operating costs of any heat transfer system.

In designing a heat exchanger, it is necessary to determine the optimal dimensions of the

exchanger with the given conditions of the equipment operation.

The goal is to obtain the most economically optimal design. An economic assessment allows a

comparable estimation of various alternatives. The total annual cost consisting of fixed and

variable costs of the heat exchanger were selected as a criterion that summarizes different factors

of influence into one objective function. Major cost components of a heat exchange system are

capital, operating.

A thermal-hydraulic model for shell and tube heat exchangers has been derived. It represents the

relationship between heat transfer, pressure drop and exchanger area, and gives the possibility to

predict heat transfer coefficients from pressure drops. It is used in the optimal design of shell and

tube heat exchangers.

School of Engineering and Technology 2

Optimization of shell and tube heat exchanger

Contents

. Nomenclature

1. Introduction

2. Background theory

2.1 Heat exchanger

2.2 Shell and tube heat exchanger

2.3 Heat exchanger performance

2.4 Heat exchanger performance improvement

2.5 The case study

3. Data procedures for heat exchanger optimization

4. Calculation and results

5. Conclusions

6. Future work

7. Reference:

8. Appendix

School of Engineering and Technology 3

Optimization of shell and tube heat exchanger

Nomenclature

A Heat transfer area, m²

b spacing between bafflers, mm

c clearance between tubes, mm

Cp heat capacity per unit mass at constant pressure, j/kgk

Cmin small thermal capacity

d diameter of tubes, mm

D diameter of shell, mm

ε effectiveness of heat transfer, dimensionless

G mass flow rate, kg/sm²

h film heat transfer coefficient, w/m²k

hf fouling factor, w/m²k

j heat transfer factor, dimensionless

k thermal conductivity, w/mk

L length of tube per pass, m

m number of rows of tubes accommodated in half the shell, dimensionless

M mass flow rate, kg/s

nd maximum number of tubes on inside diameter of shell, dimensionless

nn equivalent number of tubes for two nozzles, dimensionless

nt total number of tubes, dimensionless

np equivalent number of tubes for two passes divider, dimensionless

NTU number of transfer units, dimensionless

Pr prandtl number, dimensionless

p tube pitch, mm

P power, w

R heat capacity ratio, dimensionless

Re Reynolds number, dimensionless

T temperature, ºC

u mean linear velocity, m/s

U overall heat transfer coefficient, w/m²k

School of Engineering and Technology 4

Optimization of shell and tube heat exchanger

x thickness of tube wall, mm

∆p pressure drop, N/m²

μ dynamic viscosity of fluid, Ns/m²

ρ density of fluid, kg/m³

Subscripts

C referring to cooler fluid

e referring to equivalent

H referring to hotter fluid

i referring to inside

o referring to outside

s referring to shell

t referring to tube

School of Engineering and Technology 5

Optimization of shell and tube heat exchanger

1. Introduction

Shell and tube heat exchangers the most commonly used in process industries because of their

relatively simple manufacturing and their adaptability to different operating conditions.

The principle of operation is simple enough: Two fluids of different temperatures are brought

into close contact but are prevented from mixing by a physical barrier. The temperature of the

two fluids will tend to equalize. By arranging counter-current flow it is possible for the

temperature at the outlet of each fluid to approach the temperature at the inlet of the other. The

heat contents are simply exchanged from one fluid to the other and vice versa. No energy is

added or removed.

High primary energy consumption is typical of the chemical and process industries. Each

production is tied up with requirements for profitability and process efficiency.

Shell and tube heat exchangers distinguishes itself by low-pressure drops with high flow

velocities; the capital requirement of it, as well as the associated flow (i.e. the combined power

and capital) cost requirement due to pressure drops of the pumped streams in a unit can be very

expensive. In addition, the dependence of total cost to capital or current requirements is highly

affected by commercial policies of the company Optimization of shell and tube heat exchangers

from an economic point of view involves both capital and operating costs, those which gain

importance because of the current and future share of the market of this heat exchanger type in

various industries. Unfortunately, the known commercial design procedures and tools do not

consist of optimization strategies. However they are presented as simplified expressions

describing interactions between heat transfer and pressure drop which can be used to optimize

the design of these kinds of heat exchangers.

The objective is to illustrate the use of the transfer method for optimum size on basis of

minimum annual cost of a 1 – 2 shell and tube heat exchanger used by Jowfe oil

Technology Company at Libya, required to cool an organic liquid by using water flowing

through the shell as coolant [13].

School of Engineering and Technology 6

Optimization of shell and tube heat exchanger

2. Background Theory

Heat Transfer Concepts Heat is a form of energy that is transferred from one body to another

body flows due to difference in temperature, the heat transfers from the hotter body to the colder

one. This will continue until the temperatures of the bodies are the same (thermal equilibrium).

The transfer of heat occurs via one or any combination of the three modes of heat transfer -

conduction, convection and radiation. Generally, the radiation heat transfer is of little importance

for heat exchangers operating at low temperatures.

Heat Flow through a Pipe The heat transfer through a pipe is dependent on the thickness of the

pipe layer. The thickness of the pipe can be defined by the radius of layers i.e. Din, and Dout the

thermal conductivity of layer is, K The fluid within the pipe is at temperature Tin, and the heat

transfer coefficient from fluid to the wall is h in. The temperature and heat transfer coefficient

for the fluid outside the pipe are Tout and h out. By using Fourier’s law of conduction and

Newton’s law of cooling, it can be shown that for a steady state heat transfer [6]:

din

Rin Rw Rout

Tin,hin T1 T2 Tout,hout Tin T1 T2 Tout

dout

Figure (1) Pipe drawing show heat flow

·

Q = UA(Tin - Tout ) ……………………………………………………………………………... (1)

2.1 Heat exchanger.

Heat Exchanger many engineering applications involve a process of heat exchange it’s built for

efficient heat transfer from one fluid to another. Some examples of application are intercoolers,

preheaters, boilers, condensers in chemical processing, and air conditioning [6].

School of Engineering and Technology 7

Optimization of shell and tube heat exchanger

2.1.1 Types and classification of heat exchanger:

1. Recuperative type: In which fluids exchange heat from hot fluid to the cold fluid.

2. Regenerative type: in which hot and cold fluids works alternatively as a sink or source

for heat flow through a matrix.

