Professional Documents

Culture Documents

Horizontal Flare Knock Out Drum Sizing (FPS Units)

Horizontal Flare Knock Out Drum Sizing (FPS Units)

Uploaded by

Haseeb KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Horizontal Flare Knock Out Drum Sizing (FPS Units)

Horizontal Flare Knock Out Drum Sizing (FPS Units)

Uploaded by

Haseeb KhanCopyright:

Available Formats

Horizontal Flare Knock Out Drum Sizing (FPS

Units)

Standard Calculation WS-PR-CA-012, Rev. 1, "Re-Issued for Use", 2-Sep-02

Validated: Verification of WS-PR-CA-012, Rev. 1, "Re-Issued for Use", 2-Sep-02 Autocalc

CLIENT PROJ No

PROJECT CALC No

SUBJECT SHEET OF

REVISION DATE BY CHECKED REVISION DATE BY CHECKED REVISION DATE BY CHECKED

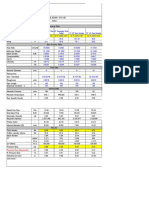

Input Data

Liquid Mass Rate = 31000 lb/hr Storage for Misc. Liquids = 67 ft3

Liquid Density = 31 lb/ft 3

Release Time (Liquid Holdup) = 30 min

Vapour Mass Rate = 169000 lb/hr

Vapour Density = 0.18 lb/ft3

Vapour Viscosity = 0.01 cP

Particle Diameter = 300 micron

Vessel Diameter = 8 ft

Vessel Length = 19 ft

L/D Ratio = 2.4

Vapour Passes = 1

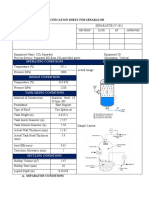

Calculated Parameters

Horizontal Vessel Rating Vertical Vessel Rating

Liquid Flow Rate = 0.28 ft /s

3

Required Cross Sectional Area = 111 ft2

Vapour Flow Rate (Rv) = 261 ft /s

3

Liquid Volume = 567 ft3

Gas Disengagment Length = 11.9 ft

Particle Diameter = 0.00098 ft

C(Re)^2 = 5025 Minimum Diameter Required = 11.9 ft

Drag Coefficient ( C ) = 1.3 Minimum Length = 15.0 ft

Dropout Velocity (Uc) = 2.34 ft/s

Drag Coefficient to be entered using

Areas Occupied by Gas, Liquids and Slops Figure 16 API 521, 5th. Ed., January 2007

TOTAL Vessel CSA (At) = 50.3 ft2

- Misc. Slops Fluids (AL1) = 3.53 ft2

- Inlet Liquids (AL2) = 26.32 ft2

- Gas Flow CSA (AV) = 20.42 ft2

Heights For Gas Flow Area, Liquid and Slops

TOTAL Vessel Height (ht) = 8 ft

- Liquid + Slops Height (hL1+L2) = 4.6 ft Total Liquid A

- Gas Flow Height (hv) = 3.4 ft Vessel Radiu

Area Base on

Vapour Space Adequacy Check Area Diff

Liquid Dropout Time (q) = 1.46 s

Vapour Velocity (Uv) = 12.8 ft/s

Minimum Drum Length (Lmin) = 18.59 ft

Horizontal Flare Knock Out Drum Sizing (SI

Units)

