0% found this document useful (0 votes)

72 views11 pagesSieve Analysis and Concrete Mix Design

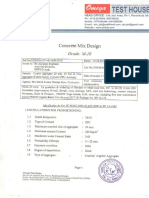

This document contains the results of a sieve analysis test performed on recycled concrete gravel (RCG) and natural sand. It also includes the recommended gradation limits for natural fine aggregate. A blend grading was developed using 22.5% RCG, 31.9% sand B, and 45.6% natural sand. A concrete mix design was then created to have a water-cement ratio of 0.48 and aggregate-cement ratio of 4.26 to achieve a target compressive strength of 37.94 MPa. The required quantities of materials for producing 255 kg of concrete were calculated.

Uploaded by

ST capitanioCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

72 views11 pagesSieve Analysis and Concrete Mix Design

This document contains the results of a sieve analysis test performed on recycled concrete gravel (RCG) and natural sand. It also includes the recommended gradation limits for natural fine aggregate. A blend grading was developed using 22.5% RCG, 31.9% sand B, and 45.6% natural sand. A concrete mix design was then created to have a water-cement ratio of 0.48 and aggregate-cement ratio of 4.26 to achieve a target compressive strength of 37.94 MPa. The required quantities of materials for producing 255 kg of concrete were calculated.

Uploaded by

ST capitanioCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLSX, PDF, TXT or read online on Scribd