Professional Documents

Culture Documents

Metal Beam Crash Barrier

Uploaded by

vivekOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metal Beam Crash Barrier

Uploaded by

vivekCopyright:

Available Formats

METHODOLOGY FOR ERECTION OF

METAL BEAM CRASH BARRIER

-1- VKLR - QME

Methodology For Erection of Metal Beam Crash Barrier.

1.1 General

1.1.1 Purpose / aim of the Method Statement submission:

Erection of metal beam crash barrier will be carried as per Tech. Specification and

working drawings or as directed by the Engineer.

1.1.2 Scope of the Method of Statement:

The work consists of furnishing and erection of metal beam crash barrier of dimensions

and at locations as shown in the drawings or as directed by the Engineer.

1.1.3 Reference to other controlling documents where appropriate:

As per the contract drawings and technical specification Clause No: 810, BOQ item

No.11.12.

1.2 Temporary Works

Safety works i.e. traffic regulation will be taken where ever necessary while erection of

metal beam crash barrier.

1.3 Surveys

Erection of metal beam crash barrier will be started after completion of all necessary

alignment checks by supervision staff and as specified in the working drawings.

1.4 Traffic Arrangements

Necessary manpower and display boards will be placed to regulate the flow of traffic with

out causing any congestion or stagnation.

1.5 Materials

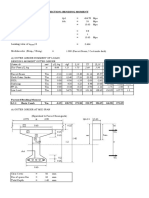

Metal beam is a “W”profiled corrugated beam as specified in drawings made out of cold

roll forming from steel strip of 2.67 mm thick using high strength steel of IS: 5986 Fe 510

grade and have properties as under.

1. Ultimate Tensile Strength (Min) : 483 Mpa.

2. Yield (Min) : 345 Mpa.

3. Elongation (Min) : 12%

-2- VKLR - QME

The beam after forming will have formed width of 310 mm and depth of 83 mm and will

have punched holes for fixing as specified in the drawings.

The metal crash barrier post consists of a cold roll formed from steel strip of 5 mm

thickness and of steel confirming to IS: 5986 grade Fe 360 as specified in drawings.

The spacer is made of cold roll formed channel with cross section and material same as

that of post.

All bolt nuts and washers as specified in drawings will conform to IS: 1367 class 4.6

unless otherwise specified and are hot dip galvanized.

1.6 Construction operation, Installation and Erection

1. The line and grade of railing will be true to that shown on the plans. The railing

will be carefully adjusted prior to fixing in place, to ensure proper matching at

abutting joints and correct alignment and camber throughout their length. Holes

for field connection will be drilled with the railing in place in the structure at proper

grade and alignment.

2. Splices and end connections will be of the type and designs specified or shown

on the plans and will be of such strength as to develop full design strength of the

rail elements.

3. For installation of posts, holes will be dug or drilled to the depth indicated on the

plans or posts may be driven by approved methods and equipments, provided

these are erected in proper position and free from distortion and burring or any

other damage.

4. All post holes are dug or drilled will be such size as will permit proper setting of

the posts and allow sufficient room for backfilling and tapping.

5. Holes will be backfilled with selected earth or materials in layers not exceeding

100 mm thickness and each layer will be thoroughly tamped and rammed. When

backfilling and tamping are completed, the posts or anchors will be held securely

in place.

6. Post holes that are drilled in rock and holes for anchor posts will be backfilled

with concrete.

7. Posts for metal beam guardrails on bridges will be bolted to the structure as

detailed on plans. The anchor will be set to proper location and elevation with

templates and carefully checked.

8. All guardrail anchors will be set and attachments made and placed as indicated

on the plans or as directed by the Engineer.

9. All bolts or clips used for fastening the guardrail or fittings to the posts will be

drawn up tightly. Each bolt will have sufficient length to extend at least 6 mm

through and beyond the full nut, except where such extensions might interfere

with or endanger traffic in which case the bolts will be cut off flush with the nut.

-3- VKLR - QME

10. All railings will be erected, drawn and adjusted so that the longitudinal tension will

be uniform throughout the entire length of the rail.

