Professional Documents

Culture Documents

Prathna Alloys WC6 Page-2

Uploaded by

Kishan ChauhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prathna Alloys WC6 Page-2

Uploaded by

Kishan ChauhanCopyright:

Available Formats

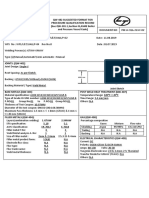

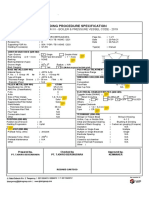

PROCEDURE QUALIFICATION RECORDS (PQR)

Section IX, ASME Boiler and Pressure Vessel Code

PQR No. PR/PQR/02 PAGE-2

Tensile Test REPORT NO. ULR-TC715219000018391F

DATE : 08-12-2019

Ultimate Ultimate

Width Type of Failure and

Specimen No. Thickness Area Total Load Unit Stress

(mm) Location

(N) (N/mm²)

SAMPLE-1 - NO.1 18.96 19.98 378.821 203880 538.2 OUTSIDE WELD

SAMPLE-1 - NO.2 19.05 19.92 379.476 197900 521.5 OUTSIDE WELD

SAMPLE-2 - NO.1 19.02 19.89 378.303 202660 535.7 OUTSIDE WELD

SAMPLE-2 - NO.2 18.95 19.92 377.484 198480 525.8 OUTSIDE WELD

Remark : REQUIRED VALUE (485 min) { Result meet the requirement of ASME BPVC SECTION lX (17) }

Guided-Bend Tests REPORT NO. ULR-TC715219000018391F DATE : 08-12-2019

Bend Specimen Size Mandrill Dia. for Bend Remark Result

Side Bend 1 W: 39.98, T: 9.98 4t (40.00 mm) Satisfactory Tests meet he

Side Bend 2 W: 40.06 , T: 10.01 4t (40.00 mm) Satisfactory requirement of ASME

Side Bend 3 W: 40.02 , T: 10.092 4t (40.00 mm) Satisfactory BPVC SECTION lX

Side Bend 4 W:40.08 , T: 9.98 4t (40.00 mm) Satisfactory (17)

Remark : Bend to 180°

Hardness Tests (HRBW) REPORT NO. ULR-TC715219000018391F DATE : 08-12-2019

Location Hardness (HRBW) Hardness in (BHN) bv Conversion Chart

Weld 93 , 94 , 95 169 , 172 , 176

HAZ 86 , 87 , 88 200 , 205 , 210

Base 78 , 79 , 80 144 , 147 , 150

Remark :

Microstructure : NA Report No. NA Date NA

Macrostructure : NA Report No. NA Date NA

Welders :

1. Welder Name Rajkumar

2. Welder No. PR/W01

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in accordance with the requirements of Section IX of the ASME

BOILER AND PRESSURE VESSEL CODE.

Prepaid & Checked By : Reviewed & Approved By :

Sign : Sign :

Name : KISHAN A. CHAUHAN Name : KISHAN A CHAUHAN

Date : 10-12-2019 Date : 10-12-2019

You might also like

- 6WG1 TQA Workshop Manual N2223 Ex PDFDocument3 pages6WG1 TQA Workshop Manual N2223 Ex PDFmasakp75% (8)

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- Benz 501la Repair ManualDocument174 pagesBenz 501la Repair ManualJacob Vengal93% (40)

- P QUIP Swab and Pony RodDocument5 pagesP QUIP Swab and Pony Rodkrishnsgk0% (1)

- Electrode Test Record E6010Document9 pagesElectrode Test Record E6010Veeraraghavan GuruNo ratings yet

- Polyacrylamide Plant: Mechanical Datasheet For Steam TrapsDocument2 pagesPolyacrylamide Plant: Mechanical Datasheet For Steam Trapsbecpavan100% (1)

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- Tes-K-100.01-R-1 - Hvac PDFDocument87 pagesTes-K-100.01-R-1 - Hvac PDFMohammed Abdul Moied100% (2)

- Manual On Engineering Student Design Project1Document17 pagesManual On Engineering Student Design Project1Raven Seanne Leaño MawiratNo ratings yet

