Professional Documents

Culture Documents

ICNMM2009-82032: Keynote Paper

Uploaded by

aliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ICNMM2009-82032: Keynote Paper

Uploaded by

aliCopyright:

Available Formats

Proceedings of the ASME 2009 7th International Conference on Nanochannels, Microchannels and Minichannels

ICNMM2009

June 22-24, 2009, Pohang, South Korea

ICNMM2009-82032

KEYNOTE PAPER

THE THERMAL TRANSPORT PROPERTIES OF ETHYLENE GLYCOL BASED MGO

NANOFLUIDS

Wei Yu, Hua-Qing Xie﹡, Yang Li and Li-Fei Chen

/ School of Urban Development and Environmental Engineering, Shanghai Second Polytechnic University,

Shanghai 201 209, China /hqxie@eed.sspu.cn

ABSTRACT conductivity even when the concentration of suspended

Ethylene glycol based nanofluids containing MgO nanoparticles is less than 5% in volume fraction. Many kinds of

nanoparticles (MgO-EG) were prepared, and the transport nanomaterials are used as the additives of nanofluids, such as

properties including thermal conductivity and viscosity were some metallic nanoparticles [9-10], metallic oxide particles

measured. The results show that the thermal conductivity of [11], carbon nanotubes [12-13] and TiO2 nanotubes [6]. At

MgO-EG nanofluid depends strongly on particle concentration, present the thermal conductivity data measured by different

and it increases nonlinearly with the volume fraction of groups are scattered. The dispersion is believed to be due to

nanoparticles. The thermal conductivity of MgO-EG nanofluids various factors such as the measuring techniques, the particle

is larger than that of nanofluids containing the same volume size and shape, the particle clustering and sedimentation. Many

fraction of TiO2, ZnO, Al2O3 and SiO2, maybe due to its papers neglect some important factors including the measured

lowest viscosity among the tested metallic oxide nanofluids. temperature, and the settlement time after nanofluid

Thermal conductivity enhancement of MgO-EG nanofluids preparation. Although the significant dependence of nanofluid

appears weak dependence on temperature from 10 to 60℃, and thermal conductivity on temperature has clearly been shown,

the enhanced ratios are almost constant. Viscosity the amount of data remains very limited [14-15]. The

measurements show that MgO-EG nanofluids demonstrate settlement time is another vital factor. The measured data

Newtonian behavior, and the viscosity significantly decreases demonstrate that the apparent thermal conductivity is highest

with temperature. The thermal conductivity and viscosity right after nanofluid preparation and decreases considerably

increments of nanofluids are higher than those of the existing with elapsed time, showing a time-dependent characteristic.

classical models for the solid-liquid mixture. However, most of the papers have not stated the settlement time

clearly [16]. The viscosity of nanofluids is another important

INTRODUCTION transport property for applications of nanofluids as a new class

of heat transfer fluids in thermal devices or systems such as

Heating or cooling fluids are important to many industrial heat exchangers or cooling systems. Experimental data for the

sectors, including transportation, energy supply and electronics. viscosity of nanofluids are rare compared with their thermal

The thermal conductivity of these fluids plays a vital role in the conductivity [17-18].

development of energy-efficient heat transfer equipment [1].

However, conventional heat transfer fluids have poor heat To the best of our knowledge, the thermal transport

transfer properties compared to most solids. Nanofluids, properties of MgO nanofluids have not well been investigated.

produced by dispersing nanoparticles into conventional heat In this paper, the effects of the particle volume fraction,

transfer fluids, are proposed as the next generation heat transfer settlement time, measured temperature and viscosity on the

fluids due to the reports of great enhancement of heat transfer thermal transport are investigated. Furthermore, the thermal

[2-4], mass transfer [5] and wetting and spreading [6] than conductivities of different metallic oxide nanofluids are

those of the base liquids. These enhanced properties have measured using the same measurement techniques and

attracted great interest from many researchers because of the measurement conditions in order to ensure the consistency of

potential applications including thermal management, thermal experimental data.

therapy, microfluidics and novel detergent formulation [7-8].

To now, more than twenty laboratories worldwide have EXPERIMENTAL SECTION

published experimental data on the thermal conductivity of

nanofluids, and the results show that nanofluids exhibit The nanoparticles used in the experiments were pursued

substantially higher thermal properties particularly thermal from Hangzhou WanJing New Material Company, and the

mean diameters of the nanoparticles were about 20 nm. The

1 Copyright © 2009 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 04/03/2014 Terms of Use: http://asme.org/terms

density and crystal style are shown in Table 1, and some data of loading (0.5-1%), the thermal conductivity enhancement versus

Table 1 are from the reference [19]. The typical procedure is as volume fraction is larger than that at higher volume fraction

follows: The fixed quality of MgO (or other metallic oxide) (2.0-5.0%). This demonstrates that the enhanced rate of thermal

nanoparticles with different volume concentrations (φ: 0.5~ conductivity decrease with the increase of volume fraction,

5%) was dispersed in ethylene glycol. Sample preparation was mainly due to the particle agglomeration at higher volume

carried out by using a sensitive mass balance with an accuracy fraction. The conclusion is similar to nanofluids of CuO-EG

of 0.1 mg. The volume fraction of the powder was calculated [21-22].

from the weight of dry powder using the density provided by

supplier and the total volume of suspension. The nanofluid

40

mixture was stirred and ultrasonic sonicated continuously for 3 Experimental Values

h. This ensured uniform dispersion of nanoparticles in the base H-C or Maxwell Model