1.7 Tolerance

The posts will be vertical with a tolerance not exceeding 6 mm in a length of 3 meter. The

railing barrier will be erected true to line and grade.

1.8 Measurement for Payment

Metal beam crash barrier will be measured by linear meter of completed length as per

plans and accepted in place. Terminals / anchors of various types will be paid for by

numbers.

-4- VKLR - QME

You might also like

- MethodologyDocument42 pagesMethodologyCIVIL ENGINEERING100% (1)

- CTSB & GSB Comparision Reg.Document10 pagesCTSB & GSB Comparision Reg.Bidur JhaNo ratings yet

- Morth 2900 Pipe CulvertsDocument5 pagesMorth 2900 Pipe CulvertsRamesh100% (3)

- Method Statement For Wet Mix MacadamDocument7 pagesMethod Statement For Wet Mix Macadammadhu arepelliNo ratings yet

- DBM Mix Design No.-1Document81 pagesDBM Mix Design No.-1pujan patel100% (1)

- Marth 1800 PrestressingDocument17 pagesMarth 1800 PrestressingRamesh100% (4)

- BS 873 - Road StudsDocument18 pagesBS 873 - Road StudsVicky Munien100% (1)

- Methodology For Water Tightness Test For Expansion JointDocument1 pageMethodology For Water Tightness Test For Expansion Jointvenkateswara rao PothinaNo ratings yet

- Policy to eliminate at-grade junctions on 4/6 lane highwaysDocument1 pagePolicy to eliminate at-grade junctions on 4/6 lane highwaysKarthik Reddy ArekutiNo ratings yet

- Adoption of Geo-Composites in Construction of RE WallsDocument1 pageAdoption of Geo-Composites in Construction of RE WallsVijayakrishna SingamsettiNo ratings yet

- Rate Analysis: Metal Beam Crash BarrierDocument1 pageRate Analysis: Metal Beam Crash BarrierNilay BhavsarNo ratings yet

- IRC 37 2018 Guidelines For The Design of Flexible Pavements PDFDocument3 pagesIRC 37 2018 Guidelines For The Design of Flexible Pavements PDFKhairul HoqueNo ratings yet

- IRC 82 2015 Maintenance of Bitumen Surface PDFDocument82 pagesIRC 82 2015 Maintenance of Bitumen Surface PDFanant11235100% (7)

- Ministrycirculars PDFDocument80 pagesMinistrycirculars PDFnaba1577100% (1)

- WMM Mix DesignDocument57 pagesWMM Mix Designp. kiran kuamrNo ratings yet

- Mix Design Using RAP 30Document4 pagesMix Design Using RAP 30Raghav100% (2)

- GSB (SOURCE - BATHU UNA QUARRY) Grade - IIIDocument27 pagesGSB (SOURCE - BATHU UNA QUARRY) Grade - IIIjitendra100% (1)

- Morth 3100 Reinforce EarthDocument5 pagesMorth 3100 Reinforce EarthRamesh67% (3)

- IRC SP 112-2017 Manual For Quality Control in Road - Bridge WorksDocument221 pagesIRC SP 112-2017 Manual For Quality Control in Road - Bridge WorksjitendraNo ratings yet

- Larsen & Toubro Limited - Ecc Division: Page 1 of 4Document4 pagesLarsen & Toubro Limited - Ecc Division: Page 1 of 4Akhilesh DwivediNo ratings yet

- Draft Letter Permission For Casting Percast Girder PDFDocument2 pagesDraft Letter Permission For Casting Percast Girder PDFSachin RamaniNo ratings yet

- INFRACON CV of SPS BalasubramanyamDocument32 pagesINFRACON CV of SPS BalasubramanyamAarvee67% (3)

- MBIU Report Gorakhpur BypassDocument167 pagesMBIU Report Gorakhpur BypassRaghav SharmaNo ratings yet

- SMART TITLEDocument47 pagesSMART TITLErajibchattarajNo ratings yet

- Temp ArrangementDocument83 pagesTemp ArrangementShubam Mota100% (1)

- Retro-Reflectivity TestDocument8 pagesRetro-Reflectivity Testjitendra100% (1)

