Professional Documents

Culture Documents

New Flowchart For Concrete Approval: Start

Uploaded by

Thai Hai LyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

New Flowchart For Concrete Approval: Start

Uploaded by

Thai Hai LyCopyright:

Available Formats

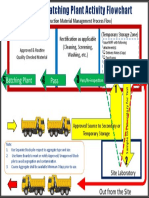

NEW FLOWCHART FOR CONCRETE APPROVAL

FLOW CHART THINGS NEED TO BE DONE

START - Working on blant scall accuracy and calibration

Batching plant

setting up - Train batcher for getting familiar with sleeper concrete

Batching plant

- Finallize at least 4 mixes for submission (7d & 28 strength, 2 differrent

setting up

Technical Design approval admixture suppliers, target 2 weeks, carry out at laboratory

Plant trials

(assum spec.) - Plant trial using assumed materials mixes

Plant trials

Test specification/ITP,FAT

(assum spec.)

approval

- Internal visit stone & M. Sand quarry (possibly invite HTC after internal

Raw material/

mixture selection visit)

Raw material/

mixture selection (Assum test spec.) - Prepare raw material for assumed test spec. if Technical design from HTC

(Assum test spec.) takes long

Incoming raw Incoming raw - Send raw materials to approved LAB for testing straight away after

material testing material testing Technical design is approved with possibly HTC

(kick-off meeting) Trial mix procedure Trial mix procedure - Kick-off meeting with NJPT/HTC to get agreements

agreement agreement

Mix design submision Mix design submision - Ensure 100% pass for trial mixes

Trial mix carry out Trial mix carry out & - In charge carrying out the trial mix and liaising for resulting

concrete results

Sampling raw material - Try to avoid sources approval before mix design proportion

NO

Sampling @ Sampling at - In charge raw material sampling possibly rougly same time with trial mix's

PSM's plant sources?

time

- Collect all documents for final submission

YES

Internal test results

Trial mix carry out to submit

Sampling Concrete

@ sources test results

FINISH

Raw material

Quatest3 testing

test results

Launch

trial production

You might also like

- 3.0 Research MethodologyDocument3 pages3.0 Research MethodologyAizat Sera SuwandiNo ratings yet

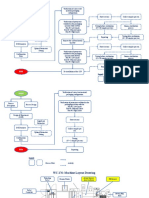

- Proposed Source To Batching Plant Flowchart - Edited - 06.04.2022 PDFDocument1 pageProposed Source To Batching Plant Flowchart - Edited - 06.04.2022 PDFudayNo ratings yet

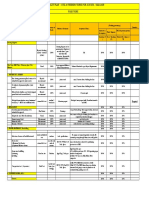

- Frequency Rate of Concrete Quality ControlDocument2 pagesFrequency Rate of Concrete Quality Controlmoundjed hamzaouiNo ratings yet

- Er. Jagadiswar M. ShresthaDocument106 pagesEr. Jagadiswar M. ShresthaAkash KhanalNo ratings yet

- Electrical Control Cabinet (TAG22T3 100B) 7 Mar 2023 Sierra BlassingameDocument10 pagesElectrical Control Cabinet (TAG22T3 100B) 7 Mar 2023 Sierra BlassingameMohamed AminNo ratings yet

- Company Name and Document DetailsDocument1 pageCompany Name and Document DetailsDilnesa EjiguNo ratings yet

- Action Plan For Oil ProcessingDocument2 pagesAction Plan For Oil ProcessingmelkuNo ratings yet

- Development Process LifecycleDocument8 pagesDevelopment Process LifecycleSamratNo ratings yet

- PP Module 5 - Production Execution 1 - Confirm ENGDocument135 pagesPP Module 5 - Production Execution 1 - Confirm ENGhuynh thi y vi100% (1)

- QAD Procedure - Lab Management P1Document1 pageQAD Procedure - Lab Management P1sumanNo ratings yet