3. Direct type: in which fluids direct contact in the same space.

The recuperative type of heat exchanger which is the most common in practice can be classified

according to one of the following types Parallel-flow, Counter-flow, and Cross-flow as in fig (2)

[3].

Th

Tc

Tc

Th

Figure (2) Heat exchanger classification

2.2 Shell and tube Heat exchanger

The most common type of heat exchanger used in industry contains a number of parallel tubes

enclosed in a shell and is thus called a shell and tube heat.

School of Engineering and Technology 8

Optimization of shell and tube heat exchanger

The shell and tube heat exchanger consists of a cylinder (shell) to pack in a large number of

tubes. The inner fluid flow through several of tubes, the outer fluid flow through the shell and

forced be buffers, which provided to support the tubes, and direct the fluid flow and increase the

turbulence, consequently improve the convection heat transfer [7].

Tube outlet Shell inlet

Baffles Shell outlet Tube inlet

Figure (3) Shell and tube heat exchanger

2.2.1 Type of shell tube exchanger

1. Fixed – tube plate.

2. U – tube.

3. Internal floating head without clamp ring.

4. Internal floating head with clamp ring.

5. External floating head packed gland.

6. Kettle reboiler with U – tube bundle [7].

2.2.2 Tube arrangements

The tubes are usually arranged in equilateral triangular or square pattern as shown in figure (4)

di

[7] do

Flow

P C P

Figure (4) Tube arrangement

School of Engineering and Technology 9

Optimization of shell and tube heat exchanger

2.2.3 Tube passes

The fluid in the tube is usually directed to flow back and forth in a number of passes to increase

the length of the flow path. The arrangement of the pass partition for 2, 4, and 6 tubes are shown

in figure (5) [7].

Figure (5) Tube passes

2.2.4 Baffles

Baffles are used in the shell to direct the fluid stream across the tube, to increase the fluid

velocity and so improve the rate of transfer. The most commonly used type of baffle shown in

figure (6) [7].

Figure (6) Baffles

School of Engineering and Technology 10

Optimization of shell and tube heat exchanger

2.3 Heat exchanger performance:

2.3.1 Heat Exchanger Effectiveness

Heat Exchanger Effectiveness is defined as the ratio of the actual rate of heat transfer Q to the

maximum theoretically possible of heat transfer Qmax [4]

e = Q Qmax …………………………………………………………………………………... (2)

2.3.2 The Number of Transfer Units

The number of transfer units (NTU) is a measure of a heat exchanger's ability to transfer heat by

consider of heat exchanger size factor [4].

NTU = UA C min ……………………………………………………………………………... (3)

2.4 Heat exchanger performance improvement

To get the most out of a heat exchanger means saving money, particularly if the process is built

for a long-term operations. Some ways to improve the performance of a heat exchanger:-

1. Heat transfer area .

2. Fluid flow velocity .

3. Temperature gradient [4].

2.4.1 Heat transfer area

As the equation (1), the heat transfer area is directly proportional to the heat transfer rate. As the

heat transfer area increases, heat transfer rate increases.

2.4.2 Fluid flow rate velocity

As the cooling fluid velocity increases, the cooling fluid is able to dissipate heat more

effectively.

School of Engineering and Technology 11

Optimization of shell and tube heat exchanger

2.4.3 Temperature gradient

Temperature gradient is an important factor of heat transfer. It is the driving force for heat

transfer. If we can introduce fluids with larger temperature difference into the heat exchanger,

the heat transfer rate (Q) will be higher [4] .

2.5 The case study.

To optimize the size of a 1 – 2 shell and tube heat exchanger required to cool 20 kg/s of an

organic liquid from 70°c to 50°c using water flowing through the shell as coolant. The water

enters at 20°c and leaves at a temperature not exceed 50°c. The steel tubes used of 20SWG

thickness having an outside diameter of 19 mm. the tube have a length of 2.4 and are laid out on

a 25mm triangle pitch. The shell contains 25 per cent cut segmental baffles space 15.25mm apart

[13].

Chemical Chemical

reactor N1 reactor N2

Heat exchanger

Chemical pump

To cleaning taps

Water pump

Figure (7) Plant layout

School of Engineering and Technology 12

Optimization of shell and tube heat exchanger

2.5.1 Equipment data for 1-2 Exchanger fig. (8) [13].

L

Shell

di do

Tubes

Di

Figure (8) Exchanger dimension describe

Data of heat exchanger an on Jowfe Oil Company [13]

b = 152.4 mm , d o =19 mm , p = 25 mm , De = 17.27 mm , L =2.4 mm , x=2 mm

c = 6 mm , d i =15 mm , d m = 17 mm , At = 8.835 ´ 10 -5 nt mm²

As = 0.036576 Ds mm² , k = 45 W/mk

2.5.2 Physical data [13].

Tube side Organic liquid [13]

µ = 0.00045 Ns/m²

ρ = 881 kg/m³

Cp = 1675 j/kgk

k = 0.1731 W/mk

Pr = 4.35

Shell side Water specification in appendix (1)

School of Engineering and Technology 13

Optimization of shell and tube heat exchanger

3. Data procedures for heat exchanger optimization

To optimize the heat exchanger calculations proceeded as follow:

1- One of the factors which effective on the performance of the exchanger is heat transfer area

accordingly, to optimize the exchanger five inside shell diameters selected Ds (0.25, 0.3, 0.35,

0.4,and 0.45 m) based the exchanger used by the company.

2- Tube side heat transfer calculations as in appendix (1).

3- Shell side heat transfer calculations as in appendix (1)

4- Overall heat transfer calculations as in appendix (1).

5- plot the actual and the required heat transfer coefficient vs. the heat transfer area for each

value of the water outlet temperature Tc(outlet), from these curves read off the values of area at

the point where the actual and the required overall heat transfer coefficients U are the same, at

each value of Tc(outlet)

6- plot the values of the temperatures Tc(outlet) which actual and required U are the same vs. the

area, and read off the values of the water outlet temperature Tc(outlet) which correspond to the

heat transfer areas of the 1-2 shell and tube heat exchangers with standard shell inside diameters.

7- The pressure drop, pressure drop and power calculations an in appendix (1).

8- Estimation the fixed capital cost for the equipment from figure. [11]

9- Power consuming cost calculated basis of the electrical power cost rate 0.15£/kW

10- Plot the total power cost for 5 years operating vs. the operating hours per day to select the

optimum heat exchanger according to the daily operating hours.