- Method Statement For Cement Concrete Wearing Coat: Simplex Infrastructures LTDDocument3 pagesMethod Statement For Cement Concrete Wearing Coat: Simplex Infrastructures LTDSreedhar BhuduruNo ratings yet

- WMM Calibration of PlantDocument7 pagesWMM Calibration of PlantKaushlendra Singh80% (5)

- Form Work, Reinforcement & Concreting - MethodologyDocument10 pagesForm Work, Reinforcement & Concreting - MethodologyRabnawaz ImamNo ratings yet

- Drawings of Crash Barrier PDFDocument1 pageDrawings of Crash Barrier PDFRajesh100% (1)

- Job Mix For BM 50 MMDocument3 pagesJob Mix For BM 50 MMSOIGNE ENGINEERING CONSULTANTSNo ratings yet

- Government issues guidelines for utility services along highwaysDocument14 pagesGovernment issues guidelines for utility services along highwayspiuhyderabadNo ratings yet

- Job Mix FormulaDocument10 pagesJob Mix FormulaBijay Krishna Das100% (3)

- Civil Engineering Practices Volume-01 - BY SH - JP Mishra 06.11.2019Document106 pagesCivil Engineering Practices Volume-01 - BY SH - JP Mishra 06.11.2019Ashok kumar100% (1)

- IRC-SP-41-Design of at Grade IntersectionDocument70 pagesIRC-SP-41-Design of at Grade IntersectionRamesh85% (13)

- Trial 1 Analysis of Report (DBM 2)Document12 pagesTrial 1 Analysis of Report (DBM 2)JaneshaNo ratings yet

- BLENDING of MSS Mix Design TypeDocument3 pagesBLENDING of MSS Mix Design TypeEnd EndNo ratings yet

- BBS Retaining WallDocument7 pagesBBS Retaining WallRoushan Rai50% (2)

- NHAI highway design mix summaryDocument21 pagesNHAI highway design mix summaryvikas kumar100% (1)

- Mastic Asphalt Design (With Ca)Document36 pagesMastic Asphalt Design (With Ca)Soundar Pachiappan100% (1)

- Technical Specifications For Self Drilling Anchors (Sda)Document2 pagesTechnical Specifications For Self Drilling Anchors (Sda)SOMNATH JANA100% (1)

- Method Statement For BC From RAP MaterialDocument6 pagesMethod Statement For BC From RAP Materialvenkateswara rao Pothina100% (1)

- Irc SP 042 2014Document148 pagesIrc SP 042 2014roshanrsv100% (6)

- Hand Book On Road PDFDocument56 pagesHand Book On Road PDFrajan sharma100% (1)

- IRC SP 84 2014 - Manual of Specifications & Standards For Four Laning of Highways Through PPPDocument2 pagesIRC SP 84 2014 - Manual of Specifications & Standards For Four Laning of Highways Through PPPvtsh100100% (2)

- What Is The Difference Between Codes IRC 37-2001 & 2012Document5 pagesWhat Is The Difference Between Codes IRC 37-2001 & 2012Bijay Krishna Das100% (1)

- Approach Slab Plans for Highway BridgesDocument9 pagesApproach Slab Plans for Highway BridgesV Venkata Narayana100% (1)

- Annexure 5.14 Mix DesignDocument10 pagesAnnexure 5.14 Mix Designmiesty50% (2)

- 4 Construction and QC in Flexible Pavements As Per MORTH 5th Revision ADocument236 pages4 Construction and QC in Flexible Pavements As Per MORTH 5th Revision AVallabhareddy Nageswara Rao60% (5)

- Sieve Analysis of Wet Mix MacadamDocument2 pagesSieve Analysis of Wet Mix Macadamjitendra100% (1)

- PQC Cracks Repair 1Document3 pagesPQC Cracks Repair 1Deven PatleNo ratings yet

- OHLDocument106 pagesOHLvaithy1990No ratings yet

- Technical Specifications 11kvDocument106 pagesTechnical Specifications 11kvprasanthvenkatesh60% (5)

- QES PEVC-EnG245-Checklist For Design & Drawing of Compound Wall and Main GateDocument2 pagesQES PEVC-EnG245-Checklist For Design & Drawing of Compound Wall and Main GateRupesh KhandekarNo ratings yet

