Professional Documents

Culture Documents

B.Tech. (Mechanical Engineering) Semester VII

Uploaded by

Vipin NathOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B.Tech. (Mechanical Engineering) Semester VII

Uploaded by

Vipin NathCopyright:

Available Formats

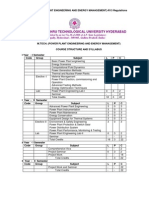

MALAVIYA NATIONAL INSTITUTE OF TECHNOLOGY JAIPUR

DEPARTMENT OF MECHANICAL ENGINEERING

B.Tech. (Mechanical Engineering)

Semester VII

Syllabus

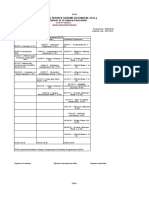

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG Department: Mechanical Engineering

Course Code: ME-314 Course Name: Power Plant Engineering

Credit: 4 L-T-P: 3-1-0

Syllabus

Present Energy Scenario: World, India, Rajasthan and future prospects.

Power Plant Economics: Various Terms and definitions, load curves, cost of electricity

generation, performance and operating characteristics, combined operation of power plants, load

division.

Steam Power Plant: Layout, site selection, coal burning methods, disposal of ash and dust,

combined cycle power plants, integrated coal gasification, major plant components: condensers,

cooling towers.

Diesel and Gas Turbine Plant: General Layout, plant components, comparison with steam

plant.

Nuclear Power Plants: Location, component of nuclear plants, types of reactors, Uranium

enrichment, safety, disposal of nuclear waste, comparison with thermal plants.

Hydro-electric Power Plant: Classification, layout, components and auxiliaries of hydro power

plant, Selection of turbines, micro hydro plants, pumped storage.

Other power plants: Wind resource assessment, types and selection of wind turbines; operation

and control of machines; Solar PV power plants: system components, selection criteria; Solar

Thermal Power Pants: Types of solar thermal plants, component description, auxiliary heating

requirement.

Books:

1. Frederick T. Morse “Power Plant Engineering” East West Press.

2. Skrotzki&Vopat. “Power Station Engineering & Economy” Tata McGraw Hill.

3. EI-Wakil M.M, “Power Plant Technology,” Tata McGraw-Hill

4. P.K. Nag “Power Plant Engineering” Tata McGraw Hill, New Delhi.

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG Department: Mechanical Engg.

Course Code: ME 411 Course Name: Air Conditioning System Design

Credit: 4 L-T-P: 3-1-0

Pre-requisite course: Engg. Thermodynamics, Fluid Mechanics and Machines, Heat Transfer

and Refrigeration and air conditioning

Syllabus

Detail study of Load Estimating: comfort conditions, weather data, solar heat gain,

cooling and heating loads

Air conditioning systems: central and unitary systems, heating and cooling coil design,

cooling tower design and selection, air cleaners and scrubbers, hydronic heating and

cooling systems, humidification and dehumidification equipments, duct design and fan

selection automatic controls, noise reduction,

Energy conservations and air conditioning for special applications: waste heat recovery,

cogeneration of power and refrigeration, industrial air conditioning for textile processing

and other applications, clean spaces, passive cooling and heating, geothermal and earth

air tunnel heat exchanger (EATHE) air conditioning system

Books:

1. Air conditioning principles and systems by Edward G. Pita, PHI (Prentice Hall of India)

2. Prasad, M., “Refrigeration and Air Conditioning”, 2nd Ed., New Age International

3. Howell, R.H., Saucer, H.J., and Coad, W.J., “Principles of Heating, Ventilation and Air

Conditioning”, ASHRAE

4. Arora, C. P., “Refrigeration and Air Conditioning”, Tata McGraw-Hill

5. ASHRAE Handbook (Fundamentals) 2005

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

Program: B.Tech. Mechanical Engineering Department: Mechanical Engineering

Course Code: ME-404 Course Name: Gas Dynamics

Credit: 4 L-T-P: 3-1-0

Syllabus

Mach number; Mach angle and cone; types of flows; Isentropic one-D flows; Adiabatic and

isentropic flows of a perfect gas; Choking and nozzle operation; Normal shock waves; Normal

and oblique shocks; Governing equations of normal shocks; Convergent – Divergent nozzles;

Constant area duct flows; Governing equation; Fanno and Rayleigh flows and lines; Steady

isothermal flow in Long pipe lines; Governing equations and features.

Books for Reference:

1. Zucker: Fundamentals of Gas dynamics

2. Shiparo: Fundamentals of Compressible Fluid flow

3. Yahya, S.M. , Introduction to compressible fluid flow

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG/PG:UG Department: Mechanical Engineering

Course Code: ME-280 Course Name: Renewable Energy Sources

Credit: 4 L-T-P: 3-1-0

Syllabus

1. INTRODUCTION: Energy demand growth and supply : Historical Perspectives ; Fossil

fuels: Consumption and Reserve ; Environmental Impacts of Burning of Fossil fuels ;

Sustainable Development and Role of Renewable Energy

2. SOLAR ENERGY BASICS: Solar geometry; Primary and Secondary Solar energy and

Utilization of Solar Energy. Characteristic advantages and disadvantages. Low temperature

applications: solar water heating, space heating, drying.

