Professional Documents

Culture Documents

FINANCE

Uploaded by

Vandana AggarwalOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FINANCE

Uploaded by

Vandana AggarwalCopyright:

Available Formats

CMYK

These days the decision to buy an apparel product is, to an extent, governed by aesthetics and

visual appeal, as a result of which the quality of finish is gaining importance. In garment

manufacture, creases and crushing occur as a result of operator handling; this undesirable

deformation is at its maximum when garments are handled between sewing operations in

bundles, whether tied up tightly or piled up on trolleys or in boxes. Final pressing or finishing,

which refreshes the fabric texture after manufacture, is undertaken to smoothen away unwanted

creases and crush marks. Continuing in the series of technology level articles, the authors will

discuss different levels of technology solutions available, makes and models of machinery and

equipment available in the market. The authors would like to acknowledge the contributions

from both Veit and Macpi.

Technology for Finishing Shirts

Varsha Verma, Student of Bachelor of Fashion Technology

(Apparel Production) and Professor Prabir Jana, NIFT

M

en’s shirt finishing involves formal dress shirt may require part use garment. The hot steam produced at

combination of ironing, pressing of basic technology (in touch up high pressure and temperature

and finishing. Important factors operations) over the highest level of helps remove wrinkles easily. Macpi’s

for shirt finishing would be a completely technology, viz, tunnel finisher. ‘precise’ iron and VEIT ‘HP 2003’

pressed collar, flat-pressed shoulder and offers accurate temperature control

armhole seams, flat-pressed pockets and a Basic Level of Technology [within +/- 20C (+/- 30F)], which aids in the

smooth hem without any wrinkles. In the Steam Irons ironing of temperature sensitive fabrics

finishing process for shirts, formal and without marks.

casual, the equipment being used can be

with Vacuum Tables

The vacuum table comes generally in a

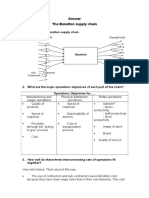

classified into the following categories Typical Work-Cycle Elements of Ironing: rectangular shape with pedal controlled

based on the level of automation: air suction. The vacuum helps in retaining

Pick up ÆPosition (vacuum on) ÆSteam

(vacuum off) ÆIron ÆVacuum (remove the garment flat and wrinkle free in shape

Basic Level

residual steam) Æ Dispose off during ironing and removing the residual

Steam Irons with Vacuum Tables

steam after ironing. A good industrial

Intermediate Level This is the oldest and popular method for vacuum board may have features like:

Buck Presses & Form Finishers finishing shirts. Steam irons are superior and selective suction, durable

Highest Level ergonomically designed to provide components, sound insulation and anti-

Tunnel Finishers effortless operation and superb finish. rust features. The vacuum table also

Steam irons may have several unique comes with certain additions like

It is important, at this stage, to distinguish features like digital temperature inclination (Macpi 17.701), electrically

between the finish of a casual shirt with control, detachable heater elements, a heated buck (Macpi 17.701), height

that of a formal dress shirt. Interestingly, hard-coated aluminum base, Teflon shoe adjustment (Veit HD 2128) with the

while a casual shirt can be finished with and silicon pad. The steam passages allow possibility to be fitted with one or two

the help of any level of technology, a unilateral flow of steam all over the swing-arms (to facilitate buck ironing).

34 StitchWorld z JULY 2007

CMYK

Vacuum tables are universal and primarily Machinery and Equipment Required for Basic Level of Technology (Steam Irons):

used for ironing woven garments. Steam Iron, Boiler assembly, Power Supply, Vacuum table, Storage rack

Upsteam table (for knitwear) and an air

Makes and Models Features and Specification of Machinery and Equipment

blow table (for gathered/frilled garments)

are other variations of the ironing table. VEIT iron HP Ironing surface: 220 x 105 mm to 200 x 115 mm to 1300 x 700 mm

2003 & VEIT table Connected Load W/ Volt/ Hz:1250/ 230/ 50-60

Ironing using vacuum tables is HD 2128,

Macpi iron Consumption: 1,8/4,65 Kw/h (according to the model)

characterized by the rubbing of two

035.90 & Macpi Iron weight : 1.25 to 3.5 Kg

surfaces (thus altering fabric texture), a table 167.701

small area of contact (thus less Temp: 130 - 2500C

productive), batch processing (thus less

productive) and lastly, the need for

skilled labour, which are the basic

disadvantages at this level.

