Professional Documents

Culture Documents

LPG Project 3

Uploaded by

Jehirul IslamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LPG Project 3

Uploaded by

Jehirul IslamCopyright:

Available Formats

1

CHAPTER 1

INTRODUCTION, SCOPE AND OBJECTIVES

OF THE STUDY

1.1 INTRODUCTION

The major challenges to be met by the world population of the 21st

century are safety, health and environmental (SHE) risks. The concern for

managing them continues to prevail and tends to increase year after year due

to the exponential growth of industries. International agencies viz., United

Nations Environment Program (UNEP), United Nations Industrial

Development Organization (UNIDO) and International Labor Organization

(ILO) periodically review the ongoing regional development in

industrialization, urbanization, environment, health of the community and

risks in industrial operations. India being a signatory of the above agencies is

obliged to comply with the guidelines, regulations and planning process as

suggested by those agencies from time to time. Besides, the national agencies

such as Directorate of Industrial Safety and Health, Director General Factory

Advice Service and Labour Institutes (DGFASLI), Ministry of Labour and

Employment, Government of India, Petroleum and Explosives Safety

Organization, Manufacture Storage Import of Hazardous Chemical Rules

(MSIHC Rules 1989 & amended 2000) etc., provide guidelines and stipulate

standards for storage and handling of hazardous materials etc. to be complied

with by industries.

2

Environmental Impact Assessment is considered to be one of the

tools in the management of safety, health and environment risks. The

Planning Commission of India conceived the concept of Environmental

Impact Assessment (EIA) in India during 1976-1977. The commission was

designated the task of examining cursorily river-valley projects from the

environmental standpoint and addressed the Department of Science and

Technology (DST), Government of India. This was subsequently extended to

cover other projects in need of approval by the Public Investment Board

(Ministry of Finance, Government of India). These were administrative

decisions without any legislative support. The Government of India, therefore,

enacted the Environment (Protection) Act, 1986 (in the Ministry of

Environment and Forest-MOEF). The Act enunciates set of legal instruments.

The decisions taken by the Government was to make environment impact

assessment as a statutory requirement before setting up of any production

activity in any part of the country. Risk Assessment, which is an integral part

of EIA, provides operable scientific frameworks for protecting the

environment and for decision-making. The scientific approach for conducting

the risk assessment study is essential to sustain long term benefits not only for

the industry but also for the overall general environmental resources including

air, water, land and noise affecting the public in the vicinity of the Industrial

site.

Energy is a basic need for operations. Liquefied Petroleum Gas -

LPG / Propane is commonly and continuously used in industries as an energy

source (e.g. heat treatment, power generation and drying etc). Consequently,

there is a substantial release of end products (Green house gases) after

combustion of LPG causing death, injury to persons and damage to the

properties. Energy, environment, safety, etc. exclusively with the use of LPG

have not been given due consideration by the planners as well as scientists.

3

The study on risk assessment in LPG / Propane using industry

demands first-hand knowledge of the accident scenario. Also, a number of

institutions in India have studied possibilities and probabilities of the hazards

occurring within the industrial premises due to LPG storage. There are well-

defined parameters for quantification of flue gas release. These include flash

point, degree of flammability, explosion, toxicity to humans etc. Besides the

location of industry, the engineering design and systems implementation

during operation (production and maintenance) are important. Consequence

Analysis of an emergency situation at the industrial site and risk management

is the most important factors of risk analysis concerning hazardous

installations.

1.2 ROLE OF ENVIRONMENT RISK ASSESSMENT (ERA) IN

EIA PROCESS

One of the key components of EIA process is Environment Risk

Assessment (ERA). ERA is the development of EIA and Risk Assessment.

ERA provides theoretical and scientific frameworks for environmental

protection, decision making and for setting up of any Industry. With the rapid

economic growth and globalization movement, development of new

industries with sophisticated technologies is on the rise at an alarming rate all

over the world. However, it is imperative that a systematic approach be

adopted before setting up of a new industry, taking into consideration various

safety issues, health and environmental aspects of the inhabitants living in the

surrounding areas to safeguard them from possible accidents / incidents

arising out of the industrial activity. The scientific approach of conducting an

Environment Risk Assessment study before setting up of an industry is

essential to sustain long term benefit not only for the industry but also for the

general environment and the inhabitants living in the area24, 46,49.