3. SOLAR THERMAL ELECTRICITY GENERATION: Solar concentrators and tracking ;

Dish and Parabolic trough concentrating generating systems, Central tower solar thermal

power plants ; Solar Ponds.

4. SOLAR PHOTOVOLTAIC SYSTEMS: Basic principle of power generation in a PV cell ;

Band gap and efficiency of PV cells ; Manufacturing methods of mono- and poly-crystalline

cells ; Amorphous silicon thin film cells, Single and multi junction cells ; Application of PV

; Brief outline of solar, PV stand-alone system design ; Storage and Balance of system.

5. WIND Energy Systems: Types of turbines, Coefficient of Power, Betz limit, Wind electric

generators, Power curve; wind characteristics and site selection; Windfarms for bulk power

supply to grid; Potential of wind electricity generation in India and its current growth rate.

6. BIOMASS ENERGY: Biomass: Sources and Characteristics; Wet biogas plants ; Biomass

gasifiers: Classification and Operating characteristics; Updraft and Downdraft gasifiers;

Gasifier based electricity generating systems; Maintenance of gasifiers.

7. OCEAN ENERGY: Tidal power plants : single basin and two basis plants, Variation in

generation level ; Ocean Thermal Electricity Conversion (OTEC) ; Electricity generation

from Waves : Shoreline and Floating wave systems.

8. GEOTHERMAL ENERGY: Geothermal sites in India ; High temperature and Low

temperature sites ; Conversion technologies- Steam and Binary systems ; Geothermal power

plants.

Books:

1. Twidell J and Weir T., Renewable Energy Resources, Taylor & Francis

2. Godfrey Boyle, Renewable energy, Oxford Press

3. V.V.N. Kishore, Renewable Energy engineering and Technology: Principles and Practice,

TERI Press.

4. Rai G.D., Non-Conventional Energy Sources, Khanna publication

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG Department: Mechanical Engineering

Course Code: ME 417 Course Name: Project Management

Credit: 4 L-T-P: 3-1-0

Syllabus

Project Management Concepts, Project Planning, Resource Scheduling, Critical Chain

Scheduling, Project Quality Management, Project performance Measurement and Control,

Project Closure/ Termination, Managing Project Teams, IT in Projects, International Projects:

Issues in managing international projects, Selection and training of employees, cross cultural

considerations.

Reference Books

1. Clifford F Gray, Erik W Larson, “Project Management-The Managerial Process”, Tata

Mcgraw-Hill Publishing Co Ltd

2. Jack Meredith, Samuel J. Mantel Jr. “Project Management- A Managerial Approach”, John

Wiley and Sons

3. John M Nicholas “Project Management For Business And Technology” Prentice Hall of

India Pvt Ltd

4. James P Lewis “Project Planning, Scheduling And Control” Tata Mcgraw-Hill Publishing

Co Ltd.

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG Department: Mechanical Engineering

Course Code: Course Name: Lean Manufacturing

Credit:4 L-T-P:3-1-0

Syllabus

Introduction to Lean Manufacturing, Value, The Value Stream, Flow, Pull, Kaizen Facilitation ,

Quick Changeover, Perfection, Value stream mapping, 5S and Visual Workplace, Agile

manufacturing, Six Sigma.

Reference Books:

1. The transition to agile manufacturing staying flexible for competitive advantage-J. C.

Montigomery, L.O.Levine-ASQC Quality press

2. Agile product development for mass customization –D. M. Anderson, Joseph Pine-Irwin

Professional Publishing

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG Department: Mechanical Engineering

Course Code: ME 422 Course Name: Supply Chain Management

Credit: 4 L-T-P:3-1-0

Syllabus

Supply Chain Management introduction, Strategic Fit & Scope, Supply Chain Drivers and

Obstacles, Designing the distribution network , Planning demand and supply in supply chain,

Planning and managing inventories in a supply chain, Transportation Sourcing, and pricing

products, Coordination and Technology in the Supply Chain

Reference Books

1. Sunil Chopra & Peter Meindl: “Supply Chain Management: Strategy, Planning and

Operation”, Pearson Education, Third Edition 2007.

2. Donal J. Bowersox, David J. Closs, M. Bixby Cooper, “Supply Chain Logistics

Management”, Tata McGraw Hill, 2nd edition. 2007.

3. Ronald H. Ballou, “ Business Logistics and Supply Chain Management”, Pearson

Education, 5th Edition, 2004.

