Professional Documents

Culture Documents

Ingersollrand: Capacitors

Ingersollrand: Capacitors

Uploaded by

Gustavo HuertasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ingersollrand: Capacitors

Ingersollrand: Capacitors

Uploaded by

Gustavo HuertasCopyright:

Available Formats

INGERSOLLrAND ®

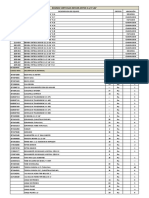

CAPACITORS CAPACITOR CALCULATING CHART

To find the “Percent Capacitor Kvac” necessary to raise

To assist the user in arriving at the correct capacitors for the power factor from “Present Power Factor” to “Desired

his requirements together with estimated costs, the fol- Power Factor”, lay a straight edge across the chart con-

lowing data is provided. necting these two values. Read the “Capacitor Kvac” in

percent of the present kilowatt load on the middle scale.

From the capacitor pricing, the initial cost can be deter-

mined and probable savings can be calculated against

IMPORTANT NOTE:

present monthly billings.

On all machines

with factory

The example given below is based on the capacitor cal-

installed power fac-

culating chart shown opposite which simplifies the selec-

tor correction

tion of the correct kvac.

capacitors,a fan

starter has been

By substituting appropriate figures for those in the exam-

added.This is used

ple, other capacitor costs can be closely estimated.

to disconnect the

fan motor from the

INDUSTRIAL PLANT EXAMPLE

line to ensure the

capacitor dis-

Assume a load of 100 kw 480 volts at 60 percent power

charges only

factor. If this power factor is raised to 95 percent, a con-

through the main

siderable monthly saving in power bills will result.

drive motor shut-

Referring to the chart, you will find that 100 percent

down.This will keep

capacitor kvac is required.This equals 100 percent of

the capacitor from

present kw load or 1000 kvac.

discharging through

the fan motor wind-

The capacitors may be safely connected directly to motor

ing which may be

terminals for all such motors whose performance data is

too small to handle

equal to or lower than the above and for motors with belt

the surge.

driven loads. If motor performance data is better than the

above or where high inertia loads are direct-coupled and

the motor may be restarted before it comes to rest, the

recommended values should not be used without first

consulting with your Ingersoll-Rand representative giving

full details on motor power factor, efficiency, degree of

loading, type of load and method of coupling.

HOWTO COMPUTE POWER FACTOR

P-F = Watts

Volts x Amperes

Determining watts:

1. From watthour meter: watts = rpm of disc x 60 x kh

(where kh is meter constant printed on face or nameplate

of meter).

If metering transformers are used, above must be multi-

plied by the transformer ratios.

2. Directly from wattmeter reading (where volts = line-to-

line voltage as measured by voltmeter and amps = cur-

rent measured in line wire (not neutral) by ammeter).

WIRING DIAGRAM

CCN: 80440118 Rev. A

APDD 330

February 1990

Retyped 1997

You might also like

- Duderstadt Nuclear Reactor AnalysisDocument670 pagesDuderstadt Nuclear Reactor AnalysisBen Clemens100% (3)

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- Power Factor ImprovementDocument8 pagesPower Factor ImprovementmshahidshaukatNo ratings yet

- Deployable StructureDocument17 pagesDeployable StructureSOUMITHA KRNo ratings yet

- 3BHE009017R0102: C724 Be102 Vlscd-Board, Coat. XVDocument2 pages3BHE009017R0102: C724 Be102 Vlscd-Board, Coat. XVSuzell Fiorella AscañoNo ratings yet

- Standards For Low Voltage Embedded GenerationDocument26 pagesStandards For Low Voltage Embedded GenerationCliffNo ratings yet

- Ijsea03031002 PDFDocument5 pagesIjsea03031002 PDFAbdul HamidNo ratings yet

- Microsoft Word - Power Factor Correction Note 1Document18 pagesMicrosoft Word - Power Factor Correction Note 1Swagatam BanerjeeNo ratings yet

