Professional Documents

Culture Documents

Ultrasonic Testing Thickness Measurement Report: Component Description

Ultrasonic Testing Thickness Measurement Report: Component Description

Uploaded by

Pand AemonaEonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ultrasonic Testing Thickness Measurement Report: Component Description

Ultrasonic Testing Thickness Measurement Report: Component Description

Uploaded by

Pand AemonaEonCopyright:

Available Formats

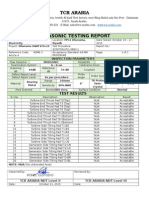

ULTRASONIC TESTING THICKNESS MEASUREMENT REPORT

PREVIOUS EXAMINATION

PLANT : COGEN : 6/03/2016

DATE

CURRENT EXAMINATION

TAG NO : V1-2801C : 5/03/2019

DATE

DESCRIPTION :NATURAL GAS SURGE DRUM C DOSH REG NO (if any): : PMT-140508

MATERIAL OF CONSTRUCTION : CARBON STEEL INSTRUMENT TYPE/BRAND : OLYMPUS

SEARCH UNIT SIZE : 10mm INSTRUMENT MODEL : 38DL PLUS

SEARCH UNIT TYPE : TWIN CRYSTAL COUPLANT TYPE : WALLPAPER PASTE

SEARCH UNIT FREQUENCY : 5MHz CALIBRATION BLOCK : STEP WEDGE

□ High temp couplant & search unit

□ Hot plates

SURFACE TEMPERATURE : AMBIENT CORRECTIVE PROCEDURE □ Temperature Correction Factor

□ No corrective procedure required

COMPONENT DESCRIPTION:

NOMINAL MINIMUM PREVIOUS CURRENT CORRECTED

REF. PRBI THICKNESS

DESCRIPTION THICKNESS THICKNESS PRBI MEASURED THICKNESS

POINT (mm)

(mm) (mm) THICKNESS THICKNESS (mm)

(mm) (mm)

HT01 HEAD TOP 43.00 42.54 43.04

HT02 HEAD TOP 43.00 42.42 43.89

HT03 HEAD TOP 43.00 42.84 43.37

HT04 HEAD TOP 43.00 42.78 43.40

HB01 HEAD BOTTOM 43.00 43.10 43.39

HB02 HEAD BOTTOM 43.00 43.20 43.59

HB03 HEAD BOTTOM 43.00 43.15 43.56

HB04 HEAD BOTTOM 43.00 43.00 43.35

SA01 SHELL 39.00 37.72 37.63

SA02 SHELL 39.00 37.73 37.73

SA03 SHELL 39.00 37.69 37.61

SA04 SHELL 39.00 37.70 37.74

SA05 SHELL 39.00 37.78 37.71

SA06 SHELL 39.00 37.70 37.62

SA07 SHELL 39.00 37.80 37.71

SA08 SHELL 39.00 37.78 37.71

NB01 NOZZLE 21.44 21.42 17.76

NA01 NOZZLE N/A N/A 20.72

Reviewed By : _____________. Approved By : _____________.

Position: Position:

Examined By : AHMAD AZMI. □ Risk Based Inspection Engineer

□ Inspection Engineer

□ Inspection Technician □ Corrosion Engineer

Date : 5.9.2018.

Date:______________. Date:______________.

FORM NO : OeXMS-06.01.02 L3 UTTM/F05 REVISION NO : 3 DATE :

PAGE NO : 1 OF 1 TITLE : ULTRASONIC TESTING THICKNESS MEASUREMENT REPORT

You might also like

- Procedure For Manual Ultrasonic Testing PDFDocument17 pagesProcedure For Manual Ultrasonic Testing PDFbaskaran ayyapparaj100% (2)

- Storage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFDocument1 pageStorage Tank Hydrostatic Test Quality Control and Inspection Report Form PDFNatarajan Raja100% (2)

- UT ASME Report FormatDocument2 pagesUT ASME Report Formatrifa100% (1)

- ASME VIII CalculationDocument15 pagesASME VIII CalculationJoao Osmar Correa100% (1)

- DP Format Bhel 1Document1 pageDP Format Bhel 1narayandasraikwar100% (1)

- Api Ut Thickness Procedure PDFDocument7 pagesApi Ut Thickness Procedure PDFShreekanthKannath100% (1)

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- RT Technique Sheet + Report Rev 4Document2 pagesRT Technique Sheet + Report Rev 4g_sancheti100% (3)

- MPT Report FormatDocument1 pageMPT Report Formatvalararumugams100% (1)

- QCF304 Magnetic Particle Testing ReportDocument2 pagesQCF304 Magnetic Particle Testing Reportminhnn100% (1)