School of Engineering and Technology 14

Optimization of shell and tube heat exchanger

4. Calculation and results

4.1 tube side coefficient:

Table (1) shows an example of the results obtained for the heat transfer in the tube side

(complete results shown on table (1) appendix (2). the principles of the study are as follow:

1- As the inside shell diameter increase the number of the tubes increases consequently the

heat transfer area increase.

2- From the results the Reynolds number is > 2100 the flow is therefore well into the turbulent

region for all options.

3- Since the mass flow rate of the organic liquid is constant, therefore as the number of the

tubes increases the (Re) decreases.

Table (1) Tube side heat transfer calculations (organic liquid)

Options selected 1

Ds ( inside shell diameter(m)) 0.25

nt (corrected no. of tubes) 60

At (the cross sectional flow area(m²)) 0.00529875

u s (the mean linear velocity(m/s²)) 4.284307732

G h (the mass flow rate(kg/sm²)) 3774.475112

Re (Reynolds number) 125815.8371

j h (heat transfer factor) 0.002578794

hi (inside film heat transfer coefficients(w/m²k)) 6117.773381

As (the cross sectional flow area for the shell stream(m²)) 0.009144

A (heat transfer area(m²)) 6.7854

School of Engineering and Technology 15

Optimization of shell and tube heat exchanger

4.2 Shell side coefficient:

Table (2) shows an example of the results obtained for the heat transfer in the shell side.

(Complete results shown on table (2) appendix (2)). The principles of the study are as follow:

1- For different outlet temperatures the mass flow rate of water decreases as the outlet

temperatures increases.

2- As the outlet temperature, and the inside shell diameter increases, the flow forward to the

laminar flow.

Table 2 Shell side heat transfer calculations (water)

Tc(outlet(ºC)) 26

mc (mass flow rate(kg/s)) 26.69399606

Tc(mean(ºC) 23

Cp(heat capacity of water(j/kgk)) 4183.212825

µ(dynamic viscosity of water) 0.000939019

k c (thermal conductivity of water(w/mk)) 0.6146288

Pr (Prandtl number) 6.391035246

(Gc)s (mass flow rate (kg/m²s)

for Di = .25 2919.290908

(Re)s (Reynolds number)

for Di = .25 53690.26573

( j h )s (heat transfer factor)

for Di = .25 0.002611284

(hi )s (film heat transfer coefficient(w/m²k))

for Di = .25 9253.91388

School of Engineering and Technology 16

Optimization of shell and tube heat exchanger

4.3 Overall coefficient

Table (3) shows an example of the results obtained for the overall heat transfer in the heat

exchanger, (complete results shown on table (3) appendix (2)).

By Comparing between the required and actual overall heat transfer coefficient for each inside

shell diameter and the tube outlet temperature, the results plot on figure (9).

Table 3 Overall heat transfer calculations

Tc(outlet(ºC)) 26

mc*Cp 111666.6667

E (effectiveness of heat transfer) 0.4

R (heat capacity ratio 0.3

NTU ( number of transfer units) 0.64

UiAi (w/k) 21440

Ui(overall heat transfer coefficient (w/m²k))

required for Di = .25 3159.725293

actual for Di = .25 2341.972084

Ai (area (m²) where required U = actual U) 9.3

School of Engineering and Technology 17

Optimization of shell and tube heat exchanger

heat transfer coefficient vs heat transfer Area figure (9)

4600

4100

3600

3100

2600

U

2100

1600

1100

600

9.3 12.9 17.7 23.9

0.00 5.00 10.00 15.00 20.00 25.00 30.00

Area

Actual U at Tc(outlet)=26 Actual U at Tc(outlet)=32 Actual U at Tc(outlet)=38

Actual U at Tc(outlet)=44 Actual U at Tc(outlet)=50 Required U at Tc(outlet)=26

Required U at Tc(outlet)=32 Required U at Tc(outlet)=38 Required U at Tc(outlet)=44

Required U at Tc(outlet)=50

From these curves read off the values of area at the point where the actual and the required

overall heat transfer coefficients U are the same and compare with the outlet water

temperature as shown in figure (10)

heat transfer area vs cooling water temp.figure(10)

25

Area of exchanger

20 A=19.6,Di=.4

heat transfer area vs

cooling water temp.

15 A=14.7,Di=.35

A=10.4,Di=.3

10

5

26 31 36 41 46

Cooling water tempetature

- It's clearly from fig (10) that as outlet water temperature arise the heat exchanger needs

bigger.

- To find for the optimum heat exchanger power consuming must be calculate.

School of Engineering and Technology 18

Optimization of shell and tube heat exchanger

4.4 Pressure drop and power

Complete results shown on table (4) appendix (2). The principles of the study are as follow:

1- As the inside shell diameter increase the pressure drop in the exchanger reduced

consequently the power required to pumping the fluids though the exchanger reduced

2- As the heat exchanger area increased fixed capital cost for the heat exchanger and pumps

increase.

3- As the heat exchanger area increased the variable (operating) cost decreases.

4- the best results is the summation of all capital and operating costs for 5 years operating

and find the lower overall cost figure (11).

total cost figure (11)

35000

total power cost for 5 years operating

33000

31000

29000

27000

(£)

25000

23000

21000 Total cost =19820 £

19000

shell inside diameter0.3 m

17000

15000

shell inside diameter0.35 m

8 9 101112131415161718192021222324

operating hours per day(h) shell inside diameter0.4m

School of Engineering and Technology 19

Optimization of shell and tube heat exchanger

4.5 Specification for optimum exchanger

Data for the optimum 1-2 Shell and tube heat exchanger, selected on basis of minimum annul

cost, are summarized in table (4)

Table 4 specification for optimum exchanger

Inside diameter of shell Di 0.4 m

Total number of tubes nt 174

Heat transfer area A 19.677 m²

Flow rate of water through the shell mc 8.092 kg/s

Outlet temperature of water Tc 40ºC

School of Engineering and Technology 20

Optimization of shell and tube heat exchanger

5. Conclusions

- The most economical design of heat exchangers, depends upon an optimum balance

between the heat transfer area and the energy consumption arising because from the

pressure drop of streams on both sides of the exchanger.

- It was found that the 0.4 m inside shell diameter exchanger, gave the economical design

for 5 years operating 24hrs a day.

