Professional Documents

Culture Documents

OEC-7700 - Calibration PDF

OEC-7700 - Calibration PDF

Uploaded by

Daniel Parada VanegasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OEC-7700 - Calibration PDF

OEC-7700 - Calibration PDF

Uploaded by

Daniel Parada VanegasCopyright:

Available Formats

KV Calibration

Attention: Newer systems contain B300 Boards – in this case you

should use the Potentiometer or Pot which is noted in dashes

behind it!! The position should be the same.

WARNING:

Electrical circuits inside the equipment use voltages that are capable of causing

serious injury or death from electrical shock. Use appropriate precautions.

NOTES :

(a) Allow a 30 minute warm up time prior to performing the calibration.

(b) You can verify kV calibration with a calibrated, non- invasive meter such as the

Keithley Triad System with the wide range filter pack or the Victoreen 4000 Plus.

1. Place a lead shield in the X- ray beam to protect the I. I. and the CCD camera.

2. Extend PCB B64 and clip the positive lead of your DVM on pin 17c on PCB B64.

Place the negative lead on pin 31a. Refer to Figure 1 for the location of pins 17 and 31.

3. Manually select 75 kVp. Do not make an exposure. Adjust P1 on PCB B64 to

achieve a reading of 10.125 VDC. Refer to Figure 1 for the location of P1.

4. Check the reference voltage on TP c (located between TP-f and 12V point) on PCB

B54 for 6V DC (allowed from 5.95V to 6.05V). If not, adjust with R4 potentiometer

which is located on the left edge of the B54 PCB.

5. Place the DVM lead on TP f on PCB B54 and use the ground reference on PCB B54

located within the Monoblock assembly card rack (Figure 2). TP- f represents the high

voltage ratio of 10,000: 1.

6. Select a 75kV standard fluoro exposure and adjust R28 on the Control Rack B100

PCB (R49 on B300) (see Figure 1) so that the measured voltage on PCB B54 TP- f =

7.5VDC.

7. While taking a 36kV standard fluoro exposure, verify that the measured voltage on

PCB B54 TP-f =3.6VDC.

8. While taking a 100kV standard fluoro exposure, verify that the measured voltage on

PCB B54 TP-f=10VDC.

9. Repeat steps 6 - 8, if necessary.

Date: 28.09.01 Page 1 of 3

>56 kV Hip Mode “HV Power” Calibration

1. Use your DVM to monitor the “HV Power.” GND = Chassis. Do this at either:

a.) X1 - 2 or XP1 - 2 on the Filter PCB .

b.) Positive (+) side on capacitor C1 in the power plate assembly. Capacitor

C1 resides behind the terminal strip of the power plate assembly. Refer

to Figure 2 in the Component Location Assembly/Disassembly section of

this service manual for the location of the terminal strip.

2. Manually select 36kV in the standard mode and note the voltage displayed on the

DVM.

3. Select the hip mode.

4. While observing the DVM display, manually increase the kV and note at what kV the

DVM display increases sharply. You should also hear a relay energize at this time. The

relay should energize at 56kV - 57kV. If it does not energize at this time go to step 5. If

it does energize, the kV calibration is complete.

5. Manually decrease the kV to 36kV and take an exposure.

NOTE:

This step should discharge C1 and return the charge to the lower value observed in

step 2.

6. Adjust R29 on PCB B100 (R50 on B300) to obtain the results listed in step 4.

Date: 28.09.01 Page 2 of 3

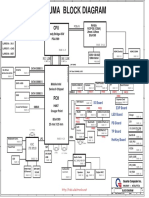

Figure 1

Figure 2 Figure 3

Date: 28.09.01 Page 3 of 3

MA Calibration

WARNING:

Electrical circuits inside the equipment use voltages that are capable of

causing serious injury or death from electrical shock. Use appropriate

precautions.

NOTES :

(1) All adjustment Pots and Test Points are on the Control Rack PCB B143 unless

instructed otherwise.

