Professional Documents

Culture Documents

Experiment 2 E H T M P: Icrostructure

Uploaded by

afnene1Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Experiment 2 E H T M P: Icrostructure

Uploaded by

afnene1Copyright:

Available Formats

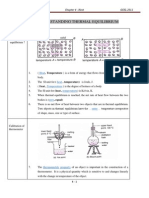

Experiment 2

Effects of heat treatment on carbon steel

microstructure and properties.

Purpose: Understand the effect of cooling rates and reheating on microstructure and

properties of carbon steel.

We will use carbon steel. The four steel samples will be austenitized at 880o C for 35 minutes.

Two samples will then be cooled in two manners. The first will be a slow air cooling, which

should result in a sample experiencing approximately equilibrium cooling.

The two remaining samples will be quenched in water resulting in a sample with non-equilibrium

cooling. Then, one of each group samples will then be reheated to a temperature that will allow

limited diffusion for 35 minutes as in table below.

Samples Stainless steel

Heat to 800o C

1 Quench in H2O

(35 minutes)

Heat to 800o C

Quench in H2O

2

Reheat to 350 C

o

(35 minutes)

Heat to 800o C

3

Cool slowly

Heat to 800o C

Cool slowly

4 Reheat to 350 C

o

(35 minutes)

- Take hardness measurements using Rockwell C and/or Rockwell B scales. Take at

least 3 measurements on each sample and average the values. Compare the hardness property

the steel at after all heat treatments and explain the results.

- Grind and polish all samples and use the appropriated solution to reveal the

microstructure. Comment on the microstructures in your lab report.

You might also like

- Specifying Harmonized Standard Grade Compositions For Wrought Carbon, Low-Alloy, and Alloy SteelsDocument13 pagesSpecifying Harmonized Standard Grade Compositions For Wrought Carbon, Low-Alloy, and Alloy Steelsalucard375100% (2)

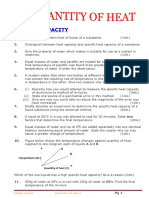

- Level Past Paper Questions - Hysics O P: TOPIC-8 Heat Capacity PAPER-1 Multiple ChoiceDocument3 pagesLevel Past Paper Questions - Hysics O P: TOPIC-8 Heat Capacity PAPER-1 Multiple Choiceelty Tan50% (2)

- Form 3 Holiday Assignment November December 2017Document14 pagesForm 3 Holiday Assignment November December 2017maxwel oboraNo ratings yet

- Thermal GuideDocument34 pagesThermal GuideMazinNo ratings yet

- To Prepare Chinese TeaDocument4 pagesTo Prepare Chinese TeaKong MikeNo ratings yet

- 7.1.2 - Heat Thermal Expansion WorksheetDocument1 page7.1.2 - Heat Thermal Expansion WorksheetNadeenMohamedNo ratings yet

- Chapter 12a Specific Heat Capacities, Specific Latent HeatDocument4 pagesChapter 12a Specific Heat Capacities, Specific Latent HeatPathmanathan NadesonNo ratings yet

- Extension Worksheet - Topic 3, Worksheet 1Document2 pagesExtension Worksheet - Topic 3, Worksheet 1Anonymous oATq0YNo ratings yet

- 4 0heat 130415001626 Phpapp01Document14 pages4 0heat 130415001626 Phpapp01sherlyn may lolNo ratings yet

- Heat Capacity ExperimentsDocument18 pagesHeat Capacity ExperimentsKisaka GNo ratings yet

- Item 0 20181223050211203Document10 pagesItem 0 20181223050211203DeepNo ratings yet

- Tutorial 2 Specific Heat and Latent HeatDocument3 pagesTutorial 2 Specific Heat and Latent HeatYAN XIN TENGNo ratings yet

- Assignment Book - CH 1 - 4Document2 pagesAssignment Book - CH 1 - 4云吸仓鼠吉尼斯保持者No ratings yet