- Exchangers with 0.25, and .45 m inside shell diameter rejected because it's not met the

operation conditions.

- Because the owner using the outlet water for cleaning purpose not recycling, which mean

no extra energy added to the cycle, and the higher outlet water temperature 40ºC will be a

benefit for the cleaning.

School of Engineering and Technology 21

Optimization of shell and tube heat exchanger

6. Future work

According to the study on this project, it is necessary to enhance the overall surface heat transfer

rate. This may achieved by lowering the convective resistance by increasing the convective heat

transfer coefficient or from the lowering the conductive resistance by increasing the surface area,

the latter can be achieved by extending the surface area through the addition of fins.

Future work will be to study the fins and how it will improve the heat exchanger which is

optimized on this part of project.

Gantt chart for future task

Project part one January 04 July04 August 04 Septemer04

Task description w1 w2 w3 w4 w1 w2 W3 w4 w1 w2 w3 w4 w1 w2 w3 w4

1 Supervisor meeting ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌

▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌

2 Library search for useful books ▌ ▌ ▌

▌ ▌ ▌ ▌

3 Internet search for useful website ▌

▌

4 Available source study ▌ ▌ ▌

▌ ▌ ▌ ▌

5 Data submissions ▌

▌

6 Calculation ▌ ▌ ▌ ▌

▌ ▌ ▌ ▌

7 Result analysis ▌ ▌

▌ ▌

8 Report writing ▌

▌ ▌

9 Report submission ▌

▌

▌Planning ▌Actual

Project part two October 04 November 04 December 04 January 05

Task description w1 w2 w3 w4 w1 w2 w3 w4 w1 w2 w3 w4 w1 w2 w3 w4

1 Supervisor meeting ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌ ▌

2 Library search for useful books ▌▌▌▌ ▌▌ ▌▌

3 Internet search for useful website ▌▌

4 Available source study ▌▌▌▌▌▌▌▌

5 Data submissions ▌▌

6 Calculation ▌▌▌▌▌▌▌▌

7 Result analysis ▌▌▌▌

8 Report writing ▌▌▌

9 Report submission ▌

w = weeks

4 hr daily study

School of Engineering and Technology 22

Optimization of shell and tube heat exchanger

7. Reference:

1. James P. Hartnett, Tomas F. Irvine, Advances in heat transfer, vol.15, Academic press,

1982.

2. J. P. Holman, Heat transfer, ed.7, McGraw-Hill, 1992

3. Christopher long, Essential heat transfer, Longman, 1999

4. Donald R. Pitts, Leighton E. Sissom, Theory and problems of heat transfer, ed 2,

schaum’s outline series, McGraw-Hill, 1997.

5. Jesse S. Doolittle, Francis J. Hale, Thermodynamics for engineers, John Wiley & sons,

1984.

6. T. D. Eastop, A. Mcconkey, Applied thermodynamics for engineering technologists, ed 5,

Longman, 1993.

7. R. K. Sinnott, Chemical engineering, Vol. 6, ed. 3, Butterworth Heinemann, 1999.

8. Howard F. rase, Chemical reactors design for process plants, Vol. 1, principles and

techniques, John Wiley & sons, 1977

9. Zhang Zhnegguo, Experimental study on heat transfer enhancement of a helically

baffled heat exchanger combined with three-dimensional finned tubes, Science direct ,

Applied thermal engineering, vol.24, issue 14-15, February 2004

10. B. Khalifeh Soltan, M. Saffar-AvvalMinimizing ,capital and operating costs of shell and

tube condensers using optimum baffle spacing Science direct , Applied thermal

engineering, June 2004

11. Thomas Aichera, Holger Martin Rayleigh–Benard convection in vertical shell and tube

heat exchangers ,Science direct, Chemical Engineering and Processing

Volume 38, Issues 4-6 , September 1999,

12. Equipment costs. www.matche.com.

13. Data source, operation manger, Jowfe Oil Technology Libya

School of Engineering and Technology 23

Optimization of shell and tube heat exchanger

Appendix 1(equations used for calculation)

In this appendix show all equations used to optimize the exchanger:-

1- Physical data of Water [7].

1

µ = 0.1/ [2.14819{(TºK -281.635) + [8087.4+ (TºK – 281.635)²] 2 } - 120] …...........................(1)

ρ= 1200.92 – 0.015739TºK + 0.0010824(TºK) ² …………………………………...(2)

Cp = 0.015539(TºK – 308.2) ²+4180.9 …………………………………………...(3)

k =0.34+0.0009278 TºK …………………………………………………………...(4)

2- Data procedures for heat exchanger optimization

2.1- The heat flow rate Q (w), given by: [2]

Q = m h (c p )h [Th (inlet ) - Th (outlet )] = m c (c p )c [Tc (outlet ) - Tc (inlet )] …………………...(5)

· ·

·

2.2- The flow rate of water m c (kg s ) , given by: [2]

· Q

mc =

(c p )c [Tc (outlet ) - Tc (inlet )] ……………………………………………………….(6)

2.3- The total numbers of tubes nt for several 1-2 shell and tube heat exchangers each with a

standard shell inside diameter, given by: [7]

nt = m(2nd - m ) ………………………………………………………………...............(7)

Di

nd = - 1 ……………………………………………………………………………...(8)

p

m = .577n d + .423 ………………………………………………………………………(9)

2.4- The Reynolds number Re, given by: [5]

Gd i

Re = ……………………………………………………………………………...(10)

m

2.5- Heat transfer factor jh, given by: [2]

0.027

2.5.1- For tube side Re greater than 10000 j h = ………………….........................(11)

Re 0.2

School of Engineering and Technology 24

Optimization of shell and tube heat exchanger

0.351

2.5.2- For shell side Re greater than 5000 j h = ………………………….............(12)

Re 0.45

2.6- The film heat transfer coefficient hi, given by: [2]

j h (c p )h G h

2.6.1- For tube inside ji = …………………………………………………….(13)

prh2 3

j h (c p )c Gc

2.6.2- For shell side ji = 2

…………………………………………………….(14)

prc 3

Where:

cpm

2.6.3- Pr is the Prandtl number = ……………………………………………………(15)

k

2.7- The cross sectional flow area As for shell side, given by: [7]

As =

( pt - d o )bDi …………………………………………………………………….(16)

pt

2.8- The heat transfer area At based on the inside diameter of the tubes, given by: [7]

At = p .d i L.nt …………………………………………………………………………..(17)

2.9- Actual overall heat transfer U, given by: [6]

æd ö

d i ln çç i ÷÷

1 1 d

= + i + è do ø + 1 ……………………………………………………(18)

U i hi hs d o 2k hf

2.10- The effectiveness of heat transfer e , search for (mc p )min given by: [2]

c h (Th,i - Th ,o ) cc (Tc ,o - Tc ,i )

e= = ………………………………………………….(19)

c min (Th,i - Tc,i ) c min (Th ,i - Tc ,i )

2.11- The of heat capacity rate ratio, given by: [7]

(mc )p min

R= ………………………………………………………………………….(20)

(mc )p max

2.12- The number of transfer units NTU, read of from the graph of e vs. NTU for each value

of e and R.