- Savings and Application Guide For Power Factor Correction and Harmonic SolutionsDocument20 pagesSavings and Application Guide For Power Factor Correction and Harmonic SolutionsRonish ChandraNo ratings yet

- Savings and Application Guide For Power Factor Correction and Harmonic SolutionsDocument19 pagesSavings and Application Guide For Power Factor Correction and Harmonic Solutionsimran MohammadNo ratings yet

- How To Apply Capacitors To Low Voltage Power Systems.Document13 pagesHow To Apply Capacitors To Low Voltage Power Systems.Ahmed Reda Abdou MohamedNo ratings yet

- Introduction To Power Factor 17.4.2007Document12 pagesIntroduction To Power Factor 17.4.2007phamdangphucthinh24101999No ratings yet

- Q@nightwp Uus134511pDocument9 pagesQ@nightwp Uus134511pNguyen DanhNo ratings yet

- 463152ijsetr1597 559Document12 pages463152ijsetr1597 559ssvasavaongcNo ratings yet

- Power Factor CorrectionDocument6 pagesPower Factor Correctionmostafa HusseinNo ratings yet

- Dry Type Power Factor Correction Capacitors: Application ManualDocument18 pagesDry Type Power Factor Correction Capacitors: Application ManualososdeanNo ratings yet

- Reactive Power Compensation and Power Factor Correction by Reactive VAR CompensatorDocument5 pagesReactive Power Compensation and Power Factor Correction by Reactive VAR CompensatorEditor IJTSRDNo ratings yet

- Power Factor Technical OverviewDocument6 pagesPower Factor Technical OverviewMatt SmithNo ratings yet

- # Attachment E.01Document4 pages# Attachment E.01Guns DrummerNo ratings yet

- Reactive Power Compensation For Transmission and Distribution SystemsDocument4 pagesReactive Power Compensation For Transmission and Distribution SystemsSuranjana DasNo ratings yet

- Pages From L&T APFC Troubleshooting ManualDocument3 pagesPages From L&T APFC Troubleshooting Manualrajpre1213No ratings yet

- Power Factor CorrectionDocument2 pagesPower Factor CorrectionGeo ThaliathNo ratings yet

- 5 - Correcting Power Factor at Your Motor TerminalsDocument2 pages5 - Correcting Power Factor at Your Motor TerminalsQM_2010No ratings yet

- 15IPST013Document7 pages15IPST013Ahmed GhamriNo ratings yet

- Efficient Power Factor Imp. TechDocument4 pagesEfficient Power Factor Imp. Techsadia_murshad171No ratings yet

- PF Corrrection Application GuideDocument15 pagesPF Corrrection Application Guidedip461No ratings yet

- 45 16255 EE543 2015 1 1 1 Week 8 9Document25 pages45 16255 EE543 2015 1 1 1 Week 8 9Kristel Mae Hertz CastilloNo ratings yet

- AC CIRCUIT Power AnalysisDocument48 pagesAC CIRCUIT Power AnalysisFerrer Francia Nel SabasNo ratings yet

- Power Factor CorrectionDocument15 pagesPower Factor CorrectionRalph Jason Alvarez100% (1)

- Apfc PanelDocument7 pagesApfc PanelChander MohanNo ratings yet

- P9 Materials For Discussion and ConclusionsDocument8 pagesP9 Materials For Discussion and Conclusionslinkin_slayerNo ratings yet

- BATCH 4-Power QualityDocument22 pagesBATCH 4-Power QualityVasanthNo ratings yet

- TrancientDocument3 pagesTrancientReneNo ratings yet

- Apnot 125Document4 pagesApnot 125wilson2142No ratings yet

- Pre Lab 6Document4 pagesPre Lab 6Maaz HussainNo ratings yet

- Compensating Reactive Energyinlvormv?Document2 pagesCompensating Reactive Energyinlvormv?Hani Adib AzadNo ratings yet

