Professional Documents

Culture Documents

Welding Procedure Specification (WPS)

Welding Procedure Specification (WPS)

Uploaded by

mahendraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification (WPS)

Welding Procedure Specification (WPS)

Uploaded by

mahendraCopyright:

Available Formats

Sheet 1 of 3

Welding Procedure Specification (WPS)

Code: AWS D1.1

Company Name: www.WPSAmerica.com Identification #:

Address: info@WPSAmerica.com, 1 (877) WPS-WELD GMAW-DEMO

WPS Prequalified:

Yes

Welding Process: Process Type: Position(s): Supporting PQR No.(s):

GMAW Semi-Automatic Flat N/A

Base Metal Part I (Material Spec., type or grade): Base Metal Part II (Material Spec., type or grade):

Steels in Group I and II of Table 3.1-AWS D1.1 Steels in Group I and II of Table 3.1-AWS D1.1

Qualified Thickness and Diameter Range: Filler Metals:

Groove (Fillet): mm (in) AWS Classification/AWS Specification:

T > = 6 mm (1/4 in) E70C-6M H4

A5.18

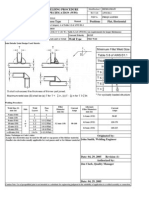

Joint Details/Sketch:

Joint Design Used: mm (in)

Root Opening G: 0 Root Face RF: > = 3 mm (1/8 in.) Groove Angle: 60 ° Radius (J-U): N/A

Weld Type: Joint Type:

Partial Joint Penetration Groove Weld Butt Joint Corner Joint

Backing Option: Backing Material: Back Gouging Method:

Welded without backing N/A N/A

Identification #: GMAW-DEMO Sheet 2 of 3

Electrical Characteristics: Shielding:

Current Type/Polarity: DCEP Gas Composition (Flux for SAW): Ar + 5 to 15% CO2

Transfer Mode (GMAW): Spray

Gas Flow Rate: lt/min. (CFH) 40 to 50 CFH

Tungsten Electrode (GTAW):

Gas Cup Size: 5/8 in.

Type: N/A

Size: mm (in) N/A

Welding Procedure

Filler

Current Wire Feed Travel Remarks

Weld Pass Filler Metal Metal Current

Process Type & Speed Volts Speed [Heat Input]

Layers No. Classification Diameter Amps

Polarity (in/min) (in/min) J/mm (J/in)

mm (in)

1.4 mm

1 1 GMAW E491C-6M-H4 200-250 DCEP 200-250 25-27 10-14 Root Pass

(0.052)

1.4 mm

1 to 2 2 to 3 GMAW E491C-6M-H4 200-250 DCEP 200-250 25-27 10-14 Fill Pass

(0.052)

Weld Size > =

1.4 mm

2 to n 3 to n GMAW E491C-6M-H4 270-300 DCEP 270-320 26-28 12-18 10 mm (3/8

(0.052)

in.)

Technique:

Stringer or Weave Bead: Stringer Bead Contact Tube to Work Distance: 1 to1-1/8 in.

Initial/Interpass Cleaning: Wire Brush, Grind Peening: N/A

Number of Electrodes: Single

Electrodes Spacing: Longitudinal: N/A Lateral: N/A Angle: N/A

Heat Treatment:

Preheat Temp. Min °C (°F): 0 to 10 °C-Table 3.2 AWS D1.1 Interpass Temp. Min/Max °C (°F): 0 to 10 °C-Table 3.2 AWS D1.1

Postweld Heat Treatment: Temp. °C (°F): N/A Time: N/A

Additional Notes:

The end of contact tube recommended to be recessed in the cup nozzle at least 6 mm (1/4 in.)

Manufacturer/ Contractor Authorized by:

Welding Engineer:

Name: Jim Clark Name: John Smith

Title: Welding Engineer Title: QA Manager

Date: 12/12/2005 Date: 12/12/2005

Identification #: GMAW-DEMO Sheet 3 of 3

Heat Treatment (AWS Code’s Guideline):

PREHEAT TABLE:

Preheat and interpass temperature shall be sufficient to prevent cold cracking.

The need for and the temperature of preheat are dependent upon a number of factors

such as chemical analysis, degree of restraint of the parts being joined, elevated temperature

mechanical properties, and material thicknesses.

AWS D1.1, Table 3.2 Prequalified Minimum Preheat and Interpass Temperature °F (°C):

Preheat and Interpass temperature is provided for each material and thickness and

process type on this material group.

Guideline on Alternative Methods for Determining Preheat/Interpass: See Annex XI of AWS D1.1

Preheat requirements shall be based on Welding Procedure Specification (WPS).

POSTWELD HEAT TREATMENT:

PWHT requirements shall be based on Welding Procedure Specification (WPS).