4

The use of LPG / Propane is continuously on the increase in

industries as a standard energy source for various purposes including heat

treatment processes. Consequently, there is a substantial release of LPG and

other hazardous materials into the ambient environment causing personal

injury or death of workers and people in the surrounding locality, damage to

property and environment. The study on Risk Assessment in LPG/Propane

using industry demands first-hand in depth knowledge of the accident

scenario possibilities and probability of the hazards responsible for damage to

the property and health of the general public. Hence, the first step in hazard

analysis is to quantify the substances released. There are well-defined

parameters for quantification that include flash point, degree of flammability,

explosion, toxicity etc. Besides this, the subjectivity factor of location,

engineering design and systems implementation during operation (production

and maintenance) are important and involve the engineering aspects of the

Risk Assessment. In addition to these, Consequence Analysis of an

emergency situation at the industrial site and risk management are the two

most important factors of Risk Analysis concerning hazardous installations in

the industries24, 46.49.

Hence, the Environmental Impact and Risk Assessment for LPG

Installations in Automobile Industries detailing the release scenarios and

consequence analysis for these LPG handling industries are to be studied.

This study explains the Environmental consequences associated with LPG

storages, located and installed particularly in Automobile industries in

Tamilnadu. At present, the LPG utilizing automobile industries are not

required to conduct Environment Impact Assessment studies since they are

not listed in the EIA Notification issued by the Ministry of Environment and

Forest. Even though these industries do not have the requirement for the EIA

study, the rise in the number of industries utilizing LPG for energy purpose

due to its convenience, availability and other technical requirements has

5

become a serious concern, requiring special attention from the perspective of

the Government and other stakeholders. The environment impact from these

industries taking into account of the hazard potential of LPG Bullets is to be

studied.

1.3 LPG BULLET INSTALLATION IN AUTOMOBILE

INDUSTRIES

1.3.1 Features of LPG

With its intrinsically clean burning characteristics, LPG offers a

practical avenue for clean air since use of LPG reduces black carbon and

particulate matter emissions, which not only compromise outdoor and indoor

air quality but can cause serious health problems.

Since LPG is a low carbon fuel, it is used in thousands of industrial

and commercial applications. It is cleaner than any other fossil fuel, highly

energy efficient and safe to use. LPG is one of the most preferred energy

sources today because of its immense benefits.

LPG is an energy-rich fuel source with a higher calorific value per

unit than other commonly used fuels, including coal, natural gas, diesel,

petrol, fuel oils and biomass-derived alcohols. LPG generates fewer carbon

emissions than gasoline (petrol) and has similar emissions when compared

with diesel. Therefore, it can make a positive contribution toward

improvement of air quality when compared to diesel, heating oil and solid

fuels. In addition to these factors, LPG is immediately available and supports

the use of renewable technologies. The advantages of using LPG as an energy

source are:

Increased fuel savings

High rate of heating – as high as 400 °C per hour

6

Uniformity in temperature and precise temperature control

Better heat transfer with LPG firing

No wastage of fuel due to spillage and adulteration

Uniformity and increased end product quality

Lower maintenance costs of burners, ovens and furnaces

Lower shut down time of machinery

Cleaner burning and sulfur-free emission

1.3.2 Mode of Storage of LPG

Refrigerated storage is used to store large volumes of LPG. The

main form of LPG storage is in special tanks known as 'pressure tanks'.