Intermediate Level

of Technology:

Buck Presses & Form

Finishers

Work-Cycle Elements of Steam Buck

Press Operation:

Collar and cuff buck press – Veit

Load & position ÆSteam ÆBuck head close

(predetermined time) ÆVacuum ÆBuck head

open Æ Unload

BUCK PRESSES

Buck presses are primarily for shaped

garments where flat surface ironing is

not possible, like suits, dress shirts, etc., as

they give faster and superior quality

pressing and are less labour intensive.

Buck presses for dress shirts are classified

by an apparel section name, such as collar,

sleeve, front, back or shoulder which 1. Automatic adjustment of heating Air cushioning system in collar and

mat for the lower form 2. Radius cuff buck press – Macpi

describes the basic form and utility of the

with different adjustments for long

buck. A typical buck press system for a and short sleeves –Veit

dress shirt will require an assembly for

different bucks for pressing different pressing forms for cuffs to adjust adjusted very sensitively for all kinds of

parts of the garment. automatically to the shape of the lower fabrics. Features like digital temperature,

The various categories of buck presses form. Flexible heating mats guarantee an electric heated mat, adjustable cuff size,

have been discussed below. even distribution of temperature and vertical closing of the heat mats, mat to

pressure over the whole surface. There take the shape of the lower buck are

Collar and Cuff Buck Press may be a manual spraying device and a typical /unique advantages of VEIT-

This machine has been especially suction unit. The suction unit makes it Kannegieser Triostar while Macpi

designed for pressing collars and cuffs of easier to position collars and cuffs before 209.07.9109 scissor press for collar and

both blouses and shirts. It can also be pressing and optimises cooling down cuff is supplied with an Air Cushion

used as a neck press. There are adjustable after pressing. The pressure can be System and Spray Unit.

JULY 2007 z StitchWorld 35

CMYK

Front Placket Buck Press Machinery and Equipment Required for Intermediate Level of Technology (Buck

Presses): Buck presses, boiler assembly

A good example is the Veit-Kannegieser

FPD, which can combine both the fusing Makes and Models Features and Specification of Machinery and Equipment

and pressing.

Cuff Buck Press

VEIT – TrioStar, Dimensions in mm: 1100x1150x1600 approximately

For Collar and

The design of the heating plate is Macpi 209.07.9109 Working Air Pressure: 6kg/cm2

arranged to avoid temperature

fluctuations, thus guaranteeing a stable Air Consumption in l/min: 31.45

set temperature. Sensitive setting for Connected Load kW/ Volt/ Hz: 2/ 3 x 23 0/ 50-60

different materials is possible as pressure

is infinitely adjustable. The padding of the

bucks assures an ideal fusing and For Front Placket Dimensions mm: 1400x1120x1600

finishing result. The programmer ensures Buck Press Weight kg: 420

VEIT – FPD

exact adjustment of pressing time, actual Working Air Pressure bar: 6

Macpi 506.17.9120

and set temperature and suction time. Air Consumption in l/min: 1200

Suction makes it easier to position the Connected Load kW/ Volt/ Hz: 2.1/ 400/ 50

garment exactly before pressing and

guarantees an optimal cooling down after

For Sleeve Finishing

pressing. A clamp at the front of the Dimensions mm: 1350x2540x1900

Buck Press

machine can hold a number of front Weight kg: 460

plackets in order to work according to VEIT – SFD

Working Air Pressure bar: 6

Macpi 506.17.8506

the waterfall principle. It also helps to Air Consumption in l/min: 860

improve workplace design. Apart from

Connected Load kW/ Volt/ Hz: 10.6/400/50

the placket, there are also scissor presses

for front and back shirt pressing (e.g.,

Macpi 209.17.9102).