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG Department: Mechanical Engineering

Course Code: Course Name:Total Productive Maintenance

Credit:4 L-T-P:3-1-0

Syllabus

Introduction to Maintenance Systems, Maintainability, Condition-Based Maintenance (CBM),

Reliability – Centred Maintenance (RCM), Asset and Spare Parts Management, Maintenance

Lubricants and Their Applications, Safety Engineering and Fault Tree Analysis, Total Productive

Maintenance, Maintenance Planning and Scheduling, Computer Applications in Maintenance

Management, Statistical Distribution in Preventive Maintenance, Maintenance Integration,

Maintenance Effectiveness

Reference Books:

1. Mishra R.C. & K. Pathak, Maintenance Engineering and Management, Prentice-Hall of

India., 2002

2. Sushil Kumar Srivastava, Industrial Maintenance Management, S. Chand & Company,

2002.

3. Krishnan N.V., Safety Management in Industry, Jaico Publishing House, 1993.

4. L M Deshmukh, Industrial Safety Management, TMH, 2006.

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG Department: ME

Course Code: ME-405 Course Name: Finite Element Methods

Credit: 4 L-T-P: 3-1-0

Syllabus

(i) Introduction, Fundamentals of continuum mechanics, Boundary conditions, Rayleigh-Ritz

Method, Galerkin’s Method.

(ii) One Dimensional Problems: Finite Element Modeling, Coordinates and Shape Functions,

Galerkin’s approach, Assembly of the Global stiffness Matrix and Load Vector, Treatment

of Boundary Conditions – Elimination Approach, Penalty Approach, Multipoint

Constraint, Quadratic Shape Functions, Temperature Effects.

(iii) Plane Trusses: Local and Global Coordinate System, Element Stiffness Matrix, Stress

Calculations, Temperature Effects.

(iv) Two Dimensional Problems using Constant Strain Triangle Element: Isoparametric

Representation, Potential Energy Approach, Element Stiffness Matrix, Force Terms,

Galerkin’s Approach, Stress Calculations, Temperature Effects.

(v) Axisymmetric Solids Subjected to Axisymmetric Loading: Formulation, Potential Energy

Approach, Body Force, Rotating Flywheel, Surface Traction, Galerkin’s Approach, Stress

Calculations, Temperature Effects.

(vi) Two Dimensional Isoparametric Elements and Numerical Integration: Four nodded

quadrilateral, Numerical Integration, Higher Order Elements

(vii) Beams and Frames: Finite Element Formulation using Potential Energy Approach and

Galerkin’s Approach, Load Vector, Boundary Conditions, Shear Force and Bending

Moment, Beams on Elastic Supports, Plane Frames.

(viii) Dynamic Considerations: Formulation, Element Mass Matrix, Eigenvalue and Eigenvector

evaluation, Determination of Critical Speeds, Guyan Reduction, Rigid Body Modes.

Books

(i) C.S. Krishnamurthy, “Finite Element Analysis”, Tata McGraw Hill, New Delhi.

(ii) TripathiR , “Introduction to Finite Element Engineering”, Prentice Hall of India, Pvt.Ltd

New Delhi.

(iii) Klaus, Jurgen Bathe, “Finite Element Procedures in Engineering Analysis”, Prentice Hall

of India Pvt. Ltd. New Delhi.

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG Department: ME

Course Code: ME-414 Course Name: CAD

Credit: 4 L-T-P: 3-1-0

Syllabus

Introduction to Computer Graphics Fundamentals: Output primitif (points, lines, curves etc.,), 2-

D & 3-D transformation (Translation,scaling,rotators) windowing - view ports - clipping

transformation. Representation of curves – Bezier curves - cubic spline curve - B – Spline

curves - Rational curves –Surface Modeling techniques - surface patch – Coons patch- bi-cubic

patch – Bezier and B-spline surfaces – Volume modeling – Boundary models – CSG- other

modeling techniques.

Writing interactive programs to solve design problems and production of drawings - using any

languages like Auto LISP/C/FORTRAN etc.- creation of surfaces - solids etc. using solid

modeling packages (prismatic and revolved parts).

Solid Modeling:Regularized Boolean set operations - primitive instancing - sweep

representations - boundary representations - constructive solid Geometry - comparison of

representations - user interface for solid modeling. Graphics and computing standards– Open GL

Data Exchange standards – IGES, STEP etc– Communication standards.

Assembly of Parts:Assembly modeling - interferences of positions and orientation - tolerances

analysis - mass property calculations - mechanism simulation.

Product Dissection:Experiments using building blocks, mechanisms, small motor mechanisms

and build a product working model etc; Dissection using dissection modules. Dissection of

common consumer product and mapping of function, concept and form.

References:

1. William M Neumann and Robert F.Sproul “Principles of Computer Graphics”, McGraw Hill

Book Co. Singapore, 1989.