- CAP PLANT VIETNAM GLASSDocument6 pagesCAP PLANT VIETNAM GLASSCuong PhanNo ratings yet

- Lab Equipment and Reagent Kits for Genetic TestingDocument7 pagesLab Equipment and Reagent Kits for Genetic TestingGuneyden GuneydenNo ratings yet

- Acceptance Testing For Continuous Farley Acceptance Testing Acceptance TestingDocument136 pagesAcceptance Testing For Continuous Farley Acceptance Testing Acceptance TestingKai ChapterNo ratings yet

- CH Dilawar C.VDocument1 pageCH Dilawar C.Vwali mustafaNo ratings yet

- Laboratory Flow: Pre-Analytical Analytical Post-AnalyticalDocument1 pageLaboratory Flow: Pre-Analytical Analytical Post-AnalyticalLoiLoiChanNo ratings yet

- Civil Works Inspection - QA - QC-Construction LTDDocument1 pageCivil Works Inspection - QA - QC-Construction LTDNashrul KarimNo ratings yet

- Data Structure WorkbookDocument111 pagesData Structure WorkbookFaraz Hassan KhanNo ratings yet

- Data 1 To 8 LabDocument78 pagesData 1 To 8 LabMudassar VirkNo ratings yet

- 2014 - Curs VerifDocument7 pages2014 - Curs VerifMihaita SmintinaNo ratings yet

- 015 Sop External Test ProcedureDocument2 pages015 Sop External Test ProcedureHeri N HNo ratings yet

- Area of Concern Objectives Strategies/Activities Responsible Persons Expected Outcomes Time Frame Budget SourceDocument2 pagesArea of Concern Objectives Strategies/Activities Responsible Persons Expected Outcomes Time Frame Budget SourceJonabe RanaraNo ratings yet

- STLC PreviewDocument3 pagesSTLC Previewrayone9No ratings yet

- 05 Slides Ute KATRANSKI Vector Testing Symposium 2019 EnDocument18 pages05 Slides Ute KATRANSKI Vector Testing Symposium 2019 Entripplemmousavi404No ratings yet

- Modul Paint ProductionDocument16 pagesModul Paint Productiongeeky geekzNo ratings yet

- Brenno C. Menezes, Marcel Joly, Lincoln F. L. MoroDocument31 pagesBrenno C. Menezes, Marcel Joly, Lincoln F. L. MoroNathalia DelgadoNo ratings yet

- DirectFuzz Automated Test Generation For RTL Designs Using Directed Graybox FuzzingDocument6 pagesDirectFuzz Automated Test Generation For RTL Designs Using Directed Graybox Fuzzingcs TianNo ratings yet

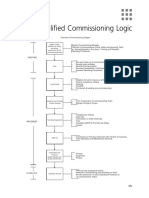

- A Simplified Commissioning L - 2012 - Chemical and Process Plant Commissioning HDocument1 pageA Simplified Commissioning L - 2012 - Chemical and Process Plant Commissioning HGabriel BarretoNo ratings yet

- Production Part ApprovalDocument3 pagesProduction Part Approvalvidya410gmailcomNo ratings yet

- ITP For Electrical WorksDocument22 pagesITP For Electrical WorksDebesh Chaudhary100% (6)

- Itp Lot 28Document94 pagesItp Lot 28Wahyu Rohmad DiantoNo ratings yet

- Rules To Manage Claims From Renault and SMART 18122019Document4 pagesRules To Manage Claims From Renault and SMART 18122019Nikolay DilanovNo ratings yet

- ReleasePlan FinalDocument11 pagesReleasePlan Finalsaurav kumarNo ratings yet

- Delivery Label For SamplesRevADocument1 pageDelivery Label For SamplesRevAHusain MilanoNo ratings yet

- Materials and MethodsDocument16 pagesMaterials and MethodsMark Cyrus LipasanNo ratings yet

- STLC Stage Entry Criteria Activity Exit Criteria DeliverablesDocument10 pagesSTLC Stage Entry Criteria Activity Exit Criteria DeliverablesAnkit TrivediNo ratings yet