- LG GR382R LRTP1231W Manual de ServicioDocument45 pagesLG GR382R LRTP1231W Manual de Serviciocarlos500% (1)

- DS-02 - LR BendsDocument1 pageDS-02 - LR BendsMecon LtdNo ratings yet

- DS-01 - LR BendsDocument1 pageDS-01 - LR BendsMecon LtdNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- Smash Enterprises, Pune SME/PQR/51/20-21/GSU SME/WPS/51/20-21Document3 pagesSmash Enterprises, Pune SME/PQR/51/20-21/GSU SME/WPS/51/20-21Meghan GhoneNo ratings yet

- PQR PT Bse WPS 07Document2 pagesPQR PT Bse WPS 07Muhammad Fitransyah Syamsuar PutraNo ratings yet

- PQR With-PwhtDocument2 pagesPQR With-PwhtKarthikNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- PQR Format PDFDocument2 pagesPQR Format PDFHarshit Adwani100% (2)

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPQR No. 2016 02Document14 pagesWPQR No. 2016 02GANESH ANo ratings yet

- Pqr-Band Ring PDFDocument3 pagesPqr-Band Ring PDFamitNo ratings yet

- TENSILE TEST - FLAT Test Method: AWS D1.1/D1.1MDocument2 pagesTENSILE TEST - FLAT Test Method: AWS D1.1/D1.1MJawad MunirNo ratings yet

- Compressor Welding Procedure (1-25)Document25 pagesCompressor Welding Procedure (1-25)mohammed talha khanNo ratings yet

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Bdde PQR CS 001Document2 pagesBdde PQR CS 001mainur mechanical engineer0% (1)

- Conexiones 3 SCH 160Document29 pagesConexiones 3 SCH 160RodolfoNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- FISHERDocument3 pagesFISHERPower Booster Sdn BhdNo ratings yet

- Qw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument4 pagesQw-483 Procedure Qualification Record (PQR) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86No ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- Phased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateDocument1 pagePhased Array Ultrasonic Examination Report: Contractor: Report No.: Client: Exam DateshervinyNo ratings yet

- WB920410Document1 pageWB920410nima mniNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Gpti Qicl J931 Mut 041Document3 pagesGpti Qicl J931 Mut 041uselessinstaid52No ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Drain Pump, Data Sheet and Performance Curve: Genral Arrangement ofDocument11 pagesDrain Pump, Data Sheet and Performance Curve: Genral Arrangement ofAshish Gupta100% (1)

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- Data Sheet Item 2Document3 pagesData Sheet Item 2Bagus SigitNo ratings yet

- WPS 684 CS 012Document3 pagesWPS 684 CS 012siva8000100% (1)

- Strength Calcul SheetDocument379 pagesStrength Calcul Sheetmustufa akolawalaNo ratings yet

- Slip StreamDocument1 pageSlip StreamvietsdsNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure SpecificationDocument4 pagesWelding Procedure SpecificationBhargav BbvsNo ratings yet

- Test Manifold Package No:: Client Saudi Aramco Oil CoDocument7 pagesTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- BSI Combustion Chamber LEAP NOV-01-2022Document45 pagesBSI Combustion Chamber LEAP NOV-01-2022Jason LapeNo ratings yet

- WPS & PQR VVSPLDocument3 pagesWPS & PQR VVSPLBhargav BbvsNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WpsDocument3 pagesWpsPankaj KumarNo ratings yet

- ON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty DesignationDocument27 pagesON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty Designationkien Duy PhanNo ratings yet

- Swathi Industries: JOINT (QW 402)Document10 pagesSwathi Industries: JOINT (QW 402)Mustu AkolawalaNo ratings yet

- RTCC Manual WPS Approval WE-WPS-001Document7 pagesRTCC Manual WPS Approval WE-WPS-001Akansha SharmaNo ratings yet

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- BH MT 199 2022 T&aDocument1 pageBH MT 199 2022 T&aDeanz KmcNo ratings yet

- Tube Move Version 6.4Document25 pagesTube Move Version 6.4edisoncontreraspNo ratings yet

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- A-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Please Circulate and Post TO: From:: Lynne M. MotylDocument1 pagePlease Circulate and Post TO: From:: Lynne M. MotylKishan ChauhanNo ratings yet

