Professional Documents

Culture Documents

Typical experimental heat pipe results summary

Uploaded by

Akash sainiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Typical experimental heat pipe results summary

Uploaded by

Akash sainiCopyright:

Available Formats

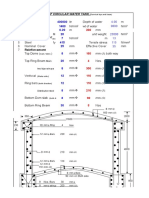

Some typical experimental heat pipe results

Working Operati Wick Design Wall Dimensions Axial Axial Heat Radial Heat

Fluid ng Material Heat Transport Flux (W/cm2)

Temper Transport Capability

ature (W) (W-m)

Methane -140°C Circumferential Stainles Lt = 0.4 m 12 3.93 1.82

mesh wick and s steel

arterial wick Le = 3 cm

Lc = 11.5 cm

Di = 7 mm

Ammonia 25°C Monogroove Aluminu Lt = 5.5 m 700 3200 7.26

m

Le = 0.91 m

Lc = 0.91 m

Dv = 13.4 mm

Dl = 6.32 mm

slot width =

0.381 mm

Water 50°C Axial grooves Copper Outer pipe 1300 940 Inner pipe: 2.32

same as

above; Inner Outer pipe: 1.47

pipe:

Do = 29.7 mm

Di = 25.4 mm

Water 50, 70, 3 wraps of a Copper Do = 19.05 20-180 4.6-41 0.33-2.96

80°C copper wire mm

screen mesh

with a wire Di = 15.75 mm

diameter of Lt = 355.6 mm

0.11 mm and

3937 strands Le = 101.6 mm

per meter Lc = 152.4 mm

Water 60-95°C Micro capillary Copper Lt = 120.65 130 15.6 90 (horizontal)

grooves mm (horizontal

(trapezoidal ) 20.4 150 (vertical)

and W = 13.41 mm

rectangular) 170

Le = 15.6 mm (vertical)

Lc = 34.4 mm

La = 70 mm

Water 75°C Circumferential Copper L = 1.0 m 392 283 1.92

copper screen

(50 mesh) Le = (4)@6.4

cm

Lc = 30 cm

Dv = 25.4 mm

Di = 22 mm

Water 100°C Axial grooves Copper Lt = 120 mm 70 8.4 35

with

rectang H = 2 mm

ular W = 7 mm

cross Le = 20 mm

section

Lc = 20 mm

Water 100°C Copper wick, Copper Do = 19.1 mm 570 187 2.4

150 mesh

Di = 17.3 mm

Lt = 610 mm

Le = 393 mm

Lc = 170 mm

Water Axial Copper Lt = 82 mm 40 20

rectangular

grooves

Water 100 °C Axial Copper Lt = 120 mm 50 25 (horizontal)

rectangular (horizontal

grooves W = 7 mm ) 35 (vertical)

H = 3 mm 70

(vertical)