(2) Allow 30 minute warm up time prior to performing the calibration.

(3) Complete the kV Calibration prior to performing the mA calibration.

Fluoro

1. Remove the X- Ray tube cover.

2. Adjust P5 for a meter reading of 10VDC (± 5mv) on TP5 (TP6 Gnd).

3. Adjust P1 for a meter reading of 0VDC on TP3 (TP6 Gnd).

4. Place a meter (set to milliamps) in place of the mA jumper on the X- ray head

assembly. Refer to Figure 3 for the location of the mA jumper.

5. Place a jumper across R52 or jumper from TP8 to TP9 on PCB B143.

6. Select the manual fluoro mode and dial in 36kVp.

7. While making an X- ray, adjust the current to 150microA ±10microA with P3.

8. Remove the jumper across R52 or TP8 and TP9 on PCB B143.

9. Remove the meter and replace the mA jumper.

Film

1. Select the film mode and dial in 36kVp.

2. Place a voltmeter between TP6 (GND) and X3, pin 4 on PCB B143.

3. Press the handswitch button for less than 1 second, this will place K2 on PCB B143

in the film mode without producing X- rays, and adjust the voltage to 15.5 volts ±0.5

volts using P4.

4. Step 3 may have to be repeated to achieve the desired voltage output.

Date: 03.09.01 Page 1 of 4

Overshoot

1. Select film mode and dial in 110kVp.

2. Dial in a time of 1.5 seconds.

3. Place a storage capable oscilloscope between TP1 (-) and TP2 (+).

4. Press the handswitch until the exposure terminates.

5. Check the leading edge for overshoot or undershoot. If either overshoot or

undershoot occurs trim it with P4. Refer to Figure 2.

mA Output

1. Place a lead shield in the X- ray beam to protect the I. I. and the CCD camera.

2. Remove power to the system.

3. Place a meter, set to measure milliamps, across the mA jumper on the X- ray head

assembly. Refer to Figure 18 for the mA jumper location.

4. Manually fluoro at 36kV, adjust P7 (Figure 1) for a meter reading of 0.2mA.

5. Manually fluoro at 80kV, adjust P6 (Figure 1) for a meter reading of 3.0mA.

6. Adjust R55 on PCB B100 (R51 on B300) (Figure 3 in kV Calibration part) to

display 0.2 on the mA display during a 36kV manual fluoro.

7. During a 80kV manual fluoro exposure adjust R49 on PCB B100 (R68 on B300)

(Figure 3 in kV Calibration part) so the control panel display matches the actual mA

displayed on the DVM. This should be 3.0 mA.

8. During a 36kV manual fluoro exposure verify that the actual mA on the DVM is

0.2mA and the control panel display matches. If the control panel display does not

match the DVM mA, repeat steps 7 - 8. If the DVM mA is not 0.2 at 36kV., repeat

steps 4 - 5 .

9. Select the film mode.

10. During a 2 second, 36kV exposure, adjust P2 (Figure 1) for a 20mA reading on the

multimeter.

11. Replace the mA jumper.

Date: 03.09.01 Page 2 of 4

Entrance Exposure

NOTE: Measure the entrance exposure 12 inches (30cm) above the center of the I. I.

1. Replace the X- ray cover.

2. Select the Hip mode.

3. During a manual fluoro 110kV exposure, adjust P8 ( Figure 1) for the maximum mA

(not to exceed 6.0mA) at the control panel.