2. Donald Hearn and M. Pauline Baker “Computer Graphics”, Prentice Hall, Inc., 1992.

3. Ibrahim Zeid Mastering CAD/CAM – McGraw Hill, International Edition, 2007.

4. Foley, Wan Dam, Feiner and Hughes – Computer graphics principles & practices, Pearson

Education – 2003.

5. Donald Heam and M. Pauline Baker “Computer Graphics”, Prentice Hall, Inc., 1992.

6. YousefHaik, Engineering Design Process, Vikas Publishing house, New Delhi, 2003.

7. G. Pahl, and W. Beitz, Engineering Design – A Systematic Approach, Springer – Verlag,

1996.

8. K. Otto and K. wood, Product Design – techniques in reverse engineering and new product

development, Pearson Education, New Delhi, 2004.

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG Department: ME

Course Code: ME-416 Course Name: Design of Mechanisms

Credit: 4 L-T-P: 3-1-0

Pre-requisite course: Engineering Mechanics, Kinematics and Dynamics of Machines

Syllabus

Study of existing mechanisms used in industry, machine tools, vehicles, high speed machinery.

Classification of mechanisms. Structural analysis and synthesis for conceptual design. Theory of

path curvature and finitely movements. Kinematic and dynamic design. Spatial Mechanisms.

Errors in mechanisms and machines. Coding, evaluation and dimensional synthesis of

mechanisms.

Text Books:

1. Mechanism Design: Analysis and Synthesis, Vol. I & II, A.G. Erdman and G.N. Sandor,

Prentice-Hall

2. Geometric Design of Linkages, J.M. McCarthy, Springer

3. Kinematic Synthesis of Linkages, R. S.Hartenberg, and J Denavit,., McGraw-Hill

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG/PG : UG Department: Mechanical Engineering

Course Code: Course Name: Advanced Metal Forming

Credit: 4 L-T-P:3-1-0

Syllabus

UNIT I:

Fundamentals of Metal Forming: Classification of forming processes, mechanism of metal

forming, temperature of metal working, hot working, cold working, friction and lubricants.

UNIT II:

Rolling of metals: Rolling processes, forces and geometrical relationship in rolling, simplified

analysis, rolling load, rolling variables, theories of cold and hot rolling, problems and defects in

rolling, torque and power calculations.

UNIT III:

Forging: Classification of forging processes, forging of plate, forging of circular discs, open die

and closed-die forging, forging defects, and powder metallurgy forging.

UNIT IV:

Extrusion: Classification, Hot Extrusion, Analysis of Extrusion process, defects in extrusion,

extrusion of tubes, production of seamless pipes.

UNIT V:

Drawing: Drawing of tubes, rods, and wires: Wire drawing dies, tube drawing process,analysis

of wire, deep drawing and tube drawing.

UNIT VI:

Sheet Metal forming: Forming methods, Bending, stretch forming, spinning and Advanced

techniques of Sheet Metal Forming, Forming limit criteria, defect in formed parts. Advanced

Metal forming processes: HERF, Electromagnetic forming, residual stresses, in-process heat

treatment and computer applications in metal forming.

UNIT VII:

Introduction to Press tool design: Design of various press tools and dies like piercing dies,

blanking dies, compound dies and progressive blanking dies, design of bending, forming

and drawing dies.

UNIT VIII:

Analysis of Forming Process, Slab method, Upper & lower bound, FEM based simulation, slip

line theory, Use of CAE platform for Die Design & Simulation.

Books:

1. Mechanical Metallurgy / G.E. Dieter / Tata McGraw Hill, 1998. III Edition2. Principles of

Metal Working / Sunder Kumar

2. Principles of Metal Working processes / G.W. Rowe

3. ASM Metal Forming Hand book

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG/PG : UG Department: Mechanical Engineering

Course Code: Course Name: Design for Manufacturing

Credit: 4 L-T-P: 3-1-0

Syllabus

Introduction: Need Identification and Problem Definition, Concept Generation and Evaluation,

Embodiment Design.

Selection of Materials and Shapes: Properties of Engineering Materials, Selection of Materials,

Use of software database for material selection e.g. Plastic Adviser, Selection of Shapes, Co-

selection of Materials and Shapes, Case Studies.

Selection of Manufacturing Processes: Review of Manufacturing Processes, Design for

Casting, Design for Bulk Deformation Processes, Design for Sheet Metal Forming Processes,

Design for Machining, Design for Powder Metallurgy, Design for Polymer Processing , Co-

selection of Materials and Processes, Case-Studies, DFM module of CAD/CAM/CAE Tools e.g.

DFM Pro etc..

Design for Assembly: Review of Assembly Processes, Design for Welding, Design for Brazing

and Soldering, Design for Adhesive Bonding, Design for Joining of Polymers, Design for Heat

Treatment, Case-Studies.

