Professional Documents

Culture Documents

Innova Pressure Control BD Installation PDF

Innova Pressure Control BD Installation PDF

Uploaded by

bruce huOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Innova Pressure Control BD Installation PDF

Innova Pressure Control BD Installation PDF

Uploaded by

bruce huCopyright:

Available Formats

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

DR0391 - Vacuum Sensor Module Replacement

1 Personnel Requirements

Required Persons Preliminary Reqs Procedure Finalization

1 Not Applicable 30 mins 30 mins

2 Preliminary Requirements

2.1 Tools and Test Equipment

Item Qty Effectivity Part# Manuf

Standard Field Engineering 1 - - -

Tools

2.2 Consumables

No consumables required.

2.3 Replacement Parts

Item Qty Effectivity Part# Manuf

Pressure Control Module 1 - 5160007 -

2.4 Safety

RISK OF ELECTRIC SHOCK

HAZARDOUS VOLTAGE PRESENT

BEFORE ANY INTERVENTION SWITCH OFF THE SYSTEM (REFER TO

PROTECTION AGAINST ELECTRICAL HAZARDS IN SAFETY AND REGULATORY

AND QUALITY ASSURANCE PROGRAM DOCUMENTATION)

2.5 Required Conditions

No required conditions.

3 Procedure

3.1 Disassembly

1. Remove Gantry rear trim cover.

2. Disconnect data cable ( , Illustration 1 and Illustration 2 ) and remove it.

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging Page 1 of 9

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

Illustration 1: Old version

Illustration 2: New version

3. Disconnect ground cable and hose but do not remove them ( Illustration 1 and Illustration

2 ).

4. Remove the vacuum sensor module and door assy.

5. Unscrew the three screws securing the vacuum sensor module to the door and remove it.

3.2 Reassembly

1. Install the new Pressure Control Module to the door.

2. Re-install the door.

NOTE: Illustration 3 , Illustration 4 , Illustration 5 , Illustration 6 gives the pinouts of the cables:

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging Page 2 of 9

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

Illustration 3: LC2 Cable, 27588, P/N 514457-2

Illustration 4: LP1 Cable, 26963, P/N 5144452-2

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging Page 3 of 9

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

Illustration 5: LP2 Cable, 27017, P/N 5144454-2

Illustration 6: LP3 Cable, 27249, P/N 5145223-2

3. Reconnect ground cable and hose .

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging Page 4 of 9

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

Illustration 7:

4. Connect the data cable 27588 between J1 of Pressure Control Module and J212 of LC

Restpoint Board.

Illustration 8:

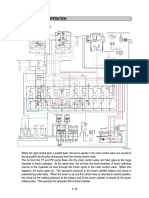

3.3 Adjustment of the “old” version Board

3.3.1 Factory setup values

The following procedure verifies factory setup values for the collision sensing system. When the system

is working correctly (without a collision), you will observe the following on the regulator assembly circuit

board:

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging Page 5 of 9

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

• The Sensor Fail LED is not lit.

• The Level 1 OK and Level 2 OK LEDs are lit.

• Jumper JP1 is in the normal operating position (position A between pins 1 and 2).

• The 7-segment display reads 0.00 +/- 0.02” (0.00 +/- 0.051 cm) of H 2 O pressure.

NOTE: The 7-segment display always reads in inches of H 2 O pressure.

If the display does not read 0.00 +/- 0.02, remove the sealant from R19 and adjust it until the

reading is 0.00 +/- 0.02.

Depress switch S2 and verify that all numerical segments, the negative sign segment, and the

decimal point segment (on DS2), are lit.

Illustration 9: Pneumatic Collision Sensor Location

NOTE: The following steps verify correct collision sensor performance.

