Professional Documents

Culture Documents

BS 1881-129-1992

Uploaded by

Thai Hai Ly0 ratings0% found this document useful (0 votes)

46 views10 pagesBS

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentBS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views10 pagesBS 1881-129-1992

Uploaded by

Thai Hai LyBS

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 10

BRITISH STANDARD

Testing concrete —

Part 129: Method for determination of

density of partially compacted semi-dry

%

ado /ua aa

fresh concrete

BS, 51D.

1

6 |

[NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW

BS 1881-129:

1992

BS 1881-129:1992

——————_—_—____

Committees responsible for this

British Standard

‘The preparation of this British Standard was entrusted by the Technical Sector

‘Board for Building and Civil Engineering (B/.) to Technical Committee CAB/4,

‘upon which the following bodies were represented:

‘Association of Lightweight Aggrogate Manufacturers

‘Association of Metropolitan Authorities

Association of Quality Pulverised Fuel Ash Suppliers

British Aggregate Construction Materials Industries

British Cement Aseociation

British Civil Engineering Test Equipment Manufacturers Association

British Precast Concrete Federation

British Ready Mixed Concrete Association

Building Employers Confederation

Cement Admixtures Association

(Cementitious Slag Makers Association

Concrete Society

County Surveyars’ Society

Department of the Environment (Building Research Establishment;

Department ofthe Environment (Property Services Agency)

Department of Transport

Department of Transport (Transport and Road Research Laboratory)

Blectricity Industry in United Kingdom

Federation of Civil Engineering Contractors

Institute of Concrete Technology

Institution of Civil Engineers

Institution of Highways and Transportation

Institution of Structural Engineers

Institution of Water and Environmental Management

‘National House-building Council

Sand and Gravel Association

Society of Chemical Industry

‘The following bodies were also represented in the drafting of the standard,

through subcommittees and panele:

‘Association of Consulting Scientists

Department of Trade and Industry (National Measurement Accreditation Service)

funder

Seeman Bewdsed” Amendments issued since publication

Amd.No. | Date ‘Comments

onst 12-1986

‘The following BSI references

‘ete tothe work on this

‘Randard:

(Committee reference CABV4

Draft for comment 91/13264 DC

ISBN 0 680 20442 1

BS 1881-129:1992

Contents

Page

‘Committees responsible Inside front cover

Foreword i

1 Scope 1

2 Definitions 1

3 Apparatus 1

4. Calibration ofthe container 1

5 Sampling 2

Preparing the sample for test 3

7 Procedure 3

8 Calculation and expression of results 3

9 Precision 4

10 _Test report 4

Figure 1— ‘Typical tamper for partially compacted semi-dry fresh

concrete density test

‘Table 1 — Dimensions of container

‘Table 2— Precision data for density of partially compacted semi-dry

fresh concrete 4

Publication(e) referred to Taside back cover

BS 1881-129:1992

Foreword

‘This Part of BS 1881 has been prepared under the direction of the Technical

‘Sector Board for Building and Civil Engineering. It describes a method of test for

determining the density of partially compacted semi-dry fresh concrete, primarily

to establish the correct yield when this type of concrete is produced by a ready

‘mixed concrete plant for applications such as kerb backing and blinding.

‘The density of compacted fresh concrete can be measured by the method

described in BS 1861-107 but that method is not applicable to concrete that

‘cannot be compacted by vibration alone. Semi-dry concrete has a very low

workability, with a slump gonerally not more than 5 mm when measured in

accordance with BS 1881-102. The method developed for this type of concrete

relics on compacting it by tamping, as used in the method for making no-fines

conerete test cubes described in BS 1881-113.

‘Tests in accordance with this Part of BS 1881 are not applicable to lean concrete

for road bases and other fully compacted very low workability concretes which

hhave their own methods of density measurement included in their specifications,

‘0g, the Department of Transport Specification for Highway Works in respect of

‘cement bound material for roadbase and eub-baso.

‘A British Standard does not purport to include all the necessary provisions of a

‘contract. Users of British Standards are responsible for their correct application.

.ce with a British Stasidard does not of itself confer immunity

legal obligations.

‘Summary of pages

This document comprises a front cover, an inside front cover, pages i and ii,

pages 1 to 4, an inside back caver and a back cover.

‘This standard has been updated (eee copyright date) and may have had

‘amendments incorporated. This will be indicated in the amendment table on

the inside front cover.