Bruggeman Model

fluid. 30

-kf) / kf (%)

The transient hot-wire is more appropriate than the steady-

state technique due to numerous advantages such as the

20

elimination of natural convection effects and faster

nf

experimental response. A transient short hot-wire (SHW)

(k

technique was applied to measure the thermal conductivities of 10

the nanofluids from 10 to 60℃ [20]. In addition to hot-wire

system, a temperature-controlled bath was used to maintain

0

different temperatures of nanofluids during the measurement 0 1 2 3 4 5

process. The experimental apparatus was calibrated by Volume fraction (vol.%)

measuring the thermal conductivity of ethylene glycol, and the

accuracy of these measurements was estimated to be within Fig. 1 Comparison between experimental and predicted thermal

±1%. The thermal conductivity of the fluid was measured after conductivity of MgO-EG nanofluids

the nanofluid was settled for more than 30 minutes to ensure 44

the temperature equilibrium of nanofluids. The rheological

property of nanofluids was measured by a viscometer (LV DV-

Ⅱ+ Brookfield programmable viscometer, America) with a 42

temperature-controlled bath. Viscosity measurements were

- kf) / kf (%)

started at 60℃, and temperature was gradually reduced to 10℃

40

in 10℃ increments. Spindle SC-18 was used in this viscometer

and was calibrated by using Brookfield viscosity standard

eff

(k

fluids. All the viscosity measurements were recorded at steady

38

state conditions, and the time of nanofluids sample in the

sample chamber was 10 minutes.

36

RESULTS AND DISCUSSION 0 5 10 15 20 25

Settlement time (h)

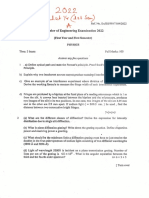

Table 1. Comparison between MgO-EG and other metallic Fig. 2. The influence of settlement time on the enhancement

oxide nanofluids. ratios of thermal conductivity

Thermal Density Crystal Viscosity (Cp) Enhancement of

conductivity (g/cm3) style with 5.0 vol. nanofluids with

5.0 vol. % 48

% 30℃

W/(m·K)

MgO 48.4 2.9 Cubic 17.4 40.6% 45

- kf) / kf (%)

TiO2 8.4 4.1 Anatase 31.2 27.2%

42

ZnO 13 5.6 Wurtzite 129.2 26.8%

Al2O3 36 3.6 γ 28.2 28.2% 39

nf

(k

SiO2 10.4 2.6 noncrysta 31.5 25.3%

lline 36

33

MgO-EG nanofluids with different volume fractions (0.5-

5.0%) at 30℃ were tested to measure the thermal conductivity

30

(shown in Fig. 1). The experimental results indicate that the 10 20 30 40 50 60

thermal conductivity of MgO-EG nanofluids increases with Temperature (OC)

particle volume fraction. The maximum enhancement is 40.6%

for a particle volume fraction of 5%. It is apparent that the Fig. 3. Thermal conductivity enhancement of MgO nanofluids

thermal conductivity of the nanofluid increases nonlinearly with 5.0 vol.% as a function of temperature

with the volume fraction of nanoparticles. At lower volumetric

2 Copyright © 2009 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 04/03/2014 Terms of Use: http://asme.org/terms

25 keff k p + 2k f − 2φ (k f − k p )

Experimental data = (1)

Fit linear kf k p + 2k f + φ ( k f − k p )

20

For solid-liquid mixtures in which the ratio of conductivity of

Shear Stress ( Dyne / cm )

2

two phases is larger than 100, Hamilton and Crosser (H-C)

15

developed the following model [24]:

keff k p + (n − 1)k f − ( n − 1)φ ( k f − k p )

10 = (2)

kf k p + (n − 1)k f + φ (k f − k p )

5 For spherical particles, the H-C model is the same as the

Maxwell model. Bruggeman model can be applied to calculate

the thermal conductivity of aggregates, which can be regarded

0

0 20 40 60 80 100 120 140 160 as concentrated liquid-solid mixtures [1]:

1 k

Shear rate (RPM) keff = ⎡⎣ (3φ − 1) k p + (2 − 3φ )k f ⎤⎦ + f Δ

4 4 (3)

Fig. 4 Shear stress versus shear rate for 5.0 vol.% MgO at 30℃

kp kp

Δ = (3φ − 1) 2 ( ) 2 + (2 − 3φ ) 2 + 2(2 + 9φ − 9φ 2 )( )

kf kf

In order to compare the heat transfer ability of MgO-EG

nanofluids with other metallic oxide nanofluids, the thermal

conductivities of different metallic oxide nanofluids were

35

measured using the same measuring techniques and measuring

conditions, and the results are presented in Table 1. It can be 30

Einstein model

Brinkman model

Relative viscosity enhancement (%)

seen that the thermal conductivities of MgO-EG nanofluids are Batchelor model

larger than those of nanofluids containing the same volume 25 Experimental data

fraction of TiO2, ZnO, Al2O3 and SiO2. In our opinion, the

enhancement of thermal conductivity of nanofluids is not only 20

related to the thermal conductivity of the additive nanoparticles,

15

but also related to the viscosity of nanofluids. The viscosity of

MgO-EG nanofluid is lowest among the tested metallic oxide

10

nanofluids. The viscosity of nanofluid not only depends on the

particle volume fraction, but also depends on the interface 5

property of nanoparticles and the interaction between

nanoparticles and base fluid. There is no doubt that the great 0.00 0.01 0.02 0.03 0.04 0.05 0.06

enhancement of viscosity will increase the thermal resistance Particle volume fraction

and weaken the thermal conductivity. This will offset the

benefit from enhanced thermal conductivity. Fig. 6. Relative viscosity enhancement of nanofluids with