- Oil-Wo-118-Rt-011 DT 25.01.2019 PDFDocument1 pageOil-Wo-118-Rt-011 DT 25.01.2019 PDFKishan ChauhanNo ratings yet

- John Lucas PDFDocument30 pagesJohn Lucas PDFKishan ChauhanNo ratings yet

- Why Studying in TurkeyDocument6 pagesWhy Studying in TurkeyalmadhagiNo ratings yet

- Colchester Alpha Brochure 2021Document7 pagesColchester Alpha Brochure 2021KhalilullahNo ratings yet

- KEB - proII ppt2 Sheet MetalDocument85 pagesKEB - proII ppt2 Sheet MetalKEBIRNo ratings yet

- Air Conditioning Systems in BuildingsDocument38 pagesAir Conditioning Systems in BuildingsFarhan Danish100% (1)

- Brittle FractureDocument2 pagesBrittle Fractureraju1559405No ratings yet

- Rigging GuideDocument142 pagesRigging GuideJB MadeleineNo ratings yet

- Teknik Dan Management Maintenance Dr. Muhammad Nur Yuniarto Waktu: 90 Menit (Open Any BOOKS)Document2 pagesTeknik Dan Management Maintenance Dr. Muhammad Nur Yuniarto Waktu: 90 Menit (Open Any BOOKS)Atuk GaekNo ratings yet

- Nicrofer 3220 3220h eDocument15 pagesNicrofer 3220 3220h eKevinCollinNo ratings yet

- Peng Robinson Virial Equations of State ComparisonDocument7 pagesPeng Robinson Virial Equations of State Comparisondix6ieNo ratings yet

- Question and Answer On Steam TurbinesDocument33 pagesQuestion and Answer On Steam TurbineschunkyNo ratings yet

- Standard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Document31 pagesStandard Specification FOR High Frequency Welded (HFW) Line Pipe (Onshore)Agniva DuttaNo ratings yet

- Chapter 4 PDFDocument48 pagesChapter 4 PDFmidju dugassaNo ratings yet

- Figure R4-1: Vacuum Column FlowsheetDocument18 pagesFigure R4-1: Vacuum Column Flowsheetnico123456789No ratings yet

- Steel Grades Comparison ADocument1 pageSteel Grades Comparison ANithin KottarathilNo ratings yet

- L PDFDocument5 pagesL PDFElgi Alam PangestuNo ratings yet

- Integration of A Single Cylinder Engine Model and A Boost System Model For Efficient Numerical Mapping of Engine Performance and Fuel ConsumptionDocument8 pagesIntegration of A Single Cylinder Engine Model and A Boost System Model For Efficient Numerical Mapping of Engine Performance and Fuel ConsumptionNambi RajanNo ratings yet

- Answer All Questions. Each Question Carries 2 Marks.: Sixth Semester B.Tech Degree ExaminationDocument3 pagesAnswer All Questions. Each Question Carries 2 Marks.: Sixth Semester B.Tech Degree ExaminationKrishna YadavNo ratings yet

- HSM01 - Erection Manual en Rev02Document20 pagesHSM01 - Erection Manual en Rev02jokoNo ratings yet

- Volvo Tad 1640 1642 Workshop ManualDocument276 pagesVolvo Tad 1640 1642 Workshop ManualAbd Elsalam EmzikaNo ratings yet

- Generator and Regulator - Gtdi 2.0L Petrol - Generator - Component LocationDocument11 pagesGenerator and Regulator - Gtdi 2.0L Petrol - Generator - Component LocationKent WaiNo ratings yet

- Industrial Electronics Motor ControlsDocument65 pagesIndustrial Electronics Motor ControlsOnofre Algara Jr.No ratings yet

- Honda Goldwing GL1500 1994 Service Manual-6051BDocument761 pagesHonda Goldwing GL1500 1994 Service Manual-6051BPeter KnellekenNo ratings yet

- Pinned Base Plates 5Document1 pagePinned Base Plates 5pawkomNo ratings yet

- Basic Naval Architecture Ship StabilityDocument215 pagesBasic Naval Architecture Ship StabilityJøn Bilbao Mallona100% (2)