Professional Documents

Culture Documents

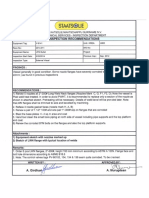

2014-011 v-8141 External Visual Inspection

Uploaded by

jose corrosionCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2014-011 v-8141 External Visual Inspection

Uploaded by

jose corrosionCopyright:

Available Formats

STAATSOLIE MAATSCHAPPIJ SURINAME N.V.

TECHNICAL SERVICES - INSPECTION DEPARTMENT

INSPECTION RECOMMENDATIONS

Equipment Tag: V-8141 Unit / AREA: U800

Reco No.: 2014-011 WO No:

Equipment Name: LPG Bullet Project:

Inspection Start Date: 5/22/2014 Previous Insp.: Sep. 2012

Inspection Type: External Visual

FINDINGS :

Vessel generally in good condition. Some nozzle flanges have severely corroded to 14-16 mm thick

(original 22mm ) as found in previous inspections

RECOMMENDATIONS :

1) Renew 5 nozzles all 2"-300# Long Weld Neck flanges (Nozzles Mark C, G, F1, F2, D). Note the

vessel is Post weld heat treated. In order to avoid PWHT, it is recommended to replace only a section of

the nozzle as shown in attached sketch. Preheating will be necessary. Details of weld bevel will be

provided later. Note: theLWN flanges shall be trimmed to size and bevelled by machining.

2. Reface 3 nozzle gasket faces (nozzle mark H, A, B)

3. Renew a pair of 1 1/2" 150# and one pair 1"-300# slip on flanges that are corroded

4. Blast the base plates +/- 4 sq.m area and coat

5. Hand tool clean the small bore piping at north side of vessel including pipe supports and the top

platform and coat.

6) Renew the corroded B7M bolts on the flanges and also the top platform supports.

Attachments :

1) Equipment sketch with nozzles marked up

2) Sketch of LWN flange with typical location of welds

Remarks:

1. Order 6 pcs LWN flanges, 2"-300#, height 150 mm minimum according to ASTM A 105N. Flange face

and bolt hole dimensions according to ASME B16.5

2. Note: The control valves tags PV-80102, 104, 134 & 136 seem quite corroded. To be checked.

WRITTEN BY : APPROVED BY:

You might also like

- Reactor R 3001Document3 pagesReactor R 3001jose corrosionNo ratings yet

- 2014-005 Procurement of New Tube Bundles (T&I 2014)Document3 pages2014-005 Procurement of New Tube Bundles (T&I 2014)jose corrosionNo ratings yet

- 2014-015 Tank 741 A InspectionDocument1 page2014-015 Tank 741 A Inspectionjose corrosionNo ratings yet

- Dilatation Register of The Reactor: Location Date X Y-1 Y-2 Date X Y-1 Y-2Document1 pageDilatation Register of The Reactor: Location Date X Y-1 Y-2 Date X Y-1 Y-2jose corrosionNo ratings yet

- 2014-014 VBU Unit 200 Transfer Line RenewalDocument1 page2014-014 VBU Unit 200 Transfer Line Renewaljose corrosionNo ratings yet

- 2014-005 Procurement of New Tube Bundles (T&I 2014)Document1 page2014-005 Procurement of New Tube Bundles (T&I 2014)jose corrosionNo ratings yet

- 2014-013 Waste Gas HeaderDocument1 page2014-013 Waste Gas Headerjose corrosionNo ratings yet

- 561-19 SW CSDocument1 page561-19 SW CSjose corrosionNo ratings yet

- 2014-007 T-8031 RW Discharge LineDocument1 page2014-007 T-8031 RW Discharge Linejose corrosionNo ratings yet

- 2014-006 FW P-8023 Discharge LineDocument1 page2014-006 FW P-8023 Discharge Linejose corrosionNo ratings yet

- 000 Reco IndexDocument3 pages000 Reco Indexjose corrosionNo ratings yet

- Inspection Monthly Report - Oct 2014Document1 pageInspection Monthly Report - Oct 2014jose corrosionNo ratings yet

- 2014-002 OffplotDocument6 pages2014-002 Offplotjose corrosionNo ratings yet

- Inspection Dept Action List: Date What Who Due Date Remarks Status Item #Document14 pagesInspection Dept Action List: Date What Who Due Date Remarks Status Item #jose corrosionNo ratings yet

- Insp Monthly Report Jan 2014Document1 pageInsp Monthly Report Jan 2014jose corrosionNo ratings yet

- OCN Review Team Matrixes and Project Categorization MatrixDocument2 pagesOCN Review Team Matrixes and Project Categorization Matrixjose corrosionNo ratings yet

- Inspection - Action List May 2014Document2 pagesInspection - Action List May 2014jose corrosionNo ratings yet

- Safety Observation June 2015Document7 pagesSafety Observation June 2015jose corrosionNo ratings yet

- Highlights TS TemplateDocument1 pageHighlights TS Templatejose corrosionNo ratings yet

- SAFETY OBSERVATION 01-2015 Week J Y Rev1Document2 pagesSAFETY OBSERVATION 01-2015 Week J Y Rev1jose corrosionNo ratings yet

- Belzona Protective LiningsDocument32 pagesBelzona Protective Liningsjose corrosion100% (2)