For Shirt Body

VEIT –VertoStar, Dimensions mm: 1800x1300x1810, 2345x113 5x1745

Press

Sleeve Finishing HPV2

Macpi - 288.00,

Working Air Pressure bar: 4.49-8.63

Buck Press Colmac 3-CPU

Air Consumption in l/min: 120 – 215

Connected Load kW/Volt/Hz: 12.5/3x400/50-60

This machine gives a good pressing result

for all kinds of sleeves due to its variable The above specifications are indicative and may vary from company to company. Also the working

adjustment possibilities. The design of the principle may differ, e.g., while the Veit-Kannegieser machines are actually electric heated and do not

consume steam, Macpi machines are steam heated and the utility consumptions are different.

heating plate is arranged to avoid

temperature fluctuations, thus

guaranteeing a stable set temperature.

Sensitive setting of different materials is working principle consists on the upwards

possible as the pressure is infinitely extension of the dummy after the

adjustable. For example, in the Veit pressing plates closure. In this way, the

Kannegieser SFD, the lower pressing fabric is spread perfectly on the shoulder,

buck can be moved sideways and securing a faultless result. The automatic

oscillated. This guarantees ideal pressing water spaying unit is also very innovative.

of all kinds of armhole designs without While Macpi 288.00 has revolutionary

change over. A laser pointer shows the dummies with vacuum and with

exact position of the sleeve. The extensible devices on the sides for

programmer ensures an exact adjustment different sizes, retractable sleeve supports

of pressing time, actual and set and pneumatic collar clamp, Veit

temperature and suction time. Suction Kannegieser’s oil heated, stainless steel

makes it easier to position the garment bucks help to press post cure /vapour

exactly before pressing and guarantees an phase wrinkle free processed shirts.

optimal cooling down after pressing. The shirt forms are available in different

sizes (for wide, standard and narrow

Shirt Body Press shoulders) the shirt forms adjust

The shirt body press presses the complete automatically to every side seam form.

back, yoke, shoulders and front part Productivity of up to 1900 shirts/ 8 hours

including the breast pocket. Main features can be achieved due to the overlap

are vacuum dummies, double operating operation method (simultaneous pressing

dummy for left and right, computerised and loading). Through the extensions like

control, built-in vacuum unit and loading systems and transfer systems, up

automatic water spraying unit. The to 2400 shirts/8 hours can be pressed. Yoke pressing – Macpi

36 StitchWorld z JULY 2007

CMYK

CMYK

The shirt can also be pressed also by Machinery and Equipment Required for Intermediate Level of Technology

means of a carousel. The Macpi - (Form Finisher): Form finisher, boiler assembly

506.17.9119 carousels have been

designed to grant high productivity and Makes and Models Features and Specification of Machinery

and Equipment

reduced running consumptions,

mantaining a high standard quality. Working Air Pressure bar: 6

Macpi models are 180° and 1200 VIET- 8346, 8325 Air Consumption in l/min: 12 l/cycle

carousels for small and big shapes. Macpi 389.00 Steam consumption: 40 Kg/h

Working on 2 traditional pressing Connected Load kW/ Volt/ Hz: Around 2.2/ 400/ 50 and 2.2/

machines the operator moves between 200-240/ 50-60

both machines for the shirt loading/

unloading. With the new carousel, the

shapes move and the operator stand still

with a considerable reduction of

production downtime.

Form Finishers

Form finishers achieve crease free

hem finishing and operate on

continuous cycles of steam and hot air.

It is ideal for achieving final finish of The shaped pressing 1. Air bags for wrinkle- The back pleat can be

shirts removing all tardy wrinkles. plates press the whole free pressing, finishing formed without problems

shoulder area of shoulders; 2.