Water 160°C Double-wall Copper Lt = 1.2 m 900 900 6.45

artery

Le = 0.2 m

Lc = 0.2 m

Dv = 13.4 mm

Do = 22.2 mm

Thermino 300- Thermosyphon 316- Do = 15.8 mm 35-70 4.8-9.6 1.57-3.13

l VP-1 400°C stainles

s steel Di = 6 mm

Lt = 209 mm

Le = 45 mm

Lc = 100 mm

Sulfur- 350°C Thermosyphon Mild Do = 25 mm 390 204.8 1.24

Iodine 5% steel

wt Di = 20 mm

Lt = 1000 mm

Le = 400 mm

Lc = 550 mm

Sodium 430- Circumferential Stainles Lt = 1.0 m 1309 979 6.64

790°C stainless steel s steel

screen (100 Le = (4)@5.3

mesh) cm

Lc = 29.2 cm

Do = 26.7 mm

Di = 21.5 mm

Sodium 650°C Nickel sintered Stainles Do = 21.3 mm 1400 322 21

powder metal s steel

wick and an Di = -

artery Lt = 460 mm

Le = 100 mm

Lc = 160 mm

Lc,inactive =

100 mm

Sodium 800°C Double-wall Stainles Lt = 2.0 m 758 1076 4.35

artery s steel

Le = 25 cm

Lc = 91 cm

Do = 2.22 cm

Mercury 630°C Thermosyphon 316L Do = 25.4 mm 1922 1115 12

stainles

s steel Di = 21 mm

Lt = 1000 mm

Le = 200 mm

Lc = 640 mm

Do = 19.1 mm

NaK (with 700°C 304 stainless 304L 250 57 3.65

Argon as wick stainles Di = -

NCG) s steel

Lt = 600 mm

Le = 114 mm

Lc,1 = 73 mm

Lc,2 = 66 mm

Lc,inactive =

50 mm

Lithium 1227°C Free-floating molybde Do = 19.1 mm 4000 3660 22.2

(1500 Mo-41wt.%Re num

K) 400-mesh Di = 16.06 mm

screen wick Lt = 1800 mm

(0.41 mm

thick) Le = 300 mm

A 0.37 mm Lc = 1470 mm

annular gap

separates the

wick from the

wall

You might also like

- Whalen Uy Residences 2CS-1 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 0.50 MDocument1 pageWhalen Uy Residences 2CS-1 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 0.50 MWilliam ProvidoNo ratings yet

- Whalen Uy Residences 2S-2 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 1.90 MDocument1 pageWhalen Uy Residences 2S-2 125.00 125.00 3.00 Ksi 40 Ksi 10 12.00 1.90 MWilliam ProvidoNo ratings yet

- SlabDocument18 pagesSlabRajesh PatelNo ratings yet

- Design of StaircaseDocument3 pagesDesign of StaircaseMainali IshuNo ratings yet

- Plate and Bolt H Beam 350.175 Pmax 30 TDocument1 pagePlate and Bolt H Beam 350.175 Pmax 30 TYenni Gusrina SiregarNo ratings yet

- BeamDocument5 pagesBeamsteveassaNo ratings yet

- BeamDocument10 pagesBeamsteveassaNo ratings yet

- Underground Water Tank DesignDocument24 pagesUnderground Water Tank Designsujan100% (1)

- Circular Water Tank RC Design To IsDocument29 pagesCircular Water Tank RC Design To IsSteve JsobNo ratings yet

- Circular Water Tank Design and Reinforcement LayoutDocument28 pagesCircular Water Tank Design and Reinforcement LayoutLachu M. SharmaNo ratings yet

- General Equation For Fluid FrictionDocument8 pagesGeneral Equation For Fluid FrictionAyub Ali Wehelie100% (1)

- Double RC Beam (WSD)Document15 pagesDouble RC Beam (WSD)api-19753598No ratings yet

- Design of Circular Water TankDocument27 pagesDesign of Circular Water TankAbhay Thakur100% (1)

- Slab Design - Roof: Ca CBDocument26 pagesSlab Design - Roof: Ca CBAnissah ManialaNo ratings yet

- Sample Estimate SheetDocument26 pagesSample Estimate SheetKaJong JaclaNo ratings yet

- Design of floor beam and roof beam reinforcementDocument50 pagesDesign of floor beam and roof beam reinforcementKimberly Mae SantosNo ratings yet

- Circular Water Tank With Domcal Top and BaseDocument32 pagesCircular Water Tank With Domcal Top and BaseHanafiahHamzahNo ratings yet

- B1 Beam DesignDocument7 pagesB1 Beam DesignakhilNo ratings yet

- Reinforcement design of RCC slab panelDocument15 pagesReinforcement design of RCC slab panelTechnical OriliteNo ratings yet

- Data Profil Struktur AtapDocument137 pagesData Profil Struktur AtapFALwilliamsNo ratings yet

- Reinforced Concrete Two Way SlabDocument3 pagesReinforced Concrete Two Way SlabMark Brien Vincent YbañezNo ratings yet

- Design of 7.5m long box culvert with reinforcement detailsDocument2 pagesDesign of 7.5m long box culvert with reinforcement details98675No ratings yet

- Grid 84-Concentric-Coated Bottom PlateDocument5 pagesGrid 84-Concentric-Coated Bottom PlateMostafa SarvariNo ratings yet

- M1 Activity 1 GALIASDocument9 pagesM1 Activity 1 GALIASJonica HarkessNo ratings yet

- Slab-Steel-Calculation-Excel-Sheet 2020-2Document3 pagesSlab-Steel-Calculation-Excel-Sheet 2020-2Karzan Rwandzi100% (3)

- Canal Data: FOR AQUEDUCT (Vertical Section)Document5 pagesCanal Data: FOR AQUEDUCT (Vertical Section)nsiyamNo ratings yet