Design for Reliability and Quality: Failure Mode and Effect Analysis(FMEA), Design for

Quality, Design for Reliability, Approach to Robust Design, Design for Optimization

Books:

1. M F Ashby and K Johnson, Materials and Design - the art and science of material selection in

product design, Butterworth-Heinemann, 2003.

2. G Dieter, Engineering Design - a materials and processing approach, McGraw Hill, NY,

2000.

3. M F Ashby, Material Selection in Mechanical Design, Butterworth-Heinemann, 1999.

4. T H Courtney, Mechanical Behavior of Materials, McGraw Hill, NY, 2000.

5. K G Swift and J D Booker, Process selection: from design to manufacture, London: Arnold,

1997.

6. S SRao, Engineering Optimization: theory and practice, John Wiley, NY, 1996.

7. G Boothroyd, P Dewhurst and W Knight, Product design for manufacture and assembly,

John Wiley, NY: Marcel Dekkar, 1994.

8. J G Bralla, Handbook for Product Design for Manufacture, McGraw Hill, NY, 1998.

9. Houldcroft, Which Process – an introduction to welding and related processes and guide to

their selection, Cambridge, Abington Pub., 1990.

10. ASTM Design handbook.

11. Engineering Design and Design for Manufacturing by Dixen& Poly, University of Mas.

Press

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

UG/PG : UG Department: Mechanical Engineering

Course Code: Course Name:Product Engineering

Credit: 4 L-T-P:3-1-0

Syllabus

UNIT-I – Project Management

Introduction to Project Management (PM), Collaborative Working, PM Tutorials and their

implementation for the same in their projects in tools such as Microsoft Projects.

UNIT-II – Ideation & conceptual Design

Elements of design; Product development cycle overview; Market demands and trends for

products; Product Lifecycle Management (PLM) overview; Ideation and conceptual design phase

introduction; Benefits and use cases of ideation and conceptual design, Capturing Voice of the

customer (VOC), Use of Trizz in ideation, Intellectual Property Rights (IPRs).

UNIT-III - Product Engineering – Component Design

Product Design Phase – I: The evolution of CAD: Benefits of Digital Prototyping Design:

General 3D Design Concepts.

Product Design Phase–Part 2; Design for manufacturing, introduction; Design styled

components.

Product Design Phase – Part 3; Top Down and Bottom Up Design Methods; Manufacturing and

Engineering Bill of Materials (BOMs); Team and Collaborative based Design.

UNIT-IV - Product Engineering – Documentation (Drawings)

Design Documentation Requirements; Importance and benefits of design documentation; When

do you need documentation and when do you not; Drawings requirements (Detailed drawings &

Assembly Drawings), Design changes and Automation & Visualization Extending DesignData.

UNIT – V – Prototyping, Testing & User Trials

Need - Development of RP systems, RPT Technologies, Rapid Tooling & Case Studies.

Books:

1. Joseph E. Shigley& Larry D. Mitchell, “Mechanical Engineering Design”, Fourth Edition,

McGraw-Hill International Book Company.

2. Machine Design - An Integrated Approach -- Robert L. Norton – Pearson Education.

3. Mastering Autodesk Inventor by Sybex

4. Autodesk Inventor 2012 for Designers by CADCIM Technologies

5. Rapid prototyping, Andreas Gebhardt, Hanser Gardener Publications, 2003.

6. Rapid Prototyping and Engineering applications : A tool box for prototype development,

LiouW.Liou, Frank W.Liou, CRC Press, 2007.

7. Rapid Prototyping: Theory and practice, Ali K. Kamrani, EmadAbouel Nasr, Springer, 2006

8. Engineering Design and Design for Manufacturing by Dixen& Poly, University of Mas.

Press

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

DUGC Convener Curriculum Committee Convener SUGB Chairman

Date:

You might also like

- Advanced Power Plant EngineeringDocument2 pagesAdvanced Power Plant EngineeringRaja RKNo ratings yet

- Technologies for Solar Thermal Energy: Theory, Design and, OptimizationFrom EverandTechnologies for Solar Thermal Energy: Theory, Design and, OptimizationMd HasanuzzamanNo ratings yet

- Polyethylene Plastic Production ProcessDocument8 pagesPolyethylene Plastic Production Processkiki haikalNo ratings yet

- Worm Drives PDFDocument6 pagesWorm Drives PDFdesetekNo ratings yet

- Physiology MCQDocument3 pagesPhysiology MCQDr Md Abedur Rahman90% (10)

- The Detection of Earnings Manipulation Messod D. BeneishDocument27 pagesThe Detection of Earnings Manipulation Messod D. BeneishOld School Value100% (13)