3.3.2 Collision Level 1 Setup

1. Apply pressure to the pneumatic collar.

2. Verify that the Level 1 OK LED turns off, the system audio signal sounds, and the status display

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging Page 6 of 9

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

flashes when the display reads 0.30 +/- 0.03. If Level 1 requires readjustment, do the following:

a. Place JP1 so that pins 2 & 3 are connected (position B).

b. Turn R5 fully counterclockwise.

c. Adjust R12 clockwise until DS5 comes on.

d. Adjust R12 counterclockwise until the 7-segment display reads 0.30 +/- 0.01” of H 2 O.

e. Slowly turn R5 clockwise until DS5 turns off again.

f. Go back to the beginning and check again Level 1.

3. Verify that the Level 1 OK light turns on, and that the system status display stops flashing when

the pressure decreases to 0.12 +/- 0.03” of H 2 O.

3.3.3 Collision Level 2 Setup

1. Apply pressure to the pneumatic collar.

2. Verify that the Level 2 OK light turns off, the system audio signal sounds, and the status display

flashes at 5.0 +/- 0.2” of H O readout on the 7-segment display. If Level 2 requires

2

readjustment, adjust pressure switch S0 until the Level 2 OK light turns off at 5.0 +/- 0.2” of H

2 O.

Illustration 10: Level 2 Adjustment

3. Verify that the Level 2 OK light turns on and the status display stops flashing when the pressure

decreases to 2.5 +/- 0.5” of H 2 O.

3.3.4 Verification of Settling Time

1. Apply more than 5.0” of H 2 O pressure to the pneumatic collar and quickly release.

2. Verify that the pressure readout returns to 0.00 +/- 0.02 within 30 seconds.

3.3.5 Sensor Fail LED Verification

1. Apply more than 5.0” of H 2 O pressure to the pneumatic collar and quickly release. .

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging Page 7 of 9

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

2. Verify that the Sensor Fail LED is lit and the Level 1 OK LED is not lit when negative pressure

causes the sensor fail circuit to momentarily trip

3.3.6 Leakage Test

1. Slowly drive the II pneumatic collar into the table top to create a stable collision of more than 5.00”

of H 2 O. The pressure reading on the display must not drop by more than 0.2” of H 2 O in 1

minute.

2. Gently move and flex the collar to tubing connection to verify the integrity of the connection.

3.3.7 Pressure Change Response

1. Verify that application of smoothly increasing and decreasing pressure to the pneumatic collar

results in a correspondingly smooth increase and decrease of displayed pressure.

2. Apply pressure to the pneumatic collar and verify that the pressure readout reaches or exceeds

10” of H 2 O.

3.4 Autotest of the “new” version Board

1. Power ON the system.

2. Check level 1 and level 2 collision detection at system level by pressing the bumper.

3. Remove J4 jumper and insert it on J6 to launch autotest.

Illustration 11:

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging Page 8 of 9

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

4. When pump starts, remove J6 jumper.

5. At the end of the test (this check takes approximately 3 minutes) check Leds status:

• DS4 and DS5 must be ON.

• DS3 and DS6 must be OFF.

NOTE: If DS3 blinks, there is a leakage in pneumatic circuit. Check the complet pneumatic circuit (Pressure

Control Module, bumper, hoses).

6. When test ok, re-install jumper between 2 and 3 of J4.

7. Re-install Gantry rear trim cover.

4 Finalization

No finalization steps.

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging Page 9 of 9

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

DR0391 - Vacuum Sensor Module Replacement

GE Medical Systems Direction 2360772-11-200 , Revision 1

Blank page.

Innova 2100-IQ, 3100/3100-IQ, 4100/4100-IQ Cardiovascular Imaging

System Renewal Parts and Disassembly / Reassembly Procedures

Copyright © 2007 by General Electric Company Inc. All Rights Reserved.