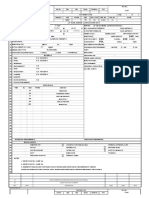

Standard Calculation WS-PR-CA-012, Rev. 1, "Re-Issued for Use", 2-Sep-02

Validated: Verification of WS-PR-CA-012, Rev. 1, "Re-Issued for Use", 2-Sep-02

CLIENT PROJ No

PROJECT CALC No

SUBJECT SHEET OF

REVISION DATE BY CHECKED REVISION DATE BY CHECKED REVISION DATE BY CHECKED

Input Data

Liquid Mass Rate = 14061 kg/hr Storage for Misc. Liquids = 1.89 m3

Liquid Density = 496.6 kg/m 3

Release Time (Liquid Holdup) = 30 min

Vapour Mass Rate = 76680 kg/hr

Vapour Density = 2.9 kg/m3

Vapour Viscosity = 0.01 cP

Particle Diameter = 10 micron

Vessel Diameter = 2.88 m

Vessel Length = 5.79 m

L/D Ratio = 2.0

Vapour Passes = 1

Calculated Parameters

Horizontal Vessel Rating Vertical Vessel Rating

Liquid Flow Rate = 0.01 m3/s Required Cross Sectional Area = 56.4 m2

Vapour Flow Rate (Rv) = 7.34 m /s3

Liquid Volume = 16 m3

Gas Disengagment Length = 8.5 m

Particle Diameter = 0.00001 m

C(Re)^2 = 0 Minimum Diameter Required = 8.5 m

Drag Coefficient ( C ) = 1.3 Minimum Length = 7.3 m

Dropout Velocity (Uc) = 0.13 m/s

Drag Coefficient to be entered using

Areas Occupied by Gas, Liquids and Slops

Figure 16 API 521, 5th. Ed., January 2007

TOTAL Vessel CSA (At) = 6.51 m2

- Misc. Slops Fluids (AL1) = 0.33 m2

- Inlet Liquids (AL2) = 2.45 m2

- Gas Flow CSA (AV) = 3.74 m2

Heights For Gas Flow Area, Liquid and Slops

TOTAL Vessel Height (ht) = 2.88 m

- Liquid + Slops Height (hL1+L2) = 1.27 m

- Gas Flow Height (hv) = 1.61 m

Vapour Space Adequacy Check

Liquid Dropout Time (q) = 12.35 s

Vapour Velocity (Uv) = 2.0 ft/s

Minimum Drum Length (Lmin) = 24.23 m

You might also like

- Line Sizing ReportDocument7 pagesLine Sizing Reportmichael chiwuezeNo ratings yet

- Flare Ko Drum SizingDocument5 pagesFlare Ko Drum SizingSujith Sekar100% (2)

- Vertical Knock Out Drum With Wire Mesh For NDocument1 pageVertical Knock Out Drum With Wire Mesh For Nteegala_1967% (3)

- Equipment Sizing Criteria TDEDocument32 pagesEquipment Sizing Criteria TDEEngr. Anees Ahmad100% (1)

- Master - Three Phase Horizontal Separator Rev 0Document6 pagesMaster - Three Phase Horizontal Separator Rev 0Naeem HussainNo ratings yet

- JACOBS Flare KO Drum SizingDocument35 pagesJACOBS Flare KO Drum SizingVan Le50% (2)

- Vessel Sizing SpreadsheetDocument28 pagesVessel Sizing SpreadsheetEmamokeNo ratings yet

- Horizontal Three Phase Separator vap-IPDocument5 pagesHorizontal Three Phase Separator vap-IPasifhameed1100% (8)

- LP Flare Network Calculation Rev - E0Document18 pagesLP Flare Network Calculation Rev - E0Rexx Mexx100% (3)

- Calculate The Relieving Temperature & Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP MethodDocument3 pagesCalculate The Relieving Temperature & Latent Heat of Vaporization For Fire Case PSV Sizing by Shell DEP Methodrohitkush80% (5)

- Demister SizingDocument3 pagesDemister SizingD K SNo ratings yet

- Calculation Sheet Flare Knock Out Drum: Sheet No: Job No: REV Date Made by Chkd. by Appr. by DescriptionDocument2 pagesCalculation Sheet Flare Knock Out Drum: Sheet No: Job No: REV Date Made by Chkd. by Appr. by Descriptionsanjay100% (4)

- Vertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFDocument4 pagesVertical Two-Phase Separator Sizing (SI Units) : Client Proj No Project Calc No Subject Sheet OFJhonnatan Fredy Gomez DominguezNo ratings yet

- 2 Phase Vertical Separator Sizing Calculation-AUHDocument26 pages2 Phase Vertical Separator Sizing Calculation-AUHMike Dukas100% (1)

- Gas-Liquid Vertical Separator PDFDocument2 pagesGas-Liquid Vertical Separator PDFRathish RagooNo ratings yet

- Scenarios in PSV Sizing During Gas BlowbyDocument94 pagesScenarios in PSV Sizing During Gas BlowbyMiquel Àngel Artiol FerroNo ratings yet

- Line Sizing Philosophy PDFDocument21 pagesLine Sizing Philosophy PDFmohammadhadiNo ratings yet

- PSV Sizing Psv-414 UpdateDocument7 pagesPSV Sizing Psv-414 UpdateBui Khoi NguyenNo ratings yet

- Vertical 2 Phase Separator SizingDocument5 pagesVertical 2 Phase Separator SizingJermaine Heath100% (1)

- Liquid Hold Up Change and Slug Catcher SizingDocument2 pagesLiquid Hold Up Change and Slug Catcher SizingEbby Onyekwe100% (1)

- Spreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2Document24 pagesSpreadsheet - Gas Blanketed Tanks - Outbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- Column PSV SizingDocument10 pagesColumn PSV SizingbalajikrishnanNo ratings yet

- Gas Line Size-1Document12 pagesGas Line Size-1svnaik14No ratings yet

- Gas Line Sizing - Api 14E Input Description Unit: General DataDocument13 pagesGas Line Sizing - Api 14E Input Description Unit: General DataSamuel Onyewuenyi100% (1)