‘ost 12-1998

BS 1881-129:1992

1 Scope

‘This Part of BS 1881 describes a method for

determining the density of partially compacted

semi-dry fresh concrete. The method applies to plain

‘and air-entrained concrete, made with aggregates

‘Table 1— Dimensions of container

having a nominal maximum size of 40

but not to conerete with a slump of more than 5 mm

when tested in accordance with BS 1881-102.

2 Definitions

For the purposes of this Part of BS 1881 the

definitions given in BS 6928-1 and BS 1881-101

apply, together with the following.

2a

density

‘mass of a quantity of partially compacted semi-dry

fresh concrete divided by ite volume, expressed

in kg/m’

22

‘semi-dry concrete

very low workability concrete with a low water

content and of a consistence producing a slump of

less than 5 mm, which is too low to be measured

with precision by the tost described in BS 1881-102

3 Apparatus

3.1 Scales or balonce, capable of weighing the

container (8.2) to1an accuracy of 19 g or better at

calibration and to an accuracy of 25 g or better

during the measurement of density. Suitable

‘capacities are likely to be 20 kg for the calibration

‘and 60 kg for the measurement of density.

‘The balance shall be calibrated on initial

commissioning and at least annually thereafter

‘using weights of which the accuracy can be traced to

the national standard of mass. The balance shall be

recalibrated after relocation or disturbance. A

certificate stating the accuracy shall be obtained

from the organization carrying out these

calibrations.

3.2 Container, watertight rigid eylinder of the

dimensions specified in Table 1, made of metal not

readily attacked by cement paste, having a smooth

internal face, the rim machined to a plane surface,

the rim and base at right angles to the axis, and

provided with handles.

Nowalaal | Inside | Toside | Minimam | Nominal

‘capacity |alameter| belght | thicknes | Interaa

‘ctmecat | radius

between

ralland

ork are

oor 2000 {320.0 |40 20.0

+15 [216

8.8 Scoop, as described in 3.1 of BS 1881-101:1983.

8.4 Tamper, made of metal and of robust

construction comprising arammer and a guide tube,

secured to the base of which is a flat metal bearing

plate. (See Figure 1 for typical construction) The

rammer shall have a mass of 2 500 + 25 g and the

complete tamper of 7 700+ 100 g. The rammer shall

be able to fall 300 + 8 mm. The bearing plate shall

be cireular of diameter 197.0 1.5 mm and

thickness not loss than 12 mm.

NOTE _A suitable apparatus is the 2.5 rammer for the

standard compaction text specfod in BS 1977-4, made of i

‘Meal and having a circular mild sto! bearing plate welded

‘centrally tothe botiom of the ide tube. A stnilar, but not

‘gatiel, spperatus that can als be ced is described

inBS 1881113.

3.5 Straightedge, made of steel, not less

then 300 mm in length and not less than 4 mm in

thickness.

3.6 Glass pipette, (if required), of known volume.

3.7 Sampling tray, minimum

dimensions 900 mm x 900 mm x 50 mm deep of

rigid construction and made from a non-absorbent

‘material not readily attacked by cement paste.

8.8 Square mouthed shovel, size 2 in accordance

with BS 3388,

8.9 Thermometer, 100 mm immersion, accurate to.at

least 0.5 °C and complying with BS 693 or BS 1704.

4 Calibration of the container

‘Weigh the empty container, place it on a horizontal

surface and fill it with water at a temperature

of 205 Ceo that no meniscus is above the rim. If

necessary, remove by means ofa pipette sulficient

known volume of water to allow the container to be

liked and placed on the balance platform without

loss of water. Weigh the container and water. Add

the mass of any removed water tothe mass of water

remaining in the container.

Calculate the capacity of ch cuniaines, ¥3 by

dividing by 1 000 kg/m? the mass of water, to the

nearest 10 g, required to fill the container. Express

the capacity to the nearest 0.00001 m°. Calibrate

‘the container before intial use and at least annually

thereafter.

BS 1881-129:1992

———————

5 Sampling

Obtain the sample of fresh concrete by the

procedure described in BS 1881-101 or BS 1881-125.

Keep the sample covered to minimize evaporation,

‘Commence the determination of the density as soon

‘as possible, and not more than 30 min, after

‘sampling.

W115 diaxt2ain,

[NOTE 2. Tha ign ha ben found safety, but wera drag may be wee pried Ya

| OT A iene re en mines

| thermal earner ae

Figure 1 — Typical tamper for partially compacted semi-dry fresh concrete density test

‘OBST 12-1998

BS 1881-129:1992

iss

6 Preparing the sample for test

CAUTION. When cement mized with water, alkalis rlenod.