- Slab 02Document1 pageSlab 02Jason LegacyNo ratings yet

- Circular Water Tank With Domcal Top and Base UmwDocument24 pagesCircular Water Tank With Domcal Top and Base UmwLeeCH LeeCHNo ratings yet

- ArcelorMittal Beams Calculator PDFDocument8 pagesArcelorMittal Beams Calculator PDFAndreja GjureskiNo ratings yet

- Blower and Air PipeDocument30 pagesBlower and Air PipeRavindra DarjiNo ratings yet

- Sludge Thickener Pump Head CalculationDocument4 pagesSludge Thickener Pump Head CalculationgawtomNo ratings yet

- ArcelorMittal Beams CalculatorDocument9 pagesArcelorMittal Beams CalculatorAndreja GjureskiNo ratings yet

- Gal, 2TKG2, SB1BL K2018Document3 pagesGal, 2TKG2, SB1BL K2018galihNo ratings yet

- Retaining Wall DesignDocument12 pagesRetaining Wall DesignEwanNo ratings yet

- Reinforcement: V, F: Project: Staircase Design - STC 1Document4 pagesReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNo ratings yet

- Design of One Way Slab Project: Title: Design ParametersDocument26 pagesDesign of One Way Slab Project: Title: Design Parametersjay bNo ratings yet

- Jembatan OwenDocument10 pagesJembatan OwenStefan MandalahiNo ratings yet

- 175kl Design Upto Bottom DomeDocument24 pages175kl Design Upto Bottom DomeOm MeenaNo ratings yet

- Design of Tie Beam Design Of: Tb5 at AxisDocument7 pagesDesign of Tie Beam Design Of: Tb5 at AxisSuhail AhamedNo ratings yet

- Formwork & Scaffolding Material-2-20Document19 pagesFormwork & Scaffolding Material-2-20belal545No ratings yet

- Slab Design 1 WayDocument16 pagesSlab Design 1 WaySayavi Nicole Sayavi NickNo ratings yet

- Design of Singly Reinforced RCC T-Beam Girder: M Value 10.0Document3 pagesDesign of Singly Reinforced RCC T-Beam Girder: M Value 10.0Rudranath BhattacharyaNo ratings yet

- Isolated ColumnDocument2 pagesIsolated ColumnFrancisco DeLos Angeles IIINo ratings yet

- C RAYMUNDO Structural Analysis PDFDocument33 pagesC RAYMUNDO Structural Analysis PDFMark Christian Esguerra100% (1)

- Project Name: Component Name:water Tank Base M11, V13 Mom Capacity 117.31 Shear Capacity 130.16Document10 pagesProject Name: Component Name:water Tank Base M11, V13 Mom Capacity 117.31 Shear Capacity 130.16Bibek WagleNo ratings yet

- Material Estimate: Layouting and StakingDocument12 pagesMaterial Estimate: Layouting and StakingPamela Joanne Falo Andrade100% (1)

- Perancangan Kopling Flens Dan GesekDocument15 pagesPerancangan Kopling Flens Dan GesekBayu WibisonoNo ratings yet

- Penulangan Kolom Diagram InteraksiDocument3 pagesPenulangan Kolom Diagram InteraksiRizki Ade KhoirNo ratings yet

- Design of Two Way Slab (I.S Method) : Input DatasDocument6 pagesDesign of Two Way Slab (I.S Method) : Input DatasKARTHIK SGNo ratings yet

- CVE 372 Exercise Problems - Pipe FlowDocument10 pagesCVE 372 Exercise Problems - Pipe FlowMahmoud I. MahmoudNo ratings yet

- Grid 84-Parallel - Coated Bottom PlateDocument9 pagesGrid 84-Parallel - Coated Bottom PlateMostafa SarvariNo ratings yet

- Calculation Head LossvDocument14 pagesCalculation Head LossvcylinderNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 3Rating: 3 out of 5 stars3/5 (2)

- Water Level Indicator Circuit Using Bipolar Junction TransistorFrom EverandWater Level Indicator Circuit Using Bipolar Junction TransistorRating: 4.5 out of 5 stars4.5/5 (7)

- NGPDU For BS SelectDocument14 pagesNGPDU For BS SelectMario RamosNo ratings yet