Around 40-160 garments can be form Pneumatic pressure

finished in an hour. system; 3. Improved

shaping of side area

Basically, form finishers are designed to

eliminate positioning and repositioning

time in a ironing/pressing work cycle.

Work-Cycle Elements of Steam Bag Form

Finishers Without Timers

Loading and Positioning ÆSteaming

(predetermined time) ÆHot Air Blowing

(predetermined time) Æ Unloading

The main features of the form finisher

are the body, back, shoulders, sleeves and

Shirt no. 1 Is Shirt no. 1 Left front Shirt no. 1 Right front Shirt no. 1 Right front

sides locking devices. Other features are loaded part is pressed part pulled on; Shirt part is pressed; Shirt

automatic clamps adjustable in height, no. 2 Left front part no. 2 Left front part is

is pulled on pressed

automatic side tensioning – hot and cold

air blowing – turning and translating All seven photographs above courtesy Veit

front plate. The pneumatic sleeve

tensioners finish the cuffs without

leaving marks. All functions are

programmable by a Programmable Logic

Controller(PLC), but can be manually

overridden to obtain the best finish

under any conditions and with any kind

of fabric. The finisher is equipped with a

powerful hot-air fan that reduces fixing

and drying time and thus increases

productivity. A clearly arranged display

panel shows all the important functions

at a glance. Tandem processing can

increase the productivity.

Macpi 389.00 adopts a special plate

movement for the pressing of shirt front

placket, which allows getting the dummy

to a lower position, facilitating the shirt The combination of shirt body press, automatic unloading device

loading operations. and transfer system – Veit

37 StitchWorld z JULY 2007 JULY 2007 z StitchWorld 37

CMYK

Highest Level Machinery and Equipment Required for Highest Level of Technology:

Tunnel finisher & conveyer system (optional)

of Technology

Steam Tunnel Finishers Makes and Models Features and Specification of Machinery and Equipment

This is a finishing process where pressure Operating unit: Touch screen

is not applied to the garments but where Distance between hooks (optional) mm: 200-900

handling during the process is reduced. It Centrifugal fans with electronic control of variable capacity: 2

can be used mainly for casual shirts in VEIT 8346, Heat exchanger: 2

man-made fibres and blends. The VEIT 8656, Steam pressure: 7/9 BAR

garments are mounted on hangers and Macpi 533.01, Steam consumption: 75/115 Kg/h to 100/150 Kg/h

are fed under automatic control through a Macpi 533.02,

Length/length with conveyor mm: 2280Height and width mm:

Colmac CFS1200

cabinet on a motorised rail, passed 2300x1950/2750, 2280x2700/3500

though sections with superheated steam, Connection to compressed air: 4.49-8.63 BAR

and dried by air blowing. With these Installed power: 2.3-4Kw

finishers one can achieve high output Electric feeding: 3+N~50Hz 400 V

capacities (up to 3000 garments/h) with

consistent high quality.

Tunnel finishers usually are made up

of modules, which can be combined as

per requirement.

1. Pre-heating Module: this is optional, to

refinish the garments. In this process, the

garments are pre-heated with medium

temperature and air to ensure better

absorption of the steam.

2. Steam Module: The finishing process

requires that the garments are sprayed

with steam directly or, depending on the

length of the fibres, indirectly. The

required amount of steam can be

regulated infinitely from 0 up to 100%.

In each steam module, the amount of

steam and the injection can be

adjusted individually.

Tunnel finisher – Veit

3. Air Module: One or more air modules

smooth and dry the garments. In this

process the programmed quantity of air

with the corresponding temperature flows

down the module past the garments.