Date: 03.09.01 Page 3 of 4

Figure 1

Figure 2

Figure 3

Date: 03.09.01 Page 4 of 4

You might also like

- Siemens Mobilett XP Replacement of PartsDocument186 pagesSiemens Mobilett XP Replacement of PartsDhoy Gaviola83% (6)

- Manual Servicio Arco en CDocument191 pagesManual Servicio Arco en CNovoa Flores Tito MauryNo ratings yet

- Siremobil Compact L Troubleshooting Guide PDFDocument216 pagesSiremobil Compact L Troubleshooting Guide PDFKhon ReaksaNo ratings yet

- Everview 7500 C-Arm X-Ray Imaging System: Operator ManualDocument162 pagesEverview 7500 C-Arm X-Ray Imaging System: Operator ManualJairo ManzanedaNo ratings yet

- EVA - HF 525: Technical DescriptionDocument10 pagesEVA - HF 525: Technical DescriptionFouad Inr100% (1)

- Technical Arco en CDocument427 pagesTechnical Arco en CChris Valdez DrumsNo ratings yet

- Oec 7600 Service Manual Руководство По ОбслуживаниюDocument110 pagesOec 7600 Service Manual Руководство По ОбслуживаниюJuriyNo ratings yet

- Plymobil 10 Service InstructionsDocument50 pagesPlymobil 10 Service InstructionslorisaszigiNo ratings yet

- Optimus 50-65-80 SpecDocument6 pagesOptimus 50-65-80 SpecFarukhRabbaniNo ratings yet

- Siremobil PartsDocument20 pagesSiremobil PartsOscar OcañoNo ratings yet

- OEC-7700 - Service SetupDocument18 pagesOEC-7700 - Service Setuplorisaszigi100% (3)

- Apple Macbook PRO A1286 (Late 2008-Early 2009), Laptop Logic Board Schematic DiagramDocument96 pagesApple Macbook PRO A1286 (Late 2008-Early 2009), Laptop Logic Board Schematic Diagramjuz22100% (2)

- Samsung RV508 SCALA-15UL-IstanbulDocument74 pagesSamsung RV508 SCALA-15UL-IstanbulWade Dyer0% (2)

- Samsung RV508 SCALA-15UL-IstanbulDocument74 pagesSamsung RV508 SCALA-15UL-IstanbulWade Dyer0% (2)

- Panasonic Microwave InverterDocument17 pagesPanasonic Microwave Inverterboroda2410No ratings yet

- Ziehm 7000 Compact Main. Pro PDFDocument40 pagesZiehm 7000 Compact Main. Pro PDFLuis Fernando Garcia S100% (1)

- ArcadisOrbic ReplacementDocument120 pagesArcadisOrbic ReplacementEduardo Saul Mendoza100% (1)

- Arcadis VaricDocument476 pagesArcadis VaricHamed64No ratings yet

- Polymobile Plus Service PDFDocument52 pagesPolymobile Plus Service PDFajcneto82100% (1)

- Kodak Setup ManualsDocument256 pagesKodak Setup Manualsapi-2689284880% (5)

- DC30-010 - ODYSSEY Operator Manual - Rev PDocument92 pagesDC30-010 - ODYSSEY Operator Manual - Rev PYolanda Peña100% (1)

- Phillips Setup ManualsDocument994 pagesPhillips Setup Manualsapi-2689284867% (9)

- Copl-136 841 01Document52 pagesCopl-136 841 01Lucila Figueroa GalloNo ratings yet

- Siemens Setup ManualsDocument858 pagesSiemens Setup Manualsapi-2689284867% (9)

- Siemens Siremobil 2000 PDFDocument247 pagesSiemens Siremobil 2000 PDFTeresa Rosas Guzmán100% (5)

- 726 602 G1Document270 pages726 602 G1PatriciaAraujo100% (2)

- MARS SeriesDocument4 pagesMARS SeriesEla Nurlaela ElsmuslimahNo ratings yet

- Amx 4Document123 pagesAmx 4Francisco Diaz50% (2)

- Dc30 040 QW 400, QW 420, QW 420 D, QW 420 S Service Manual RDocument56 pagesDc30 040 QW 400, QW 420, QW 420 D, QW 420 S Service Manual RYolanda Peña100% (1)

- 6600 Service ManualDocument232 pages6600 Service Manualmohameed ahmedNo ratings yet

- Siremobil Siemens PDFDocument40 pagesSiremobil Siemens PDFhector anguiano100% (1)