Commonly, these pressure tanks are termed as 'bulk tanks' or LPG

Bullets/Spheres. Automobile industries have installed bullets/spheres in their

premises to store the LPG. Gas suppliers to store large volumes of LPG use

refrigerated storage. Since LPG has a high coefficient of expansion in its

liquid phase, the tanks are never completely filled with liquid (tanks are filled

to approximately 85% of their water capacity), the remaining space being

taken up with vapour (often referred to as the vapour space) to facilitate

expansion without allowing the liquid to become 100% full (often known as

hydraulically full)

7

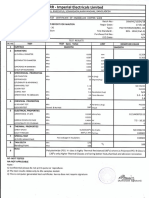

Figure 1.1 LPG Bullets

1.3.3 Working Features of a LPG Bullet

As LPG gas (vapour) is drawn from the tank, the vapour pressure in

the tank falls and the liquid boils, producing more vapour and restoring the

pressure to maintain boiling, the liquid absorbs heat from itself, from the

metal of the tank in contact with the liquid (known as the wetted surface area)

and from the air surrounding the tank. The available gas 'off take', therefore,

is dependent upon the surface area of the tank, the quantity of liquid within

the tank and the temperature. The low temperature of the liquid (often

indicating excess off take) may be indicated as 'sweating' (where the water

vapour in air condenses on the wetted surface area of the tank) and if the off

take is large enough 'frosting' (where the condensed water vapour freezes)

occurs on the walls of the tank.

When the liquid temperature rises, for instance in summer, the

vapour pressure increases and when the liquid temperature drops, the vapour

pressure also drops. Under normal Indian conditions, the pressure will range

between 2-9 bars. These are designed as per the recommendations in IS-2825

/ASME Sec VIII Dl-1 codes and the material of construction is SA-516/ IS-

8

2062/ IS-2002/SS-304 or as per the specific requirement of the customer.

Steel used for the tank and its fittings meets the Low Temperature Carbon

Steel criteria and is tested thoroughly before fabrication. During fabrication,

stringent quality norms are followed. The vessels are inspected stage wise by

Inspection Engineers / Third party Inspectors as per the recommendations of

the relevant code and the Chief Controller of Explosives norms. Qualified

welders perform welding of joineries. Finally, it is hydro tested and de-

hydrated with dry nitrogen. Each tank undergoes various NDT and other

inspection stages and tests like Penetration Test, Radiographic Examination

and the Hydro test are conducted before dispatch.

These storage tanks are equipped with all standard instruments and

controls like Rochester gauge, excess flow check valves, safety valves,

pressure gauges, LPG Transfer compressor, valves, pipes, drains, pressure

regulators, water sprinkling system, gas leak detection system and control

panel. Most LPG storage tanks in standby-plant service are steel, non-

refrigerated pressure vessels. Tanks are available in many sizes for both above

the ground and underground services. New LPG tanks are built to ASME

standards and are designed for maximum working pressure.

1.4 STATEMENT OF PROBLEM

The earlier studies by the researchers focussed on the risk

associated with the hazardous materials. Specific studies on LPG were not

undertaken, despite the fact that the LPG was a hazardous substance

consumed in large quantities. However, LPG is favoured over other fuels like

coal, oil and electricity, which are fast becoming scarce these days. Hence,

hazard scenario created by the intensive use of LPG is required to be studied

and hence, a systematic study covering risks, safety, health and environment

is essential. Automobile industries in India have grown concomitantly with

9

the production of components. Therefore it is necessary to study the pattern of

consumption of LPG and hazards attributed to LPG installation.

Since Risk analysis is considered as an integral component of

environmental impact study, the release scenarios and consequence analysis

for LPG handling industries need to be focussed upon.

The current guidelines of the Ministry of Environment, Forest and

Wild Life, Government of India with the EPAct, 1986 do not include LPG as

a hazardous material. As a result, these industries are not required to carry out

environmental impact assessment study. Nevertheless, LPG utilizing

automobile industries has to necessarily conduct environmental impact

assessment studies.

Therefore, it is imperative that the government gives their attention

to protect the society at large and averting the possible impact on

environment.

1.5 PURPOSEOF THIS STUDY

LPG/Propane has been increasingly used in automobile industries

for the heat treatment process. Increase in use of LPG has resulted in its

substantial release into the ambient environment inflicting damage to property

and environment besides having near fatal to fatal effects on the residents

around the area.