4. Blow-off funnel: To give the garments

the corresponding volume when leaving

the Tunnel Finisher (doll effect), the

Special plate movement – Macpi Forced circulation of steam and

garments are opened from below with the superheated air – Macpi

remaining heat to give them the

appropriate shape. Each module has its

own display with a bar chart and direct productivity. The working cycle starts managed by PLC through a pressure

input for the parameters to be behind closed doors and with stationary transmitter and electronic converter.

programmed. The programmed and the garments. The fluids (steam and The closed (batch) processing method

actual temperature are displayed in a superheated air) are introduced with a creates the most versatile finishing system,

corresponding colour combination. In Veit forced circulation in both directions, enabling the economic production of very

Model 8625, it is also possible to activate allowing the garment to be treated long or short runs on a Quick Response

interface links and program settings via effectively, reaching also the most inner basis. Furthermore through this system we

an RFID interface. fibres. A located airflow allows cooling of can obtain total control of any internal

Macpi 533.01/02 introduces a new concept, the hanger in the most critical point (see parameters: air (quantity, flow, temperature,

based on research and tests, providing picture), avoiding its deformation at high direction speed) steam (quantity and

results which demonstrate significant temperatures. The steam humidity level is quality, degree of humidity) and times,

improvement in efficiency and controlled by an electropneumatic valve giving the best quality results.

38 StitchWorld z JULY 2007

You might also like

- Ironing and Pressing EquipmentDocument39 pagesIroning and Pressing Equipmentumailsushant100% (5)

- Endeavor-Gilbarco MEADocument2 pagesEndeavor-Gilbarco MEAgilbarcomarketing123100% (3)

- Innovation in Fluid MixingDocument29 pagesInnovation in Fluid Mixingalek_a1No ratings yet

- Ch13 Case1 ADocument2 pagesCh13 Case1 AVandana Aggarwal100% (1)

- Light As WaveDocument39 pagesLight As WaveJhon Vincent C. PerezNo ratings yet

- Complete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques: More Than 30 Essential Sewing Techniques for You to MasterRating: 3.5 out of 5 stars3.5/5 (2)

- Continuous Dyeing RangeDocument48 pagesContinuous Dyeing RangeImran Malik100% (1)

- Design of Mechanical Press PDFDocument8 pagesDesign of Mechanical Press PDFArsl RanaNo ratings yet

- Spme-2 Final AssignmentDocument30 pagesSpme-2 Final AssignmentIshikaNo ratings yet

- Complete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterFrom EverandComplete Book of Sewing Techniques, New 2nd Edition: More Than 30 Essential Sewing Techniques for You to MasterRating: 4 out of 5 stars4/5 (3)

- Hvac Design of Textile IndustryDocument9 pagesHvac Design of Textile Industrymahboob100% (1)

- Powder Ehandbook Effective Powder Processing v5Document54 pagesPowder Ehandbook Effective Powder Processing v5iman zareieNo ratings yet

- Rittal SK - 3302100 PDFDocument49 pagesRittal SK - 3302100 PDFSisminto Hardjo100% (3)

- Pre Test Math7 - Q1Document3 pagesPre Test Math7 - Q1Michelle Jane Evangelista100% (2)

- ScP031 States LADocument2 pagesScP031 States LAORBeducation100% (4)

- Mayer Cie MBF 3.2 Knit MachineDocument4 pagesMayer Cie MBF 3.2 Knit Machineadali2020No ratings yet

- Shoe Machinery Unit II & IIIDocument106 pagesShoe Machinery Unit II & IIIashutosh100% (1)

- Wkze AhuDocument18 pagesWkze AhuShahrukh AnsariNo ratings yet

- Apparel Internship Orient CraftDocument87 pagesApparel Internship Orient CraftVandana AggarwalNo ratings yet

- Garmnet Fusing MachineDocument9 pagesGarmnet Fusing MachineARPITA SELOTNo ratings yet

- Cape Sewing - Industrial Sewing TechnologyDocument33 pagesCape Sewing - Industrial Sewing TechnologyMonika GadgilNo ratings yet

- Ams 224 eDocument8 pagesAms 224 eUnggul NasrullohNo ratings yet

- Spme IIDocument73 pagesSpme IIAnshuman PandeyNo ratings yet

- Ironing and Pressing Equipment: Group: Ravi Kant Singh, Ayush Gautam, Prerna Khatri, Preksha PandeyDocument64 pagesIroning and Pressing Equipment: Group: Ravi Kant Singh, Ayush Gautam, Prerna Khatri, Preksha PandeyRavi SinghNo ratings yet