60 particle volume fraction

50 The measured and predicted thermal conductivity of

nanofluids are shown in Fig. 1. The measured thermal

Viscosity (cP)

40 conductivity displays an apparently higher value than the

5.0vol.% MgO-EG

4.0vol.% MgO-EG existing models. Jang and Choi suggested that the variation

30

3.0vol.% MgO-EG between the measured and predicted results stemmed from the

2.0vol.% MgO-EG

1.0vol.% MgO-EG fundamental limits of conventional models [25]. These

Pure EG

traditional models do not take particle size, particle Brownian

20

motion, nanolayering, and effect of nanoparticle clustering into

account.

10

Fig. 2 shows the enhanced ratio of thermal conductivity as a

function of the settlement time. It is found that the conductivity

0

10 20 30 40 50 60

decreases with elapsed time in 6 h, and the decreased value is

O

within 3%. When the settlement time is over 6 h, it will reach a

Temperature ( C)

constant value of about 39%. The tendency of the settlement

Fig. 5. The viscosity of MgO nanofluids as a function of

time dependence of thermal conductivity enhancements has

temperature

also been observed in water based Cu nanofluids and Fe

nanofluids [26-27]. Previous literatures proposed that the

Various mechanisms and models have been proposed for

decrease was probably due to the appreciable particle

explaining the enhanced thermal conductivity of nanofluids

agglomeration. When nanoparticles get agglomerated, the ratio

using various assumptions. Maxwell model is known as

of the effective area to the volume decreases. The effective

following equation [23]:

area reduction of the thermal interaction of particles causes a

decrease in the thermal conductivity of the fluid. Kim et al [2]

3 Copyright © 2009 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 04/03/2014 Terms of Use: http://asme.org/terms

found that the thermal conductivity decreased rapidly for increasing concentration would have a directly influence on

nanofluids without surfactants after preparation. But no obvious internal viscous shear stresses [17].

changes in the thermal conductivity of the nanofluids with In general, the viscosities of nanofluids are abnormally

sodium dodecyl sulfate (SDS) as surfactant were observed even increased. Higher concentrations of nanofluids possess higher

after 5 h settlement. It is clear that the thermal conductivity viscosity. Fig. 6 illustrates the relationship between relative

reflects stability of nanofluid to some extent. For the MgO-EG viscosity enhancement and volume fraction. When the particle

nanofluids, the decrease of enhancement of thermal volume fraction of MgO-EG is 0.01, 0.03 and 0.05, the relative

conductivity with 24 h is within 5%, indicating the stability of viscosity enhancement is 3.5, 15.1 and 29.2%, respectively.

the nanofluids. There is a nonlinear relationship between the relative viscosity

Although some groups have reported studies of the thermal enhancement and particle volume fraction. This maybe due to

conductivity enhancement at elevated temperatures, there are the clusters of nanoparticles when the concentration is higher.

relative fewer effective data to reach a unanimous conclusion There exist some theoretical formulas that can be used to

about the influence of temperature on thermal conductivity. In estimate particle suspension viscosities. Almost all such

this paper, the effect of temperature on the enhancement of formulas have been derived from the pioneering work of

effective thermal conductivity of nanofluids was investigated Einstein (1906) which is based on the assumption of a linearly

by measuring the thermal conductivity of nanofluids for viscous fluid containing dilute, suspended, spherical particles.

different temperatures with 5.0 vol.% ranging from 10-60℃, His formula is as follows:

shown in Fig. 3. The result shows that the absolute thermal μnf

conductivities increase with the increasing temperature, while μr = = 1 + 2.5ϕ (4)

the enhanced ratios are almost constant, and the thermal μbf

conductivities of the nanofluids track the thermal conductivities where φ and μ are particle volume fraction and fluid dynamic

of the base liquid, which is similar to the conclusion of viscosity, respectively; the subscripts bf, nf and r refer

Timofeeva et al [14], while several groups have reported the respectively to the base-fluid, the nanofluid and to the

contrary conclusions [18]. The discrepancy demonstrates that ‘nanofluid to base fluid’ ratio of viscosity. The famous formula

many factors affect the measured thermal conductivity. For the was found valid for a very low particle volume fraction

influence of temperature on thermal conductivity, there is no (φ<0.02). Since the publication of Einstein’s work, there are

doubt that the increase of temperature of nanofluids improves some theoretical works to provide some corrections to his

the Brownian motion velocity of nanoparticles in base fluid, formula. Brinkman (1952) extended the Einstein’s formula to a

which contributes to the enhancement of thermal conductivity. moderate particle volume concentration (φ<0.04), he proposed:

While the decrease of viscosity will lead to form larger μ nf 1

agglomerates, which will not only reduces the Brownian = (5)

motion velocity, but also reduces the ratio of the effective area μbf (1 − ϕ ) 2.5

to the volume.

Batchelor (1977) considered the effect due to the Brownian

Viscosity is related to molecular momentum transport, and

motion of particles for an isotropic suspension of rigid and

determining the viscosity of the nanofluid is necessary to

spherical particles, and proposed:

calculate the pumping power. There are some debates about

whether the nanofluids are Newtonian or Non-Newtonian fluids μ nf

= 1 + 2.5ϕ + 6.5ϕ 2 (6)

[28]. The analysis of Kabelac [28] shows that the viscosities of μbf

Al2O3 nanoparticle suspensions decrease with the shear rates.