- M.tech SyllabusDocument41 pagesM.tech SyllabusRushikeshKatkarNo ratings yet

- List of Indian Standard Code For Civil and Structural Works PDFDocument148 pagesList of Indian Standard Code For Civil and Structural Works PDFKalipada Sen100% (1)

- Chemistry For Engineers REVIEWEEERDocument26 pagesChemistry For Engineers REVIEWEEERJames Philip Relleve100% (5)

- Renewable Energy Sources and Engery Conservation PDFDocument6 pagesRenewable Energy Sources and Engery Conservation PDFYugalNo ratings yet

- Teachers Manual Diploma Hydropower EngineeringDocument270 pagesTeachers Manual Diploma Hydropower EngineeringVanu Vamalai60% (5)

- Methods of Analysis and Solutions of Crack ProblemsDocument562 pagesMethods of Analysis and Solutions of Crack ProblemsgedysonlimaNo ratings yet

- Energy Storage for Multigeneration: Desalination, Power, Cooling and Heating ApplicationsFrom EverandEnergy Storage for Multigeneration: Desalination, Power, Cooling and Heating ApplicationsVeera Gnaneswar GudeNo ratings yet

- Elect3 2Document2 pagesElect3 2pranav10dulkarNo ratings yet

- B.Tech. (Mechanical Engineering) Semester IVDocument11 pagesB.Tech. (Mechanical Engineering) Semester IVmahavircNo ratings yet

- MNIT Jaipur Mechanical Engineering SyllabusDocument9 pagesMNIT Jaipur Mechanical Engineering SyllabusRana SinghNo ratings yet

- M Tech - Energy-Technology Course STR and SyllabusDocument1 pageM Tech - Energy-Technology Course STR and SyllabusAnkur MaheshwariNo ratings yet

- Power Plant Engineering and Energy Management 2Document22 pagesPower Plant Engineering and Energy Management 2RAPRATSINNo ratings yet

- Engineering Colleges: Department of Mechanical EngineeringDocument126 pagesEngineering Colleges: Department of Mechanical EngineeringchandramouliNo ratings yet

- M.M.University, Mullana 2008: B.Tech. (Eighth Semester) Mechanical Engineering ME-404 Power Plant EngineeringDocument5 pagesM.M.University, Mullana 2008: B.Tech. (Eighth Semester) Mechanical Engineering ME-404 Power Plant Engineering11090482No ratings yet

- Third Year Second Semester: Department of Mechanical Engineering - Course CatalogueDocument8 pagesThird Year Second Semester: Department of Mechanical Engineering - Course CatalogueSudeep GamerNo ratings yet

- Btech Vi Sem Syallbus 21-22030622124018Document22 pagesBtech Vi Sem Syallbus 21-22030622124018Manish NayakNo ratings yet

- SyllabusDocument4 pagesSyllabusArjun SainiNo ratings yet

- Renewable Energy Sources Professional ElDocument6 pagesRenewable Energy Sources Professional Elசற்குணத்தமிழன் செNo ratings yet

- M.SC - in Mechanical EngineeringDocument41 pagesM.SC - in Mechanical EngineeringIslam FattouhNo ratings yet

- Course File FormatDocument3 pagesCourse File FormatThiaga RajanNo ratings yet

- New SME Lab ManualDocument64 pagesNew SME Lab ManualSahil GupteNo ratings yet

- Course File PPE OriginalDocument16 pagesCourse File PPE OriginalMadan Mohan ReddyNo ratings yet

- Department of Mechanical Engineering: B. Tech. Detailed Syllabus (Semester-V)Document4 pagesDepartment of Mechanical Engineering: B. Tech. Detailed Syllabus (Semester-V)Thennarasu RamachandranNo ratings yet

- NEW AND RENEWABLE ENERGY SYSTEMS INTRODUCTIONDocument32 pagesNEW AND RENEWABLE ENERGY SYSTEMS INTRODUCTIONdondbNo ratings yet

- BME Course Data SheetDocument5 pagesBME Course Data SheetBasilNo ratings yet

- Course Information Confidential: Universiti Teknologi MaraDocument6 pagesCourse Information Confidential: Universiti Teknologi MaraFaiz BakarNo ratings yet

- Basic Mechanical EngineeringDocument3 pagesBasic Mechanical EngineeringAkshay KharmateNo ratings yet

- Institute of Engineering & Technology, Devi Ahilya University, Indore, (M.P.), India. (Scheme Effective From July 2015)Document2 pagesInstitute of Engineering & Technology, Devi Ahilya University, Indore, (M.P.), India. (Scheme Effective From July 2015)NARESH KUMARNo ratings yet

- B. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalDocument10 pagesB. Tech. 8 Semester Mechanical Engineering: Theory Sessional TotalAbhishek MeNo ratings yet

- Beme805T: Energy Conversion - Iii (Theory)Document2 pagesBeme805T: Energy Conversion - Iii (Theory)Saifuddin AhmedNo ratings yet