- SS1 Physics - Thermal CapacityDocument3 pagesSS1 Physics - Thermal CapacityAbimbola Brodie-MendsNo ratings yet

- 2013 IB Thermal Questions: (22 Marks)Document2 pages2013 IB Thermal Questions: (22 Marks)GajendraNo ratings yet

- Topik 6b - ExerciseDocument4 pagesTopik 6b - ExerciseMd KhairulNo ratings yet

- Specific Heat Capacity1Document2 pagesSpecific Heat Capacity1ayeayeNo ratings yet

- Physics Form 4 Chapter 4 Heat NoteDocument4 pagesPhysics Form 4 Chapter 4 Heat Notecyric wongNo ratings yet

- TranscriptDocument29 pagesTranscriptNurAfifah OsmanNo ratings yet

- 3 Markscheme SL Paper2Document41 pages3 Markscheme SL Paper2maddiemads562No ratings yet

- Ch11 CalorimetryDocument2 pagesCh11 Calorimetrynayanpandey7323No ratings yet

- Worksheet 21 PDFDocument3 pagesWorksheet 21 PDFVijay Bhaskar0% (1)

- 3 3 01 PDFDocument3 pages3 3 01 PDFKiara BaylonNo ratings yet

- Thermal Properties of MatterDocument10 pagesThermal Properties of MatteraliNo ratings yet

- Temperature and HeatingDocument4 pagesTemperature and HeatingMark ProchaskaNo ratings yet

- Exercise - III: (Subjective Problems)Document3 pagesExercise - III: (Subjective Problems)RishabhNo ratings yet

- Chapter 9 Tutorial: Heat EnergyDocument1 pageChapter 9 Tutorial: Heat EnergySahida IshakNo ratings yet

- SHCDocument6 pagesSHCAlyssa ColeNo ratings yet

- Form 4 Physics Chapter 4 - Teacher'sDocument9 pagesForm 4 Physics Chapter 4 - Teacher'sPavithiran50% (2)

- Specific Heat CapacityDocument7 pagesSpecific Heat Capacitykeeesh4100% (1)

- Tutorial 5Document1 pageTutorial 5Mimi SaffrinNo ratings yet

- Specific Heat Capacity Physics Form 4 TopicDocument7 pagesSpecific Heat Capacity Physics Form 4 TopicRusnizaARNo ratings yet

- Revision Worksheet On Sound Calorimetry and Radioactivity - Numericals Assignment 3Document2 pagesRevision Worksheet On Sound Calorimetry and Radioactivity - Numericals Assignment 3Eren JaegerNo ratings yet

- 2223 Level M Physics Course Questions PDFDocument76 pages2223 Level M Physics Course Questions PDFOmar HamadNo ratings yet

- HKDSE Physics Paper 1A Heat Capacity CalculationsDocument8 pagesHKDSE Physics Paper 1A Heat Capacity Calculationsjackson wongNo ratings yet

- Heat of Fusion of Ice: ScientificDocument4 pagesHeat of Fusion of Ice: ScientificSubha ShankareeNo ratings yet

- Phys 161Document5 pagesPhys 161Collins BichiyNo ratings yet

- Analyze math problems instructionsDocument5 pagesAnalyze math problems instructionsJan Ebenezer MorionesNo ratings yet

- Dynamic transformation of α → β titanium at temperatures below the β -transus in commercially pure titaniumDocument4 pagesDynamic transformation of α → β titanium at temperatures below the β -transus in commercially pure titaniumLucas SerenaNo ratings yet

- Exercise 4.2 SECTION A: Choose The Best AnswerDocument2 pagesExercise 4.2 SECTION A: Choose The Best AnswerSuriyati LatipNo ratings yet

- TUTORIAL CH 1 - Part 2Document3 pagesTUTORIAL CH 1 - Part 2Adam MrsmNo ratings yet

- JC 2 Temperature Thermodynamics Thermal Properties Work SheetDocument8 pagesJC 2 Temperature Thermodynamics Thermal Properties Work SheetPaul PandianNo ratings yet