On the contrary, Prasher’s results demonstrate that the From Fig.6, it can be seen that the measured viscosities of

viscosities of nanofluids of Al2O3-propylene glycol are nanofluids are underpredicted by three models. This is probably

independent of shear rates, indicating that nanofluids are because these models only take particle volume fraction into

Newtonian fluids in nature [29]. In order to investigate the account, whereas the nanoparticles in fluids can easily form

rheological behaviour, whether MgO-EG nanofluid is clusters. Besides the particle volume fraction, the nature of the

Newtonian or Non-Newtonian fluid should be verified firstly. particle surface, ionic strength of the base fluid, inter-particle

The equation governing Newtonian behavior of a fluid is given potentials such as repulsive (electric double layer force) and

by attractive (van der Waals force) forces may play significant role

τ = μγ (3)

to alter the viscosity of nanofluids.[18]. Such enhancement of

viscosity may diminish the potential benefits of nanofluids.

where τ is the shear stress, μ is the coefficient of viscosity, and Therefore, it is imperative to conduct more comprehensive

γ is the shear strain rate. The shear stress versus shear rate for 5 studies on the viscosity of nanofluids.

vol.% MgO nanofluid at 30℃ is shown in Fig. 4. The linear

relation between shear stress and shear rate shows that MgO-

EG nanofluids demonstrate Newtonian behavior.

ACKNOWLEDGMENTS

Fig. 5 shows the viscosity of nanofluids with different

concentrations as a function of temperature. With the increase

of temperature, the viscosity of nanofluids decreases rapidly. The work was supported by the National High Technology

The reason of viscosity’s decrease with the increase in Research and Development Program of China

temperature is the weakening effect on the inner-particle/inter- (2006AA05Z232), Shanghai Educational Development

molecular forces [17]. The viscosities of nanofluids Foundation and Shanghai Municipal Education Commission

considerably increase with increasing particle volume fraction. (08CG64) and the Program for Professor of Special

The effect due to the particle fraction is linked to the fact that Appointment (Eastern Scholar) at Shanghai Institutions of

4 Copyright © 2009 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 04/03/2014 Terms of Use: http://asme.org/terms

Proceedings of the ASME 2009 7th International Conference on Nanochannels, Microchannels and Minichannels

ICNMM2009

June 22-24, 2009, Pohang, South Korea

ICNMM2009-82032

KEYNOTE PAPER

THE THERMAL TRANSPORT PROPERTIES OF ETHYLENE GLYCOL BASED MGO

NANOFLUIDS

Wei Yu, Hua-Qing Xie﹡, Yang Li and Li-Fei Chen

/ School of Urban Development and Environmental Engineering, Shanghai Second Polytechnic University,

Shanghai 201 209, China /hqxie@eed.sspu.cn

ABSTRACT conductivity even when the concentration of suspended

Ethylene glycol based nanofluids containing MgO nanoparticles is less than 5% in volume fraction. Many kinds of

nanoparticles (MgO-EG) were prepared, and the transport nanomaterials are used as the additives of nanofluids, such as

properties including thermal conductivity and viscosity were some metallic nanoparticles [9-10], metallic oxide particles

measured. The results show that the thermal conductivity of [11], carbon nanotubes [12-13] and TiO2 nanotubes [6]. At

MgO-EG nanofluid depends strongly on particle concentration, present the thermal conductivity data measured by different

and it increases nonlinearly with the volume fraction of groups are scattered. The dispersion is believed to be due to

nanoparticles. The thermal conductivity of MgO-EG nanofluids various factors such as the measuring techniques, the particle

is larger than that of nanofluids containing the same volume size and shape, the particle clustering and sedimentation. Many

fraction of TiO2, ZnO, Al2O3 and SiO2, maybe due to its papers neglect some important factors including the measured

lowest viscosity among the tested metallic oxide nanofluids. temperature, and the settlement time after nanofluid

Thermal conductivity enhancement of MgO-EG nanofluids preparation. Although the significant dependence of nanofluid

appears weak dependence on temperature from 10 to 60℃, and thermal conductivity on temperature has clearly been shown,

the enhanced ratios are almost constant. Viscosity the amount of data remains very limited [14-15]. The

measurements show that MgO-EG nanofluids demonstrate settlement time is another vital factor. The measured data

Newtonian behavior, and the viscosity significantly decreases demonstrate that the apparent thermal conductivity is highest

with temperature. The thermal conductivity and viscosity right after nanofluid preparation and decreases considerably

increments of nanofluids are higher than those of the existing with elapsed time, showing a time-dependent characteristic.

classical models for the solid-liquid mixture. However, most of the papers have not stated the settlement time

clearly [16]. The viscosity of nanofluids is another important

INTRODUCTION transport property for applications of nanofluids as a new class

of heat transfer fluids in thermal devices or systems such as

Heating or cooling fluids are important to many industrial heat exchangers or cooling systems. Experimental data for the

sectors, including transportation, energy supply and electronics. viscosity of nanofluids are rare compared with their thermal

The thermal conductivity of these fluids plays a vital role in the conductivity [17-18].

development of energy-efficient heat transfer equipment [1].