- Checklist For Design & Drawing of Compound Wall and Main GateDocument2 pagesChecklist For Design & Drawing of Compound Wall and Main GateRupesh KhandekarNo ratings yet

- Prestressing ReinforcementDocument6 pagesPrestressing ReinforcementApon khanNo ratings yet

- W Metal Beam Crash Barrier - ACMDocument4 pagesW Metal Beam Crash Barrier - ACMpatel jatinNo ratings yet

- Section 09100 Metal Framing SystemDocument5 pagesSection 09100 Metal Framing Systemestimasi100% (1)

- Aashto M-180 PDFDocument11 pagesAashto M-180 PDF48181No ratings yet

- Guardrail Installation ProcedureDocument5 pagesGuardrail Installation ProcedureThandabantu Magengelele50% (2)

- Design of 15m Span Superstructure Re - 19Document1 pageDesign of 15m Span Superstructure Re - 19vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 412Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 412vivekNo ratings yet

- EROWDocument138 pagesEROWvivekNo ratings yet

- Stress Check Rare MaxDocument1 pageStress Check Rare MaxvivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 387Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 387vivekNo ratings yet

- Design of 15m Span Superstructure Re - 20Document1 pageDesign of 15m Span Superstructure Re - 20vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 233Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 233vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 234Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 234vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 415Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 415vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 379Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 379vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 231Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 231vivekNo ratings yet

- Design of 15m Span Superstructure Re - 17Document1 pageDesign of 15m Span Superstructure Re - 17VivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 421Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 421vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 232Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 232vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 416Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 416vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 4Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 4vivekNo ratings yet

- Design of 15m Span Superstructure Re - 62Document1 pageDesign of 15m Span Superstructure Re - 62vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 230Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 230vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 5Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 5vivekNo ratings yet

- Design of 15m Span Superstructure Re - 20Document1 pageDesign of 15m Span Superstructure Re - 20vivekNo ratings yet

- Design of Bridges at Ch. 7+780 and Ch. 10+600 - 119Document1 pageDesign of Bridges at Ch. 7+780 and Ch. 10+600 - 119vivekNo ratings yet

- Design of 15m Span Superstructure Re - 63Document1 pageDesign of 15m Span Superstructure Re - 63vivekNo ratings yet

- Design of 15m Span Superstructure Re - 18Document1 pageDesign of 15m Span Superstructure Re - 18vivekNo ratings yet

- Design of 15m Span Superstructure Re - 64 PDFDocument1 pageDesign of 15m Span Superstructure Re - 64 PDFvivekNo ratings yet

- Design of 15m Span Superstructure Re - 2Document1 pageDesign of 15m Span Superstructure Re - 2vivek100% (1)

- Design of 15m Span Superstructure Re - 10Document1 pageDesign of 15m Span Superstructure Re - 10vivekNo ratings yet

- Design of 15m Span Superstructure Re - 19Document1 pageDesign of 15m Span Superstructure Re - 19vivekNo ratings yet

- Design of 15m Span Superstructure Re - 4Document1 pageDesign of 15m Span Superstructure Re - 4vivekNo ratings yet

- Design of 15m Span Superstructure Re - 3Document1 pageDesign of 15m Span Superstructure Re - 3vivekNo ratings yet

- Design of 15m Span Superstructure Re - 2Document1 pageDesign of 15m Span Superstructure Re - 2vivek100% (1)

- Net CallDocument2 pagesNet CallFerdinand Monte Jr.100% (2)

- A Phenomenological Research Design IllustratedDocument15 pagesA Phenomenological Research Design IllustratedMATEI100% (1)

- The PersonalityDocument7 pagesThe PersonalityMeris dawatiNo ratings yet

- Valve Control System On A Venturi To Control FiO2 A Portable Ventilator With Fuzzy Logic Method Based On MicrocontrollerDocument10 pagesValve Control System On A Venturi To Control FiO2 A Portable Ventilator With Fuzzy Logic Method Based On MicrocontrollerIAES IJAINo ratings yet