- 11 Dynarad Hf-110a Service ManualDocument41 pages11 Dynarad Hf-110a Service Manualkizen_50% (1)

- VISION Service ManualDocument241 pagesVISION Service ManualCENSOREDNo ratings yet

- AXIOM Luminos DRF, System Options CSTD AXD3-500.805.01 AXD3-500.814.01 PDFDocument80 pagesAXIOM Luminos DRF, System Options CSTD AXD3-500.805.01 AXD3-500.814.01 PDFIzzeldin ZakiNo ratings yet

- Siemens Orbic Software RecoveryDocument65 pagesSiemens Orbic Software RecoveryJoel Grullon100% (1)

- OEC-7700 - Block DiagramsDocument36 pagesOEC-7700 - Block DiagramsWalky Ulloa100% (5)

- 7700 PM Procedure PDFDocument40 pages7700 PM Procedure PDFlorisaszigi100% (1)

- Ge Amx 4 Error CodesDocument2 pagesGe Amx 4 Error CodesAbood Ali60% (5)

- 4512 152 76611Document37 pages4512 152 76611Yolanda PeñaNo ratings yet

- Replacement of Parts Cios SelectDocument155 pagesReplacement of Parts Cios SelectMedizintechnik Fritze GmbHNo ratings yet

- SiemensDocument130 pagesSiemensFrancisco DiazNo ratings yet

- AXIOM Iconos R200, Replacement of The Lift-Tilting Base CSTD AXD3-340.805.04 AXD3-340.841.03Document32 pagesAXIOM Iconos R200, Replacement of The Lift-Tilting Base CSTD AXD3-340.805.04 AXD3-340.841.03ROMANNo ratings yet

- 4512 984 06661Document90 pages4512 984 06661Yolanda Peña100% (1)

- Qdr4500 Technical ManualDocument250 pagesQdr4500 Technical Manualcrisbar80% (5)

- MobileDart Evolution MX8cDocument15 pagesMobileDart Evolution MX8cAbel Chaiña Gonzales100% (1)

- Polymat Plus S PDFDocument116 pagesPolymat Plus S PDFEdward Pérez ArangurenNo ratings yet

- Manuale D'uso NEEO - InGDocument75 pagesManuale D'uso NEEO - InGZaheer AhmadNo ratings yet

- Oec Flexiview 8800 Illustrated Parts Manual: 5628469-1en-01 Rev 13Document90 pagesOec Flexiview 8800 Illustrated Parts Manual: 5628469-1en-01 Rev 13mohadeseNo ratings yet

- Siemens Mobilett Plus, E, M X-Ray - Service ManualDocument114 pagesSiemens Mobilett Plus, E, M X-Ray - Service ManualAhmed Hameed100% (1)

- Practix 33Document6 pagesPractix 33Johan Luna100% (1)

- 01 - Aq - Xray18Document73 pages01 - Aq - Xray18katabalwa eric100% (3)

- BV300 Service Manuals (Volume 1 and 2)Document1,100 pagesBV300 Service Manuals (Volume 1 and 2)James GiancolaNo ratings yet

- MX-600 S3 CalibrationDocument30 pagesMX-600 S3 Calibrationnery castroNo ratings yet

- ArcoCeil Service ManualDocument310 pagesArcoCeil Service ManualNauman100% (2)

- Ziehm Imaging C Arm Quantum User ManualDocument216 pagesZiehm Imaging C Arm Quantum User ManualСергей ЖивиловNo ratings yet

- Wiring Mobillet PDFDocument11 pagesWiring Mobillet PDFM Ilham R PNo ratings yet

- Quantum Odyssey HF SeriesDocument102 pagesQuantum Odyssey HF SeriesMohammed AliNo ratings yet

- Siemens Iso CDocument6 pagesSiemens Iso CFrancisco Diaz100% (2)

- KV Calibration 7700 NewDocument3 pagesKV Calibration 7700 NewEduardo Saul MendozaNo ratings yet