- Basic Thermodynamics (BTME-305-18)Document14 pagesBasic Thermodynamics (BTME-305-18)Surjit Kumar GandhiNo ratings yet

- Btech Viii Sem Syallbus 21-22030622124052Document16 pagesBtech Viii Sem Syallbus 21-22030622124052Manish NayakNo ratings yet

- MTech EnergyDocument28 pagesMTech EnergyPrashant100% (1)

- Production ElectivesDocument20 pagesProduction ElectivesAdhi ThyanNo ratings yet

- Iii Mech Vi Sem QB 2013 2014 Even PDFDocument137 pagesIii Mech Vi Sem QB 2013 2014 Even PDFSiva RamanNo ratings yet

- Syllabus NITH ME 7th SemDocument36 pagesSyllabus NITH ME 7th SemVijay KumarNo ratings yet

- Cse-I-Elements of Mechanical Engg. l1Document11 pagesCse-I-Elements of Mechanical Engg. l1Hemanth Kumar ReddyNo ratings yet

- Department of Mechanical Engineering, SJBITDocument65 pagesDepartment of Mechanical Engineering, SJBITMahavir DamakaleNo ratings yet

- Department of Mechnical Engineering: CreditsDocument7 pagesDepartment of Mechnical Engineering: CreditsRoshan Virat PandeyNo ratings yet

- Course Module (VI Sem)Document7 pagesCourse Module (VI Sem)Vijay KumawatNo ratings yet

- And Domkundawar, S., A Course in Power Plant Engineering, Dhanpatrai (2002)Document2 pagesAnd Domkundawar, S., A Course in Power Plant Engineering, Dhanpatrai (2002)Dr. Gollapalli NareshNo ratings yet

- Syllabus Final YearDocument5 pagesSyllabus Final YearPradeep JangidNo ratings yet

- Eee4003 Generation and Utilization of Electrical Energy Eth 1.0 37 Eee4003Document2 pagesEee4003 Generation and Utilization of Electrical Energy Eth 1.0 37 Eee4003Akash JhaNo ratings yet

- Energy. Syllabus 2009 - Sem 2Document31 pagesEnergy. Syllabus 2009 - Sem 2Suseel Jai KrishnanNo ratings yet

- Comprehensive VivaDocument9 pagesComprehensive VivaSAURABH KUMAR PANDEY Research Scholar, Chemical Engg. & Technology , IIT(BHU)No ratings yet

- EN3ES03 Basic Mechanical Engineering SyllabusDocument2 pagesEN3ES03 Basic Mechanical Engineering SyllabusRahul ThakurNo ratings yet

- 8th Sem EEEDocument34 pages8th Sem EEERahul PandeyNo ratings yet

- Subject PlanDocument4 pagesSubject PlanAya HassanNo ratings yet

- Gujarat Technological University: W.E.F. AY 2018-19Document3 pagesGujarat Technological University: W.E.F. AY 2018-19AkashNo ratings yet

- Power Plant Engg SyllabusDocument2 pagesPower Plant Engg SyllabusPdisk LinksNo ratings yet

- SyllabusDocument6 pagesSyllabusAbhishek KumarNo ratings yet

- Mepc23 Energy Conversion Systems A&bDocument4 pagesMepc23 Energy Conversion Systems A&bNarendra SinghNo ratings yet

- Renewable Energy ResourcesDocument3 pagesRenewable Energy ResourcesSandeep SunnyNo ratings yet

- ME6352 Manufacturing Technology LTPC 3 0 0 3 ObjectivesDocument14 pagesME6352 Manufacturing Technology LTPC 3 0 0 3 ObjectivespugazhNo ratings yet

- 15 Scheme 7th SEM Lesson Plans Compressed PDFDocument25 pages15 Scheme 7th SEM Lesson Plans Compressed PDFSmithaNo ratings yet

- Conventional Power Engineering - Institute Elective - IIDocument2 pagesConventional Power Engineering - Institute Elective - IIBhavesh PipaliyaNo ratings yet

- Csvtu 8th Sem Syllabus For Mechanical EngineeringDocument34 pagesCsvtu 8th Sem Syllabus For Mechanical Engineeringveer_s0% (1)

- B.Tech Non-Conventional Energy Sources SyllabusDocument4 pagesB.Tech Non-Conventional Energy Sources Syllabusarunscribd20No ratings yet

- EE Module 2Document52 pagesEE Module 2Dhanush S GowdaNo ratings yet

- Renewable Energy Production and Distribution Volume 2: Solutions and OpportunitiesFrom EverandRenewable Energy Production and Distribution Volume 2: Solutions and OpportunitiesMejdi JeguirimNo ratings yet

- Advanced Materials based Thermally Enhanced Phase Change Materials: Fundamentals and ApplicationsFrom EverandAdvanced Materials based Thermally Enhanced Phase Change Materials: Fundamentals and ApplicationsNo ratings yet