- Establishing IOW'sDocument28 pagesEstablishing IOW'sjose corrosion100% (1)

- Piping General Rev06 REPDocument445 pagesPiping General Rev06 REPjose corrosionNo ratings yet

- Pdvsa: Engineering Design ManualDocument3 pagesPdvsa: Engineering Design Manualjose corrosionNo ratings yet

- Pennsylvania Public Utility Commission: Corrosion Control InspectionDocument6 pagesPennsylvania Public Utility Commission: Corrosion Control Inspectionjose corrosionNo ratings yet

- Manlift Rev by ASME 30. 23Document1 pageManlift Rev by ASME 30. 23jose corrosionNo ratings yet

- Training Schedule Confined Space Entry and Self RescueDocument7 pagesTraining Schedule Confined Space Entry and Self Rescuejose corrosionNo ratings yet

- T&I Kick-Off Meeting Regr FormDocument1 pageT&I Kick-Off Meeting Regr Formjose corrosionNo ratings yet

- Tray Installation Instructions - EnglishDocument3 pagesTray Installation Instructions - Englishjose corrosion100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Buoyancy Calculation Report For 10INCH PipelineDocument7 pagesBuoyancy Calculation Report For 10INCH PipelineEmmanuel LawrenceNo ratings yet

- Production & Downstream Processing of Baker's Best FriendDocument26 pagesProduction & Downstream Processing of Baker's Best FriendMelissaNo ratings yet

- MOLYKOTE 1000 Paste 71-0218H-01Document2 pagesMOLYKOTE 1000 Paste 71-0218H-01Victor PomboNo ratings yet

- MMFSLDocument9 pagesMMFSLsachin11hahaNo ratings yet

- DS 1 CatDocument38 pagesDS 1 CatMuhammad Bilal Khattak100% (1)

- 2019 PSRANM Conference Program FinalDocument24 pages2019 PSRANM Conference Program FinalKimmie JordanNo ratings yet

- Book Review - Black Skin, White MasksDocument9 pagesBook Review - Black Skin, White MasksKaren A. LloydNo ratings yet

- Amp-Eng Anger Management ProfileDocument6 pagesAmp-Eng Anger Management Profileminodora100% (1)

- Cable Test Bridge KMK 7Document2 pagesCable Test Bridge KMK 7zaki3speedNo ratings yet

- Neonatal SepsisDocument29 pagesNeonatal SepsisElton Ndhlovu100% (3)

- Varisco Solid Pumping SolutionsDocument12 pagesVarisco Solid Pumping SolutionsCatalin FrincuNo ratings yet

- SD502 (V22) 05.2021Document4 pagesSD502 (V22) 05.2021Beaulah HunidzariraNo ratings yet

- SAVULESCU, Julian - A Simple Solution To The Puzzles of End of LifeDocument5 pagesSAVULESCU, Julian - A Simple Solution To The Puzzles of End of Lifediradosta_1992No ratings yet

- API 510 Study GuideDocument3 pagesAPI 510 Study GuidedanikakaNo ratings yet

- Unit 1 Marks: 15 Introduction To Micro System and Smart SystemsDocument9 pagesUnit 1 Marks: 15 Introduction To Micro System and Smart SystemsSudarsh KNo ratings yet

- MAPEH Assignment For Mr. Felicilda (Only)Document6 pagesMAPEH Assignment For Mr. Felicilda (Only)Jericho Green Gerona100% (1)

- Project PPT Spot WeldingDocument19 pagesProject PPT Spot WeldingMehul BariyaNo ratings yet

- The European Board of Anaesthesiology.2Document4 pagesThe European Board of Anaesthesiology.2readririNo ratings yet

- New Fda Nutrition Label Guidelines For Food ManufacturersDocument17 pagesNew Fda Nutrition Label Guidelines For Food ManufacturersSurendra RamkissoonNo ratings yet

- Anesthesiology GuideDocument4 pagesAnesthesiology GuideGeorge Wang100% (1)

- ASME Single Certification MarkDocument3 pagesASME Single Certification MarkahmadghasusNo ratings yet

- Mechanical Operation Slurry TransportDocument113 pagesMechanical Operation Slurry TransportIsrarulHaqueNo ratings yet

- Benefits of Playing Badminton (An Essay)Document2 pagesBenefits of Playing Badminton (An Essay)Haryoung Sta CruzNo ratings yet

- ISO 9001 - 14001 - 2015 enDocument2 pagesISO 9001 - 14001 - 2015 enVĂN THÀNH TRƯƠNGNo ratings yet

- Climate Responsive ArchitectureDocument32 pagesClimate Responsive ArchitectureNikhila CherughattuNo ratings yet

- Pressure Regulator FRSDocument6 pagesPressure Regulator FRSTobiasAngererNo ratings yet

- PERDEV FIRST Periodical Test (2022)Document5 pagesPERDEV FIRST Periodical Test (2022)jeadryl LinatocNo ratings yet

- IDSA Guias Infeccion de Tejidos Blandos 2014 PDFDocument43 pagesIDSA Guias Infeccion de Tejidos Blandos 2014 PDFyonaNo ratings yet

- 12 29 11editionDocument27 pages12 29 11editionSan Mateo Daily JournalNo ratings yet

- PilatesDocument65 pagesPilatesAna MariaNo ratings yet