- Method Statement For Dye Penetrant Test For Storage TanksDocument5 pagesMethod Statement For Dye Penetrant Test For Storage Tanksmecmacho100% (3)

- Oil Chalk Test/Penetrating Oil TestDocument6 pagesOil Chalk Test/Penetrating Oil TestWeld ManiacNo ratings yet

- Bolt Tightening ReportDocument2 pagesBolt Tightening Reportrimshadtp67% (3)

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Wtm-046 RT Procedure Aws D 1.1 2010-V01Document16 pagesWtm-046 RT Procedure Aws D 1.1 2010-V01Wisüttisäk Peäröön100% (2)

- PT NDT Sample Test Report Format PDFDocument1 pagePT NDT Sample Test Report Format PDFVarun Malhotra100% (1)

- Dye Penetration Inspection Report SampleDocument2 pagesDye Penetration Inspection Report Samplehafizi salimanNo ratings yet

- Automated Ultrasonic Report Sample PHASE ARRAYDocument2 pagesAutomated Ultrasonic Report Sample PHASE ARRAYAzrul Hanif100% (2)

- DPT Test Report FormatDocument1 pageDPT Test Report FormatAlam MD SazidNo ratings yet

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 pagesP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal Menon100% (1)

- PCN Examination and Training Fee StructureDocument3 pagesPCN Examination and Training Fee StructureKarthik Karunanidhi67% (3)

- Inspection Report Radiographic TestingDocument1 pageInspection Report Radiographic TestingJindarat Kasemsooksakul0% (1)

- Ut FormDocument1 pageUt FormTrung Tinh Ho100% (1)

- Sample Magnetic Particle Inspection ReportDocument3 pagesSample Magnetic Particle Inspection ReportOby100% (2)

- MPI Report FormatDocument4 pagesMPI Report Formatpankaj ranaNo ratings yet

- Mpi Report SampleDocument6 pagesMpi Report SampleGowrisanthosh PalikaNo ratings yet

- Plate Inspection ReportDocument1 pagePlate Inspection ReportlalitaliNo ratings yet

- Flushing Cleaning of Piping ReportDocument1 pageFlushing Cleaning of Piping ReportAhmed GomaaNo ratings yet

- VACCUM BOX Test ReportDocument1 pageVACCUM BOX Test ReportYu Haiyue100% (1)

- Positive Material Identification ProcedureDocument6 pagesPositive Material Identification Procedureomar100% (1)

- Communication Systems by B P Lathi PDFDocument2 pagesCommunication Systems by B P Lathi PDFAshley0% (3)

- Vacuum Box Test Report of Tank T-8112 Bottom PlatesDocument8 pagesVacuum Box Test Report of Tank T-8112 Bottom PlatesShalom LivingstonNo ratings yet

- UT Thickness ProcedureDocument8 pagesUT Thickness ProcedureManoj Balla100% (3)

- Liquid Penetrant Examination ReportDocument7 pagesLiquid Penetrant Examination ReportmizanNo ratings yet

- HT - Paut-Asme-01: Hi-Tech NDT Inspections Services (S) Pte. LTDDocument25 pagesHT - Paut-Asme-01: Hi-Tech NDT Inspections Services (S) Pte. LTDphanthanhhungNo ratings yet

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (5)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (5)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (5)

- Daily Painting Inspection Report 01Document1 pageDaily Painting Inspection Report 01Oussama Ben AbbesNo ratings yet

- Ultrasonic Testing Report Format Based On IACSDocument1 pageUltrasonic Testing Report Format Based On IACSDeepak100% (6)

- C - 1531 RLDocument11 pagesC - 1531 RLPand AemonaEonNo ratings yet

- Marine Ultrasonic Testing ReportDocument1 pageMarine Ultrasonic Testing ReportRonanki RaviNo ratings yet

- Vacuum Box Test Report - Eff.170628Document1 pageVacuum Box Test Report - Eff.170628Jindarat KasemsooksakulNo ratings yet

- UTGDocument16 pagesUTGPackirisamy Baskar100% (2)

- T Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Document16 pagesT Header For AFC Calculation (PER UG-34) :, With The Limitation That Z Need Not Be Greater Than 2.5 (UG-34.B3)Pand AemonaEonNo ratings yet

- Pipe Wall Thickness - Report PDFDocument1 pagePipe Wall Thickness - Report PDFPetroNo ratings yet

- Sample Leak Testing Report For Ast TankDocument1 pageSample Leak Testing Report For Ast Tankchandra sonar100% (3)