- NSS Volunteer Activity ChartDocument1 pageNSS Volunteer Activity ChartVipin NathNo ratings yet

- National Service Scheme (Technical Cell) : Directorate of Technical EducationDocument1 pageNational Service Scheme (Technical Cell) : Directorate of Technical EducationVipin NathNo ratings yet

- National Service Scheme (Technical Cell) : Directorate of Technical EducationDocument1 pageNational Service Scheme (Technical Cell) : Directorate of Technical EducationVipin NathNo ratings yet

- National Service Scheme (Technical Cell) : Directorate of Technical EducationDocument1 pageNational Service Scheme (Technical Cell) : Directorate of Technical EducationVipin NathNo ratings yet

- National Service Scheme (Technical Cell) : Directorate of Technical EducationDocument1 pageNational Service Scheme (Technical Cell) : Directorate of Technical EducationVipin NathNo ratings yet

- National Service Scheme (Technical Cell) : Directorate of Technical EducationDocument1 pageNational Service Scheme (Technical Cell) : Directorate of Technical EducationVipin NathNo ratings yet

- Prestress ConcreteDocument10 pagesPrestress Concretebemd_ali6990No ratings yet

- Unirub Techno India PVT 7Document7 pagesUnirub Techno India PVT 7BalajiYachawadNo ratings yet

- 3 D Via Composer Error LogDocument9 pages3 D Via Composer Error LogNilesh A. KhedekarNo ratings yet

- RunEco EP600 Datasheet 2018Document2 pagesRunEco EP600 Datasheet 2018widnu wirasetiaNo ratings yet

- Unit 5 HomeworkDocument5 pagesUnit 5 HomeworkjonahNo ratings yet

- Atoms and Molecules Multiple Choice Questions SolvedDocument7 pagesAtoms and Molecules Multiple Choice Questions SolvedDevendra ShuklaNo ratings yet

- NORSOK BULK SYSTEM STANDARDDocument3 pagesNORSOK BULK SYSTEM STANDARDnurwinanto01No ratings yet

- 1 to 10 DSBDA case studyDocument17 pages1 to 10 DSBDA case studyGanesh BagulNo ratings yet

- SREye - Fisheye Image Dewarping Module For NVR and Viewer PDFDocument16 pagesSREye - Fisheye Image Dewarping Module For NVR and Viewer PDFyshim_4No ratings yet

- Math403 - 4.0 Continuous Probability DistributionDocument42 pagesMath403 - 4.0 Continuous Probability DistributionMae FalcunitinNo ratings yet

- 2023 2024 S1 SB Assignment CorrectedDocument3 pages2023 2024 S1 SB Assignment Corrected31231022022No ratings yet

- Varisoft Eq 100 Ti c0920 CosmotecDocument3 pagesVarisoft Eq 100 Ti c0920 CosmotecHayala MotaNo ratings yet

- Preprint Xyz IsmcDocument9 pagesPreprint Xyz IsmcThien MaiNo ratings yet

- GEN SPQ RN MSM6280 Based Firmware Release FW2.4.6 v12 F2Document32 pagesGEN SPQ RN MSM6280 Based Firmware Release FW2.4.6 v12 F2djnhh0an100% (1)

- Introduction To Bioinformatics: Database Search (FASTA)Document35 pagesIntroduction To Bioinformatics: Database Search (FASTA)mahedi hasanNo ratings yet

- Power Control in Ac Isolated Microgrids With Renewable Energy Sources and Energy Storage SystemsDocument1 pagePower Control in Ac Isolated Microgrids With Renewable Energy Sources and Energy Storage SystemssriluNo ratings yet

- Pivot and UnpivotDocument5 pagesPivot and UnpivotSuzan FernandesNo ratings yet

- Mechanical Engineering Laboratory InstrumentationDocument1 pageMechanical Engineering Laboratory InstrumentationGonzalo LNo ratings yet

- Brochure Allweiler AllfuelDocument12 pagesBrochure Allweiler AllfuelbalramkinageNo ratings yet

- Probability and Statistical Inference AssignmentsDocument3 pagesProbability and Statistical Inference AssignmentsDemi AlantéNo ratings yet

- PS3 Prompt Explained With Examples in LinuxDocument2 pagesPS3 Prompt Explained With Examples in LinuxSaka KelyNo ratings yet

- ISO 15614 vs ASME IX welding standards comparisonDocument2 pagesISO 15614 vs ASME IX welding standards comparisontuanNo ratings yet

- FOG HORN Suppressors and Shooting AngleDocument2 pagesFOG HORN Suppressors and Shooting AngleTwobirds Flying PublicationsNo ratings yet

- BE Information Technology 0Document655 pagesBE Information Technology 0virendra giraseNo ratings yet