2.13- The required overall heat transfer coefficient U. since UA is the multiplication of NTU

by the (mc p )min , [7]

School of Engineering and Technology 25

Optimization of shell and tube heat exchanger

NTU (mc p )min

U= ……………………………………………………………………..(21)

A

2.14- The pressure drop ∆p for the tube and shell sides, given by: [7]

æ l ö ru 2

Dp = 8 j f çç ÷÷ ……………………………………………………………………(22)

è di ø 2

For tube side multiply by the number of the passes for this case 2 passes.

2.15- The electric power consumption to pumping the fluids, given by: [11]

·

Dp m

P(w ) = …………………………………………………………………………..(23)

r

2.16- Annual electric power consumption, given by: [11]

Pa = P(operating × hours ) ……………………………………………………………..(24)

School of Engineering and Technology 26

Optimization of shell and tube heat exchanger

Appendix 2 (results)

This is full results obtained by use of the speared sheet (excel program) as on the attached disc.

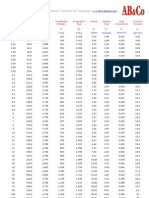

Table 1 Tube side heat transfer calculations (organic liquid)

Option selected 1 2 3 4 5

(Di)s( inside shell diameter(m)) 0.25 0.3 0.35 0.4 0.45

Nd(max. number of tubes on inside diameter of shell) 9 11 13 15 17

m(number of rows of tubes ) 5.616 6.77 7.924 9.078 10.232

nT(max. number of tubes) 70 104 144 190 244

nN(equivalent no. of tubes from two nozzles) 5 6 7 8 9

Np(equivalent no. of tubes from two pass arrangement) 5.616 6.77 7.924 9.078 10.232

nT(corrected no. of tubes) 60 92 130 174 224

At(the cross sectional flow area(m²)) 0.00529 0.00812 0.01148 0.01536 0.01978

u(the mean linear velocity(m/s)) 4.28430 2.79411 1.97737 1.47734 1.14758

GH(the mass flow rate(kg/sm²)) 3774.47 2461.61 1742.06 1301.54 1011.02

Re(Reynolds number) 125815.8 82053.8 58068.8 43384.7 33700.6

jH(heat transfer factor) 0.00257 0.00280 0.00301 0.00319 0.00335

hi(inside film heat transfer coefficients(w/m²k)) 6117.77 4345.94 3295.79 2610.20 2132.63

As(the cross sectional flow area for the shell stream(m²)) 0.00914 0.01097 0.01280 0.01463 0.01645

A (heat transfer area(m²)) 6.7854 10.4042 14.7017 19.6776 25.3321

Table 2 Shell side heat transfer calculations (water)

Tc(outlet(ºC)) 26 32 38 44 50

mC(mass flow rate(kg/s)) 26.69399 13.3501 8.90164 6.67693 5.34175

TC(mean(ºC)) 23 26 29 32 35

Cp(heat capacity of water(j/kgk)) 4183.212 4182.21 4181.49 4181.05 4180.90

µ(dynamic viscosity of water) 0.000939 0.00087 0.00082 0.00077 0.00072

kC (thermal conductivity of water (w/mk)) 0.614628 0.61741 0.62019 0.62297 0.62576

Pr(Prandtl number) 6.391035 5.93888 5.53432 5.17086 4.84312

(Gc)s(mass flow rate (kg/m²s))

for Di = .25 2919.290 1459.99 973.496 730.198 584.181

for Di = .30 2432.742 1216.66 811.246 608.498 486.817

for Di = .35 2085.207 1042.85 695.354 521.570 417.272

for Di = .40 1824.556 912.496 608.435 456.374 365.113

for Di = .45 1621.828 811.107 540.831 405.665 324.545

(Re)s(Reynolds number)

for Di = .25 53690.2 28758.7 20481.6 16367.5 13917.9

for Di = .30 44741.8 23965.6 17068.0 13639.6 11598.2

for Di = .35 38350.1 20541.9 14629.7 11691.0 9941.3

for Di = .40 33556.4 17974.2 12801.0 10229.7 8698.70

for Di = .45 29827.9 15977.0 11378.7 9093.06 7732.18

(Jh)s(heat transfer factor)

for Di = .25 0.00261 0.00345 0.00402 0.00445 0.00479

for Di = .30 0.00283 0.00375 0.00437 0.00483 0.00520

for Di = .35 0.00303 0.00402 0.00468 0.00518 0.00557

School of Engineering and Technology 27

Optimization of shell and tube heat exchanger

for Di = .40 0.00322 0.00427 0.00497 0.00550 0.00592

for Di = .45 0.00340 0.00450 0.00524 0.00580 0.00624

Hs(film heat transfer coefficient(w/m²k)

for Di = .25 9253.91 6435.12 5238.83 4547.73 4088.24

for Di = .30 8370.96 5821.13 4738.98 4113.82 3698.17

for Di = .35 7690.50 5347.94 4353.75 3779.41 3397.55

for Di = .40 7145.94 4969.25 4045.46 3511.79 3156.97

for Di = .45 6697.69 4657.54 3791.70 3291.51 2958.94

Table 3 Overall heat transfer calculations

Tc(outlet(ºC)) 26 32 38 44 50

Mc*Cp 111666.6 55833.3 37222.2 27916.6 22333.3

E (effectiveness of heat transfer) 0.4 0.4 0.4 0.48 0.6

R (heat capacity ratio) 0.3 0.6 0.9 0.83333 0.66666

NTU ( number of transfer units) 0.64 0.7 0.78 1 1.38

UiAi 21440 23450 26130 27916.6 30820

Ui(overall heat transfer coefficient (w/m²k))