- Panasonic TC-21FX20,21 Service ManualDocument29 pagesPanasonic TC-21FX20,21 Service ManualPratik Gandhi83% (12)

- Calib 2Document26 pagesCalib 2Larry Alegria PerezNo ratings yet

- Panasonic Tc-21pm30rDocument29 pagesPanasonic Tc-21pm30rKasun Chamara Prathapasingha0% (1)

- Panasonic TX-14b4tp B Tc-14b4rp B CH z185Document17 pagesPanasonic TX-14b4tp B Tc-14b4rp B CH z185Marius IonescuNo ratings yet

- Panasonic Tc-21gx30p Chassis Gl1 SMDocument29 pagesPanasonic Tc-21gx30p Chassis Gl1 SMsontuyet82No ratings yet

- 42lw570g-zd 42lw570s-zd 42lw573s-zg 42lw575s-zc 42lw579s-zd Chassis ld12c PDFDocument68 pages42lw570g-zd 42lw570s-zd 42lw573s-zg 42lw575s-zc 42lw579s-zd Chassis ld12c PDFlachiondoNo ratings yet

- Dell Inspiron 17r n7110 Quanta V03a Rev 2a SCHDocument50 pagesDell Inspiron 17r n7110 Quanta V03a Rev 2a SCHWade Dyer100% (1)

- 17ips11 R4Document1 page17ips11 R4zokiNo ratings yet

- Asus Laptop Schematic DiagramDocument56 pagesAsus Laptop Schematic Diagramlisycat100% (1)

- HP Notebook DMI OverviewDocument4 pagesHP Notebook DMI OverviewWade DyerNo ratings yet

- Proforma Invoice: Guangzhou Jingjie Electronic Equipment Co., LTDDocument1 pageProforma Invoice: Guangzhou Jingjie Electronic Equipment Co., LTDWade DyerNo ratings yet

- Samsung Bn44-00357a (SCH)Document4 pagesSamsung Bn44-00357a (SCH)Wade DyerNo ratings yet

- Lavadora EleytroluxDocument132 pagesLavadora EleytroluxWade DyerNo ratings yet

- F5SR Repair GuideDocument3 pagesF5SR Repair GuideWade DyerNo ratings yet

- TouchKit ManualDocument1 pageTouchKit ManualWade DyerNo ratings yet

- Samsung GT-P7500 Galaxy Tab 10.1 3G 04 - 2 Cellular Phone Parts ListDocument1 pageSamsung GT-P7500 Galaxy Tab 10.1 3G 04 - 2 Cellular Phone Parts ListWade DyerNo ratings yet

- M 227 W DP PC Service ManualDocument47 pagesM 227 W DP PC Service ManualWade DyerNo ratings yet

- Sony Vaio Vpc-Ef34fx Ef2e1e Efpcg Pcg-71511v Quanta Ne8 Amd Danube Rev 2a SCHDocument42 pagesSony Vaio Vpc-Ef34fx Ef2e1e Efpcg Pcg-71511v Quanta Ne8 Amd Danube Rev 2a SCHWade DyerNo ratings yet

- HP Mini 210 - 110 - Mini 210 010153H00-600-GDocument40 pagesHP Mini 210 - 110 - Mini 210 010153H00-600-Ggraanpirata100% (2)

- VRS-6200 DesbloqueadoDocument22 pagesVRS-6200 DesbloqueadoWade DyerNo ratings yet

- COMPAQ A900 LA-3981P v10 1022 - JBL81Document42 pagesCOMPAQ A900 LA-3981P v10 1022 - JBL81Abubakar SidikNo ratings yet

- Thermal Profiler HC-40 60 80 12 ChannelDocument4 pagesThermal Profiler HC-40 60 80 12 ChannelWade DyerNo ratings yet

- K42Jr PDFDocument97 pagesK42Jr PDFguvenelktNo ratings yet

- Reading And, Resetting of Various Numerical RelaysDocument6 pagesReading And, Resetting of Various Numerical RelaysAnand SundaramNo ratings yet