However, conventional heat transfer fluids have poor heat To the best of our knowledge, the thermal transport

transfer properties compared to most solids. Nanofluids, properties of MgO nanofluids have not well been investigated.

produced by dispersing nanoparticles into conventional heat In this paper, the effects of the particle volume fraction,

transfer fluids, are proposed as the next generation heat transfer settlement time, measured temperature and viscosity on the

fluids due to the reports of great enhancement of heat transfer thermal transport are investigated. Furthermore, the thermal

[2-4], mass transfer [5] and wetting and spreading [6] than conductivities of different metallic oxide nanofluids are

those of the base liquids. These enhanced properties have measured using the same measurement techniques and

attracted great interest from many researchers because of the measurement conditions in order to ensure the consistency of

potential applications including thermal management, thermal experimental data.

therapy, microfluidics and novel detergent formulation [7-8].

To now, more than twenty laboratories worldwide have EXPERIMENTAL SECTION

published experimental data on the thermal conductivity of

nanofluids, and the results show that nanofluids exhibit The nanoparticles used in the experiments were pursued

substantially higher thermal properties particularly thermal from Hangzhou WanJing New Material Company, and the

mean diameters of the nanoparticles were about 20 nm. The

1 Copyright © 2009 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/ on 04/03/2014 Terms of Use: http://asme.org/terms

You might also like

- A Review On Preparation Methods, Stability and Applications of Hybrid NanofluidsDocument11 pagesA Review On Preparation Methods, Stability and Applications of Hybrid NanofluidsmilitiamonNo ratings yet

- ORINOX-Catalogue Commercial GuideDocument11 pagesORINOX-Catalogue Commercial Guidevinurules20No ratings yet

- Astm A 694Document4 pagesAstm A 694Alexander MonroyNo ratings yet

- Astm A 694Document4 pagesAstm A 694Alexander MonroyNo ratings yet

- Astm A 694Document4 pagesAstm A 694Alexander MonroyNo ratings yet

- Nano Structured Materials) Selected Synthesis Methods, Properties and ApplicationsDocument186 pagesNano Structured Materials) Selected Synthesis Methods, Properties and ApplicationsEduardo Wohlers Junior100% (1)

- IELTS Reading Answer SheetDocument1 pageIELTS Reading Answer Sheetskuppal50% (2)

- Calculation of Safety Factor Guarding Against Joint OpeningDocument12 pagesCalculation of Safety Factor Guarding Against Joint OpeningPandiyarajan RajuNo ratings yet

- Nanotechnology in Civil EngineeringDocument34 pagesNanotechnology in Civil EngineeringA R Senthil ArumugamNo ratings yet

- Flange: 규격표 (ANSI Code)Document12 pagesFlange: 규격표 (ANSI Code)aliNo ratings yet

- Thermal Conductivity and Viscosity Measurements of Ethylene Glycol-Based Al O NanofluidsDocument11 pagesThermal Conductivity and Viscosity Measurements of Ethylene Glycol-Based Al O NanofluidsoblacaktanjaNo ratings yet

- CFD MgoDocument8 pagesCFD MgoSrini RaoNo ratings yet

- Investigation of Thermal Conductivity and Rheological Properties of Nanofluids Containing Graphene NanoplateletsDocument12 pagesInvestigation of Thermal Conductivity and Rheological Properties of Nanofluids Containing Graphene NanoplateletsWalter RubyNo ratings yet

- 1 s2.0 S0017931012001500 MainDocument6 pages1 s2.0 S0017931012001500 MainoblacaktanjaNo ratings yet

- Experimental Study of Heat Transfer Characteristics of Al O and Cuo Nanofluids For Machining ApplicationDocument10 pagesExperimental Study of Heat Transfer Characteristics of Al O and Cuo Nanofluids For Machining ApplicationAnjali prajapatiNo ratings yet

- Bou Guerra 2018Document5 pagesBou Guerra 2018khebab hafsiNo ratings yet

- Nanoparticles Suspended in Ethylene Glycol Thermal Properties andDocument7 pagesNanoparticles Suspended in Ethylene Glycol Thermal Properties andAbdullah AlkalaliNo ratings yet

- ANSYS Simulation For Ag/HEG Hybrid Nano Uid in Turbulent Circular PipeDocument17 pagesANSYS Simulation For Ag/HEG Hybrid Nano Uid in Turbulent Circular Pipelavadagopal10No ratings yet

- Estimation of Nanofluids Viscosity Using AIDocument11 pagesEstimation of Nanofluids Viscosity Using AIMikhail TarabrinNo ratings yet

- Nano ExpressDocument11 pagesNano ExpressJACOB RUBASINGH BNo ratings yet

- Thermophysical Properties and Heat Transfer in Mono and Hybrid Nanofluids With Different Base Fluids: An OverviewDocument18 pagesThermophysical Properties and Heat Transfer in Mono and Hybrid Nanofluids With Different Base Fluids: An Overviewm9966822No ratings yet

- 1 s2.0 S0032591020305209 MainDocument9 pages1 s2.0 S0032591020305209 Mainم. م. ابراهيم خضرNo ratings yet

- Applications of Nanofluids: NanomaterialsDocument3 pagesApplications of Nanofluids: NanomaterialsManjunath V BNo ratings yet

- Articulo 1Document13 pagesArticulo 1Ariana NuñezNo ratings yet

- Experimental Investigations and Theoretical Determination of ThermalDocument7 pagesExperimental Investigations and Theoretical Determination of ThermalkemalNo ratings yet

- Meyer Viscosity 2016 PDFDocument100 pagesMeyer Viscosity 2016 PDFanon_805157267No ratings yet

- Effect of Base Fluids On Thermo-Physical Properties of SiO2Document19 pagesEffect of Base Fluids On Thermo-Physical Properties of SiO2mpjwbxjy2hNo ratings yet

