100% found this document useful (1 vote)

614 views4 pagesPrying Action

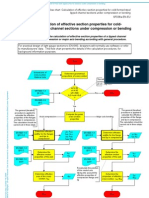

The document discusses prying effects in bolted end-plate connections. It describes different failure modes based on end-plate thickness and provides equations to calculate design resistance considering factors like bolt strength, plate thickness, and prying coefficient. The document also outlines standards for minimum plate thickness in preloaded and non-preloaded connections.

Uploaded by

Nguyen Quoc VuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

614 views4 pagesPrying Action

The document discusses prying effects in bolted end-plate connections. It describes different failure modes based on end-plate thickness and provides equations to calculate design resistance considering factors like bolt strength, plate thickness, and prying coefficient. The document also outlines standards for minimum plate thickness in preloaded and non-preloaded connections.

Uploaded by

Nguyen Quoc VuCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Prying Effect in Bolted End – Plate Connections