- Ams Series: Ams-210EN and Ams-224EDocument21 pagesAms Series: Ams-210EN and Ams-224EAshish KumarNo ratings yet

- Form Finisher For Jackets and CoatsDocument23 pagesForm Finisher For Jackets and CoatsV B NagarajanNo ratings yet

- Finishing and PressingDocument42 pagesFinishing and PressingKushagra Jain100% (1)

- Iff 50 PDFDocument14 pagesIff 50 PDFrasdasdNo ratings yet

- Blown Film CoexDocument4 pagesBlown Film CoexTaeng SoshiNo ratings yet

- Spreading and Cutting Equipments: Spme-IiDocument23 pagesSpreading and Cutting Equipments: Spme-IiNeetek SahayNo ratings yet

- Minimizing Variations On The Yankee Dryer: Magnus Högman Valmet ABDocument55 pagesMinimizing Variations On The Yankee Dryer: Magnus Högman Valmet ABApitNo ratings yet

- BM 2500 DLDocument7 pagesBM 2500 DLanthonynr94No ratings yet

- Finishing EquipmentDocument8 pagesFinishing EquipmentDas and DasNo ratings yet

- Recent Developments in Knitting MachineryDocument11 pagesRecent Developments in Knitting MachinerypriyanshiNo ratings yet

- INTERNSHIP REPORT (United)Document18 pagesINTERNSHIP REPORT (United)Zakeesh FatimaNo ratings yet

- 10 Fusing Machines EDocument20 pages10 Fusing Machines EskgolbanNo ratings yet

- Form Finishing Equipment - TT SP Collar Cuff PressDocument19 pagesForm Finishing Equipment - TT SP Collar Cuff PressV B NagarajanNo ratings yet

- 10 VEIT Hand Ironing Technology EDocument36 pages10 VEIT Hand Ironing Technology EAlquin MabutasNo ratings yet

- Latest Development in Pressing and Finishing TechniquesDocument20 pagesLatest Development in Pressing and Finishing TechniquesVikash Kumar100% (1)

- AMS - 224EN SeriesDocument8 pagesAMS - 224EN SeriesJose Antonio Rojas BautistaNo ratings yet

- 15) Pressing & FinishingDocument16 pages15) Pressing & FinishingMd. Asiqul AlamNo ratings yet

- 2015 3 CFI KrautwurstDocument3 pages2015 3 CFI Krautwurstanil kapadiaNo ratings yet

- Agh Calculation Guide Wdp100 AlDocument11 pagesAgh Calculation Guide Wdp100 AlAnonymous nPK85ZFzNo ratings yet

- Roof-Tile Presses: Nova Ii/ WegaDocument6 pagesRoof-Tile Presses: Nova Ii/ WegaBane NikolicNo ratings yet

- The Spectacular Debut Will Lead The New Era of Weaving.: ZAX9100 Air Jet LoomDocument16 pagesThe Spectacular Debut Will Lead The New Era of Weaving.: ZAX9100 Air Jet LoomSyeda Fariya Nisar Ali67% (3)

- Pressing AdvancementDocument32 pagesPressing AdvancementSalujatirkeyNo ratings yet

- Kautex K3DDocument8 pagesKautex K3DAmitava DattaNo ratings yet

- 12-Product Catalog GirbauDocument8 pages12-Product Catalog Girbausumit11235No ratings yet

- 17 Pressing 2Document28 pages17 Pressing 2Niha Rika100% (1)

- For Sales and Service Contact Jay Heap 973-372-1559Document48 pagesFor Sales and Service Contact Jay Heap 973-372-1559mihret henokNo ratings yet

- KLIEVERIK ProductLeaflet VERTEXDocument2 pagesKLIEVERIK ProductLeaflet VERTEXgamerskamalNo ratings yet

- BM 2500 T ModifiedDocument8 pagesBM 2500 T Modifiedhungthienphu999No ratings yet