- Capacitor Banks in Power System Part FourDocument4 pagesCapacitor Banks in Power System Part FourTigrillo100% (1)

- Sistema de Compenaciyn de Potencia ReactivaDocument4 pagesSistema de Compenaciyn de Potencia ReactivaManuel Corona CárdenasNo ratings yet

- Iccicct - 122 PDFDocument6 pagesIccicct - 122 PDFGlan DevadhasNo ratings yet

- ON Reactive Power Compensation: A Seminar ReportDocument17 pagesON Reactive Power Compensation: A Seminar ReportBineilKcThapaNo ratings yet

- A Review On Power Factor Correction For Single-Phase Motor: Mechanical and Petroleum Engineering DepartmentDocument15 pagesA Review On Power Factor Correction For Single-Phase Motor: Mechanical and Petroleum Engineering Departmentsabelle ilaganNo ratings yet

- Single-Phase Induction Motor With An Electronically Controlled CapacitorDocument6 pagesSingle-Phase Induction Motor With An Electronically Controlled CapacitorRavindranath NaikNo ratings yet

- 8.application of CapacitorsDocument19 pages8.application of CapacitorsImjusttryingtohelpNo ratings yet

- Engine Governing Systems: GOVERNORS AMERICA CORP. - 720 Silver Street - Agawam, MA 01001-2907, USADocument7 pagesEngine Governing Systems: GOVERNORS AMERICA CORP. - 720 Silver Street - Agawam, MA 01001-2907, USAlethanhtu0105No ratings yet

- Reactive PowerDocument15 pagesReactive PowerJoanna BaileyNo ratings yet

- Power System Stability Enhancement Using FACTS Devices: Ravinder Goud, Dola Gobinda Padhan, Naspuri Arun RajuDocument4 pagesPower System Stability Enhancement Using FACTS Devices: Ravinder Goud, Dola Gobinda Padhan, Naspuri Arun RajudolaNo ratings yet

- Automatic Power Factor Correction: International Research Journal of Engineering and Technology (IRJET)Document4 pagesAutomatic Power Factor Correction: International Research Journal of Engineering and Technology (IRJET)Abhíñåv PrâjãpätîNo ratings yet

- New Chapter 11 Power Factor CorrectionDocument28 pagesNew Chapter 11 Power Factor CorrectionmohammadkassarNo ratings yet

- Reactive Power Supplied by PV Inverters - Cost-Benefit-AnalysisDocument8 pagesReactive Power Supplied by PV Inverters - Cost-Benefit-AnalysisNitishPaudelNo ratings yet

- Single Phase To Three Phase Converter: Naung Cho Wynn, and Tun Lin NaingDocument5 pagesSingle Phase To Three Phase Converter: Naung Cho Wynn, and Tun Lin NaingLindsay Fidel Margareth RumapeaNo ratings yet

- Introduction To Power Factor Correction PDFDocument8 pagesIntroduction To Power Factor Correction PDFErlangga SatyawanNo ratings yet

- Q at Night: ContentDocument9 pagesQ at Night: ContentBharathwaaj JagannathanNo ratings yet

- Capacitor Placement in A Distribution System For Power Factor Correction: An Optimization ApproachDocument6 pagesCapacitor Placement in A Distribution System For Power Factor Correction: An Optimization Approachrizkypratamaputra58No ratings yet

- Energy Engineering and Management: Power Factor Correction - The CalculationsDocument39 pagesEnergy Engineering and Management: Power Factor Correction - The CalculationsJohn Angelo ComiaNo ratings yet

- V.I.P. Dasanayake CapacitanceDocument5 pagesV.I.P. Dasanayake CapacitanceIsuru Pasan Dasanayake100% (1)

- Pulse Jun2008 PDFDocument16 pagesPulse Jun2008 PDFChaitanya DeshpandeNo ratings yet