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinNo ratings yet

- Knock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet NozzleDocument11 pagesKnock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet Nozzlejazeel alaviNo ratings yet

- Guide For Vessel Sizing PDFDocument24 pagesGuide For Vessel Sizing PDFManish542No ratings yet

- Thermosyphon Reboiler HydraulicsDocument2 pagesThermosyphon Reboiler HydraulicsMichael HaiseNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- Knock Out KO Drum SizingDocument10 pagesKnock Out KO Drum SizingJermaine HeathNo ratings yet

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias Elias100% (1)

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTORONo ratings yet

- API-521 Flare KOD Design and Even More - Part 2.desbloqueadoDocument6 pagesAPI-521 Flare KOD Design and Even More - Part 2.desbloqueadoFernando Mendez100% (1)

- 2 Phase Horizontal Flow Line Sizing Cal-AUHDocument15 pages2 Phase Horizontal Flow Line Sizing Cal-AUHMike DukasNo ratings yet

- Datasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsDocument1 pageDatasheet For PACE Mist Eliminator/s (Demister) : Existing DetailsAnonymous LLLK3pq50% (2)

- Two Phase Separator SizingDocument5 pagesTwo Phase Separator SizingNoman Abu-FarhaNo ratings yet

- Three Phase Separator Sizing - Submerged WierDocument2 pagesThree Phase Separator Sizing - Submerged WierSaeid Rahimi MofradNo ratings yet

- FlareTot - Total Flare AnalysisDocument8 pagesFlareTot - Total Flare AnalysisArjun KapoorNo ratings yet

- Limpet Coil CalculationDocument1 pageLimpet Coil Calculationkirandas_mullassery100% (1)

- Horizontal Separator - V1.12 ERG PB 1Document6 pagesHorizontal Separator - V1.12 ERG PB 1Anonymous AtAGVssJNo ratings yet

- Separator (1) Sizing Spread SheetsDocument21 pagesSeparator (1) Sizing Spread SheetsSteve WanNo ratings yet

- Line Sizing and Pressure Drop PhilosophyDocument30 pagesLine Sizing and Pressure Drop PhilosophyBelos SahajiNo ratings yet

- Colum Specification SheetDocument6 pagesColum Specification SheetEddy RainNo ratings yet

- 3PHASE Gas Separator - V2105 - 4.7x16 - For - OriginalDocument44 pages3PHASE Gas Separator - V2105 - 4.7x16 - For - Originalvgogulakrishnan100% (1)

- PSV Sizing For Tube RuptureDocument25 pagesPSV Sizing For Tube Ruptureanghel_florin82No ratings yet

- EIND 3184 15 Liquid Flash Vessel SizingDocument20 pagesEIND 3184 15 Liquid Flash Vessel Sizingzamijaka100% (1)

- No Yes No Yes No Yes No Yes No Yes No YesDocument8 pagesNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnNo ratings yet

- Specification Sheet For Separator: Operating Conditions SketchDocument12 pagesSpecification Sheet For Separator: Operating Conditions SketchAngelikaOdimer100% (1)

- Petronas Design Manual: Column SizingDocument10 pagesPetronas Design Manual: Column SizingHazizi AkmarNo ratings yet

- Flare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachDocument8 pagesFlare Stack Calculation Sheet: Brzustowski's and Sommer's ApproachaltruismNo ratings yet

- Thermosyphon Reboiler (Horizontal) GPSADocument6 pagesThermosyphon Reboiler (Horizontal) GPSAsyamsudin2006No ratings yet

- 3phase Separator Size 2010 VerADocument24 pages3phase Separator Size 2010 VerACristina BarbulescuNo ratings yet

- Horizontal KO Pot V1.2Document6 pagesHorizontal KO Pot V1.2hk168No ratings yet

- DJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDocument6 pagesDJM-MBA-PCS-CA-008 Low Temperature Separator REV-BDIANTORONo ratings yet

- Horizontal KO PotDocument4 pagesHorizontal KO Pothk168No ratings yet

- DJM MBA PCS CA 011 de Butanizer Accumulator REV 1Document6 pagesDJM MBA PCS CA 011 de Butanizer Accumulator REV 1DIANTORONo ratings yet

- DJM-MBA-PCS-CA-005 De-Etanizer Accumulator REV-1Document6 pagesDJM-MBA-PCS-CA-005 De-Etanizer Accumulator REV-1DIANTORONo ratings yet

- New Gravity Flow CalculationDocument4 pagesNew Gravity Flow CalculationShiv GandhiNo ratings yet

- Vent Tip Sizing CalcDocument6 pagesVent Tip Sizing CalcPeddy Nesa0% (1)

