Professional Documents

Culture Documents

Metrode WPS Superduplex PDF

Metrode WPS Superduplex PDF

Uploaded by

cwiksjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Metrode WPS Superduplex PDF

Metrode WPS Superduplex PDF

Uploaded by

cwiksjCopyright:

Available Formats

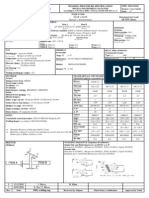

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex TIG/GTAW

Consumables Base Material

Welding process (root): TIG / GTAW Parent Material: Superduplex.

- Consumable: Zeron 100X (UNS S32750 & S32760).

- Specification: BS EN 12072: W 25 9 4 N L ASME IX: P or S number (QW422) =

Welding process (fill): TIG / GTAW 10H group 1.

- Consumable: Zeron 100X Thickness: 18.26mm (Schedule 160)

- Specification: BS EN 12072: W 25 9 4 N L Outside Diameter: 6 inch NB

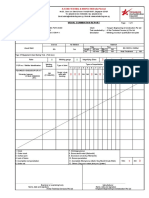

Joint Details Joint Position

Joint Type: Single side butt Welding Position: ASME 6G

Manual/Mechanised: Manual

Joint Sketch Welding Sequences

6” NB 65°±5°

Schedule 160

Split layers (2 beads per layer) from runs 4/5 onwards.

18.26mm

0.5-1.5mm .

2-4mm

Welding Details

Travel Heat

Diameter Current Voltage speed Type of current

Run Process Consumable Input

mm A V mm/min / Polarity

kJ/mm

1 TIG Zeron 100X 2.4 80-100 ~12 ~50 DC- ~1.2

2 TIG Zeron 100X 2.4 90-130 ~12 ~125 DC- ~0.8

Fill TIG Zeron 100X 3.2 200-225 ~12 100-175 DC- ~1.5

Electrode Baking or Drying: NA Notes:

Gas – root (TIG) shielding: Ar + 2% N2

1. Tack joint securely to prevent root closure using four

backing: Ar

Gas - fill/cap (TIG) – Shielding: Ar

bridging tacks.

Purge: Ar

Tungsten Electrode Type/Size: 2%Th/2.4mm 2. Weld pipe in four 90° segments to prevent excessive

Details of Back Gouging/Backing: NA overheating.

Preheat Temperature: 20°C 3. Purge to maintain 0.5% oxygen max.

Interpass Temperature: 150°C max 4. Ar + 2%N2 shielding gas is recommended for the root run

Post-Weld Heat Treatment and/or Ageing: None to ensure G48A properties.

Temperature: 5. Purging 20-30l/min (reduced to ~10l/min for tie-in).

Time: Maintain purge for first two runs.

6. Shielding gas flow rate 8-12l/min.

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

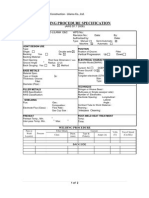

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex MMA/SMAW

Consumables Base Material

Welding process (root): TIG / GTAW Parent Material: Superduplex.

- Consumable: Zeron 100X (UNS S32750 & S32760).

- Specification: BS EN 12072: W 25 9 4 N L ASME IX: P or S number (QW422) =

Welding process (fill): MMA / SMAW 10H group 1.

- Consumable: Zeron 100XKS / 2507XKS Thickness: 18.26mm (Schedule 160)

- Specification: BS EN 1600: E 25 9 4 N L B 4 2 Outside Diameter: 6 inch NB

Joint Details Joint Position

Joint Type: Single side butt Welding Position: ASME 6G

Manual/Mechanised: Manual

Joint Sketch Welding Sequences

6” NB 70°±5°

Schedule 160

18.26mm

0.5-1.5mm .

2-4mm

Welding Details

Travel Type of Heat

Diameter Current Voltage speed

Run Process Consumable current / Input

mm A V mm/min Polarity kJ/mm

1 TIG Zeron 100X 2.4 80-100 ~12 ~50 DC- ~1.2

2 TIG Zeron 100X 2.4 90-130 ~12 ~125 DC- ~0.8

Fill MMA Zeron 100XKS / 2507XKS 3.2 75-95 ~25 75-125 DC+ ~1.2

Electrode Baking or Drying: 200°C/2 hours Notes:

Gas – root (TIG) shielding: Ar + 2% N2

1. Tack joint securely to prevent root closure using four

backing: Ar

Gas - fill/cap: Not applicable bridging tacks.