- Rheological Behavior of Stabilized Diamond-Graphene Nanoplatelets Hybrid Nanosuspensions in Mineral Oil - ILYAS 2022Document16 pagesRheological Behavior of Stabilized Diamond-Graphene Nanoplatelets Hybrid Nanosuspensions in Mineral Oil - ILYAS 2022gessicapalaoroNo ratings yet

- Energies: Forced Convection of Al O - Cu, Tio - Sio, Fwcnt-Fe O, and Nd-Fe O Hybrid Nanofluid in Porous MediaDocument19 pagesEnergies: Forced Convection of Al O - Cu, Tio - Sio, Fwcnt-Fe O, and Nd-Fe O Hybrid Nanofluid in Porous MediaLiviu BadeaNo ratings yet

- Jamei 2021Document16 pagesJamei 2021brian sanmbranoNo ratings yet

- Thermal Conductivity of NanofluidsDocument9 pagesThermal Conductivity of NanofluidsAnonymous Eta9AjEMcMNo ratings yet

- International Journal of Heat and Mass Transfer: Dan Zheng, Jin Wang, Zhanxiu Chen, Jakov Baleta, Bengt SundénDocument11 pagesInternational Journal of Heat and Mass Transfer: Dan Zheng, Jin Wang, Zhanxiu Chen, Jakov Baleta, Bengt SundénimhaNo ratings yet

- Powder Technology: Navid Nasajpour Esfahani, Davood Toghraie, Masoud AfrandDocument7 pagesPowder Technology: Navid Nasajpour Esfahani, Davood Toghraie, Masoud AfrandgessicapalaoroNo ratings yet

- International Journal of Thermal Sciences: M. Naraki, S.M. Peyghambarzadeh, S.H. Hashemabadi, Y. VermahmoudiDocument9 pagesInternational Journal of Thermal Sciences: M. Naraki, S.M. Peyghambarzadeh, S.H. Hashemabadi, Y. VermahmoudiBobyGitawanNo ratings yet

- Nanofluid Research and ApplicationsDocument23 pagesNanofluid Research and ApplicationsHaithem HammoudaNo ratings yet

- International Journal of Engineering: Thermal Conductivity of Cu and Al-Water NanofluidsDocument9 pagesInternational Journal of Engineering: Thermal Conductivity of Cu and Al-Water NanofluidsManoj SaralayaNo ratings yet

- Energies 15 02525Document21 pagesEnergies 15 02525A ALAMNo ratings yet

- 1 s2.0 S245190492300731X MainDocument11 pages1 s2.0 S245190492300731X MainMaher DhahriNo ratings yet

- 2011, CorcioneDocument5 pages2011, CorcionetangtszloongNo ratings yet

- An Experimental Investigation Into The Effect of Particle Mixtu - 2020 - PowderDocument44 pagesAn Experimental Investigation Into The Effect of Particle Mixtu - 2020 - PowderhenrymaryNo ratings yet

- Gu Et Al-2014-Polymer CompositesDocument6 pagesGu Et Al-2014-Polymer CompositesGhassan MousaNo ratings yet

- Investigation of Thermal Conductivity and Rheological Properties of Nanofluids Containing Graphene NanoplateletsDocument12 pagesInvestigation of Thermal Conductivity and Rheological Properties of Nanofluids Containing Graphene Nanoplateletsvuongcoi102No ratings yet

- International Communications in Heat and Mass Transfer: SciencedirectDocument10 pagesInternational Communications in Heat and Mass Transfer: SciencedirectYogesh KumarNo ratings yet

- FluideDocument12 pagesFluideAlexandruAlexNo ratings yet

- Thong Le BaDocument28 pagesThong Le BaAsif Abdur RehmanNo ratings yet

- Advanced Powder Technology: Karen Cacua, Robison Buitrago-Sierra, Bernardo Herrera, Farid Chejne, Elizabeth PabónDocument8 pagesAdvanced Powder Technology: Karen Cacua, Robison Buitrago-Sierra, Bernardo Herrera, Farid Chejne, Elizabeth PabónDaniel GarcíaNo ratings yet

- Roghayeh Lotfi 2012Document4 pagesRoghayeh Lotfi 2012GiovanniRoblesZarateNo ratings yet

- NF For Heat TransferDocument7 pagesNF For Heat TransferMohd Rashid SiddiquiNo ratings yet

- Review of Nanofluids For Heat Transfer Applications (Edit)Document10 pagesReview of Nanofluids For Heat Transfer Applications (Edit)mohamed mustafaNo ratings yet

- Jten 2023 9 5.20809Document17 pagesJten 2023 9 5.20809kkr.nitpyNo ratings yet

- Armsv56 N1 P1 10Document9 pagesArmsv56 N1 P1 10lavadagopal10No ratings yet

- Statistical Analysis of Thermal Conductivity of Nanofluid Containing Decorated Multi-Walled Carbon Nanotubes With Tio NanoparticlesDocument7 pagesStatistical Analysis of Thermal Conductivity of Nanofluid Containing Decorated Multi-Walled Carbon Nanotubes With Tio NanoparticlestmohanrajkecNo ratings yet

- Pei 2018Document9 pagesPei 2018Sarah RizkiaNo ratings yet

- Heat Transfer Enhancement by Nano Fluids: April 2012Document10 pagesHeat Transfer Enhancement by Nano Fluids: April 2012Jahidul IslamNo ratings yet