‘Take preentions to aver ry cement entering the eyes, mouth

{ind nose when misiegcoerets revert sin contact with wet.

ene or concrete by wering table prtive doting It

‘ament or coneret eter the ey, iumediataly wash tut

‘evoughly with clean wetarand sce media restnen without

{lay Wesh we conerte ff the sin immediatly

6.1 Empty the sample from the sample container(s)

onto the sampling tray. Ensure that no more than a”

light covering of slurry isleft adhering tothe sample

container‘).

6.2 Thoroughly mix the sample by shovelling it to

form a cone on the sampling tray and turning this

over with the shovel to form a new cone, the

‘operation being carried out three times. When

forming the cones, deposit each shovelful of the

material on the apex of the cone so that the portions

which slide down the sides are distributed as evenly

as possible and so that the centre of the cone is not

displaced. Flatten the third cone by repeated

vertical insertion of the shovel across the apex of the

cone, lifting the shovel clear of the concrete after

each insertion. Engure that the flattened heap is

uniform in thickness and diameter.

6.8 Divide the sample into four portions by

‘quartering the flattened heap along two diameters

intersecting at right angles. Replace one pair of

diagonally opposite quarters into the sample

‘ontainer(s) and shovel the remainder into a heap

and remix as before. This material will form the first

test portion. Retain the second test portion in the

sample container(s) until required for testing. Then.

‘empty it onto the sampling tray and remix it as

described in 62.

7 Procedure

"2.1 Use the scoop to place carefully a layer of

concrete about 110 mm deep into the container from

the first test portion. Level the surface of the

concrete with gloved fingers, taking care not to

compact it. Carefully place the circular bearing

plate of the tamper on top of the concrete with the

‘axis of the tamper vertical. Raise the rammer to the

‘top of its travel so that it just touches the top of the

sleeve without slack. Allow the rammer to drop

freely. Complete 16 such blows on the bottom layer

of concrete.

11.2 Repeat the procedure described in 7.1 for a

second and third layer. For the fourth layer, overil

the container and slightly heap the concrete

towards the centre and apply only five blows ofthe

rammer. Remove the tamper and add or remove

sufficient concrete auch that after a further 10 blows

the surcharge of concrete is between 6 mm

and 10 mm above the rim of the container. Ifthe

surcharge is not between 6 mm and 10 mm after

completion of compaction then repeat the tet.

17. With the straightedge, remove the surplus

conerete using a sawing action about 5 mm above

‘the rim. Remove large aggregate particles

protruding above the rim individually. Then strike

tthe concrete off level with the rim and Gill any holes

with fines from the surplus concrete, to obtain a

reasonably fiat and level surface. Care should be

taken net to overcompact the concrete by applying

tundue pressure when finishing the eurface.

Weigh the filed container, subtract the mass of the

empty container and record the mass of concrete in

the container, m, to the nearest 25 g.

714 Empty and clean the container and then repeat

the procedures described in 7.1 to7.8 on the second

test portion.

8 Calculation and expression of results

8.1 Calculation of density

Calculate the density, D, (in ke/m®) for each test

portion using the following equation:

aay,

where

m isthe mass of concrete sample in the

container (in kg);

V__ isthe capacity of the container (in m®).

Express the result to the nearest 10 kg/m®.

Calculate the average of the two determinations and

the difference between them. If the difference

is 40 kg/m® or more discard the results and repeat,

the test on a new sample of concrete.

Ifthe difference is 30 kg/m? or less, report the

average.

8.2 Calculation of the volume of concrete per

batch

Ifthe volume of concrete produced per batch, Vp, is,

required, calculate it (in m®) using the following

equation:

met my tm, my

% @

is the mass per batch of coarse aggregate,

in the condition used (in kg);

is the mass per batch of cement (in kg);

is the mass per batch of fine aggregate, in

tthe condition used (in kg);

is the mass of mixing water added to the

batch Gin kg); “

D__ isthe density of partially compacted

semi-dry fresh concrete obtained in

accordance with 8.1 (in ke/m®),

Express the result of an accuracy of 1%.

9 Precision

Precision data are given in Table 2.

‘Table 2 — Precision data for density of

Partially compacted semi-dry fresh concrete

10 Test report

‘10.1 General

‘The test report shall affirm that the density was

determined in accordance with this Part of BS 1881.

‘The report shall also state whether or not a

certificate of sampling is available. If available, a

copy of the certificate shall be provided.