required for Di = .25 3159.725 3455.95 3850.91 4114.22 4542.10

actual for Di = .25 2341.972 1883.23 1581.44 1360.67 1190.14

required for Di = .30 2060.690 2253.88 2511.46 2683.19 2962.24

actual for Di = .30 2293.635 1838.43 1542.66 1327.6 1161.97

required for Di = .35 1458.334 1595.05 1777.34 1898.87 2096.35

actual for Di = .35 2250.560 1798.75 1508.36 1298.33 1137.02

required for Di = .40 1089.560 1191.70 1327.90 1418.69 1566.24

actual for Di = .40 2211.622 1763.07 1477.56 1272.04 1114.58

required for Di = .45 846.3549 925.700 1031.49 1102.02 1216.63

actual for Di = .45 2176.039 1730.631 1449.59 1248.15 1094.17

Ai (area (m²) where required U = actual U) 9.3 12.9 17.7 23.9

School of Engineering and Technology 28

Optimization of shell and tube heat exchanger

Table 4 pressure drop and power calculation

(Di)s( inside shell diameter(m)) 0.3 0.35 0.4

Re (Reynolds number) 82053.81 58068.85 43384.77

Jh (heat transfer factor) 0.002907 0.003182 0.003434

∆p (pressure drop(N/m²) 42791.74 22641.95 13257.83

tube side theoretical power(w)/hr 971.4355 514.0057 300.9723

Tc(outlet(ºC)) 28 34.2 39.8

Tc(mean) 24 27.1 29.9

(Cp)c 4182.849 4181.92 4181.336

Mc 20.02224 11.28264 8.09272

Gs (mass flow rate 1824.715 881.3462 553.1441

µ(dynamic viscosity of water) 0.000917 0.000856 0.000805

Ρc 902.7565 899.6443 896.8334

Re (Reynolds number) 34346.68 17790.55 11864.09

Jf (heat transfer factor) 0.030241 0.034335 0.037128

Di/De 17.37116 20.26636 23.16155

∆p 122049.2 37846.31 18480.66

Shell side theoretical power(w)/hr 2706.93 474.639 166.7632

total power consumption(w/hr) 3678.365 988.6447 467.7354

Heat exchanger efficiency 43.88% 43.16% 42%

School of Engineering and Technology 29

You might also like

- Shell and Tube Heat Exchanger DesignDocument22 pagesShell and Tube Heat Exchanger Designsuperbugima100% (1)

- Heat Exchanger DesignDocument37 pagesHeat Exchanger DesignAnurag IngleNo ratings yet

- Shell and Tube Heat Exchanger Design Using CFD ToolsDocument4 pagesShell and Tube Heat Exchanger Design Using CFD ToolsChockalingam AthilingamNo ratings yet

- Agitated VesselDocument8 pagesAgitated VesselBharatShethNo ratings yet

- Heat Exchanger-Design and ConstructionDocument46 pagesHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- The Outside Diameter As Their Nominal DiameterDocument75 pagesThe Outside Diameter As Their Nominal Diameterngutor100% (2)

- HEAT TRANSFER EQUIPMENT DESIGN AND TYPESDocument26 pagesHEAT TRANSFER EQUIPMENT DESIGN AND TYPESJazer Mari CantosNo ratings yet

- Double Pipe Heat Exchanger - Excel CalculationsDocument4 pagesDouble Pipe Heat Exchanger - Excel CalculationsMmmmohNo ratings yet

- Process Design of Shell and Tube Heat ExchangersDocument41 pagesProcess Design of Shell and Tube Heat Exchangersishita.brahmbhatt100% (1)

- Design of Shell and Tube Heat ExchangerDocument4 pagesDesign of Shell and Tube Heat ExchangerIqra Safdar100% (1)

- Selection of TEMA Type and Thermal Design Optimization of Shell and Tube Heat ExchangerDocument6 pagesSelection of TEMA Type and Thermal Design Optimization of Shell and Tube Heat ExchangerPawan PatilNo ratings yet

- Hybrid Cooling TowerDocument12 pagesHybrid Cooling TowerANIMESH JAINNo ratings yet

- Design and operation of distillation columnsDocument13 pagesDesign and operation of distillation columnsAlla VijayNo ratings yet

- He SelectionDocument7 pagesHe SelectionKaizerNo ratings yet

- Design of Shell and Tube Heat Exchanger PDFDocument55 pagesDesign of Shell and Tube Heat Exchanger PDFShawez sayyed100% (1)

- Finned Tube Heat ExchangerDocument15 pagesFinned Tube Heat ExchangerAna Quintana0% (1)

- Jacketed VesselsDocument2 pagesJacketed VesselsImamRNNo ratings yet

- Shell & Tube Heat Exchanger Rating ProjectDocument20 pagesShell & Tube Heat Exchanger Rating ProjectFareeha HasanNo ratings yet

- Mechanical Design of Shell and Tube Heat ExchangerDocument69 pagesMechanical Design of Shell and Tube Heat ExchangerFazil HassanNo ratings yet

- Plate Heat ExchangersDocument9 pagesPlate Heat ExchangersPavan KumarNo ratings yet

- Design Calculations of Pitch Blade TurbineDocument6 pagesDesign Calculations of Pitch Blade TurbineAyaz_HasanjiNo ratings yet

- Efficient Heat Transfer with Counter Flow DesignDocument58 pagesEfficient Heat Transfer with Counter Flow DesigncanyourunNo ratings yet

- Tall Vessels PDFDocument29 pagesTall Vessels PDFVenkatesh Sivarchana100% (1)

- Dowtherm BookDocument30 pagesDowtherm BookMeghnad M GavitNo ratings yet

- Chemical Design of Heat Exchanger TerdesakDocument22 pagesChemical Design of Heat Exchanger TerdesakNor Ain100% (4)

- 12 PDO Heat TransferDocument55 pages12 PDO Heat Transferaxel2100No ratings yet

- Design 2 ReboilerDocument5 pagesDesign 2 ReboilerAbdulrazzaqAL-MalikyNo ratings yet

- Double Pipe Heat Exchanger - SsDocument72 pagesDouble Pipe Heat Exchanger - SsNathanian100% (2)

- Plate Heat ExchangersDocument7 pagesPlate Heat ExchangersBaneMarkovicNo ratings yet