- Sedighi 2014Document9 pagesSedighi 2014motemig144No ratings yet

- Overview of Hybrid Nano Uids Development and Benefits: A. A. Minea and M. G. MoldoveanuDocument8 pagesOverview of Hybrid Nano Uids Development and Benefits: A. A. Minea and M. G. MoldoveanuEr. Ramji TripathiNo ratings yet

- Chemical Engineering & Processing: Process IntensificationDocument12 pagesChemical Engineering & Processing: Process IntensificationPratik Kisan SatavNo ratings yet

- Applications of Nano Uids: Current and Future: Advances in Mechanical Engineering January 2010Document12 pagesApplications of Nano Uids: Current and Future: Advances in Mechanical Engineering January 2010AGNIDEEP BAIDYANo ratings yet

- Metals 12 00165Document21 pagesMetals 12 00165anjuabrahamNo ratings yet

- Assessment of The Influence of Graphene Nanoparticles On Thermal Conductivity of Graphene Water Nanofluids Using Factorial Design of ExperimentsDocument6 pagesAssessment of The Influence of Graphene Nanoparticles On Thermal Conductivity of Graphene Water Nanofluids Using Factorial Design of ExperimentsYosseline Vargas MezaNo ratings yet

- 1 PDFDocument22 pages1 PDFDrRoja A RNo ratings yet

- Intensified Convective Heat Transfer Using ZnO Nanofluids in Heat Exchanger With Helical Coiled Geometry at Constant Wall TemperatureDocument10 pagesIntensified Convective Heat Transfer Using ZnO Nanofluids in Heat Exchanger With Helical Coiled Geometry at Constant Wall TemperatureOnime No IchinoseNo ratings yet

- 2fluid Flow & Heat Transfer Analysis of Al2O3-Water Nanofluid Within MicrochannelDocument14 pages2fluid Flow & Heat Transfer Analysis of Al2O3-Water Nanofluid Within MicrochannelSujit MishraNo ratings yet

- Heat Transfer Using Nanofluids and Its Applications - A ReviewDocument6 pagesHeat Transfer Using Nanofluids and Its Applications - A ReviewIJRASETPublicationsNo ratings yet

- Powder Technology: Suleiman Akilu, Aklilu Tesfamichael Baheta, Sujan Chowdhury, Eswaran Padmanabhan, K.V. SharmaDocument12 pagesPowder Technology: Suleiman Akilu, Aklilu Tesfamichael Baheta, Sujan Chowdhury, Eswaran Padmanabhan, K.V. Sharmamalika mudaliarNo ratings yet

- International Journal of Heat and Technology: Received: 10 October 2021 Accepted: 25 December 2021Document7 pagesInternational Journal of Heat and Technology: Received: 10 October 2021 Accepted: 25 December 2021Omar RAJADNo ratings yet

- International Journal of Heat and Mass Transfer: Ravikanth S. Vajjha, Debendra K. DasDocument8 pagesInternational Journal of Heat and Mass Transfer: Ravikanth S. Vajjha, Debendra K. DasAhmedAdrarNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Revolutionizing Energy Storage Nanomaterial Solutions for Sustainable SupercapacitorsFrom EverandRevolutionizing Energy Storage Nanomaterial Solutions for Sustainable SupercapacitorsNo ratings yet

- Process Data Sheet For Crude Oil Storage Tank (TK 1150) (CH H H P ST Ti) (Cheshme Shour Pump Station)Document4 pagesProcess Data Sheet For Crude Oil Storage Tank (TK 1150) (CH H H P ST Ti) (Cheshme Shour Pump Station)aliNo ratings yet

- Gradient Head CalculationDocument4 pagesGradient Head CalculationaliNo ratings yet

- Hot Bend StandardsDocument1 pageHot Bend StandardsaliNo ratings yet

- Process Data Sheet For Gas Oil Storage Tank (Tk-1101A/B) (Cheshme Shour Pump Station)Document4 pagesProcess Data Sheet For Gas Oil Storage Tank (Tk-1101A/B) (Cheshme Shour Pump Station)aliNo ratings yet

- P (Cheshme Shour Pump Station: Rocess Data Sheet For Gas Oil Storage Tank (Tk-1101A/B)Document4 pagesP (Cheshme Shour Pump Station: Rocess Data Sheet For Gas Oil Storage Tank (Tk-1101A/B)aliNo ratings yet

- Hydrotest Test Pressure StandardsDocument2 pagesHydrotest Test Pressure StandardsaliNo ratings yet

- Hot Bend StandardsDocument1 pageHot Bend StandardsaliNo ratings yet

- Steel Grades Eg WCBDocument4 pagesSteel Grades Eg WCBsantosh shevaleNo ratings yet

- Field-Applied Coatings For Buried and Submerged Pipes Multi Component Liquids - Epoxy & PolyurethaneDocument13 pagesField-Applied Coatings For Buried and Submerged Pipes Multi Component Liquids - Epoxy & PolyurethanealiNo ratings yet

- 05-Presentationof The Road To Success Jun2016Document20 pages05-Presentationof The Road To Success Jun2016aliNo ratings yet

- Map and Directions To NCCDocument2 pagesMap and Directions To NCCAA23 AndrewNo ratings yet

- 1 21 MESC Kalayelole&Etesalat IcofcDocument10 pages1 21 MESC Kalayelole&Etesalat IcofcaliNo ratings yet

- Commandes PDMS4Document23 pagesCommandes PDMS4Anonymous TRthlKkWWNo ratings yet

- M-Mtritfzeao Analysis of GradientDocument7 pagesM-Mtritfzeao Analysis of GradientaliNo ratings yet