- Intelligent NetworkDocument9 pagesIntelligent NetworkMedhanyeNo ratings yet

- IMx-8 User Manual - EN 15V - 090 - 00049 - 100 - TCM - 12-289998Document57 pagesIMx-8 User Manual - EN 15V - 090 - 00049 - 100 - TCM - 12-289998Iv 77No ratings yet

- Circuit Power Audio Amplifier Integrated Circuit Tda2002Document7 pagesCircuit Power Audio Amplifier Integrated Circuit Tda2002Jose GarciaNo ratings yet

- ZK1510 SeriesDocument2 pagesZK1510 Seriesel marbouh bilalNo ratings yet

- DC Voltage RegulatorsDocument18 pagesDC Voltage RegulatorsAaisha TahirNo ratings yet

- Diode ApproximationDocument17 pagesDiode ApproximationAKA UA Games100% (1)

- Yamaha CLP-470 - 440 - 430 - S408 - S406 - 465GP Owner's ManualDocument3 pagesYamaha CLP-470 - 440 - 430 - S408 - S406 - 465GP Owner's ManualleonardobagNo ratings yet

- Iq 355Document2 pagesIq 355Meraki DanielNo ratings yet

- Computer Repair With Diagnostic FlowchartsDocument17 pagesComputer Repair With Diagnostic FlowchartsjonibojNo ratings yet

- SMD Components Tester: Smart TweezersDocument1 pageSMD Components Tester: Smart TweezersPravin MevadaNo ratings yet

- Gps PDFDocument1 pageGps PDFcyderNo ratings yet

- Kyle Capodice Ecet Candidate ResumeDocument1 pageKyle Capodice Ecet Candidate Resumeapi-394690479No ratings yet

- 8051 Microcontroller ProgramsDocument8 pages8051 Microcontroller ProgramsRangaraj A.GNo ratings yet

- Genie Componentes ElectronicosDocument20 pagesGenie Componentes ElectronicosGerardo G. GarcíaNo ratings yet

- Chipsetpo-com-ENE KB9012 On Precision M3800 (LA-9941P)Document15 pagesChipsetpo-com-ENE KB9012 On Precision M3800 (LA-9941P)hdd00No ratings yet

- VHDL Lab ManualDocument115 pagesVHDL Lab ManualPero PerićNo ratings yet

- Describe Your Favorite Technological Gadge1Document2 pagesDescribe Your Favorite Technological Gadge1Oscar IsmatulNo ratings yet

- XPR8300 XPR8400 Basic Service Manual 6816810H01-JDocument92 pagesXPR8300 XPR8400 Basic Service Manual 6816810H01-Jreiderickson2No ratings yet

- GPR Survey ProcedureDocument10 pagesGPR Survey Proceduresaffririzal4237No ratings yet

- Figure 1. Cisco 2900 Series Integrated Services RoutersDocument13 pagesFigure 1. Cisco 2900 Series Integrated Services RoutersJose LuisNo ratings yet

- White Paper On Inverter Matching For Trina Solar's Vertex Series Photovoltaic Modules-V3 - CompressedDocument71 pagesWhite Paper On Inverter Matching For Trina Solar's Vertex Series Photovoltaic Modules-V3 - Compressedpal rajNo ratings yet

- 2N Helios IP Force Installation Manual en 2.4Document94 pages2N Helios IP Force Installation Manual en 2.4mairenero1No ratings yet

- GSM ArchitectureDocument20 pagesGSM Architecturepradeep66100% (6)

- Compartment IPDocument13 pagesCompartment IPsecretgamerNo ratings yet

- Digital Signal Processors Application ArchitectureDocument61 pagesDigital Signal Processors Application ArchitectureanjugaduNo ratings yet

- MS-1756 Disassembly GuideDocument27 pagesMS-1756 Disassembly GuideCarlos CuboNo ratings yet

- Temperature Scanner Cat - UT-101Document2 pagesTemperature Scanner Cat - UT-101Manoj AggarwalNo ratings yet