You might also like

- Performa, Alpha RT, IQ, ST, III, Service Manual PDFDocument183 pagesPerforma, Alpha RT, IQ, ST, III, Service Manual PDFqweqwe57% (7)

- Electric Sistem SCHOTTELDocument106 pagesElectric Sistem SCHOTTELmisaelandres1100% (5)

- Trane XR202 Programmable Thermostat: TCONT202AS11MA Installation and User GuideDocument12 pagesTrane XR202 Programmable Thermostat: TCONT202AS11MA Installation and User GuideOsvaldo Milla100% (2)

- Lytron Manual and SchematicsDocument38 pagesLytron Manual and Schematicsbruce hu100% (2)

- Nissei Maintenance ManualDocument123 pagesNissei Maintenance ManualGelu Bonea100% (5)

- Over Cureent and EfDocument7 pagesOver Cureent and EfBasudev Patra100% (2)

- BFK InstructionsDocument98 pagesBFK InstructionsArturo100% (2)

- Technical Publications: GEMS Part Number 2349005Document18 pagesTechnical Publications: GEMS Part Number 2349005Jongchan Jason Moon100% (1)

- Panasonic Pt-Ae3000 Service ManualDocument81 pagesPanasonic Pt-Ae3000 Service ManualSimon Papukyan100% (1)

- HP374 Doosan Service ManualDocument90 pagesHP374 Doosan Service ManualRAPID EQUIPMENT RENTALNo ratings yet

- OPS2 Technical InformationDocument7 pagesOPS2 Technical InformationMohammad AmerNo ratings yet

- 1/16 Din Microbased Controller: Operators ManualDocument69 pages1/16 Din Microbased Controller: Operators ManualJosue Camacho100% (2)

- BenchMark XT Service Manual (New)Document311 pagesBenchMark XT Service Manual (New)bruce hu100% (1)

- Schematic C-Arm NavigationDocument7 pagesSchematic C-Arm Navigationbruce hu100% (1)

- XRD SchematicsDocument260 pagesXRD Schematicsbruce hu100% (1)

- Installation Manual COBAS TaqMan Version 2 - 6Document30 pagesInstallation Manual COBAS TaqMan Version 2 - 6bruce huNo ratings yet

- Gamma and Xray Detectors Rev1 200507 PDFDocument124 pagesGamma and Xray Detectors Rev1 200507 PDFbruce hu50% (2)

- Charing Alternator IssueDocument3 pagesCharing Alternator IssueAmmar BaigNo ratings yet

- Ams4a051 Winch Operators Display Panel RevlDocument48 pagesAms4a051 Winch Operators Display Panel Revlbaggo81No ratings yet

- Digital Readout System: Installation/User ManualDocument16 pagesDigital Readout System: Installation/User ManualLeonardNo ratings yet

- AHE27 User Manual: PrefaceDocument16 pagesAHE27 User Manual: PrefaceDinh NguyenNo ratings yet

- Service Manual SM01 - 073 - 001.00: Electronic Gauges, TroubleshootingDocument18 pagesService Manual SM01 - 073 - 001.00: Electronic Gauges, Troubleshootingluis almonacidNo ratings yet

- User Manual: Industrial Sewing Machine Digital AC Servo SystemDocument38 pagesUser Manual: Industrial Sewing Machine Digital AC Servo SystemDrchipbrNo ratings yet

- Universal Unimatic 325D X-Ray - Schematics PDFDocument40 pagesUniversal Unimatic 325D X-Ray - Schematics PDFmaya33% (3)

- DataKom 040 - USERDocument45 pagesDataKom 040 - USERKhaleel Khan100% (1)

- Diagrama Toshiba 52HM84Document40 pagesDiagrama Toshiba 52HM84Wili Alexander Interiano GarciaNo ratings yet

- DWM C ™ S - H C O P D S Ops2: Opeland EMI Ermetic Ompressors IL Ressure Ifferential WitchDocument5 pagesDWM C ™ S - H C O P D S Ops2: Opeland EMI Ermetic Ompressors IL Ressure Ifferential WitchMuhammadAmmarNo ratings yet

- Gu3311 Operation ManualDocument94 pagesGu3311 Operation ManualShahzad Ali100% (1)