- Biruk Endale Design On Heat Exchanger-1Document32 pagesBiruk Endale Design On Heat Exchanger-1nigus gereziherNo ratings yet

- Design of Tall Vessels for Chemical IndustriesDocument18 pagesDesign of Tall Vessels for Chemical IndustrieskurniahidayatNo ratings yet

- Calculation of Fuel Oil Dyke Height: Fo TankDocument2 pagesCalculation of Fuel Oil Dyke Height: Fo TankJag KhadseNo ratings yet

- Design Shell and TubeDocument15 pagesDesign Shell and TubeAhmad MaskurNo ratings yet

- Mechanical Design (Compile Draft 1)Document87 pagesMechanical Design (Compile Draft 1)IRIZREENNo ratings yet

- Plate Type Heat Exchanger Project Report 5Document26 pagesPlate Type Heat Exchanger Project Report 5ParthivNo ratings yet

- Agitated Vessel Heat Transfer PDFDocument6 pagesAgitated Vessel Heat Transfer PDFMuthuKumar ArunachalamNo ratings yet

- Helical Coil Heat Transfer CoefficientsDocument4 pagesHelical Coil Heat Transfer Coefficientsjokish100% (1)

- Jacketed Vessel Design CalculusDocument4 pagesJacketed Vessel Design Calculusmaspiqdo100% (1)

- DJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDocument3 pagesDJM-MBA-PCS-CA-018 LPG On-Spec Storage REV-BDIANTORONo ratings yet

- Design of Tall VesselsDocument54 pagesDesign of Tall VesselsboiroyNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument40 pagesShell and Tube Heat Exchanger DesignamiyachemNo ratings yet

- Chemical Engineering - Oil - Sizing Heating Coil PDFDocument5 pagesChemical Engineering - Oil - Sizing Heating Coil PDFSaira SaqibNo ratings yet

- Shell & Tube Condenser Design MethodDocument4 pagesShell & Tube Condenser Design MethodwestewrNo ratings yet

- Lecture 04c - Shortcut Exchanger Design ProcedureDocument47 pagesLecture 04c - Shortcut Exchanger Design Proceduresds0% (1)

- Heat Transfer Area For Fin Tube Heat Exchanger For FBDDocument8 pagesHeat Transfer Area For Fin Tube Heat Exchanger For FBDPrathmesh GujaratiNo ratings yet

- Heat Exchanger Design OptimizationDocument27 pagesHeat Exchanger Design OptimizationUsama AkramNo ratings yet

- Insulation For SCI ReactorDocument12 pagesInsulation For SCI ReactorJogender DhayalNo ratings yet

- Chee3004: Project 2Document43 pagesChee3004: Project 2faizzi100% (3)

- Heat Transfer Analysis of Corrugated Plate Heat ExchangerDocument6 pagesHeat Transfer Analysis of Corrugated Plate Heat Exchangerpak1t0No ratings yet

- Sizing Sheet for 2-phase separator as per API 12J standardsDocument5 pagesSizing Sheet for 2-phase separator as per API 12J standardsWickyNo ratings yet

- Bell Delaware Math Cad ExampleDocument8 pagesBell Delaware Math Cad ExampleMohammed A IsaNo ratings yet

- Jacket and Coils of Agitated Vessels PDFDocument2 pagesJacket and Coils of Agitated Vessels PDFlolofm25No ratings yet

- Universiti Kuala Lumpur Malaysian Institute of Chemical and Bioengineering TechnologyDocument24 pagesUniversiti Kuala Lumpur Malaysian Institute of Chemical and Bioengineering TechnologyHanif YusofNo ratings yet

- Heat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersDocument5 pagesHeat Transfer Coefficients of Shell and Coiled Tube Heat ExchangersShalehAhmad100% (1)

- Presentation 1Document45 pagesPresentation 1Gyan PrakashNo ratings yet

- Final ReportDocument70 pagesFinal ReportSudarshan KulandhaivelNo ratings yet

- Heat Exchanger Analysis and ModelingDocument19 pagesHeat Exchanger Analysis and ModelingJohnasGoodmanNo ratings yet

- Heat TransferDocument9 pagesHeat TransferAjinkya MoreNo ratings yet

- Heat Exhanger Individual ReportDocument16 pagesHeat Exhanger Individual ReportMusa OtoNo ratings yet

- Heat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersFrom EverandHeat Exchanger Design Guide: A Practical Guide for Planning, Selecting and Designing of Shell and Tube ExchangersRating: 4 out of 5 stars4/5 (13)

- Spray DryingDocument28 pagesSpray DryingAna QuintanaNo ratings yet

- H-HS-0040 High Shine Floor PolishDocument1 pageH-HS-0040 High Shine Floor PolishAna QuintanaNo ratings yet

- AWS90 Ch04 StaticDocument54 pagesAWS90 Ch04 StaticmuruganandamdesinghNo ratings yet

- Steam PropertiesDocument1 pageSteam PropertiesanandguptNo ratings yet

- Thesis Benazzoli Alessandra InertizationreactorDocument147 pagesThesis Benazzoli Alessandra InertizationreactorAna QuintanaNo ratings yet

- CN 100453601 CDocument7 pagesCN 100453601 CAna QuintanaNo ratings yet

- Tailoring AutoCAD P&ID and Plant 3DDocument194 pagesTailoring AutoCAD P&ID and Plant 3DTuấn Lữ100% (7)

- Finned Tube Heat ExchangerDocument15 pagesFinned Tube Heat ExchangerAna Quintana0% (1)

- Hong H. Lee Heterogeneous Reactor DesignDocument267 pagesHong H. Lee Heterogeneous Reactor DesignAna QuintanaNo ratings yet

- Soap SpitzDocument6 pagesSoap SpitzAna QuintanaNo ratings yet

- Ellen Finkelstein, Gurdy Leete-50 Fast Macromedia Flash MX Techniques-Wiley (2002)Document258 pagesEllen Finkelstein, Gurdy Leete-50 Fast Macromedia Flash MX Techniques-Wiley (2002)Ana QuintanaNo ratings yet

- Gastric Carcinoma: Professor Ravi KantDocument44 pagesGastric Carcinoma: Professor Ravi KantAna Quintana100% (1)