The purpose of this study is

(1) to have knowledge on the impending environmental

consequences associated with LPG Bullets used in the

automobile industry in the State of Tamilnadu.

10

(2) to understand whether the LPG Bullets are installed in a safe

location capable of handling the emergency situations in an

effective manner.

(3) to study the consequence scenarios like BLEVE, Thermal

Radiations, Vapour Cloud Explosions and impact on

environment due to LPG releases from the installation and

usage of the LPG Bullets in Automobile industries.

1.6 SCOPE AND OBJECTIVE OF THE STUDY

The scope of the Study is to cover LPG/Propane installation in

automobile industries located in the state of Tamilnadu. Many leading

automobile companies such as Hyundai, Nissan, Ford, BMW, Daimler,

Mahindra and Mahindra, Ashok Leyland, L&T Foundry, Lakshmi Machinery

Works etc., have their manufacturing as well as supply facilities in

Tamilnadu, utilizing LPG as a fuel to meet their energy requirements.

Automobile industries storing bulk quantities of LPG in their premises were

focused upon. These industries use and store LPG in the range of 4.6 MT to

1350 MT. Samples from thirty-five automobile industries out of one hundred

and twenty five units were taken for this study. These shortlisted industries

are located in Tamilnadu.

Research studies on safety, health and environmental impact have

been found to be scarce and case studies on accidents and other risks

associated with the automobile industries were not documented. These case

studies done on risk featured an entire range of activities without any specific

focus. No specific study was conducted with special reference to LPG storage

facilities and their associated EIA aspects. However, the documents of ILO

provided information related to the accidents.

11

The Objectives of this study are:

to conduct Environmental Impact and Risk Assessment study

in the automobile industries located in Tamilnadu, where large

quantities of Liquid Petroleum Gas (LPG) / Propane are used.

to assess the environmental impact caused by the release of

LPG from its storage and other auxiliary facilities.

to review the hazards to workers and people in the

surrounding areas, damage to property and environment due to

the release of LPG.

to study and assess the parameters for quantification which

include flash point, degree of flammability, explosion, toxicity

etc.

to study and assess the influence of various factors such as

location, engineering design and systems implementation

during operation (production and maintenance).

to carry out Consequence Analysis of an emergency situation

at the industrial site and risk management in hazardous

installations of LPG handling industries.

to recommend improvement of the operational and

maintenance procedure for enhancing reliability and safety.

to check the environmental acceptability of the proposals

compared to the capacity of the site and the environment.

to ensure that resources are used appropriately and efficiently.

to identify the appropriate measures to mitigate the potential

impacts of LPG releases.

12

to facilitate decision-making including setting the

environmental terms and conditions for implementing the

proposals of LPG handling automobile industries.

to avoid irreversible changes and damage to the environment.

to enhance the social aspects of proposals and to protect the

environment, ecology, health and safety.

to obtain primary information and acquire knowledge of

possible accident scenarios and probability of the hazards,

which are responsible for damage to property and public

health.

to enable planners to use the findings of the study while

sanctioning clearance for LPG handling automobile industries.

1.7 ORGANISATION OF THE THESIS

The thesis has been organized into six chapters as given below:

Chapter 1 provides the introductory details of the research work.

The need for the study, scope and objectives of the investigation, details of

LPG, its advantages and the organization of Thesis.

Chapter 2 describes the literature review highlighting the details of

the research work carried out pertaining to the studies on environmental

impacts and risk assessment of LPG bulk storages, modeling worst case

scenarios and past accident histories.

Chapter 3 presents the methodology adopted for the research plan

and research tool developed on line with statutory obligations and data

required for compilation of research tool.

13

Chapter 4 presents the details of selection of the model, risk

assessment for various release scenarios such as thermal radiation due to fire,

shock wave pressure due to explosion, damage distances computation and

consolidation of results.

Chapter 5 summarizes the statistical analysis of observed data,

findings and discussion of results.

Chapters 6 present the conclusions, future scope of the research

area and follow up on the work done in the thesis.