10.2 Information to be included in the report

10.2.1 Obligatory infarmation

‘The following information shall be included in the

test report: 7

a) date, time and place of sampling and sample

identity number;

b) time and place of test;

©) identification number, capacity and date of

latest calibration of the container;

4) density of partially compacted semi-dry fresh

conerete eample;

©) name of person carrying out the test,

10.2.2 Optional information

kon twa ea

2.035, 30 30

‘Average dently | Repeatability, te

NOTE 1. ‘The precision data were obtained in an experiment

‘carried out in 1968 involving 18 eperatare The experiment was

‘designed andthe date analyeed flowing the principles given

‘in BS 6497-1 The material used wae a 1.6 batch of ermidry

Sesh concrete, rized frm 20 mm gravel cares spgregna,

ating MotB 185 foe epepicand

containing 175 kgf of ordinary Portland coment. Each operator

scokasample ete §0 Land ane waterline

‘sample each text remlt being the average of two determinations

‘Sampling and sample reduction was in eccordanee

‘rch BS 1881

NOTE2 The diference between tw tat results sbtained on

‘he name comple of vemi-dry fresh concrete within «shor tine

‘nlerval, by one operator using the same euipenent wil exceed

‘he repeatability Hai (oe Table 2} om averege in not more

than in 20 casein the normal and correct operation ofthe

NOTE The difference between two tat rule obtined on

Siferentaarpies ofthe ane lad of eed free conrete,

stthin a shor ime interval, by different operators each using

‘heir own equipment will exceed the reprogucblity iit

‘00 Table 2) on average in not mare than 1 in 20 extern the

sormal and correct operation ofthe metho.

requested, the following information shall be

included in the test report:

8) name of project and place where concrete was

‘used;

) name of supplier and source of concrete;

©) date and time of production of concrete or

delivery to site;

4) specification of concrete mix, e.g. GEN, STI.

‘ost 12-1058,

BS 1881-129:1992

_———

Publication(s) referred to

[BS 599, Specification for laboratory thermometers,

BS 882, Specification for aggregates from natural sources for concrete.

BS 1877, Methods of test for soils or civil engineering purposes.

BS 1877-4, Compaction related tests.

BS 1704, Specification for solid-stem general purpose thermometers.

BS 1881, Testing concrete.

BS 1881-101, Method of sampling fresh concrete on site,

‘BS 1881-102, Method for determination of slump.

BS 1881-107, Method for determination of density of compacted fresh concrete.

BS 1881-113, Method for making and curing no-fines test cubes,

BS 1881-125, Methods for mixing and sampling fresh concrete in the laboratory.

BS 8388, Specification for forks, shovels and spades.

BS 6328, Concrete.

BS 5328-1, Guide to specifying concrete.

BS 5497, Precision of test methods,

BS 5497-1,Guide for the determination of repeatability and reproducibility for a standard test method by

inter-laboratory tests.

Department of Transport: “Specification for Highway Works”),

" Retored toi the foreword only and obtainable from HMSO.

£89 Chiswick High Road

44a.

——————

BSI — British Standards Institution

[BSI the independent national body responsible for preparing British Standards, It

presents the UK view on standards in Europe and at the international level. tis

Incorporated by Royal Charter.

Revisions

‘British Standards are updated by amendment or revision. Users of British Standards

should make sure that they possess the latest amendments or editions.

Its the constant aim of BSI to improve the quality of our products and services. We

‘would be grateful if anyone finding an inaccuracy or ambiguity while using this

British Standard would inform the Secretary of the technical committee

the identity of which can be found on the inside front cover. Tel: 20 8996 9000,

Fax 020 8996 7400.

offers members an individual updating service called PLUS which ensures that,

‘subscribers automatically receive the latest editions of standards,

Buying standards

(Orders for all BSI, international and foreign staixdards publications should be

‘dressed to Customer Services. Te: 020 8996 9001. Fax: 020 8996 7001.

In responce to orders for international standards, itis BSI policy to supply the BSI

{implementation of those that have been published as British Standards, unless

otherwise requested.

Information on standards

[BSI provides a wide range of information on national, European and international

‘standards through its Library and its Technical Help to Exporters Service. Various

BSI electronic information services are also available which give details on all its

‘products and services. Contact the Information Centre. Tel: 020 8906 7111.

Fax: 020 8006 7048,

‘Subscribing members of BSI are kept up to date with standards developments and

receive substantial discounts on the purchase price of standards. For detals of

‘these and other benefits contact Membership Administration. Tel: 020 8908 7002.

‘Fac 029 8996 7001. 5

Copyright

‘Copyright subsists in all BSI publications. BSI also holds the copyright, in the UK, of

the publications of the international standardization bodles. Except as permitted

under the Copyright, Designs and Patents Act 1988 no extract may be reproduced,

‘stored in a retrieval system or transmitted in ary form or by any means — electronic,

‘Photocopying, recording o¢ otherwise ~ without prior written permission from BSI.