- Novar 305 Commissioning InstructionsDocument8 pagesNovar 305 Commissioning InstructionsJason Berry100% (2)

- Preface: User ManualDocument16 pagesPreface: User ManualDinh NguyenNo ratings yet

- Operators Manual AND Installation and Service Manual: 8000-3488 Universal Uni-Matic 325D Generator MODEL NO. 3488/3550Document38 pagesOperators Manual AND Installation and Service Manual: 8000-3488 Universal Uni-Matic 325D Generator MODEL NO. 3488/3550Henry Sánchez EstradaNo ratings yet

- DataKom 040 USERDocument45 pagesDataKom 040 USERsebastianNo ratings yet

- DATAKOM DK40 Installation ManualDocument45 pagesDATAKOM DK40 Installation ManualVykintas ImbrasasNo ratings yet

- Diadens PC ManualDocument31 pagesDiadens PC Manualvdbroger100% (1)

- Ats 125 Amps ManualDocument10 pagesAts 125 Amps ManualJavier SilvaNo ratings yet

- Ems 55 ControllerDocument12 pagesEms 55 ControllerLa Mancha NegraNo ratings yet

- Panasonic Ptae700 Service ManualDocument215 pagesPanasonic Ptae700 Service ManualTarra Ramakrishna RaoNo ratings yet

- Chassis 449ZA: Nokia Display Products Oy P.O.Box 14 FIN - 24101 Salo, FinlandDocument66 pagesChassis 449ZA: Nokia Display Products Oy P.O.Box 14 FIN - 24101 Salo, FinlandZoran ŠušakNo ratings yet

- 6103 User Manual PDFDocument78 pages6103 User Manual PDFJorgeLuisUriarteNo ratings yet

- Service Manual: ICF-CD2000/CD2000SDocument44 pagesService Manual: ICF-CD2000/CD2000Slondon335No ratings yet

- Toshiba 62HMX84Document40 pagesToshiba 62HMX84Reginald SosaNo ratings yet

- Model 6100 Multi-Gas Calibrator: User's Guide and Technical ManualDocument96 pagesModel 6100 Multi-Gas Calibrator: User's Guide and Technical ManualJorgeLuisUriarteNo ratings yet

- TR DMO200 Manual v4 User GuideDocument36 pagesTR DMO200 Manual v4 User Guideวิรวัฒน์ ปัททุมNo ratings yet

- Distance SensorDocument5 pagesDistance Sensortuyetden613No ratings yet

- Con Trol Unit: Manual DV 60511.03 Issue1 July 1997Document30 pagesCon Trol Unit: Manual DV 60511.03 Issue1 July 1997Brasin rifaNo ratings yet

- Manual 6100 EnvironicsDocument96 pagesManual 6100 Environicsalur16552No ratings yet

- Pressure SwitchDocument8 pagesPressure SwitchMilosglNo ratings yet

- ToshibaDocument39 pagesToshibaJoshua SmithNo ratings yet

- (Smart Plus) Troubleshooting Manual - EngDocument64 pages(Smart Plus) Troubleshooting Manual - EngBrajan MontesNo ratings yet

- INVERTA (Three Phase) User ManualDocument24 pagesINVERTA (Three Phase) User ManualDario MontillaNo ratings yet

- Operators Manual AND Installation and Service Manual: 8000-3488 Universal Uni-Matic 325D Generator MODEL NO. 3488/3550Document38 pagesOperators Manual AND Installation and Service Manual: 8000-3488 Universal Uni-Matic 325D Generator MODEL NO. 3488/3550Roberto HermenegildoNo ratings yet

- Topaz DigitalDocument24 pagesTopaz DigitalLeonardNo ratings yet

- Advent 27.3251 Serv ManualDocument41 pagesAdvent 27.3251 Serv ManualNoe Vidal AspeitiaNo ratings yet