You might also like

- LPGDocument67 pagesLPGraritylim100% (3)

- Tank Design CalculatorDocument19 pagesTank Design CalculatorSunday PaulNo ratings yet

- Marine Loading ArmDocument2 pagesMarine Loading ArmAfolabi OlaniyiNo ratings yet

- Guidelines for Third Party AccessDocument21 pagesGuidelines for Third Party AccessbiondimiNo ratings yet

- Sichuan Air SeparationDocument25 pagesSichuan Air SeparationFarshad Asgari0% (1)

- LPGDocument7 pagesLPGPriyanathan Thayalan100% (1)

- 5000m3 LPG Tank FarmDocument2 pages5000m3 LPG Tank FarmLpgTankFarmNo ratings yet

- Ige TD 13Document73 pagesIge TD 13Anant RubadeNo ratings yet

- Brochure DARCO H2S Odor ControlDocument8 pagesBrochure DARCO H2S Odor ControlErick MavenNo ratings yet

- LPG RulesDocument12 pagesLPG RulesAhmed KhanNo ratings yet

- Full LPG CatalogueDocument32 pagesFull LPG CatalogueRamius HamdaniNo ratings yet

- Written Questions Coordinator Final (Apr2021)Document4 pagesWritten Questions Coordinator Final (Apr2021)Rae Marie Cadeliña ManarNo ratings yet

- Liquid Petroleum Gas (LPG) - Pressured Storage - Location, Design, Capacity and InstallationDocument14 pagesLiquid Petroleum Gas (LPG) - Pressured Storage - Location, Design, Capacity and InstallationtrungjindoNo ratings yet

- Statutory LPG standardsDocument4 pagesStatutory LPG standardsalwacsNo ratings yet

- CNG Brochure WebDocument9 pagesCNG Brochure WebMuhammad Dicky AmrullahNo ratings yet

- LPG BULK INSTALLATIONS AND PIPEWORK TOPIC PACKDocument67 pagesLPG BULK INSTALLATIONS AND PIPEWORK TOPIC PACKASKOKO100% (1)

- Aviation Refuelling Equipment CatalogueDocument180 pagesAviation Refuelling Equipment Catalogueviktor_gligorovNo ratings yet

- Bottom-And Top Loading Arms For Liquefied GasesDocument4 pagesBottom-And Top Loading Arms For Liquefied GasesprabhuarunkumarNo ratings yet

- Gas Cylinder Safety RulesDocument24 pagesGas Cylinder Safety RulesAnuj SinhaNo ratings yet

- Minimum Maximum LPG Energy Content (Btu/f)Document5 pagesMinimum Maximum LPG Energy Content (Btu/f)Mirza Aatir SalmanNo ratings yet

- Tank Jet MixersDocument2 pagesTank Jet MixersGabriela Axinte100% (1)

- LPG Storage Tank Fire and ExplosionDocument7 pagesLPG Storage Tank Fire and ExplosionULISESNo ratings yet

- D2 Dinesh Pant Biomass Technology and ImplementationDocument57 pagesD2 Dinesh Pant Biomass Technology and ImplementationBuddhi Raj SharmaNo ratings yet

- DAB 22 Fuel Hydrant PitDocument2 pagesDAB 22 Fuel Hydrant Pitzelda1022No ratings yet

- Lus-Cpall-Maq-Spe-Ut-00006 - Gas Distribution System Design Guidelines For Pressure Reducing Station (Primary Customer Meter) - Rev. 04Document20 pagesLus-Cpall-Maq-Spe-Ut-00006 - Gas Distribution System Design Guidelines For Pressure Reducing Station (Primary Customer Meter) - Rev. 04RamiAl-fuqahaNo ratings yet

- AFS, KanpurDocument5 pagesAFS, Kanpurdipmoip2210No ratings yet

- Insulation BOQ Piping DocumentDocument1 pageInsulation BOQ Piping DocumentRasool Shaik100% (1)

- Petroleum storage tank fire protection methodsDocument5 pagesPetroleum storage tank fire protection methodsSadish Nair100% (1)

- Coal Stockyard Fire Protection and Drainage SolutionsDocument6 pagesCoal Stockyard Fire Protection and Drainage SolutionsIlker CetinNo ratings yet