- Magnetic Particle Test Quality Control and Inspection Report Form PDFDocument1 pageMagnetic Particle Test Quality Control and Inspection Report Form PDFKamal Bhandari100% (1)

- Ultrasonic Testing Report For PipingDocument54 pagesUltrasonic Testing Report For Pipingeldobie3No ratings yet

- RT ProcedureDocument12 pagesRT ProcedurePRASHANTNo ratings yet

- Letbaneforum 3Document33 pagesLetbaneforum 3Pedro HenriquesNo ratings yet

- Ultrasonic Testing ReportDocument2 pagesUltrasonic Testing ReportRonel John Rodriguez Custodio100% (1)

- Ultrasonic Thickness Inspection SOPDocument2 pagesUltrasonic Thickness Inspection SOPJaya Di60% (5)

- Plano de Una Mesa para SoldarDocument1 pagePlano de Una Mesa para SoldarHugo Alfredo Ordóñez Chocano86% (7)

- Ultrasonic Testing ReportDocument3 pagesUltrasonic Testing ReportsingaduraipandianNo ratings yet

- Vacuum Box Test PDFDocument3 pagesVacuum Box Test PDFWilson RodriguezNo ratings yet

- Ut Format Report For Ut Libra (Naidu)Document4 pagesUt Format Report For Ut Libra (Naidu)vsnaiduqcNo ratings yet

- DPT Report - FormatDocument1 pageDPT Report - Formatskc0% (1)

- Paut Scan Plan - 01aDocument4 pagesPaut Scan Plan - 01aKUNDU SATYABRATANo ratings yet

- UT Report FormDocument1 pageUT Report FormElisha NguyenNo ratings yet

- Pt. Saferad Servis Indonesia: Ultrasonic Inspection ReportDocument3 pagesPt. Saferad Servis Indonesia: Ultrasonic Inspection Reportkucing_batam0% (1)

- Figure T-434.2.1 Nonpiping Calibration BlocksDocument1 pageFigure T-434.2.1 Nonpiping Calibration BlocksChandrashekhar ThiramdasuNo ratings yet

- DPT Report MBBR U-BDocument15 pagesDPT Report MBBR U-BMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Gate WCB 900 RF Size 4 BR2023084Document1 pageGate WCB 900 RF Size 4 BR2023084Natthapong ApirattanapanNo ratings yet

- FPSO Motion Load - VerticalDocument109 pagesFPSO Motion Load - VerticalSu Kil SungNo ratings yet

- Prathna Alloys WC6 Page-2Document1 pagePrathna Alloys WC6 Page-2Kishan ChauhanNo ratings yet

- PQR PDFDocument2 pagesPQR PDFNjoku ChijiokeNo ratings yet

- SAMPLE Defect SheetDocument2 pagesSAMPLE Defect SheetshafanyNo ratings yet

- fLOW PDFDocument1 pagefLOW PDFSureshNo ratings yet

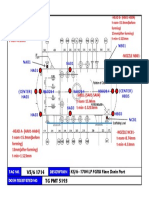

- Scheme of Examination: Cylindrical Shell SA516 GR 60 SA516 GR 60 Elliptical HeadDocument1 pageScheme of Examination: Cylindrical Shell SA516 GR 60 SA516 GR 60 Elliptical HeadPand AemonaEonNo ratings yet

- Scheme of Examination: Shell & Head SA516 Gr. 70Document1 pageScheme of Examination: Shell & Head SA516 Gr. 70Pand AemonaEonNo ratings yet

- Scheme of Examination: Shell & Head SA516 GR 60Document1 pageScheme of Examination: Shell & Head SA516 GR 60Pand AemonaEonNo ratings yet

- Scheme of Examination: Shell & Head SA516 Gr. 70Document1 pageScheme of Examination: Shell & Head SA516 Gr. 70Pand AemonaEonNo ratings yet

- E2231 UT Grid During TA16B PDFDocument4 pagesE2231 UT Grid During TA16B PDFPand AemonaEonNo ratings yet

- Scheme of Examination: Tubes SA179 Shell SA516 GR 70Document1 pageScheme of Examination: Tubes SA179 Shell SA516 GR 70Pand AemonaEonNo ratings yet

- Scheme of Examination: 1E Medium HighDocument5 pagesScheme of Examination: 1E Medium HighPand AemonaEonNo ratings yet

- The Frequency of Release From Piping: A Case-Study To Compare Approaches Quantifying Organizational and Managerial FactorsDocument6 pagesThe Frequency of Release From Piping: A Case-Study To Compare Approaches Quantifying Organizational and Managerial FactorsPand AemonaEonNo ratings yet

- Analisis Item 1 Pertghn THN 2018Document5 pagesAnalisis Item 1 Pertghn THN 2018Pand AemonaEonNo ratings yet