Tungsten Electrode Type/Size: 2%Th/2.4mm 2. Weld pipe in four 90° segments to prevent excessive

Details of Back Gouging/Backing: NA overheating.

Preheat Temperature: 20°C 3. Purge to maintain 0.5% oxygen max.

Interpass Temperature: 150°C max 4. Ar + 2%N2 shielding gas is recommended for the root run

Post-Weld Heat Treatment and/or Ageing: None to ensure G48A properties.

Temperature: 5. Purging 20-30l/min (reduced to ~10l/min for tie-in).

Time: Maintain purge for first two runs.

6. Shielding gas flow rate 8-12l/min.

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex FCAW

Consumables Base Material

Welding process (root): TIG / GTAW Parent Material: Superduplex.

- Consumable: Zeron 100X (UNS S32750 & S32760).

- Specification: BS EN 12072: W 25 9 4 N L ASME IX: P or S number (QW422) =

Welding process (fill): FCAW 10H group 1.

- Consumable: Supercore Z100XP / 2507P Thickness: 23mm (Schedule 160)

- Specification: -- Outside Diameter: 8 inch NB

Joint Details Joint Position

Joint Type: Single side butt Welding Position: ASME 6G

Manual/Mechanised: Manual

Joint Sketch Welding Sequences

8” NB 70°±5°

Schedule 160

23mm

0.5-1.5mm .

2-4mm

Welding Details

Travel Type of Heat

Diameter Current Voltage

Run Process Consumable speed current / Input

mm A V

mm/min Polarity kJ/mm

1 TIG Zeron 100X 2.4 80-100 ~12 ~50 DC- ~1.2

2 TIG Zeron 100X 2.4 90-130 ~12 ~125 DC- ~0.8

3-4 TIG Zeron 100X 2.4 140-160 ~12 ~75 DC- ~1.5

Fill FCAW Supercore Z100XP/2507P 1.2 140-180 ~26 100-175 DC+ ~1.5

Electrode Baking or Drying: NA Notes:

Gas – root (TIG) shielding: Ar + 2% N2

1. Tack joint securely to prevent root closure using four

backing: Ar

Gas - fill/cap (FCAW) – Shielding: Ar-20% CO2 bridging tacks.

Tungsten Electrode Type/Size: 2%Th/2.4mm 2. Weld pipe in four 90° segments to prevent excessive

Details of Back Gouging/Backing: NA overheating.

Preheat Temperature: 20°C 3. Purge to maintain 0.5% oxygen max.

Interpass Temperature: 150°C max 4. Ar + 2%N2 shielding gas is recommended for the root run

Post-Weld Heat Treatment and/or Ageing: None to ensure G48A properties.

Temperature: 5. Purging 20-30l/min (reduced to ~10l/min for tie-in).

Time: 6. Shielding gas flow rate: TIG = 8-12l/min, FCAW = 20-25

l/min.

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

Welding Procedure Specification (WPS)

Welding Procedure No: Superduplex SAW

Consumables Base Material

Welding process (root): TIG / GTAW Parent Material: Superduplex.

- Consumable: Zeron 100X (UNS S32750 & S32760).

- Specification: BS EN 12072: W 25 9 4 N L ASME IX: P or S number (QW422) =

Welding process (fill): SAW 10H group 1.

- Consumable: Zeron 100X Thickness: ~25mm

- Specification: BS EN 12072: W 25 9 4 N L Outside Diameter: Not applicable

Joint Details Joint Position

Joint Type: Single side butt Welding Position: ASME 1G

Manual/Mechanised: Mechanised

Joint Sketch Welding Sequences

65°±5°

Split layers (2 beads per layer) from runs 4/5 onwards.

25mm

0.5-1.5mm .