- Confetti CakesDocument208 pagesConfetti CakesAndrea CasasnovasNo ratings yet

- Drum Flaker Introduction Guide by FUJI KOKI CO.,LTDDocument20 pagesDrum Flaker Introduction Guide by FUJI KOKI CO.,LTDAna Quintana100% (2)

- Rexnord Elastomer CouplingDocument20 pagesRexnord Elastomer Couplingidontlikeebooks100% (1)

- Particle Flow OrbazDocument159 pagesParticle Flow OrbazAna QuintanaNo ratings yet

- Carcinoma PaladarDocument4 pagesCarcinoma PaladarAna QuintanaNo ratings yet

- Compact Bottom Magnetic Stirred AutoclaveDocument1 pageCompact Bottom Magnetic Stirred AutoclaveAna QuintanaNo ratings yet

- Acusol 445NDocument5 pagesAcusol 445NAna Quintana100% (1)

- 16 - Blending and AgitationDocument20 pages16 - Blending and AgitationNeha MadanNo ratings yet

- NanoparticlesDocument95 pagesNanoparticlesAna QuintanaNo ratings yet

- Extraction Techniques Medicinal PlantsDocument10 pagesExtraction Techniques Medicinal PlantsPramod Aryal100% (1)

- Second-Law-based Performance Evaluation of Cooling Towers and Evaporative Heat ExchangersDocument11 pagesSecond-Law-based Performance Evaluation of Cooling Towers and Evaporative Heat ExchangersAna QuintanaNo ratings yet

- ElastomerCompatibilityGuide020509rev3 1Document3 pagesElastomerCompatibilityGuide020509rev3 1Ana QuintanaNo ratings yet

- Abb FlowmetersDocument84 pagesAbb FlowmetersAna QuintanaNo ratings yet

- Discrete ParticleDocument10 pagesDiscrete ParticleAna QuintanaNo ratings yet

- Pipeline Drying HbspecsDocument2 pagesPipeline Drying HbspecsCharles OnyechereNo ratings yet

- Opti FloDocument11 pagesOpti FloAna QuintanaNo ratings yet

- Cloro WallaceDocument8 pagesCloro WallaceAna QuintanaNo ratings yet

- Polietileno UHMWDocument38 pagesPolietileno UHMWAna QuintanaNo ratings yet

- SOP-for RecallDocument3 pagesSOP-for RecallNilove PervezNo ratings yet

- Template WFP-Expenditure Form 2024Document22 pagesTemplate WFP-Expenditure Form 2024Joey Simba Jr.No ratings yet

- ITP Exam SuggetionDocument252 pagesITP Exam SuggetionNurul AminNo ratings yet

- Shopping Mall: Computer Application - IiiDocument15 pagesShopping Mall: Computer Application - IiiShadowdare VirkNo ratings yet

- Fast Aldol-Tishchenko ReactionDocument5 pagesFast Aldol-Tishchenko ReactionRSLNo ratings yet

- Final Year Project (Product Recommendation)Document33 pagesFinal Year Project (Product Recommendation)Anurag ChakrabortyNo ratings yet

- United States Bankruptcy Court Southern District of New YorkDocument21 pagesUnited States Bankruptcy Court Southern District of New YorkChapter 11 DocketsNo ratings yet

- GFS Tank Quotation C20210514Document4 pagesGFS Tank Quotation C20210514Francisco ManriquezNo ratings yet

- Worksheet 5 Communications and Privacy: Unit 6 CommunicationDocument3 pagesWorksheet 5 Communications and Privacy: Unit 6 Communicationwh45w45hw54No ratings yet

- LSMW With Rfbibl00Document14 pagesLSMW With Rfbibl00abbasx0% (1)

- AtlasConcorde NashDocument35 pagesAtlasConcorde NashMadalinaNo ratings yet

- Iphoneos 31Document159 pagesIphoneos 31Ivan VeBoNo ratings yet

- Critical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentDocument3 pagesCritical Methodology Analysis: 360' Degree Feedback: Its Role in Employee DevelopmentJatin KaushikNo ratings yet

- Emergency Management of AnaphylaxisDocument1 pageEmergency Management of AnaphylaxisEugene SandhuNo ratings yet

- Job Order Costing: Patrick Louie E. Reyes, CTT, Micb, Rca, CpaDocument45 pagesJob Order Costing: Patrick Louie E. Reyes, CTT, Micb, Rca, CpaClaudette Clemente100% (1)

- Evaluative Research DesignDocument17 pagesEvaluative Research DesignMary Grace BroquezaNo ratings yet

- Legends and Lairs - Elemental Lore PDFDocument66 pagesLegends and Lairs - Elemental Lore PDFAlexis LoboNo ratings yet

- NLP Business Practitioner Certification Course OutlineDocument11 pagesNLP Business Practitioner Certification Course OutlineabobeedoNo ratings yet

- Mounting InstructionDocument1 pageMounting InstructionAkshay GargNo ratings yet

- Revision Worksheet - Matrices and DeterminantsDocument2 pagesRevision Worksheet - Matrices and DeterminantsAryaNo ratings yet

- Physics Derived Units and Unit Prefixes Derived UnitDocument15 pagesPhysics Derived Units and Unit Prefixes Derived UnitJohnRenzoMolinarNo ratings yet

- 4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal DescisionDocument24 pages4 Influencing Factors of Learners Career Choice Parents Choice Vs Personal Descisionmatteo mamaloNo ratings yet

- Vector 4114NS Sis TDSDocument2 pagesVector 4114NS Sis TDSCaio OliveiraNo ratings yet

- Reading and Writing Q1 - M13Document13 pagesReading and Writing Q1 - M13Joshua Lander Soquita Cadayona100% (1)

- DBMS Architecture FeaturesDocument30 pagesDBMS Architecture FeaturesFred BloggsNo ratings yet

- Service Manual: Precision SeriesDocument32 pagesService Manual: Precision SeriesMoises ShenteNo ratings yet

- SEC QPP Coop TrainingDocument62 pagesSEC QPP Coop TrainingAbdalelah BagajateNo ratings yet

- Mosfet 101Document15 pagesMosfet 101Victor TolentinoNo ratings yet

- Damcos Mas2600 Installation UsermanualDocument26 pagesDamcos Mas2600 Installation Usermanualair1111No ratings yet

- History of Microfinance in NigeriaDocument9 pagesHistory of Microfinance in Nigeriahardmanperson100% (1)