- Nozzle Na01-T-Nom 12.7mm T-Min 4.5mm - Nozzle Nb01 - T-Nom 12.7mm T-Min 4.5mmDocument1 pageNozzle Na01-T-Nom 12.7mm T-Min 4.5mm - Nozzle Nb01 - T-Nom 12.7mm T-Min 4.5mmPand AemonaEonNo ratings yet

- Reliability EngineeringDocument6 pagesReliability EngineeringPand AemonaEonNo ratings yet

- RJ GPP6Document1,920 pagesRJ GPP6Pand AemonaEonNo ratings yet

- RJ Final Ta Gpp5 CogenDocument1,349 pagesRJ Final Ta Gpp5 CogenPand AemonaEonNo ratings yet

- 1.3 Specialized Sub-Disciplines in Mechanical Engineering - Production, Automobile, Energy EngineeringDocument37 pages1.3 Specialized Sub-Disciplines in Mechanical Engineering - Production, Automobile, Energy EngineeringMr. K.S. Raghul Asst Prof MECHNo ratings yet

- ACE300 114/116 Series: Polyphase Electricity MetersDocument4 pagesACE300 114/116 Series: Polyphase Electricity Metersasnan22No ratings yet

- CRPC Pavement Design PDFDocument20 pagesCRPC Pavement Design PDFYuoyung tinNo ratings yet

- 132KV BPI - 2700 - Habarana BayDocument6 pages132KV BPI - 2700 - Habarana Bayyogs_184No ratings yet

- Company Profile Marble PDFDocument15 pagesCompany Profile Marble PDFmsattiNo ratings yet

- Design of BeamsDocument112 pagesDesign of BeamskbkwebsNo ratings yet

- 0 - ContentsDocument31 pages0 - ContentsAmin PiNo ratings yet

- Alta Spatial: Brgy. Karuhatan, Valenzuela CityDocument1 pageAlta Spatial: Brgy. Karuhatan, Valenzuela CityJohn Errol Saldevar MarcosNo ratings yet

- Graduate Programs and CoursesDocument75 pagesGraduate Programs and CoursesDarwin Aldas BasquialNo ratings yet

- STS - Activity 4Document10 pagesSTS - Activity 4Janine PolisonNo ratings yet

- Etp Guideline September 2016Document39 pagesEtp Guideline September 2016Theeva RajNo ratings yet

- SENG 3091 Software Design and Architecture Software Design 09 Object Oriented Software EngineeringDocument3 pagesSENG 3091 Software Design and Architecture Software Design 09 Object Oriented Software EngineeringJebesaNo ratings yet

- Brochures PDFDocument12 pagesBrochures PDFHdNo ratings yet

- Zack Rimstidt Resume 03-26-19Document1 pageZack Rimstidt Resume 03-26-19api-315996754No ratings yet

- Acoplamento OKDocument28 pagesAcoplamento OKMarcelo KendrickNo ratings yet

- Manual Tecnico Termost EberleDocument8 pagesManual Tecnico Termost EberleAlfredoJoseRayaNo ratings yet

- Strategy For Extennding Gap Between Og OverhaulDocument27 pagesStrategy For Extennding Gap Between Og OverhaulSamNo ratings yet

- 20UECE7042Document1 page20UECE7042Aniket Raj MeenaNo ratings yet

- Choosing What You Need - Distributed Control System (DCS) Vs Programmable Logic Controller (PLC) - Integrated SystemsDocument13 pagesChoosing What You Need - Distributed Control System (DCS) Vs Programmable Logic Controller (PLC) - Integrated SystemsAlanNo ratings yet

- MSG 00012Document3 pagesMSG 00012forget_me_not_451No ratings yet

- THERM Thermal Bridge Calcs - PH GuideDocument17 pagesTHERM Thermal Bridge Calcs - PH GuideUBHappy100% (1)

- PrintedDocument7 pagesPrintedFari PratomosiwiNo ratings yet

- PDFDocument110 pagesPDFbaczaicarolzoltanNo ratings yet

- Prestressed ConcreteDocument18 pagesPrestressed ConcreteLarete PaoloNo ratings yet

- IMI Herion Valve CatalogDocument12 pagesIMI Herion Valve CatalogjbkimNo ratings yet

- TalentCorp CriticalOccupationsList FullList 2019-2020 V2Document279 pagesTalentCorp CriticalOccupationsList FullList 2019-2020 V2Hairul Neezam ZakariaNo ratings yet

- Resume For Biotechnology InternshipDocument6 pagesResume For Biotechnology Internshipafayeejka100% (2)