- Generator ReactancesDocument3 pagesGenerator ReactancesLora BishopNo ratings yet

- A Significant Step Forward in Electric Propulsion Increasing Vessel Efficiency Up To 20%Document2 pagesA Significant Step Forward in Electric Propulsion Increasing Vessel Efficiency Up To 20%ArturoNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Investigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsFrom EverandInvestigation of the Usefulness of the PowerWorld Simulator Program: Developed by "Glover, Overbye & Sarma" in the Solution of Power System ProblemsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Instalacion y Operacion Tablero Mando VariadorDocument95 pagesInstalacion y Operacion Tablero Mando VariadorGustavo HuertasNo ratings yet

- Manual Geo PDFDocument242 pagesManual Geo PDFGustavo HuertasNo ratings yet

- More Than Air. AnswersDocument20 pagesMore Than Air. AnswersGustavo HuertasNo ratings yet

- Manual de OperacionDocument102 pagesManual de OperacionGustavo HuertasNo ratings yet

- 80440175Document35 pages80440175Gustavo HuertasNo ratings yet

- Caution: CCN: 80440142 Rev. ADocument5 pagesCaution: CCN: 80440142 Rev. AGustavo HuertasNo ratings yet

- More Than Air. AnswersDocument7 pagesMore Than Air. AnswersGustavo HuertasNo ratings yet

- More Than Air. AnswersDocument1 pageMore Than Air. AnswersGustavo HuertasNo ratings yet

- X-Tend Food Grade Coolant: Material Safety Data SheetDocument2 pagesX-Tend Food Grade Coolant: Material Safety Data SheetGustavo HuertasNo ratings yet

- More Than Air. AnswersDocument3 pagesMore Than Air. AnswersGustavo HuertasNo ratings yet

- SSR 125-450 HOREPOWER Intellisys Units Inlet Panel Air Filters Installation/ Instruction Manual Parts List Replacement PartsDocument14 pagesSSR 125-450 HOREPOWER Intellisys Units Inlet Panel Air Filters Installation/ Instruction Manual Parts List Replacement PartsGustavo HuertasNo ratings yet

- Bomba Vertical Denver 1.5x24Document5 pagesBomba Vertical Denver 1.5x24Gustavo HuertasNo ratings yet

- Bombas Parker Pvp16Document10 pagesBombas Parker Pvp16Gustavo HuertasNo ratings yet

- C Series, Engineering, Data PackDocument37 pagesC Series, Engineering, Data PackGustavo HuertasNo ratings yet

- More Than Air. AnswersDocument1 pageMore Than Air. AnswersGustavo HuertasNo ratings yet

- Bombas Pvp16Document10 pagesBombas Pvp16Gustavo HuertasNo ratings yet

- Bombas Toyo DLDocument30 pagesBombas Toyo DLGustavo Huertas100% (1)

- Sec 05 KTZ4 67.5-63 (Angle Discharge)Document1 pageSec 05 KTZ4 67.5-63 (Angle Discharge)Gustavo HuertasNo ratings yet

- Bombas Toyo DLDocument30 pagesBombas Toyo DLGustavo Huertas100% (1)

- Bomba Vertical Denver 1.5x24Document1 pageBomba Vertical Denver 1.5x24Gustavo HuertasNo ratings yet

- 6/7/2018 Item Part No. Description QTY Size Material Notes Parts List Contractor PumpDocument4 pages6/7/2018 Item Part No. Description QTY Size Material Notes Parts List Contractor PumpGustavo HuertasNo ratings yet

- Fecha Giw 1 2035-057: Horas Trabajadas Equipos PlantaDocument4 pagesFecha Giw 1 2035-057: Horas Trabajadas Equipos PlantaGustavo HuertasNo ratings yet

- Bomba Giw DatasheetDocument4 pagesBomba Giw DatasheetGustavo Huertas100% (1)

- Instauracion de Programa de Mantenimiento PreventivoDocument1 pageInstauracion de Programa de Mantenimiento PreventivoGustavo HuertasNo ratings yet