2-4mm

Welding Details

Travel Heat

Diameter Current Voltage speed Type of current

Run Process Consumable Input

mm A V mm/min / Polarity

kJ/mm

1 TIG Zeron 100X 2.4 80-100 ~12 ~50 DC- ~1.2

2 TIG Zeron 100X 2.4 90-130 ~12 ~125 DC- ~0.8

3-4 TIG Zeron 100X 2.4 140-160 ~12 ~75 DC- ~1.5

Fill SAW Zeron 100X 2.4 300-400 ~30 300-500 DC+ ~1.5

Electrode Baking or Drying: NA Notes:

Gas – root (TIG) shielding: Ar + 2% N2

1. Tack joint securely to prevent root closure using four

backing: Ar

Flux - fill/cap (SAW) – LA491 bridging tacks.

Tungsten Electrode Type/Size: 2%Th/2.4mm 2. Purge to maintain 0.5% oxygen max.

Details of Back Gouging/Backing: NA 3. Ar + 2%N2 shielding gas is recommended for the root run

Preheat Temperature: 20°C to ensure G48A properties.

Interpass Temperature: 150°C max 4. Purging 20-30l/min (reduced to ~10l/min for tie-in).

Post-Weld Heat Treatment and/or Ageing: None Maintain purge for first two runs.

Temperature: 5. Shielding gas flow rate 8-12l/min.

Time:

n:\tech\literature\technical profiles\duplex\wps superduplex.doc

You might also like

- WPS, PQR & WPQ - Duplex 2205Document20 pagesWPS, PQR & WPQ - Duplex 2205prod41525% (4)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- Wps For Aluminium WeldingDocument8 pagesWps For Aluminium Weldingvishal bailur50% (2)

- WPS For Structure Mild Steel Fillet WeldDocument2 pagesWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- Wps For SS 304Document3 pagesWps For SS 304MuraliKrishna87% (23)

- Wps SawDocument2 pagesWps Sawdevendrasingh2021100% (6)

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- Astm A143Document4 pagesAstm A143asdrecv100% (1)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- AWS D1.1 - Example PQR & WPS DocumentsDocument4 pagesAWS D1.1 - Example PQR & WPS DocumentsPaul Cassells0% (1)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- Metrode WPS SuperduplexDocument4 pagesMetrode WPS SuperduplexClaudia Mms100% (3)

- Temper Bead Welding ProceduresDocument8 pagesTemper Bead Welding ProceduresClaudia Mms100% (1)

- Sae J417 1983 (En)Document11 pagesSae J417 1983 (En)Oh No Potato100% (1)

- KSL Wps PQR 012 DuplexDocument33 pagesKSL Wps PQR 012 DuplexJunaidi Minhat100% (6)

- Sa 516 GR 70 WPSDocument5 pagesSa 516 GR 70 WPSRajesh Owaiyar71% (7)

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (2)

- WpsDocument6 pagesWpsabhishek198327No ratings yet

- WPS, PQR, WPQ (Si007)Document5 pagesWPS, PQR, WPQ (Si007)Suresh RathodNo ratings yet

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline SungahidNo ratings yet

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS P91Document6 pagesWPS P91JoseAlbertoNeyraNo ratings yet

- P91 WPSDocument6 pagesP91 WPSPepe SagitarioNo ratings yet

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Chemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Document2 pagesChemical Analysis Test Report: Element Sample T-1 Sample B-2 SAE/AISI Gr. A356.0Claudia MmsNo ratings yet

- Owen Barfield BibliographyDocument50 pagesOwen Barfield BibliographyClaudia MmsNo ratings yet

- WRC Bulletin No 506 Half-Bead Temper-BeadDocument2 pagesWRC Bulletin No 506 Half-Bead Temper-BeadClaudia MmsNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- PQR SAW ProcessDocument1 pagePQR SAW Processdevendrasingh202133% (3)

- PQRDocument2 pagesPQRalokbdas100% (1)

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Wps 316L Gtaw R00Document3 pagesWps 316L Gtaw R00Richard Periyanayagam75% (4)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- WPS Dissimilar UpdatedDocument3 pagesWPS Dissimilar UpdatedVimin Prakash100% (1)