- Manual S22Document19 pagesManual S22Anonymous HKuYF6kNo ratings yet

- Service Manual CentrifugeDocument42 pagesService Manual CentrifugemewkaharudinNo ratings yet

- Tilt Switches Model 20-39 With Control Unit Model 20-35U ...Document13 pagesTilt Switches Model 20-39 With Control Unit Model 20-35U ...cyrano1091No ratings yet

- HGM501 enDocument17 pagesHGM501 enANDRES CELYNo ratings yet

- ED-2002-210 Nexgen-2000 8 Relay Output Module (2711) User MaDocument12 pagesED-2002-210 Nexgen-2000 8 Relay Output Module (2711) User Maambresh.09No ratings yet

- ArduinoDocument15 pagesArduinoAlvarez TomasNo ratings yet

- AH27 User Manual: PrefaceDocument16 pagesAH27 User Manual: PrefaceheribertosfaNo ratings yet

- Samsung Kct52A TV ChassisDocument78 pagesSamsung Kct52A TV ChassisWarren DunnNo ratings yet

- Pressure Switch RE B - Type HEDE10... - 2 - Operating Instructions. Replaces - 06.10Document20 pagesPressure Switch RE B - Type HEDE10... - 2 - Operating Instructions. Replaces - 06.10Ali YahiaouiNo ratings yet

- Magnetomed 7200Document28 pagesMagnetomed 7200yosbanisNo ratings yet

- 62-0331 Jade EconomizerDocument24 pages62-0331 Jade EconomizerLarry BrownNo ratings yet

- Experiment No.: 1: Title: SwitchesDocument19 pagesExperiment No.: 1: Title: SwitchesAnil NavaleNo ratings yet

- L1710S (L1710sm-Al - R, Au - R, Ad - R, Ag - R) CL-61Document18 pagesL1710S (L1710sm-Al - R, Au - R, Ad - R, Ag - R) CL-61Deki PericNo ratings yet

- Design and Implementation of Portable Impedance AnalyzersFrom EverandDesign and Implementation of Portable Impedance AnalyzersNo ratings yet

- GS Junior Installation Manual v1.3 PDFDocument61 pagesGS Junior Installation Manual v1.3 PDFbruce huNo ratings yet

- X65SCHDocument540 pagesX65SCHbruce huNo ratings yet

- JEDI 80 RD 1T Photo Tour - Chen Pei JunDocument35 pagesJEDI 80 RD 1T Photo Tour - Chen Pei Junbruce huNo ratings yet

- PS800ServiceManual PDFDocument35 pagesPS800ServiceManual PDFbruce hu100% (1)

- Pioneerpim02 (Eng)Document86 pagesPioneerpim02 (Eng)bruce huNo ratings yet

- Om PDFDocument318 pagesOm PDFbruce huNo ratings yet

- 2-1-4. Generator Cpu Board 400Pl3 Leds: Central ListingDocument3 pages2-1-4. Generator Cpu Board 400Pl3 Leds: Central Listingbruce huNo ratings yet

- PS800SM ClassA r7 PDFDocument368 pagesPS800SM ClassA r7 PDFbruce huNo ratings yet

- D6K Schematics PDFDocument262 pagesD6K Schematics PDFbruce huNo ratings yet

- Rws Service PDFDocument288 pagesRws Service PDFbruce huNo ratings yet

- D6K Schematics PDFDocument262 pagesD6K Schematics PDFbruce huNo ratings yet

- Gamma and Xray Detectors Rev1 200507Document20 pagesGamma and Xray Detectors Rev1 200507bruce huNo ratings yet

- XT ErrorcodeDocument55 pagesXT Errorcodebruce hu100% (1)

- Paxscan 3030 Amorphous Silicon Digital X-Ray Detector - PDDocument4 pagesPaxscan 3030 Amorphous Silicon Digital X-Ray Detector - PDbruce huNo ratings yet

