Professional Documents

Culture Documents

Valve Leakage Standards PDF

Uploaded by

wfjerrOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Valve Leakage Standards PDF

Uploaded by

wfjerrCopyright:

Available Formats

Domestic: 800-654-3626

International: +1 732-733-1143

301 Smalley Avenue

Middlesex, NJ 08846 USA

www.GemcoValve.com

ANSI VALVE LEAKAGE STANDARDS

There are six different seat leakage classifications as defined by ANSI FCI 70-2. The most commonly used by Gemco Valve are

CLASS I, CLASS IV and CLASS Vl.

CLASS I is also known as dust tight and can refer to metal or resilient seated valves.

CLASS IV is also known as metal to metal. It is the kind of leakage rate you can expect from a valve with a metal shut-off disc and

metal seat.

CLASS Vl is known as a soft seat classification. Soft Seat Valves are those where the seat or shut-off disc or both are made from some

kind of resilient material such as Teflon.

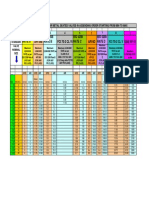

Control Valve Seat Leakage Classifications - ANSI FCI 70-2 superseding ANSI B16.104

Leakage Maximum Leakage Test Medium Test Pressure Testing Procedures Required for Establishing Rating

Class Allowable

Designation

l XXX XXX XXX No test required provided user and supplier so agree

ll 0.5% of rated Air or water 45-60 psig or max. Pressure applied to valve inlet with outlet open to

capacity at 50-125⁰ F operating differential atmosphere or connected to a low head loss measuring

(10-52⁰ C) whichever is lower device full normal closing thrust provided by actuator.

lll 0.1% of rated Air or water 45-60 psig or max. Pressure applied to valve inlet with outlet open to

capacity at 50-125⁰ F operating differential atmosphere or connected to a low head loss measuring

(10-52⁰ C) whichever is lower device full normal closing thrust provided by actuator.

lV 0.01% of rated Air or water 45-60 psig or max. Pressure applied to valve inlet with outlet open to

capacity at 50-125⁰ F operating differential atmosphere or connected to a low head loss measuring

(10-52⁰ C) whichever is lower device full normal closing thrust provided by actuator.

V 0.0005 ml per Water at Max service pressure Pressure applied to valve inlet after filling entire body cavity

minute of water per 50-125⁰ F drop across valve plug, and connected piping with water and stroking valve plug

inch of port diameter (10-52⁰ C) not to exceed ANSI body closed. Use net specified max actuator thrust, but no more,

per psi differential rating. even if available during test. Allow time for leakage flow to

stabilize.

Vl Not to exceed Air or 50 psig or max rated Actuator should be adjusted to operating conditions

amounts shown in nitrogen at differential pressure specified with full normal closing thrust applied to valve plug

following table 50-125⁰ F across valve plug seat. Allow time for leakage flow to stabilize and use suitable

based on port (10-52⁰ C) whichever is lower. measuring device.

diameter.

Control Valve Seat Leakage Classifications

NOMINAL PORT DIAMETER NOMINAL PORT DIAMETER LEAK RATE LEAK RATE

(Inches) (Millimeters) (ml per Minute) (Bubbles / minute*)

3 76 0.9 6

4 102 1.7 11

6 152 4 27

8 203 6.75 45

10 254 9 63

12 305 11.5 81

*Bubbles per minute as tabulated are a suggested alternative based on a suitable calibrated measuring device, in this case a 0.25-inch OD X 0.032-

inch wall tube submerged in water to a depth of from 1/8 to 1/4 inch. The tube end shall be cut square and smooth with no chamfers or burrs. The

tube axis shall be perpendicular to the surface of the water. Other measuring devices may be constructed and the number of bubbles per minute

may differ from those shown as long as they correctly indicate the flow in milliliters per minute.