- Commandes PDMS4Document23 pagesCommandes PDMS4Anonymous TRthlKkWWNo ratings yet

- Simulation of Heat Transfer and Fluid Flow in A Porous Bed of Iron Ore Pellets During Up-Draught DryingDocument6 pagesSimulation of Heat Transfer and Fluid Flow in A Porous Bed of Iron Ore Pellets During Up-Draught DryingaliNo ratings yet

- M-Mtritfzeao Analysis of GradientDocument7 pagesM-Mtritfzeao Analysis of GradientaliNo ratings yet

- Bolts PreloadDocument7 pagesBolts PreloadBruno GondimNo ratings yet

- Survey Map ProjectionsDocument32 pagesSurvey Map Projectionsrelu59No ratings yet

- Amani 2017Document48 pagesAmani 2017aliNo ratings yet

- PLDocument1 pagePLaliNo ratings yet

- TestDocument1 pageTestaliNo ratings yet

- Acsomega 1c05631Document17 pagesAcsomega 1c05631Siva SubramanianNo ratings yet

- 15 N.R Nik RoselinaDocument6 pages15 N.R Nik RoselinaNedelcuGeorgeNo ratings yet

- Dielectric and Magnetic Properties of CuFe2O4 CuO NanocompositesDocument18 pagesDielectric and Magnetic Properties of CuFe2O4 CuO NanocompositesMesutçekin100% (1)

- Easy Access To Metallic Copper NanoparticlesDocument35 pagesEasy Access To Metallic Copper NanoparticlesAlejandro SifuentesNo ratings yet

- Aerogel Seminar Report PDFDocument29 pagesAerogel Seminar Report PDFRakesh Patil80% (5)

- Ifrdnbt Abstract BookDocument154 pagesIfrdnbt Abstract BookSelvamani PalanisamyNo ratings yet

- 2020-Barcaro - Monti-Modeling Generation and Growth of Iron Oxide Nanoparticles From Representative Precursors Through ReaxFF Molecular DynamicsDocument4 pages2020-Barcaro - Monti-Modeling Generation and Growth of Iron Oxide Nanoparticles From Representative Precursors Through ReaxFF Molecular DynamicsRubin ZengNo ratings yet

- 2 Stage Air Compressor Report PDFDocument31 pages2 Stage Air Compressor Report PDFChandan JobanputraNo ratings yet

- NANOTECHNOLOGY IN MEDICINE Assignment Final DraftDocument9 pagesNANOTECHNOLOGY IN MEDICINE Assignment Final DraftMadhumita KumarNo ratings yet

- Role of Nanotech in Fertilizers ChapterDocument25 pagesRole of Nanotech in Fertilizers ChaptersatishNo ratings yet

- JPSR 09091741Document5 pagesJPSR 09091741Shraddha JaiswalNo ratings yet

- Sensors: Application of Gold-Nanoparticle Colorimetric Sensing To Rapid Food Safety ScreeningDocument16 pagesSensors: Application of Gold-Nanoparticle Colorimetric Sensing To Rapid Food Safety Screeningkhue tranNo ratings yet

- c3 Structure and BondingDocument2 pagesc3 Structure and BondingNavdha SachdevaNo ratings yet

- Ch10 Solid StateDocument30 pagesCh10 Solid StateKrish VeniNo ratings yet

- Nanoparticles Drug Delivery ThesisDocument5 pagesNanoparticles Drug Delivery Thesisafcngocah100% (2)

- 1st-1st Sem-2022qDocument24 pages1st-1st Sem-2022qAnshuman BanikNo ratings yet

- MN SR CoprecipitacionDocument10 pagesMN SR CoprecipitacionLizbethNo ratings yet

- Synergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeDocument8 pagesSynergetic Photocatalytic-Activity Enhancement of Lanthanum Doped TiO2 On Halloysite Nanocomposites For Degradation of Organic DyeBachi NanoNo ratings yet

- Spectrochimica Acta Part A: Molecular and Biomolecular SpectrosDocument9 pagesSpectrochimica Acta Part A: Molecular and Biomolecular SpectrosJesusNo ratings yet

- Thermal Conductivity and Stability of Paraffin Wax With Various Nanoparticles Without RevisionDocument30 pagesThermal Conductivity and Stability of Paraffin Wax With Various Nanoparticles Without Revisionvahit06No ratings yet

- 1709 LDocument164 pages1709 LANIT AGGARWALNo ratings yet

- Review On Nanomaterials: Synthesis and Applications: ArticleDocument10 pagesReview On Nanomaterials: Synthesis and Applications: ArticleDhanunjayaNo ratings yet

- Aiaa 45148 268Document6 pagesAiaa 45148 268Kiran ManoharanNo ratings yet

- Author's Accepted Manuscript: Ceramics InternationalDocument53 pagesAuthor's Accepted Manuscript: Ceramics InternationalZainab SattarNo ratings yet

- G9.Synthesis of Nickel Oxide Nanoparticles Using Nickel AcetateDocument4 pagesG9.Synthesis of Nickel Oxide Nanoparticles Using Nickel AcetateAvalos Gonzalez KevinNo ratings yet

- JNMR 04 00092Document4 pagesJNMR 04 00092Rajat BajajNo ratings yet

- Literature Review NanotechnologyDocument5 pagesLiterature Review Nanotechnologyfvfmxb2y100% (1)

- Physical Methods in Chemistry and Nano ScienceDocument706 pagesPhysical Methods in Chemistry and Nano ScienceSalma AbdelfadilNo ratings yet