- Department of Textile Engineering Assignment: Topic Name: Recent Advancement of Modern LoomsDocument10 pagesDepartment of Textile Engineering Assignment: Topic Name: Recent Advancement of Modern LoomsNakib Ibna BasharNo ratings yet

- AE NT Series BrochureDocument6 pagesAE NT Series Brochureramkisnak100% (1)

- Bekum Industrial Packagung ENDocument8 pagesBekum Industrial Packagung ENخبراء التصنيع الدوائي-اليمنNo ratings yet

- Sweater Manufacturing ProcessDocument23 pagesSweater Manufacturing ProcessManik Karmakar0% (1)

- Definition of SublimationDocument2 pagesDefinition of SublimationShivalingam MeiyyappanNo ratings yet

- MF 7800Document4 pagesMF 7800Md Sahadat UllahNo ratings yet

- Trouser Pressing Machine Brands:: Fabcar Upto 380V Upto 200Kg 15Kg/Hr 3 Phase 50/60 HZ LCD ScreenDocument18 pagesTrouser Pressing Machine Brands:: Fabcar Upto 380V Upto 200Kg 15Kg/Hr 3 Phase 50/60 HZ LCD ScreenKhushi GuptaNo ratings yet

- ProfilDocument18 pagesProfilAnonymous 6EW2MsFbkNo ratings yet

- Garments KnitDocument12 pagesGarments KnitArafat SaleheenNo ratings yet

- Recent Development of Modern Spinning and WeavingDocument20 pagesRecent Development of Modern Spinning and WeavingsuganNo ratings yet

- Finishing Line Info SoaptecDocument2 pagesFinishing Line Info SoaptecangleelamNo ratings yet

- Brochure Presses UKDocument8 pagesBrochure Presses UKEng.ibrahim FathyNo ratings yet

- ShirtsDocument18 pagesShirtsAkash SinghNo ratings yet

- Inpak-Catalogue-the GGHFFDocument12 pagesInpak-Catalogue-the GGHFFALAZAR MICHAELNo ratings yet

- Illustrated Catalogue of Cotton MachineryFrom EverandIllustrated Catalogue of Cotton MachineryNo ratings yet

- Multifunction Peripherals for PCs: Technology, Troubleshooting and RepairFrom EverandMultifunction Peripherals for PCs: Technology, Troubleshooting and RepairNo ratings yet

- FashionforGood Polybags in The Fashion Industry Whitepaper-1Document43 pagesFashionforGood Polybags in The Fashion Industry Whitepaper-1Vandana AggarwalNo ratings yet

- Consumer Perception and Brand Preference For Premium BrandedDocument66 pagesConsumer Perception and Brand Preference For Premium BrandedNagu Yk100% (2)

- Sourcing JournalDocument2 pagesSourcing JournalVandana AggarwalNo ratings yet

- Scopus 1Document9 pagesScopus 1Sarath MohanNo ratings yet

- 789-Article Text-1365-1-10-20171225Document7 pages789-Article Text-1365-1-10-20171225nishaNo ratings yet

- FashionforGood Polybags in The Fashion Industry Whitepaper-1Document43 pagesFashionforGood Polybags in The Fashion Industry Whitepaper-1Vandana AggarwalNo ratings yet

- OBDocument15 pagesOBVandana AggarwalNo ratings yet

- kbk-900 Eng PDFDocument2 pageskbk-900 Eng PDFVandana Aggarwal100% (1)

- ArrowDocument72 pagesArrowVandana AggarwalNo ratings yet

- "Pantaloons Fashion & Retail LTDDocument45 pages"Pantaloons Fashion & Retail LTDSankeitha SinhaNo ratings yet

- Retail TerminologiesDocument3 pagesRetail TerminologiesVandana Aggarwal100% (1)

- Internship at Alok Industries LTD Garments Division, Saily, 2010Document98 pagesInternship at Alok Industries LTD Garments Division, Saily, 2010Vandana AggarwalNo ratings yet