Domestic: 800-654-3626 | International: +1 732-733-1143 | www.GemcoValve.com

You might also like

- Finite Difference Methods in Heat TransferDocument599 pagesFinite Difference Methods in Heat TransferBruno Lugão100% (3)

- Check Valve Nozzle Non - SlamDocument16 pagesCheck Valve Nozzle Non - SlamPatricio AcuñaNo ratings yet

- Flow Over A Backward Facing Step: TMMV08 Assignment 3Document9 pagesFlow Over A Backward Facing Step: TMMV08 Assignment 3Arturo Mateos RodríguezNo ratings yet

- VC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesDocument8 pagesVC Series Zone Valves: Balanced 2-Way and 3-Way Hydronic ValvesGiovanni Dala PaulaNo ratings yet

- Caudalímetros Electromagnéticos ISO-9104-1991-3Document28 pagesCaudalímetros Electromagnéticos ISO-9104-1991-3pepo123100% (1)

- Singer Valve - Made in CanadaDocument250 pagesSinger Valve - Made in Canadaprobetaspro132No ratings yet

- Parker Industrial Hose Catalog 4800Document258 pagesParker Industrial Hose Catalog 4800MROstop.comNo ratings yet

- 8510-1447 Zero-Maintenance Pulsation DampenersDocument2 pages8510-1447 Zero-Maintenance Pulsation DampenersdharmeswarNo ratings yet

- Product Reference Guide - Oil and GasDocument9 pagesProduct Reference Guide - Oil and GasDavid RodriguesNo ratings yet

- Seat Leakage Article Valve WorldDocument2 pagesSeat Leakage Article Valve WorldjshadwanNo ratings yet

- Plastic Vessel Pressure DesignDocument12 pagesPlastic Vessel Pressure Designr1p2100% (1)

- TD42 Thermodynamic Steam Trap-Installation Maintenance Manual PDFDocument12 pagesTD42 Thermodynamic Steam Trap-Installation Maintenance Manual PDFAnonymous FZs3yBHh7No ratings yet

- Rite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Document8 pagesRite Sized Check Valves: ASME Class 125 - 2500 1" (25mm) - 60" (1500mm)Cristian PisitelloNo ratings yet

- 5691 CPP Me DS 0001 0 PDFDocument17 pages5691 CPP Me DS 0001 0 PDFĐiệnBiênNhâmNo ratings yet

- Types of Refrigeration Compressors: OCT. 2006 D.RavindraDocument31 pagesTypes of Refrigeration Compressors: OCT. 2006 D.RavindraDnyanesh BodreNo ratings yet

- CWA Piping Design, Layout & AnalysisDocument2 pagesCWA Piping Design, Layout & AnalysisIan LiuNo ratings yet

- Retriever Manual PDFDocument49 pagesRetriever Manual PDFJanneth Herrera FloresNo ratings yet

- Classes and Comparisons Between CompressorsDocument48 pagesClasses and Comparisons Between CompressorsVijay MeenaNo ratings yet

- 316 316L 317L Spec SheetDocument3 pages316 316L 317L Spec SheetLinnie McleodNo ratings yet

- LJ Pulsation Dampener PDS en BWDocument2 pagesLJ Pulsation Dampener PDS en BWmasimaha1379No ratings yet

- MSDS 001139212Document7 pagesMSDS 001139212danny_sosa_3No ratings yet

- Assembly TECHLOK 3 Fold English v3 2013Document2 pagesAssembly TECHLOK 3 Fold English v3 2013Chup AlaNo ratings yet

- BV Gate Valve DS 15111Document2 pagesBV Gate Valve DS 15111yulianus_srNo ratings yet

- Pressure Seal Valves-GateDocument24 pagesPressure Seal Valves-GateHieu NguyenNo ratings yet

- 037 Cryogenic ProductsDocument32 pages037 Cryogenic ProductsDennis Adriana ZuñigaNo ratings yet

- Needle ValveDocument8 pagesNeedle ValveMuhammad Chilmi100% (1)

- Sure Flow StrainersDocument13 pagesSure Flow StrainersNinad SherawalaNo ratings yet

- Praxair en 55Document34 pagesPraxair en 55StefanoNo ratings yet

- TVA Flowmeter-Technical InformationDocument2 pagesTVA Flowmeter-Technical InformationRandy PalmaNo ratings yet

- Valve Leakage Class CompDocument1 pageValve Leakage Class CompSantoshi PriyaNo ratings yet