- Software Testing Life Cycle, Types & Flavors of TestingDocument13 pagesSoftware Testing Life Cycle, Types & Flavors of TestingAbhisek MukherjeeNo ratings yet

- Turtle Diagram StoreDocument1 pageTurtle Diagram StoreRiyu RathodNo ratings yet

- Performance TestingDocument16 pagesPerformance TestingPria Rizky CandraNo ratings yet

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 pageQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- RFQ & Sample Approval ProcessDocument1 pageRFQ & Sample Approval ProcessKarthik MadhavanNo ratings yet

- Kinectrics Presentation - HV Cable Testing PDFDocument56 pagesKinectrics Presentation - HV Cable Testing PDFsulemankhalidNo ratings yet

- Site construction process flow chartDocument1 pageSite construction process flow chartSumit JoshiNo ratings yet

- CADANGAN KERJA-KERJA BAIKPULIH MASJID SAHABATDocument14 pagesCADANGAN KERJA-KERJA BAIKPULIH MASJID SAHABATDinn NsNo ratings yet

- Training PlanDocument5 pagesTraining PlanArl SolutionsNo ratings yet

- Conformiq Creator 2 Self Study Material 1Document114 pagesConformiq Creator 2 Self Study Material 1Biraja MohantyNo ratings yet

- Checkpoint of Bulding Machine PCDocument2 pagesCheckpoint of Bulding Machine PCDilnesa EjiguNo ratings yet

- DTP - Supplier Management SOP QA.008Document13 pagesDTP - Supplier Management SOP QA.008Faizah LokmanNo ratings yet

- Mekelle University Eit-M: Department of Civil EngineeringDocument34 pagesMekelle University Eit-M: Department of Civil Engineeringyeshi janexoNo ratings yet

- Operations: Support WorkflowDocument35 pagesOperations: Support WorkflowANTONIO BONITANo ratings yet

- Cohesity - HW Qual and Cert 1.0Document25 pagesCohesity - HW Qual and Cert 1.0Rupam Dutta100% (1)

- Group Memebers Layout Analysis of Dairy Plant and Suggesting Best Layout for Productivity ImprovementDocument1 pageGroup Memebers Layout Analysis of Dairy Plant and Suggesting Best Layout for Productivity ImprovementPrashant KhopadeNo ratings yet

- Procedure For NPD HandoverDocument1 pageProcedure For NPD HandoverTushar Wagh100% (1)

- TRL & MRLDocument1 pageTRL & MRLeagle novaNo ratings yet

- Machine Layout DrawingDocument30 pagesMachine Layout DrawingXavierNo ratings yet

- Introduction to Basic Signals in MATLABDocument10 pagesIntroduction to Basic Signals in MATLABEhsan ArshadNo ratings yet

- Quality Control PlanDocument1 pageQuality Control PlanScha Affin100% (1)

- Check List- F-1 SummaryDocument3 pagesCheck List- F-1 SummaryshameerkasalaNo ratings yet

- Field Quality Plan - 2022 RoadDocument9 pagesField Quality Plan - 2022 RoadMozhi Moni100% (1)

- Building a Successful Board-Test StrategyFrom EverandBuilding a Successful Board-Test StrategyRating: 4 out of 5 stars4/5 (1)

- List of Shedule For WT HCMCDocument9 pagesList of Shedule For WT HCMCThai Hai LyNo ratings yet

- BPO Study GuideDocument47 pagesBPO Study GuideLUCKY_2011No ratings yet

- Quotation Hten60-3ms1500 PSMC 301015Document10 pagesQuotation Hten60-3ms1500 PSMC 301015Thai Hai LyNo ratings yet

- Working Form-Hcmc Office - July 2016 TrangDocument4 pagesWorking Form-Hcmc Office - July 2016 TrangThai Hai LyNo ratings yet