- Offer For Portable Abrasive Blasting MachineDocument4 pagesOffer For Portable Abrasive Blasting MachineranjanNo ratings yet

- Aker Solutions LNGDocument27 pagesAker Solutions LNGruov100% (1)

- LPG InstallationDocument24 pagesLPG InstallationHaris LatifNo ratings yet

- Vol Vi A - Terminal and Tank Farm Odpcp - Donlin Gold Project - August 2012Document110 pagesVol Vi A - Terminal and Tank Farm Odpcp - Donlin Gold Project - August 2012yeNo ratings yet

- UOP Callidus Flares BrochureDocument5 pagesUOP Callidus Flares BrochureGigenaNo ratings yet

- Safety Marking Tapes for PipelinesDocument6 pagesSafety Marking Tapes for Pipelinespramod_kbNo ratings yet

- SGLPG Technical Standard One Storage of LPG in Bulk (HSE-03-10)Document39 pagesSGLPG Technical Standard One Storage of LPG in Bulk (HSE-03-10)anwar01No ratings yet

- Fire Pump FAQDocument2 pagesFire Pump FAQK SubramaniNo ratings yet

- Day 04 Maintenance of LPG SystemDocument11 pagesDay 04 Maintenance of LPG Systemkmas1612No ratings yet

- Gas Demand Forecasting Methodology 1Document55 pagesGas Demand Forecasting Methodology 1scribduserkrisNo ratings yet

- Steam Trap Cross Reference GuideDocument5 pagesSteam Trap Cross Reference GuideTONNo ratings yet

- CODEX Transport of Fats and OilsDocument15 pagesCODEX Transport of Fats and OilsDwayne A PunchNo ratings yet

- NFPA 58 & API 2510 - Vessel & Transfer Area Requirements - 2019 UpdateDocument45 pagesNFPA 58 & API 2510 - Vessel & Transfer Area Requirements - 2019 Updatedennis adamsNo ratings yet

- LPG Pipeline MeteringDocument7 pagesLPG Pipeline MeteringDinesh Pinto100% (1)

- LPG Tank Commissioning Training NotesDocument32 pagesLPG Tank Commissioning Training NotesKajubi Edris100% (1)

- TCVN 6486Document14 pagesTCVN 6486Nguyen Duc Thien PhucNo ratings yet

- Nitrogen TankDocument9 pagesNitrogen TankVirnando NainggolanNo ratings yet

- Design of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerDocument6 pagesDesign of LNG Plant Facilities.: N.Bandyopadhyay - Consulting EngineerHoàng KakaNo ratings yet

- OGRA LPG Rules 2001Document17 pagesOGRA LPG Rules 2001محمد نعمان بٹNo ratings yet

- Sri Fire Protection Equipmets PDFDocument62 pagesSri Fire Protection Equipmets PDFamal_postNo ratings yet

- Fluor Piping TraingTOCDocument1 pageFluor Piping TraingTOCSergio SmithNo ratings yet

- CLOSED SAMPLING SYSTEMDocument1 pageCLOSED SAMPLING SYSTEMvuongNo ratings yet

- FOAM TANK (1/2) : Fire Fighting Equipment Data SheetDocument24 pagesFOAM TANK (1/2) : Fire Fighting Equipment Data SheetandinumailNo ratings yet

- Large Crude Oil Storage Tank Trac-Loc Installation ... - Pentair ThermalDocument2 pagesLarge Crude Oil Storage Tank Trac-Loc Installation ... - Pentair ThermalBarmar SbahiNo ratings yet

- TGE Brochure 2010Document12 pagesTGE Brochure 2010ankeshkatochNo ratings yet

- Auto LPG Dispensing Station SpecificationDocument5 pagesAuto LPG Dispensing Station SpecificationShyBokxNo ratings yet

- Slenderness RatioDocument6 pagesSlenderness RatioDuke StonerNo ratings yet

- Es 95 ConclusionssDocument2 pagesEs 95 ConclusionssMAcryan Pacquiao PactolNo ratings yet