- VALVULASDocument58 pagesVALVULASTai FloresNo ratings yet

- General Notice For AG Piping Layout - TSA - RADocument35 pagesGeneral Notice For AG Piping Layout - TSA - RAkienhg96No ratings yet

- RPS MMR Piping ClassDocument42 pagesRPS MMR Piping ClassKathia Espinoza RojasNo ratings yet

- Serck Arduco Plug ValvesDocument20 pagesSerck Arduco Plug ValvesRominaNo ratings yet

- Garlock Gasketing Products: Performance With Proven ReliabilityDocument64 pagesGarlock Gasketing Products: Performance With Proven ReliabilitySiva SubramaniNo ratings yet

- Best Practices in Compressor MountingDocument9 pagesBest Practices in Compressor MountingDaniel Puello Rodelo100% (1)

- 76-040 - 2012 Orifice Meter RunsDocument7 pages76-040 - 2012 Orifice Meter RunspradeepNo ratings yet

- MuellerDocument24 pagesMuellerAhmad NasserNo ratings yet

- Pipes and Fittings BrochureDocument8 pagesPipes and Fittings BrochurehaggNo ratings yet

- To Rerate or Not To RerateDocument6 pagesTo Rerate or Not To ReratekblaxtonNo ratings yet

- CPDocument55 pagesCParianaseri100% (2)

- Block and Bleed ValveDocument36 pagesBlock and Bleed ValveTochukwu OnuohaNo ratings yet

- Noruegan StandardDocument152 pagesNoruegan StandarderikohNo ratings yet

- Sok7305252 003 A 001Document107 pagesSok7305252 003 A 001muhammad nazmiNo ratings yet

- MarlinDocument28 pagesMarlincumpio425428No ratings yet

- Triple-Offset Butterflyvalves PDFDocument8 pagesTriple-Offset Butterflyvalves PDFDiwakar NigamNo ratings yet

- GWC Valve International - Dual Plate Check ValvesDocument20 pagesGWC Valve International - Dual Plate Check ValvesGWC Valve InternationalNo ratings yet

- Ball Valves: Sharma MVSRK 15 October 2013Document49 pagesBall Valves: Sharma MVSRK 15 October 2013Jay Ganta100% (2)

- L&T Double Block and Bleed Plug ValvesDocument12 pagesL&T Double Block and Bleed Plug Valvesvijay10484No ratings yet

- Lateral DimensionsDocument1 pageLateral DimensionsaravindhcamNo ratings yet

- Fisher 630 Series PDFDocument10 pagesFisher 630 Series PDFClemente Rafael Marval EscalonaNo ratings yet

- Axial E Flow Check ValveDocument12 pagesAxial E Flow Check ValveBhargav Patel100% (1)

- Valves - Fundamentals of Valve Design and ConstructionDocument13 pagesValves - Fundamentals of Valve Design and Constructionzona amrullohNo ratings yet

- Kamos Gasket For PipelineDocument3 pagesKamos Gasket For PipelineKenn Way LeeNo ratings yet

- MaterialsDocument2 pagesMaterialsAkshay PoddarNo ratings yet

- L&T Ball ValveDocument12 pagesL&T Ball ValvecdsenthilNo ratings yet

- Piping ConstructionDocument17 pagesPiping Constructionadel rihana100% (1)

- Ansi Valve Leakage StandardsDocument1 pageAnsi Valve Leakage StandardsSHAHgan1No ratings yet

- Valve Leakage ClassificationDocument2 pagesValve Leakage ClassificationFacundo Argüello100% (1)

- Valves Valve LeakageDocument5 pagesValves Valve Leakagearson5646100% (1)

- Testing StandardDocument7 pagesTesting StandardDiego Fernando Pedroza UribeNo ratings yet

- Valve Leakage: Home Glossary ResourcesDocument3 pagesValve Leakage: Home Glossary Resourcesarkan1976No ratings yet

- M3 - U2 - Piping Components and FittingsDocument36 pagesM3 - U2 - Piping Components and FittingsstrikerNo ratings yet

- Valve CV Calculation Tool SteamDocument4 pagesValve CV Calculation Tool Steammohan babuNo ratings yet

- Model Question Paper-CBCS Scheme: 18ME15/25 18ME15/25 15ME742 15ME751Document2 pagesModel Question Paper-CBCS Scheme: 18ME15/25 18ME15/25 15ME742 15ME751Guru VishalNo ratings yet