- Alum 6xxx PwpsDocument1 pageAlum 6xxx PwpsAbu Zahid100% (1)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- WPS D1.6 Annex m1 PDFDocument1 pageWPS D1.6 Annex m1 PDFbollascribdNo ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- 03 WPS PQR For FCAWDocument3 pages03 WPS PQR For FCAWBrijesh Yadav100% (1)

- WPS 304L &316LDocument2 pagesWPS 304L &316LShakeel Memon100% (1)

- WPS Format For ASME IX - PQR-AllDocument3 pagesWPS Format For ASME IX - PQR-AllThe Welding Inspections Community100% (1)

- Visual Examination ReportDocument47 pagesVisual Examination ReportalouisNo ratings yet

- PWPS WPS PQR WPQDocument21 pagesPWPS WPS PQR WPQcsolanki658688% (8)

- WPS Aws D1.1Document2 pagesWPS Aws D1.1tuatk67% (6)

- Welding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2Document2 pagesWelding Procedure Specification (WPS) : FM-87 Issue - 01 Date: Feb, 12,2015 Page 1 of 2tayyabNo ratings yet

- WPS - PQR (Sa516 GR.70)Document4 pagesWPS - PQR (Sa516 GR.70)miltonangulomorrisNo ratings yet

- Qualified Welders ListDocument3 pagesQualified Welders ListdavNo ratings yet

- Welding Procedure and PQR SSDocument18 pagesWelding Procedure and PQR SSmonchai_626No ratings yet

- SS WPSDocument1 pageSS WPSMOHAMEDABBASNo ratings yet

- En Iso 9606 1 ADocument2 pagesEn Iso 9606 1 AvitharvanNo ratings yet

- Welding Procedure SpecificationDocument3 pagesWelding Procedure SpecificationAhmed saber100% (2)

- WQT - 1 PDFDocument2 pagesWQT - 1 PDFLuttpi100% (1)

- WPS & PQRDocument46 pagesWPS & PQRJohn Candidate CIns88% (8)

- WPS CuNiDocument4 pagesWPS CuNiSripathyNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKparesh2387No ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsManzar KhanNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- Advantages and Limitations of Martensitic Steels For FusionDocument4 pagesAdvantages and Limitations of Martensitic Steels For FusionClaudia MmsNo ratings yet

- How To Become Certified by ASME 2010Document2 pagesHow To Become Certified by ASME 2010quiron2010No ratings yet

- Titanium Spec - Chart PDFDocument1 pageTitanium Spec - Chart PDFClaudia MmsNo ratings yet

- What Is Bellows Pressure Thrust PDFDocument2 pagesWhat Is Bellows Pressure Thrust PDFClaudia MmsNo ratings yet

- An Introduction To Cathodic Protection PDFDocument5 pagesAn Introduction To Cathodic Protection PDFGERMAN1979No ratings yet

- Expansion of The Sourcebook For Hydrogen Applications 03-10-2006Document1 pageExpansion of The Sourcebook For Hydrogen Applications 03-10-2006Claudia MmsNo ratings yet

- DPVC 09 PetrobrasDocument47 pagesDPVC 09 PetrobrasClaudia MmsNo ratings yet

- In Situ Repair Welding of Steam Turbine ShroudDocument7 pagesIn Situ Repair Welding of Steam Turbine ShroudClaudia Mms100% (1)

- EPRI Repair & Replacement Apps Center - Socket Weld Repair Issues 1013562Document20 pagesEPRI Repair & Replacement Apps Center - Socket Weld Repair Issues 1013562Claudia Mms100% (1)

- Inspection and Welding Repairs of Pressure VesselsDocument9 pagesInspection and Welding Repairs of Pressure VesselsClaudia Mms100% (1)

- Condition of The Firetube Right After Removal From ServiceDocument1 pageCondition of The Firetube Right After Removal From ServiceClaudia MmsNo ratings yet

- Welding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Document18 pagesWelding of Stainless Steels and Other Joining Methods: A Designers' Handbook Series N 9 002Sreenivas GuduruNo ratings yet