- Document From SuperjimmyDocument4 pagesDocument From SuperjimmyNoverian Ruzqia SyardiNo ratings yet

- A. Mathematics: Civil Engineering Application ProblemDocument2 pagesA. Mathematics: Civil Engineering Application ProblemJULIE JAMERO DELIZO, JRNo ratings yet

- Mixing Studies of Non-Newtonian Uids in An Anchor Agitated VesselDocument10 pagesMixing Studies of Non-Newtonian Uids in An Anchor Agitated VesselJose Davi Rodrigues Silva UFC100% (1)

- Latest Copy of Class 8 Physics Question Bank 1Document101 pagesLatest Copy of Class 8 Physics Question Bank 1KAMLESH PATIDARNo ratings yet

- Design Process en 1993-1!3!2006Document22 pagesDesign Process en 1993-1!3!2006Bun KunNo ratings yet

- RC-I Chapter 1 PDFDocument14 pagesRC-I Chapter 1 PDFWendimu TolessaNo ratings yet

- Foundation Design Dd+9 Tower Partially SubmergedDocument21 pagesFoundation Design Dd+9 Tower Partially SubmergedZeenat AraNo ratings yet

- Units of Energy Transfer of Heat: This Is Not For SaleDocument8 pagesUnits of Energy Transfer of Heat: This Is Not For SaleLannil CalizarNo ratings yet

- Module 2 Materials For Prestressed ConcreteDocument17 pagesModule 2 Materials For Prestressed ConcreteJay BarotNo ratings yet

- Physics Depth StudyDocument11 pagesPhysics Depth StudySyed Arafat KadriNo ratings yet

- 100L Course Outlines by Derudite AcademyDocument4 pages100L Course Outlines by Derudite Academyshinebassey119No ratings yet

- Caluse 6.2.8 ValidationDocument5 pagesCaluse 6.2.8 ValidationGicuNo ratings yet

- W6-1-Bashir - Shear StrengthDocument41 pagesW6-1-Bashir - Shear Strength木辛耳总No ratings yet

- Counterfort Retaining WallDocument1 pageCounterfort Retaining WallAjay ThouraniNo ratings yet

- 02 1 001 PDFDocument5 pages02 1 001 PDFcmkohNo ratings yet

- EPF4802 - Chapter 5 (Part 1) Utilities and Energy Efficient Design - Video - NotesDocument14 pagesEPF4802 - Chapter 5 (Part 1) Utilities and Energy Efficient Design - Video - NoteshidayantiemNo ratings yet

- Duplomatic ValveDocument4 pagesDuplomatic ValveHBracing1No ratings yet

- Me231 Topics 2Document285 pagesMe231 Topics 2jamesphilip.esagaNo ratings yet

- Skull Crusher-5 Class XI JEE (Adv) PhysicsDocument5 pagesSkull Crusher-5 Class XI JEE (Adv) PhysicsSaurabh KatariyaNo ratings yet

- Fracture Mechanics Approach To Pressure Vessel Failures PDFDocument8 pagesFracture Mechanics Approach To Pressure Vessel Failures PDFsandeeppandey0789No ratings yet

- Guth Seat Valves: A Good DecisionDocument4 pagesGuth Seat Valves: A Good DecisionВалентин КовальчукNo ratings yet

- ME1100 Class Notes July 2013Document88 pagesME1100 Class Notes July 2013VishalNo ratings yet

- Code HistoryDocument6 pagesCode HistoryTri SeptaNo ratings yet

- Chemical3 8Document51 pagesChemical3 8Shambhu Singh RathoreNo ratings yet

- Technical Data ISD 180Q / OSA 180 Ducted Split System Air ConditionerDocument4 pagesTechnical Data ISD 180Q / OSA 180 Ducted Split System Air ConditionerFilipNo ratings yet

- Evaluation of Interaction Properties of GeosyntheticsDocument2 pagesEvaluation of Interaction Properties of GeosyntheticsRajesh DwivediNo ratings yet

- PP Lab ReportDocument23 pagesPP Lab ReportMuhammad Amir ShahzadNo ratings yet

- Hydraulic Turbines QuestionsDocument2 pagesHydraulic Turbines QuestionsMohamad MousaNo ratings yet

- 9A03501 Thermal Engineering - IIDocument1 page9A03501 Thermal Engineering - IIsivabharathamurthyNo ratings yet

- Duet CE-3301 Geotechnical Engineering - IDocument37 pagesDuet CE-3301 Geotechnical Engineering - IShekh Muhsen Uddin AhmedNo ratings yet

- 03 3 e (Physics)Document48 pages03 3 e (Physics)mrexample1017No ratings yet