- No Name of Problem Quantity Actual State Repair PriceDocument1 pageNo Name of Problem Quantity Actual State Repair PriceThai Hai LyNo ratings yet

- Quotation of Nghia Thanh BoilerDocument7 pagesQuotation of Nghia Thanh BoilerThai Hai LyNo ratings yet

- NECESSARY TEST FOR QUALITY CONTROL (Internal Quality Control)Document14 pagesNECESSARY TEST FOR QUALITY CONTROL (Internal Quality Control)Thai Hai LyNo ratings yet

- Check Levelness of Formwork: A B C D e F A-E B-FDocument7 pagesCheck Levelness of Formwork: A B C D e F A-E B-FThai Hai LyNo ratings yet

- Bao Gia Nang Cap Tram PSMC 131015Document1 pageBao Gia Nang Cap Tram PSMC 131015Thai Hai LyNo ratings yet

- MUA Mang 'Y - ), - Chi: Tho4i: 08.39142511Document3 pagesMUA Mang 'Y - ), - Chi: Tho4i: 08.39142511Thai Hai LyNo ratings yet

- Calculate Capacity of Curing PoolDocument1 pageCalculate Capacity of Curing PoolThai Hai LyNo ratings yet

- BBG Cty Ps Mitsubishi - Dai Thep 141115Document1 pageBBG Cty Ps Mitsubishi - Dai Thep 141115Thai Hai LyNo ratings yet

- GPKD Dong PhongDocument3 pagesGPKD Dong PhongThai Hai LyNo ratings yet

- Meeting AgendaDocument16 pagesMeeting AgendaThai Hai LyNo ratings yet

- Ile"Oiiaie" : Mua MangDocument4 pagesIle"Oiiaie" : Mua MangThai Hai LyNo ratings yet

- Vietnam steel trading contractDocument4 pagesVietnam steel trading contractThai Hai LyNo ratings yet

- HQP Mua Mang: Har S6: Thu6Document5 pagesHQP Mua Mang: Har S6: Thu6Thai Hai LyNo ratings yet

- Schedule of Preparation Works UpdateDocument13 pagesSchedule of Preparation Works UpdateThai Hai LyNo ratings yet

- HD Ngoc Ngoc Chau - Dong Phong (Ky)Document3 pagesHD Ngoc Ngoc Chau - Dong Phong (Ky)Thai Hai LyNo ratings yet

- Giay Phep Khai Thac - HD Chuyen Nhuong MoDocument6 pagesGiay Phep Khai Thac - HD Chuyen Nhuong MoThai Hai LyNo ratings yet

- Ha LongDocument18 pagesHa LongThai Hai LyNo ratings yet

- Remedial InspectionDocument4 pagesRemedial InspectionThai Hai LyNo ratings yet

- Test PDFDocument4 pagesTest PDFThai Hai LyNo ratings yet

- Non-Conformance Report: NCR No .Document2 pagesNon-Conformance Report: NCR No .Thai Hai LyNo ratings yet

- Schedule of Preparation Works UpdateDocument13 pagesSchedule of Preparation Works UpdateThai Hai LyNo ratings yet

- Schedule of Preparation Works UpdateDocument13 pagesSchedule of Preparation Works UpdateThai Hai LyNo ratings yet

- MMGT NCR ChartDocument1 pageMMGT NCR ChartThai Hai LyNo ratings yet

- Wedge Inspection ChecklistDocument16 pagesWedge Inspection ChecklistThai Hai LyNo ratings yet

- Request For Inspection Summary (Danieli)Document8 pagesRequest For Inspection Summary (Danieli)Thai Hai LyNo ratings yet

- Sailor 500 Fleetbroadband: Second Generation Maritime Broadband CommunicationsDocument2 pagesSailor 500 Fleetbroadband: Second Generation Maritime Broadband Communicationsjeffry.firmansyahNo ratings yet

- CL OF WB TUNNEL REINFORCEMENTDocument7 pagesCL OF WB TUNNEL REINFORCEMENTRaymond CiaoNo ratings yet