- Reliance Selection Guide - RSGBR00413Document2 pagesReliance Selection Guide - RSGBR00413AlejandroVCMXNo ratings yet

- 00.micro Schedule GenaralDocument11 pages00.micro Schedule GenaralAnujGargNo ratings yet

- Tidud 04 ADocument30 pagesTidud 04 ATari mahmanuNo ratings yet

- KOE 074 - Unit5Document114 pagesKOE 074 - Unit5Aarabh singhNo ratings yet

- Sustainable Energy Management and Green EngineeringDocument35 pagesSustainable Energy Management and Green EngineeringSamuel GarciaNo ratings yet

- 0625 s15 QP 31Document20 pages0625 s15 QP 31yuke kristinaNo ratings yet

- Direct Injection Vehicles Conversion List/ Lista Auto Ad Iniezione Diretta TrasformabiliDocument3 pagesDirect Injection Vehicles Conversion List/ Lista Auto Ad Iniezione Diretta TrasformabiliAdrianjets SouzaNo ratings yet

- Switching & Lightning Protection of Overhead Lines Using Externally Gapped Line ArrestersDocument9 pagesSwitching & Lightning Protection of Overhead Lines Using Externally Gapped Line ArrestersZoran PetrovićNo ratings yet

- KPTCL ProjectDocument38 pagesKPTCL ProjectSalman Khan50% (2)

- SHP 21 DS en 20Document4 pagesSHP 21 DS en 20Marko Maky ZivkovicNo ratings yet

- Chapter 14 Science NotesDocument4 pagesChapter 14 Science NotesSavannah MontelongoNo ratings yet

- CNSC Draft Screening ReportDocument172 pagesCNSC Draft Screening ReportAnonymous 1hOgJqwZuzNo ratings yet

- Comparison Between Different Power PlantsDocument3 pagesComparison Between Different Power Plantsasif_shafiqNo ratings yet

- The Following Are Some of The Best Books On Power ElectronicsDocument1 pageThe Following Are Some of The Best Books On Power ElectronicsShakir AhmadNo ratings yet

- APR Energy Technical BrochureDocument7 pagesAPR Energy Technical Brochured700722psNo ratings yet

- How To Calculate Generator SizingDocument2 pagesHow To Calculate Generator Sizing10rodriguezNo ratings yet

- Fundamentals of Thermodynamics 9th Editionch15Document175 pagesFundamentals of Thermodynamics 9th Editionch15Cierré No'Middlename JonesNo ratings yet

- Physics 101Document37 pagesPhysics 101emersonnoliveiraNo ratings yet

- Philippine Grid Code PDFDocument139 pagesPhilippine Grid Code PDFColeen Navarro-Rasmussen100% (2)

- Internal Combustion Engines1Document68 pagesInternal Combustion Engines1Ahmed ShaabanNo ratings yet

- The Study of Very Fast Transient Over Voltages (VFTO) For The Project of 400/220kV GIS Substation With One and Half Circuit Breaker ConfigurationDocument4 pagesThe Study of Very Fast Transient Over Voltages (VFTO) For The Project of 400/220kV GIS Substation With One and Half Circuit Breaker ConfigurationFelipe Mafioletti SchuartzNo ratings yet

- Productivity Improvement Handbook For Fossil Steam Power Plants Third Edition PDFDocument496 pagesProductivity Improvement Handbook For Fossil Steam Power Plants Third Edition PDFthinhlvt100% (1)

- Spark-Ignited Generator Set GM8.1 Series Engine: Description FeaturesDocument4 pagesSpark-Ignited Generator Set GM8.1 Series Engine: Description FeaturesWilson JustinoNo ratings yet

- Example CH 4Document4 pagesExample CH 4Uday Prakash SahuNo ratings yet

- Hoppecke FNCDocument4 pagesHoppecke FNCrocazo123No ratings yet