AWS D1.1, 5.8 Stress-Relief Heat Treatment: Where required by the contract

drawings or specifications, welded assemblies shall be stress relieved by heat treating.

(See AWS D1.1, 5.8.1, Requirements for stress-relief treatment;

Table 5.2, Minimum Holding Time; Table 5.3, Alternate Stress-Relief Heat Treatment)

See AWS D1.1, 5.8.3, Steels Not Recommended for PWHT

WPS Qualified Range (AWS Code’s Guideline):

Qualified Position (s): For Prequalified WPS, only Position (s) allowed for prequalified joint details shown in

WPS based on Figures 3.3 or 3.4 of AWS D1.1

Qualified Thicknesses: For Prequalified WPS, only thickness ranges allowed for prequalified joint details

shown in WPS based on Figures 3.3 or 3.4 of AWS D1.1

Qualified Diameters: For Prequalified WPS, pipe diameters [over or less than 24 in. (600 mm OD)] allowed

for prequalified joint details shown in WPS based on Figures 3.3 or 3.4 of AWS D1.1

Prequalified WPS Base Metal Group Allowed: Only Base Metal Group-Filler Metal Combinations for

Matching Strength as shown in Table 3.1 of AWS D1.1

Filler Metal Allowed in Prequalified WPS: Only Filler Metal-Base Metal Group Combinations for Matching

Strength as shown in Table 3.1 of AWS D1.1 (Size and other limit on electrode for prequalification of each

process, as per Table 3.7 of AWS D1.1)

You might also like

- AWS D1.1 Guides PDFDocument8 pagesAWS D1.1 Guides PDFwidada_marjiNo ratings yet

- AWS D8.8M-2007 Specification For AutomotiveWeld Quality-Arc Welding of Steel PDFDocument28 pagesAWS D8.8M-2007 Specification For AutomotiveWeld Quality-Arc Welding of Steel PDFcesardario90100% (1)

- PQR Super-Duplex ReferenceDocument48 pagesPQR Super-Duplex ReferencetalhaNo ratings yet

- Building Technology Mechanical and Electrical Systems PDFDocument2,828 pagesBuilding Technology Mechanical and Electrical Systems PDFJohn Smith50% (2)

- PQR Form (Welding)Document2 pagesPQR Form (Welding)jasmineammaNo ratings yet

- Smaw Fillet Aws d1.1Document1 pageSmaw Fillet Aws d1.1fallalovaldes100% (1)

- Aluminum Welding ProceedureDocument14 pagesAluminum Welding ProceedureGregEverett2No ratings yet

- Welding Procedure Specification Sample - New EditionDocument2 pagesWelding Procedure Specification Sample - New EditiondanteNo ratings yet

- Welding Procedure Specification SampleDocument2 pagesWelding Procedure Specification Sampleezdi2083% (23)

- API 614-Gen. PurposeDocument20 pagesAPI 614-Gen. Purposemishraengg100% (2)

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocument8 pagesApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12No ratings yet

- QC Welding Inspector (CSWIP 3.2)Document5 pagesQC Welding Inspector (CSWIP 3.2)Tanveer Ahmed QuadriNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- WPS & SmawDocument12 pagesWPS & Smawnuke apriyaniNo ratings yet

- Bread & Pastry Production NC Ii (141 HRS) : Schedule and Breakdown of Fees and Other Program CostsDocument8 pagesBread & Pastry Production NC Ii (141 HRS) : Schedule and Breakdown of Fees and Other Program CostsRhemz Guino-oNo ratings yet

- Steel Properties Material Grade Comparison ChartDocument1 pageSteel Properties Material Grade Comparison Chartgk80823No ratings yet

- Wps (Argon Welding)Document1 pageWps (Argon Welding)M. R. Shahnawaz KhanNo ratings yet

- WPS BhelDocument2 pagesWPS BhelpradhankruhsnaNo ratings yet

- AWS D1.1 Welder Quallification RequirementsDocument3 pagesAWS D1.1 Welder Quallification RequirementsKrishna VachaNo ratings yet

- NDT of WeldsDocument4 pagesNDT of WeldsVu Tung Linh100% (2)

- WQTR 004-2Document2 pagesWQTR 004-2walitedisonNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Chapter-3 General Information of WeldingDocument5 pagesChapter-3 General Information of WeldingKumar DneshNo ratings yet

- 09 Welding Procedures and Qualifcations As Per ASME SEC IXDocument7 pages09 Welding Procedures and Qualifcations As Per ASME SEC IXvilukNo ratings yet