- Comparison of ISO 14001 2015 and ISO 450Document11 pagesComparison of ISO 14001 2015 and ISO 450mete erucarNo ratings yet

- Challenges & Safety Issues in Compressed Bio Gas Plant (CBG)Document5 pagesChallenges & Safety Issues in Compressed Bio Gas Plant (CBG)Saurav Anand100% (1)

- SakthifinalDocument116 pagesSakthifinaljaituljaiNo ratings yet

- Distribution and Retailing of LPG in India: An OverviewDocument22 pagesDistribution and Retailing of LPG in India: An OverviewJehirul IslamNo ratings yet

- Ijrss ISSN: 2249-2496: Ground Realities of Self Help Group - Bank Linkage Programme: An Empirical AnalysisDocument16 pagesIjrss ISSN: 2249-2496: Ground Realities of Self Help Group - Bank Linkage Programme: An Empirical AnalysisJehirul IslamNo ratings yet

- 19Document6 pages19Pallavi PuriNo ratings yet

- Small Scale-Paper MakingDocument17 pagesSmall Scale-Paper MakingGnana SS100% (1)

- Paper Mail PDFDocument101 pagesPaper Mail PDFJehirul IslamNo ratings yet

- Reference Note: Effects of Mobile RadiationDocument10 pagesReference Note: Effects of Mobile RadiationJehirul IslamNo ratings yet

- Cell Tower Radiation Report - Sent To DOT (Department of Telecommunications)Document50 pagesCell Tower Radiation Report - Sent To DOT (Department of Telecommunications)Neha Kumar100% (9)

- LPG Project 3 PDFDocument91 pagesLPG Project 3 PDFJehirul IslamNo ratings yet

- Wooden FurnitureDocument4 pagesWooden FurnitureShree HarshaNo ratings yet

- 201 South Third Street Cell Tower Project: Initial Study - Mitigated Negative DeclarationDocument66 pages201 South Third Street Cell Tower Project: Initial Study - Mitigated Negative DeclarationJehirul IslamNo ratings yet

- Furniture Report Dicembre 2006Document91 pagesFurniture Report Dicembre 2006Ravi Shankar ReddyNo ratings yet

- Trunky Project Minral Water PlantDocument29 pagesTrunky Project Minral Water PlantAmjad PervazNo ratings yet

- Packaged Drinking Water ProductionDocument6 pagesPackaged Drinking Water ProductionismaiaaNo ratings yet

- India Urban Water Projects ReportDocument19 pagesIndia Urban Water Projects ReportJehirul IslamNo ratings yet

- A. I A. B D P: Ntroduction Rief Escription of RojectDocument23 pagesA. I A. B D P: Ntroduction Rief Escription of RojectJehirul IslamNo ratings yet

- HooooooooooDocument60 pagesHooooooooooNazru NazNo ratings yet

- Liquefied Petroleum Gas (LPG) Extraction Project: Consultative Environmental ReviewDocument84 pagesLiquefied Petroleum Gas (LPG) Extraction Project: Consultative Environmental ReviewJehirul IslamNo ratings yet

- India Urban Water Projects ReportDocument19 pagesIndia Urban Water Projects ReportJehirul IslamNo ratings yet

- Demand Forecasting of LPGDocument91 pagesDemand Forecasting of LPGNawab RaghuNo ratings yet

- E Com 2 PDFDocument72 pagesE Com 2 PDFJehirul IslamNo ratings yet

- LPG Project 3Document13 pagesLPG Project 3Jehirul IslamNo ratings yet

- E Com 2 PDFDocument72 pagesE Com 2 PDFJehirul IslamNo ratings yet

- Population Group Wise Branch ListDocument764 pagesPopulation Group Wise Branch ListrajanNo ratings yet

- Demand Forecasting of LPGDocument91 pagesDemand Forecasting of LPGNawab RaghuNo ratings yet