[If permission is granted, the terms may include royalty payments or a licensing

sgreament. Deals nd advice canbe obtained from the Copyright Manager

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Bao Gia Nang Cap Tram PSMC 131015Document1 pageBao Gia Nang Cap Tram PSMC 131015Thai Hai LyNo ratings yet

- Working Form-Hcmc Office - July 2016 TrangDocument4 pagesWorking Form-Hcmc Office - July 2016 TrangThai Hai LyNo ratings yet

- Quotation Hten60-3ms1500 PSMC 301015Document10 pagesQuotation Hten60-3ms1500 PSMC 301015Thai Hai LyNo ratings yet

- BS 1881-113-1983Document10 pagesBS 1881-113-1983Thai Hai LyNo ratings yet

- List of Shedule For WT HCMCDocument9 pagesList of Shedule For WT HCMCThai Hai LyNo ratings yet

- BS 1881-107-1983Document10 pagesBS 1881-107-1983Thai Hai LyNo ratings yet

- No Name of Problem Quantity Actual State Repair PriceDocument1 pageNo Name of Problem Quantity Actual State Repair PriceThai Hai LyNo ratings yet

- Meeting AgendaDocument16 pagesMeeting AgendaThai Hai LyNo ratings yet

- Ile"Oiiaie" : Mua MangDocument4 pagesIle"Oiiaie" : Mua MangThai Hai LyNo ratings yet

- Check Levelness of Formwork: A B C D e F A-E B-FDocument7 pagesCheck Levelness of Formwork: A B C D e F A-E B-FThai Hai LyNo ratings yet

- HQP Mua Mang: Har S6: Thu6Document5 pagesHQP Mua Mang: Har S6: Thu6Thai Hai LyNo ratings yet

- HGP Xi: Mua MangDocument4 pagesHGP Xi: Mua MangThai Hai LyNo ratings yet

- NECESSARY TEST FOR QUALITY CONTROL (Internal Quality Control)Document14 pagesNECESSARY TEST FOR QUALITY CONTROL (Internal Quality Control)Thai Hai LyNo ratings yet

- How To Fill A NCR: Non-Conformance ReportDocument1 pageHow To Fill A NCR: Non-Conformance ReportThai Hai LyNo ratings yet

- MUA Mang 'Y - ), - Chi: Tho4i: 08.39142511Document3 pagesMUA Mang 'Y - ), - Chi: Tho4i: 08.39142511Thai Hai LyNo ratings yet

- Remedial InspectionDocument4 pagesRemedial InspectionThai Hai LyNo ratings yet

- Test PDFDocument4 pagesTest PDFThai Hai LyNo ratings yet

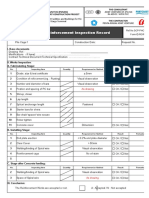

- Reinforcement Inspection Record: Girder ProductionDocument7 pagesReinforcement Inspection Record: Girder ProductionThai Hai LyNo ratings yet

- Non-Conformance Report: NCR No .Document2 pagesNon-Conformance Report: NCR No .Thai Hai LyNo ratings yet

- Girder Follow UpDocument4 pagesGirder Follow UpThai Hai LyNo ratings yet

- New Flowchart For Concrete Approval: StartDocument1 pageNew Flowchart For Concrete Approval: StartThai Hai LyNo ratings yet

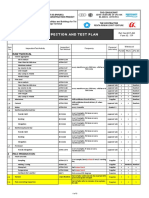

- Inspection and Test Plan: Girder ProductionDocument3 pagesInspection and Test Plan: Girder ProductionThai Hai LyNo ratings yet

- NCR Register - 14 SeptDocument2 pagesNCR Register - 14 SeptThai Hai LyNo ratings yet

- Common Register NCR - 21 Dec9Document3 pagesCommon Register NCR - 21 Dec9Thai Hai LyNo ratings yet

- Common Register NCR - 17 NovDocument2 pagesCommon Register NCR - 17 NovThai Hai LyNo ratings yet

- Common Register NCR - 16 Jan 10Document3 pagesCommon Register NCR - 16 Jan 10Thai Hai LyNo ratings yet

- Common Register NCR - 11 Jan 10Document3 pagesCommon Register NCR - 11 Jan 10Thai Hai LyNo ratings yet

- Shipping Out of Sleepers FAT-TK-011-CHKDocument4 pagesShipping Out of Sleepers FAT-TK-011-CHKThai Hai LyNo ratings yet