- WPS Format For Asme Ix - Wps - Gtaw SmawDocument1 pageWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- Repair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6Document6 pagesRepair Procedure For Carbon Steel: Rev No: 00 Date Rev: 17 Dec 2008 Page No: 1 of 6mohd as shahiddin jafriNo ratings yet

- Metal Core WireDocument30 pagesMetal Core WireHuỳnh TrươngNo ratings yet

- Welding Coordinator WeldMap Weld Data SheetDocument1 pageWelding Coordinator WeldMap Weld Data Sheetquocphong199No ratings yet

- AWS D1.1 GuidesDocument7 pagesAWS D1.1 GuidesMuhammad FakhriNo ratings yet

- Welding Technology: WELD 115 QC10Document52 pagesWelding Technology: WELD 115 QC10usto2014No ratings yet

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- Carefully Evaluate Code RequirementsDocument3 pagesCarefully Evaluate Code Requirementsmayav1No ratings yet

- Products Presentation MajorDocument47 pagesProducts Presentation MajorJuanita AndrewsNo ratings yet

- Welder and Wps Qualification Control ProcedureDocument24 pagesWelder and Wps Qualification Control ProcedurejhuliocessarsNo ratings yet

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDocument26 pagesNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNo ratings yet

- Heater DatasheetDocument3 pagesHeater DatasheetReza Muhammad100% (1)

- Welding Map & NDE Map JTBDocument7 pagesWelding Map & NDE Map JTBFarhan PutraNo ratings yet

- Filter Fundamentals and Comparison Between EN779-2002 and EN779-2012 and Revision of EN1822Document13 pagesFilter Fundamentals and Comparison Between EN779-2002 and EN779-2012 and Revision of EN1822iskandarmeranNo ratings yet

- RFI-3410 - Daily Fit Up Inspection Report-OKDocument92 pagesRFI-3410 - Daily Fit Up Inspection Report-OKnguyennamxmNo ratings yet

- ABS - APPROVED WELDING CONSUMABLES (April 09, 2007) PDFDocument10 pagesABS - APPROVED WELDING CONSUMABLES (April 09, 2007) PDFPradeeshNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- 1012835-NEROMASTIC 400 (I) Component (B)Document4 pages1012835-NEROMASTIC 400 (I) Component (B)Srikanth GantaNo ratings yet

- D1.5M D1.5 2015 AMD1 Form O 2 FillableDocument1 pageD1.5M D1.5 2015 AMD1 Form O 2 Fillablevikasphopale1No ratings yet

- GB-T 232-2010 Metallic Materials-Bend TestDocument14 pagesGB-T 232-2010 Metallic Materials-Bend TestH. Camer E.No ratings yet

- 1 WPS & PQRDocument2 pages1 WPS & PQRManoranjan sharmaNo ratings yet

- D1 3scopeDocument4 pagesD1 3scopeayub82No ratings yet

- Hydro Test ProcedureDocument17 pagesHydro Test Procedureyaser elgoharyNo ratings yet

- Certificate of Welding InspectorDocument1 pageCertificate of Welding InspectortuatkNo ratings yet

- AWS A2.4 98 Standards Symbols For Welding Bracing and Nondestructive Examination Page 107Document1 pageAWS A2.4 98 Standards Symbols For Welding Bracing and Nondestructive Examination Page 107JuniorNo ratings yet

- D1 - 1 2020 - Structural Welding Code-Steel-02Document1 pageD1 - 1 2020 - Structural Welding Code-Steel-02Trung NguyenNo ratings yet

- Astm 890Document3 pagesAstm 890bsnegi111No ratings yet

- Welder and Welding Operator Performance Qualification RecordDocument1 pageWelder and Welding Operator Performance Qualification RecordAsif HameedNo ratings yet

- Weld Visual Inspection For Store Girder 1Document1 pageWeld Visual Inspection For Store Girder 1Ashwani DograNo ratings yet

- Sample of Procedure Qualification Record (PQR) : Joint DetailsDocument4 pagesSample of Procedure Qualification Record (PQR) : Joint Detailshancur_27No ratings yet

- Welding Tolerance StandardsDocument6 pagesWelding Tolerance StandardsSowmen_CNo ratings yet

- Inspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationDocument3 pagesInspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationKhaled GamalNo ratings yet

- ASME P-NumbersDocument2 pagesASME P-NumbersAnonymous XwaOunGK100% (1)

- Material Safety Data Sheet: Poly Cell AdhesiveDocument8 pagesMaterial Safety Data Sheet: Poly Cell AdhesiveMinh BảoNo ratings yet

- MS 2571 PDFDocument1 pageMS 2571 PDFnd_teng0% (1)

- Welding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Document15 pagesWelding Procedure Specification No. Epi-11-Wp10 BW Rev. 1Felipe Vásquez ArribasplataNo ratings yet