- LPG Project2Document7 pagesLPG Project2Jehirul IslamNo ratings yet

- LPG Project2Document7 pagesLPG Project2Jehirul IslamNo ratings yet

- School Grade Level Teacher Learning Area Teaching Dates and Time QuarterDocument4 pagesSchool Grade Level Teacher Learning Area Teaching Dates and Time QuarterJan IceNo ratings yet

- Physics MCQs For Class 12 CH 11 Dual Nature of Matter and RadiationDocument7 pagesPhysics MCQs For Class 12 CH 11 Dual Nature of Matter and RadiationAkshith ReddyNo ratings yet

- Chemical Engineering, BSC PDFDocument41 pagesChemical Engineering, BSC PDFCássio Soares100% (1)

- Chapter 12 Composite Engineering MaterialDocument43 pagesChapter 12 Composite Engineering MaterialMohd Aizat Nasir100% (2)

- FluorSpec 11Document5 pagesFluorSpec 11jtolentino88No ratings yet

- SWG 30 WDocument1 pageSWG 30 WRajesh RoyNo ratings yet

- Simple Stresses and Strains PDFDocument104 pagesSimple Stresses and Strains PDFyaminiNo ratings yet

- OGJ Hot Vapor Bypass DesignDocument6 pagesOGJ Hot Vapor Bypass DesignJesse Haney III100% (2)

- Jindal Al SectionsDocument14 pagesJindal Al SectionsAMIT GUPTANo ratings yet

- Iso 10933 1997Document30 pagesIso 10933 1997gykataiNo ratings yet

- HCL Lab SheetDocument3 pagesHCL Lab Sheetapi-3552967280% (1)

- Dryness FractionDocument3 pagesDryness FractionJigme Lama100% (2)

- Chassis Grease & General Purpose Grease GuideDocument3 pagesChassis Grease & General Purpose Grease Guidevantuan17792No ratings yet

- Heat treatment and steel processes guideDocument12 pagesHeat treatment and steel processes guidevjtiitNo ratings yet

- Fluiten Plan APIDocument71 pagesFluiten Plan APImontsegran100% (1)

- Thermal Decomposition of MnCO3 (In Air)Document8 pagesThermal Decomposition of MnCO3 (In Air)Aulizar MarioNo ratings yet

- Astm D 445Document10 pagesAstm D 445Régulo RafaelNo ratings yet

- Fire Technology GuideDocument140 pagesFire Technology GuideJulius ViodorNo ratings yet

- NSS Chemistry Part 2 Microscopic World I - LQ - PDFDocument22 pagesNSS Chemistry Part 2 Microscopic World I - LQ - PDFSiu Hon ChengNo ratings yet

- Unit 2 Solutions Key ConceptsDocument32 pagesUnit 2 Solutions Key ConceptsChitrasen WangNo ratings yet

- Chemical Engineering Review QuestionsDocument19 pagesChemical Engineering Review QuestionsMarcela Godoy100% (16)

- PH3 30 Iron SteelDocument142 pagesPH3 30 Iron SteelMouna GuruNo ratings yet

- Garc Ijiet 2021 11 5 17Document7 pagesGarc Ijiet 2021 11 5 17Obidah GodwinNo ratings yet

- Importance of ProteinsDocument30 pagesImportance of ProteinsJUSTIN VICTOR ANGNo ratings yet

- Markscheme Paper2B June2018 IGCSE Edexcel BiologyDocument18 pagesMarkscheme Paper2B June2018 IGCSE Edexcel BiologyFatihun Raiyan KhanNo ratings yet

- DC SIM+User+GuideDocument115 pagesDC SIM+User+GuideSegundopqNo ratings yet

- WELDING Book AWSD1.1 Rev-3ADocument35 pagesWELDING Book AWSD1.1 Rev-3AFerdie OS100% (1)

- Fluid Mechanics FundamentalsDocument26 pagesFluid Mechanics FundamentalsEugine BalomagaNo ratings yet

- Reactivity 2.1 - How Much-The Amount of Chemical ChangeDocument34 pagesReactivity 2.1 - How Much-The Amount of Chemical ChangeLucia PesentiNo ratings yet

- Body Sealing PDFDocument22 pagesBody Sealing PDFoz23No ratings yet