- Galvanic CorrosionDocument5 pagesGalvanic Corrosionsatheez3251No ratings yet

- Lesson 4: Mean and Variance of Discrete Random Variable: Grade 11 - Statistics & ProbabilityDocument26 pagesLesson 4: Mean and Variance of Discrete Random Variable: Grade 11 - Statistics & Probabilitynicole MenesNo ratings yet

- Otimizar Windows 8Document2 pagesOtimizar Windows 8ClaudioManfioNo ratings yet

- Check List Valve PDFDocument2 pagesCheck List Valve PDFikan100% (1)

- Cedrix James Estoquia - OLLC Lesson 4.6 Presentation and Interpretation of Data ApplicationDocument4 pagesCedrix James Estoquia - OLLC Lesson 4.6 Presentation and Interpretation of Data ApplicationDeuK WR100% (1)

- Yoki 644 LPV BS - 7250215 - SDS - EU - 7923568Document14 pagesYoki 644 LPV BS - 7250215 - SDS - EU - 7923568MohamedAhmedShawkyNo ratings yet

- Teaching Speaking: Daily Activities Lesson PlanDocument3 pagesTeaching Speaking: Daily Activities Lesson PlanMARCELANo ratings yet

- Oracle Property Manager System OptionsDocument6 pagesOracle Property Manager System OptionsAhmadShuaibiNo ratings yet

- A Socio-Cultural Dimension of Local Batik Industry Development in IndoneisaDocument28 pagesA Socio-Cultural Dimension of Local Batik Industry Development in Indoneisaprihadi nugrohoNo ratings yet

- MCA 312 Design&Analysis of Algorithm QuestionBankDocument7 pagesMCA 312 Design&Analysis of Algorithm QuestionBanknbprNo ratings yet

- Product Item Code Model Item Description MRP Count Down PricesDocument1 pageProduct Item Code Model Item Description MRP Count Down Pricesලහිරු විතානාච්චිNo ratings yet

- Supply Chain Management 5th Edition Chopra Solutions ManualDocument3 pagesSupply Chain Management 5th Edition Chopra Solutions Manualdammar.jealousgvg6100% (18)

- DepEd CI GuidebookDocument244 pagesDepEd CI Guidebookasdfg100% (4)

- IGNOU - Examination Form AcknowledgementDocument2 pagesIGNOU - Examination Form Acknowledgementsinghabhithakur111No ratings yet

- Review of Train Wheel Fatigue LifeDocument15 pagesReview of Train Wheel Fatigue Lifeabdurhman suleimanNo ratings yet

- Synopsis On Training & DevelopmentDocument6 pagesSynopsis On Training & DevelopmentArchi gupta86% (14)

- Physice 2013 Unsolved Paper Outside Delhi PDFDocument7 pagesPhysice 2013 Unsolved Paper Outside Delhi PDFAbhilashaNo ratings yet

- Cause and Effect Diagram for Iron in ProductDocument2 pagesCause and Effect Diagram for Iron in ProductHungNo ratings yet

- SARTIKA LESTARI PCR COVID-19 POSITIVEDocument1 pageSARTIKA LESTARI PCR COVID-19 POSITIVEsartika lestariNo ratings yet

- 11 - Leo Vega Bolt Failure AnalysisDocument35 pages11 - Leo Vega Bolt Failure AnalysissymkimonNo ratings yet

- Radproduction Chapter 2-9Document276 pagesRadproduction Chapter 2-9Christian DioNo ratings yet

- Facts About SaturnDocument7 pagesFacts About SaturnGwyn CervantesNo ratings yet

- Details of Nodal Officer - HD Officers of Other DepttDocument46 pagesDetails of Nodal Officer - HD Officers of Other DepttManoj KashyapNo ratings yet

- METAPHYSICAL POETRY A SummaryDocument3 pagesMETAPHYSICAL POETRY A Summaryrcschoolofenglish1No ratings yet

- Learning MicroStation For General UsersDocument413 pagesLearning MicroStation For General Userslakshmi mounikaNo ratings yet

- Development of Science in Africa - CoverageDocument2 pagesDevelopment of Science in Africa - CoverageJose JeramieNo ratings yet