- FCAW Temper Bead Iamot - OrgDocument7 pagesFCAW Temper Bead Iamot - OrgClaudia MmsNo ratings yet

- Solidification Cracking in SS Welds Pe1119Document24 pagesSolidification Cracking in SS Welds Pe1119Claudia Mms100% (1)

- Pickling HandbookDocument20 pagesPickling HandbookRhona100% (1)

- Terminal Blocks: J - AccessoriesDocument24 pagesTerminal Blocks: J - Accessoriespaula09No ratings yet

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10250-2Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10250-2farshid KarpasandNo ratings yet

- Axle Shaft Strength ChartDocument1 pageAxle Shaft Strength CharthavvkxjNo ratings yet

- Style 400 Steel Coupling: (For 12" and Larger Pipe)Document4 pagesStyle 400 Steel Coupling: (For 12" and Larger Pipe)picottNo ratings yet

- Nioec-Sp-50-09 Piping Material Purchase-PipeDocument9 pagesNioec-Sp-50-09 Piping Material Purchase-PipeRae ArevalosNo ratings yet

- AISI 1018 Mild Low Carbon Steel PDFDocument3 pagesAISI 1018 Mild Low Carbon Steel PDFMayand DuaNo ratings yet

- 084 - ME8073, ME6004 Unconventional Machining Processes - NotesDocument39 pages084 - ME8073, ME6004 Unconventional Machining Processes - NotesA. AKASH 4001-UCE-TKNo ratings yet

- Magna-505-Display InforDocument2 pagesMagna-505-Display InforLee Chong EeNo ratings yet

- Thermal PropertiesDocument14 pagesThermal PropertiesLivian TeddyNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary Educationjuliemailyn9No ratings yet

- Ma3022 Propeller Drydockingworks 1 Aug05Document18 pagesMa3022 Propeller Drydockingworks 1 Aug05NAGENDRA KUMAR DNo ratings yet

- Manufacturing Processes 4-5-1539795648Document236 pagesManufacturing Processes 4-5-1539795648Eduardo UribeNo ratings yet

- Forming Questions For Entrance Exams - SanfoundryDocument4 pagesForming Questions For Entrance Exams - SanfoundryrahmaNo ratings yet

- Base Metal AlloysDocument85 pagesBase Metal AlloysmeghaNo ratings yet

- 5131 PDFDocument9 pages5131 PDFucc rd minesNo ratings yet

- Modelo Certificación Submittal F1554-55 PDFDocument2 pagesModelo Certificación Submittal F1554-55 PDFedwinsazzzNo ratings yet

- En 10270Document2 pagesEn 10270pureroNo ratings yet

- Aircraft Construction Repair and ModificationDocument49 pagesAircraft Construction Repair and Modification알신제인No ratings yet

- Steel SpecificationsDocument18 pagesSteel SpecificationssurenderbuddhaNo ratings yet

- The Welding Journal 1958 6Document161 pagesThe Welding Journal 1958 6Alexey100% (1)

- B 928 - 03 - Qjkyoc1sruq - PDFDocument11 pagesB 928 - 03 - Qjkyoc1sruq - PDF이동욱No ratings yet

- WPQT FormatDocument176 pagesWPQT FormatRafiqKu50% (2)

- Bgas Grade-1 - Model Exam No: 3Document8 pagesBgas Grade-1 - Model Exam No: 3Shamim AlamNo ratings yet

- Fcaw 16 THKDocument5 pagesFcaw 16 THKAnonymous Ij6VfaNo ratings yet

- Analysis of Rate For LinerDocument10 pagesAnalysis of Rate For LinerFahad ZulfiqarNo ratings yet

- PQR Acero Al CarbonoDocument2 pagesPQR Acero Al CarbonoROBERTO QUESADANo ratings yet

- ASTM A36 DatasheetDocument4 pagesASTM A36 DatasheetRene D. ArrietaNo ratings yet

- 1 s2.0 S092583882034603X Main - GialloDocument25 pages1 s2.0 S092583882034603X Main - GialloGiorgio VilardiNo ratings yet