- AWS N-9 Stud Welding Procedure Specification (WPS) FormDocument1 pageAWS N-9 Stud Welding Procedure Specification (WPS) FormNatalia StarkNo ratings yet

- ASME 9 - CalculatorDocument2 pagesASME 9 - CalculatorEmel Besir100% (1)

- Inspection Plan - NDTDocument4 pagesInspection Plan - NDTgymadniNo ratings yet

- Sample Welding Procedure Specification (WPS) : Joints (See 4.13.1)Document2 pagesSample Welding Procedure Specification (WPS) : Joints (See 4.13.1)muadzNo ratings yet

- Box For Vacuum TestDocument1 pageBox For Vacuum TestVăn Trường Lê0% (1)

- PRES TIG Hot Wire Narrow Gap Welding enDocument25 pagesPRES TIG Hot Wire Narrow Gap Welding enRavishankarNo ratings yet

- WPS 작성 (영)Document24 pagesWPS 작성 (영)hunghoanglongNo ratings yet

- XXXXXXXXXXX XXXXXXXXXXX XXXXXXXXXXX Welding Procedure Specification WpsDocument3 pagesXXXXXXXXXXX XXXXXXXXXXX XXXXXXXXXXX Welding Procedure Specification WpsManivannanMudhaliarNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Bunting CanisterDocument1 pageBunting CanisteriskandarmeranNo ratings yet

- Project Management - Life CycleDocument2 pagesProject Management - Life CycleiskandarmeranNo ratings yet

- Nanotec PublicationDocument2 pagesNanotec PublicationiskandarmeranNo ratings yet

- Transformative Potential of Thermal Storage Applications in Advancing Energy Efficiency and SustainabilityDocument14 pagesTransformative Potential of Thermal Storage Applications in Advancing Energy Efficiency and SustainabilityKIU PUBLICATION AND EXTENSIONNo ratings yet

- ElecrDocument11 pagesElecrRaji GoprajuNo ratings yet

- S-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDDocument12 pagesS-717 X M-12K L-8 A-2: Hyundai Welding Co., LTDamir bizhehNo ratings yet

- 1614416439961ronald Reales OriginalDocument9 pages1614416439961ronald Reales OriginalEstrada Guillan JoyNo ratings yet

- B 12 S 19Document247 pagesB 12 S 19dhakshuNo ratings yet

- Project: 2201-236 - Design and Construction of KIZAD Gas Network - Phase 1Document3 pagesProject: 2201-236 - Design and Construction of KIZAD Gas Network - Phase 1Habibur Rehman MNo ratings yet

- Nilan Ireland 2 Years Monitoring of CPH Kerry 13th See The LightDocument20 pagesNilan Ireland 2 Years Monitoring of CPH Kerry 13th See The Lightapi-252834654No ratings yet

- Welding IntroDocument38 pagesWelding IntroAloysi DelouizaNo ratings yet

- List of Welding Procedures.: Client: Emirates Aluminium Company Limited. Gmmos Job #: 801-4690Document6 pagesList of Welding Procedures.: Client: Emirates Aluminium Company Limited. Gmmos Job #: 801-4690ravi00098No ratings yet

- A3.957.2-2-4 (G1-3)Document10 pagesA3.957.2-2-4 (G1-3)pandi achmadanNo ratings yet

- Welding: Debasis Mitra Inspection DepartmentDocument31 pagesWelding: Debasis Mitra Inspection DepartmentSanjoy Kr. DeyNo ratings yet

- IJBE-9-3-2021 Bahrami Guillot 13 30Document18 pagesIJBE-9-3-2021 Bahrami Guillot 13 30Elina EsfandiariNo ratings yet

- Arc WeldingDocument8 pagesArc WeldingMrTurner HoodNo ratings yet

- Catalog AlfainDocument20 pagesCatalog AlfainAnca HritcuNo ratings yet

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- GMAW Troubleshooting GuideDocument12 pagesGMAW Troubleshooting GuideVijayan MunuswamyNo ratings yet

- S355 To Hardox 450 - Plate 60 MMDocument1 pageS355 To Hardox 450 - Plate 60 MMBien NguyenDuyNo ratings yet

- NG22 282 CST PSL 100020 - Revc0Document19 pagesNG22 282 CST PSL 100020 - Revc0Theophilus OrupaboNo ratings yet

- Api 510 Open 1Document4 pagesApi 510 Open 1melvinNo ratings yet

- Welding Process Lab ReportDocument6 pagesWelding Process Lab Reporthey soohaNo ratings yet

- New 01. Price List VS Online Welding Mechine Professional 290123Document4 pagesNew 01. Price List VS Online Welding Mechine Professional 290123Deta PutraNo ratings yet