- Three Storey Commercial BuildingDocument2 pagesThree Storey Commercial Buildingrichard romasantaNo ratings yet

- Nichias Gasket Tombo1995Document3 pagesNichias Gasket Tombo1995Richard SmithNo ratings yet

- Spare Parts Catalogue for PALFINGER Loader PK 11001Document134 pagesSpare Parts Catalogue for PALFINGER Loader PK 11001Alfred HitchcockNo ratings yet

- IFSTA EFF 5th Ed. Chapter 11 Ventilation FF1Document120 pagesIFSTA EFF 5th Ed. Chapter 11 Ventilation FF1Cesar Caballero100% (1)

- Lesson 4 Hotel Public Area MaintenanceDocument64 pagesLesson 4 Hotel Public Area MaintenanceReina100% (6)

- New Price List CPVC 2021Document2 pagesNew Price List CPVC 2021Yash ShanishvaraNo ratings yet

- Rail Handling InstructionsDocument3 pagesRail Handling InstructionsSergio AguilarNo ratings yet

- Final Report - 06.12.2018Document57 pagesFinal Report - 06.12.2018swapneelkalraNo ratings yet

- Excessive Retardation in Concrete: P.Senthamil SelvanDocument4 pagesExcessive Retardation in Concrete: P.Senthamil SelvanSelvanNo ratings yet

- How To Build A Pergola: Preparation of The AreaDocument2 pagesHow To Build A Pergola: Preparation of The AreaDarwin BajoNo ratings yet

- Urban Road ParametersDocument6 pagesUrban Road ParametersTej Bdr. paliNo ratings yet

- History of Architecture 1Document2 pagesHistory of Architecture 1Patricia Anne Manzo ModinaNo ratings yet

- Checklist For Terrace WaterproofingDocument2 pagesChecklist For Terrace WaterproofingSantosh YadavNo ratings yet

- AlSi10Mg-M270 Material Data Sheet 07-09 enDocument4 pagesAlSi10Mg-M270 Material Data Sheet 07-09 eninam758388No ratings yet

- Inventario DCDocument10 pagesInventario DCIsabelNo ratings yet

- NCHRP RPT 568 - Riprap Design Criteria, Recommended Specifications and Quality ControlDocument226 pagesNCHRP RPT 568 - Riprap Design Criteria, Recommended Specifications and Quality Controlaescarameia100% (1)

- OSB vs Plywood: Key Differences Between These Wood PanelsDocument4 pagesOSB vs Plywood: Key Differences Between These Wood Panelshviviani451No ratings yet

- Installation Check Sheet For Ahu FahuDocument2 pagesInstallation Check Sheet For Ahu FahuSamer AliNo ratings yet

- Maintenance ScheduleDocument9 pagesMaintenance ScheduleMariam SalongaNo ratings yet

- Effect of Confinement With Lateral Reinforcement On Normal & High Strength Concrete ColumnsDocument20 pagesEffect of Confinement With Lateral Reinforcement On Normal & High Strength Concrete ColumnsNandeesh SreenivasappaNo ratings yet

- Refuerzo Por Cortante y Columna Fuerte-Viga Debil ACI 318-11Document17 pagesRefuerzo Por Cortante y Columna Fuerte-Viga Debil ACI 318-11Marco Diaz SaavedraNo ratings yet

- Catalogo Rodamientos LinkBelt PDFDocument309 pagesCatalogo Rodamientos LinkBelt PDFreinaldoNo ratings yet

- Is 1498 1970 Soil ClasificationDocument28 pagesIs 1498 1970 Soil Clasificationmads70No ratings yet

- HRV DaikinDocument115 pagesHRV DaikinPityt CatalinNo ratings yet

- Medidor Digital B&W-4Document2 pagesMedidor Digital B&W-4Aaron Quispe PinedaNo ratings yet

- Modified Hydrotest 6barDocument4 pagesModified Hydrotest 6barMohamed ElarabiNo ratings yet

- Guide to Installing Condensing Boilers in Existing HomesDocument18 pagesGuide to Installing Condensing Boilers in Existing Homestexas_peteNo ratings yet

- Classic Drive Manual 2Document40 pagesClassic Drive Manual 2bizncoNo ratings yet

- Purview 42 SeriesDocument68 pagesPurview 42 SeriesbaoningningNo ratings yet