- Introduction To KliaDocument9 pagesIntroduction To Kliaanis100% (2)

- 2005-2007 Resource List HGTV's Dream HomesDocument25 pages2005-2007 Resource List HGTV's Dream HomesGuthrie GantNo ratings yet

- Gothic and Renaissance Architecture ESSAY (LC Filmbay IX) AcademicDocument7 pagesGothic and Renaissance Architecture ESSAY (LC Filmbay IX) AcademicBojana MilivojevicNo ratings yet

- Administration Installation GuideDocument64 pagesAdministration Installation GuideeumetallicaNo ratings yet

- Cisco Systems Redundant Power System 675: Data SheetDocument6 pagesCisco Systems Redundant Power System 675: Data SheetManavjit SinghNo ratings yet

- BoqDocument55 pagesBoqKrm ChariNo ratings yet

- Missing Person ScriptDocument3 pagesMissing Person Scriptapi-477398527No ratings yet

- Logo On Module Pool ScreenDocument5 pagesLogo On Module Pool ScreenAmrutha Ashok KamatNo ratings yet

- 3 NmapDocument6 pages3 NmapJohn WickNo ratings yet

- RSE Practice Skills Assessment Part 1 - PTDocument5 pagesRSE Practice Skills Assessment Part 1 - PTAdem BislimiNo ratings yet

- Qualified Vendors List (QVL) For: GA-890GPA-UD3HDocument3 pagesQualified Vendors List (QVL) For: GA-890GPA-UD3HՄիլադ ԱլեքսանդրNo ratings yet

- Expansion Valves: General DescriptionDocument2 pagesExpansion Valves: General DescriptionCislandia PereiraNo ratings yet

- Kitchen Equipment ListDocument4 pagesKitchen Equipment ListPriyadarshan BhatNo ratings yet

- HP 9200C Digital Sender Firmware ReadmeDocument29 pagesHP 9200C Digital Sender Firmware ReadmeRodrigoMachadoPevidorNo ratings yet

- SDN WebServicesDocument40 pagesSDN WebServicesdenatmaNo ratings yet

- Hampi Gokarna Muru Honn 2023Document14 pagesHampi Gokarna Muru Honn 2023Sheetal SonawaneNo ratings yet

- Vplex Customer Presentation Small SizeDocument40 pagesVplex Customer Presentation Small Sizestriker0074No ratings yet

- 2016-08 DS Osa5548c SsuDocument2 pages2016-08 DS Osa5548c SsunguyenaituyenNo ratings yet

- Max Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Document106 pagesMax Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Vashish Ramrecha100% (1)

- A N A N T: Anant Damodar RajeDocument15 pagesA N A N T: Anant Damodar RajeShivangi ShankarNo ratings yet

- Step 1: Open Google: Developer Console and Signin With Your Gmail AccountDocument11 pagesStep 1: Open Google: Developer Console and Signin With Your Gmail Accountjohn mark laquipNo ratings yet

- Nbs Plus k10 Specification DetailsDocument0 pagesNbs Plus k10 Specification Detailsmajkil1988100% (1)

- Oracle Database 10 Automatic Storage Management Technical Best PracticesDocument40 pagesOracle Database 10 Automatic Storage Management Technical Best PracticesKp SoroNo ratings yet

- Ultimate Load Capacity of Pile Foundation, Q: WhereDocument11 pagesUltimate Load Capacity of Pile Foundation, Q: WhereRgne EpehakNo ratings yet

- EaiDocument13 pagesEaiROHITH MNo ratings yet

- Troubleshooting Active Directory Replication ProblemsDocument54 pagesTroubleshooting Active Directory Replication ProblemsMohamed AliNo ratings yet

- KP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFDocument3 pagesKP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFUtku Can KılıçNo ratings yet

- Wall Sections-Built ExamplesDocument21 pagesWall Sections-Built ExamplesRoma Vadola100% (2)