- Estimating The Low-Speed Sidewash PDFDocument3 pagesEstimating The Low-Speed Sidewash PDFGabriel Rodrigues FelixNo ratings yet

- Centrifugal FanDocument14 pagesCentrifugal FanNiranjanKumarNo ratings yet

- User Manual Fine Turbo v6.2-9Document371 pagesUser Manual Fine Turbo v6.2-9jap_Bello100% (4)

- Fluid Friction in A Smooth Bore PipeDocument6 pagesFluid Friction in A Smooth Bore PipeJohn Michael Menoza ZapantaNo ratings yet

- Check Valves: Check Valve and Pre - LL Valve Type FDocument2 pagesCheck Valves: Check Valve and Pre - LL Valve Type FSaeid MirNo ratings yet

- Assignment 5-A22Document5 pagesAssignment 5-A22viky kavaNo ratings yet

- Low Speed Aerodynamics ASE 320: Lecture 2: Basics of Fluids, Fluid Properties and FieldsDocument17 pagesLow Speed Aerodynamics ASE 320: Lecture 2: Basics of Fluids, Fluid Properties and FieldsBayramNo ratings yet

- Journal of Energy Storage: SciencedirectDocument11 pagesJournal of Energy Storage: SciencedirectJoão PedroNo ratings yet

- Aerodynamics of Flight: Forces Acting On The AircraftDocument51 pagesAerodynamics of Flight: Forces Acting On The AircraftChasel LinNo ratings yet

- Pump Tech 4 CurvesDocument45 pagesPump Tech 4 CurvesGAMUCHIRAI MUGADZANo ratings yet

- Tutorial 4 Turbomachinery v2Document4 pagesTutorial 4 Turbomachinery v2Nik JaffNo ratings yet

- Hydraulic CalculationDocument46 pagesHydraulic CalculationBader ShrbajiNo ratings yet

- SPP-Bomba PRINCIPAL, Mod. TE10D-750@180-CurvaDocument2 pagesSPP-Bomba PRINCIPAL, Mod. TE10D-750@180-CurvaSergio Garcia Alfaro100% (1)

- Physics 05-05 Flow Rate and Bernoullis EquationDocument2 pagesPhysics 05-05 Flow Rate and Bernoullis Equationmechanical_lecturerNo ratings yet

- Averaging Pitot Tube: Principle of OperationDocument4 pagesAveraging Pitot Tube: Principle of OperationNícoli GaloNo ratings yet

- Slag Attack Mag CarbDocument12 pagesSlag Attack Mag CarbAnindya RoyNo ratings yet

- Central University of Punjab, BathindaDocument48 pagesCentral University of Punjab, BathindaRio RomNo ratings yet

- Fluid Flow and Simulation SoftwaresDocument57 pagesFluid Flow and Simulation Softwaressri9987100% (1)

- +++aech 4102Document7 pages+++aech 4102Mudabbir MosviNo ratings yet

- Marintek Short Course On New Techniques For Assessing and Quantifying Vessel Stabili PDFDocument442 pagesMarintek Short Course On New Techniques For Assessing and Quantifying Vessel Stabili PDFwafiq izzuddin100% (1)

- AUTO400 Homework Assignment 1 SOLUTIONDocument16 pagesAUTO400 Homework Assignment 1 SOLUTIONVinoliaEdwin100% (1)

- SI015-Catalog Flowline DIGITAL Rev3Document92 pagesSI015-Catalog Flowline DIGITAL Rev3Dwiki Ramadhani100% (1)

- Numerical Study of Gas-Solid Flow in A Cyclone Separator: B. Wang, D. L. Xu, G. X. Xiao, K. W. Chu and A. B. YUDocument6 pagesNumerical Study of Gas-Solid Flow in A Cyclone Separator: B. Wang, D. L. Xu, G. X. Xiao, K. W. Chu and A. B. YUAzharuddin Ehtesham FarooquiNo ratings yet

- Leak Detection in Pipelines and Pipe NetworksDocument10 pagesLeak Detection in Pipelines and Pipe NetworksPedro Rosas100% (1)