- Apparel Internship Orient CraftDocument81 pagesApparel Internship Orient CraftVandana AggarwalNo ratings yet

- Block-2 MS-04 Unit-2 PDFDocument21 pagesBlock-2 MS-04 Unit-2 PDFmm2014ttNo ratings yet

- Daily News Simplified - DNS Notes: SL. NO. Topics The Hindu Page NoDocument7 pagesDaily News Simplified - DNS Notes: SL. NO. Topics The Hindu Page NoSethuNo ratings yet

- 03 Transfer of HeatDocument34 pages03 Transfer of Heatmahsan abbasNo ratings yet

- Differentiation Revision (2020) : Prepared by T. PondoDocument7 pagesDifferentiation Revision (2020) : Prepared by T. PondoCourteney LungileNo ratings yet

- Presostato PM1Document30 pagesPresostato PM1tunradotNo ratings yet

- Zacharaki - A Digital SubtractionDocument14 pagesZacharaki - A Digital Subtractiondorasani99No ratings yet

- Revision of Plane Wave Propagation PDFDocument31 pagesRevision of Plane Wave Propagation PDFge120120No ratings yet

- Length and Time-NotesDocument6 pagesLength and Time-NotesBalasbramani ThangavelNo ratings yet

- A Numerical Study of Some Aspects of The Spherical Charge Cratering TheoryDocument15 pagesA Numerical Study of Some Aspects of The Spherical Charge Cratering TheoryÁALNo ratings yet

- PervaporationDocument18 pagesPervaporationKaustubh Dhabale50% (2)

- Emissivity Manuscript Revision (Final)Document28 pagesEmissivity Manuscript Revision (Final)Praful PatilNo ratings yet

- PQP 01 Puc II Maths 2024Document8 pagesPQP 01 Puc II Maths 2024Anagha BLNo ratings yet

- Enescu M. (Balas)Document6 pagesEnescu M. (Balas)FarahatNo ratings yet

- Interaction of Charged Particles With Matter: Venika GanjirDocument22 pagesInteraction of Charged Particles With Matter: Venika GanjirvenikaNo ratings yet

- Criminal Law and Jurisprudence, Law Enforcement Administration, CriminalisticDocument211 pagesCriminal Law and Jurisprudence, Law Enforcement Administration, Criminalisticsacli.valentin mjNo ratings yet

- PMR Questions.: Mathematics: Directed NumbersDocument4 pagesPMR Questions.: Mathematics: Directed NumbersTham SuperNo ratings yet

- Extending Our Assessments: Homework and TestingDocument22 pagesExtending Our Assessments: Homework and TestingRyan HoganNo ratings yet

- CZ1102 Computing & Problem Solving Lecture 7Document28 pagesCZ1102 Computing & Problem Solving Lecture 7Charmaine ChuNo ratings yet

- Huang 2018Document22 pagesHuang 2018Bendol GalihNo ratings yet

- L GCE Maths SpecDocument130 pagesL GCE Maths SpecgaryngaraNo ratings yet

- Mud 1Document5 pagesMud 1MohamedElAbbasyNo ratings yet

- Swiss Innovation in CMOS Image Sensors and CMOS CamerasDocument52 pagesSwiss Innovation in CMOS Image Sensors and CMOS CamerasTin Sing HewNo ratings yet

- Rutin Persamaan Diferensial Parsial MATLABDocument9 pagesRutin Persamaan Diferensial Parsial MATLABAlamsyahNo ratings yet

- 1,4-Butanediol: From Formaldehyde + AcetyleneDocument14 pages1,4-Butanediol: From Formaldehyde + AcetyleneRisa HashimotoNo ratings yet

- Spidi 2017 CatalogueDocument210 pagesSpidi 2017 CatalogueRoman GetmanNo ratings yet

- Questions and Speculation On Learning and Cohomology, Version 3Document136 pagesQuestions and Speculation On Learning and Cohomology, Version 3Hrittik RoyNo ratings yet