- SWITRON Make SiwitchesDocument8 pagesSWITRON Make SiwitchessparkCENo ratings yet

- Camshaft Do Double DutyDocument5 pagesCamshaft Do Double DutyHennie VeldmanNo ratings yet

- Me TECH CD54 1R0M - C501729Document9 pagesMe TECH CD54 1R0M - C501729Oussama MessaoudiNo ratings yet

- Specifications Wireless AlarmDocument10 pagesSpecifications Wireless Alarmumejiemmanuel46No ratings yet

- Fire Detection System: Prior To BB-1439Document8 pagesFire Detection System: Prior To BB-1439Alex GuáncNo ratings yet

- Oferta 01 Avion Bb-1tba King Air b200Document12 pagesOferta 01 Avion Bb-1tba King Air b200Luis HernandezNo ratings yet

- Terex RT670 PDFDocument20 pagesTerex RT670 PDFTransdepet Mantenimiento100% (1)

- Fife D-Max - Oi-TsDocument90 pagesFife D-Max - Oi-Tsmarco merizaldeNo ratings yet

- Sound Detector Using Op-Amp 741 PDFDocument22 pagesSound Detector Using Op-Amp 741 PDFDãyäñidhï Ñæïk0% (1)

- en FiDocument40 pagesen FiIulianNeǥřeßcüNo ratings yet

- Spare Parts Manual M30Z Oct-2015 - File-IIDocument62 pagesSpare Parts Manual M30Z Oct-2015 - File-IIkomalinternational5No ratings yet

- Datasheet BlueSolar Charge Controller MPPT 150 45 Up To 150 100Document1 pageDatasheet BlueSolar Charge Controller MPPT 150 45 Up To 150 100Cristian Felipe Rangel TrianaNo ratings yet

- Kuh Radio PDFDocument98 pagesKuh Radio PDFRade ČikarićNo ratings yet

- ETM50ENDocument4 pagesETM50ENDiego CordovaNo ratings yet

- Vibration Isolation Selection GuideDocument15 pagesVibration Isolation Selection GuideSk NgNo ratings yet

- Group 4 Single OperationDocument12 pagesGroup 4 Single OperationPhan DungNo ratings yet

- Falcon Die ProfilerDocument21 pagesFalcon Die ProfilerDavid ScribnerNo ratings yet

- CrutchfieldMasterSheet 0000320015 PDFDocument16 pagesCrutchfieldMasterSheet 0000320015 PDFcatchild101No ratings yet

- BSNL Training ReportDocument38 pagesBSNL Training ReportAndyNo ratings yet

- Brochure Dolphin 2014 BD-new PDFDocument20 pagesBrochure Dolphin 2014 BD-new PDFlolo100% (1)

- Voice Controlled Home AutomationDocument29 pagesVoice Controlled Home AutomationAbhijit PattnaikNo ratings yet

- TND6041-D DC Motor Driver Fundamentals PDFDocument9 pagesTND6041-D DC Motor Driver Fundamentals PDFAlex CarmonaNo ratings yet

- Cmp100 RevisionDocument23 pagesCmp100 Revisionmoha34No ratings yet

- Signal Modules: GSA-CC1, GSA-MCC1, Gsa-Cc2 & Gsa-Mcc2Document6 pagesSignal Modules: GSA-CC1, GSA-MCC1, Gsa-Cc2 & Gsa-Mcc2CarlosNo ratings yet

- Vialox Nav LampsDocument7 pagesVialox Nav LampsroyvindasNo ratings yet

- Difference Between: Turbocharger Vs SuperchargerDocument14 pagesDifference Between: Turbocharger Vs SuperchargerMohammad Al QadomeNo ratings yet

- Solar Powered Light Duty Flexible Drilling MechanismDocument4 pagesSolar Powered Light Duty Flexible Drilling MechanismOmkar SinghNo ratings yet

- Rele SiemensDocument13 pagesRele SiemensBruno DantasNo ratings yet