- SPM 2003, Section C, No. 3 (20 Marks) : Chapter 4: HeatDocument4 pagesSPM 2003, Section C, No. 3 (20 Marks) : Chapter 4: HeatSJKT LDG BUKIT 9 LADANG BUKIT 9No ratings yet

- Checkpoint 10.1Document1 pageCheckpoint 10.1Az MYNo ratings yet

- Calculating temperature changes and heat capacities in mixtures and materialsDocument1 pageCalculating temperature changes and heat capacities in mixtures and materialsAz MYNo ratings yet

- Quest 6-Additional ExerciseDocument7 pagesQuest 6-Additional Exercisebimbel onlineNo ratings yet

- Midterm Test. 08. 5. 2015Document1 pageMidterm Test. 08. 5. 2015Nguyen ChiemNo ratings yet

- Exercise 4.2 SECTION A: Choose The Best Answer: JPN Pahang Student's Copy Chapter 4: HeatDocument3 pagesExercise 4.2 SECTION A: Choose The Best Answer: JPN Pahang Student's Copy Chapter 4: HeatAlexandra ChiengNo ratings yet

- Nota Padat HeatDocument10 pagesNota Padat Heatjesunathan44@yahoo.comNo ratings yet

- 2023 MteDocument6 pages2023 MteISHAAN JAIN 22114039No ratings yet

- Chapter 4.2Document5 pagesChapter 4.2Siah Woan ChiouNo ratings yet

- 1 Calorimetry LabDocument16 pages1 Calorimetry Labeunice_fangonNo ratings yet

- Experiment 3 Thermal EquilibriumDocument2 pagesExperiment 3 Thermal Equilibriumrmm0415No ratings yet

- 1 PEAB ZC311 Assignment IDocument2 pages1 PEAB ZC311 Assignment IDedy Mustafa0% (1)

- Physics Heat Revision Test MCQsDocument28 pagesPhysics Heat Revision Test MCQsCiv NortubNo ratings yet

- Chapter 4 Heat ReviewDocument16 pagesChapter 4 Heat ReviewKurdishNo ratings yet

- Liquid Helium Technology: Proceedings of the International Institute of Refrigeration Commission 1, Boulder (U.S.A.) 1966From EverandLiquid Helium Technology: Proceedings of the International Institute of Refrigeration Commission 1, Boulder (U.S.A.) 1966No ratings yet

- Austenitic Stainless Steel Has Good Weldability But Is Sensitive To Hot Cracking Such As Solidification and Liquation CrackingDocument1 pageAustenitic Stainless Steel Has Good Weldability But Is Sensitive To Hot Cracking Such As Solidification and Liquation Crackingafnene1No ratings yet

- Experiment 2 E H T M P: IcrostructureDocument1 pageExperiment 2 E H T M P: Icrostructureafnene1No ratings yet

- Experiment 2 E H T M P: IcrostructureDocument1 pageExperiment 2 E H T M P: Icrostructureafnene1No ratings yet

- Ultrasonic 1Document39 pagesUltrasonic 1afnene1No ratings yet

- BrochureWeldability EN PDFDocument39 pagesBrochureWeldability EN PDFAl0611981No ratings yet

- Experiment 2 (High Carbon Steel Heat Treatment)Document1 pageExperiment 2 (High Carbon Steel Heat Treatment)afnene1No ratings yet

- Experiment - Cold WorkDocument2 pagesExperiment - Cold Workafnene1No ratings yet

- Test BB 2510 Phase DiagramDocument2 pagesTest BB 2510 Phase Diagramafnene1No ratings yet

- Experiment 3 (High Carbon Steel Heat Treatment) : ProcedureDocument1 pageExperiment 3 (High Carbon Steel Heat Treatment) : Procedureafnene1No ratings yet

- Etchant Selection Guide (SS Superalloy) 11-2015Document3 pagesEtchant Selection Guide (SS Superalloy) 11-2015Malik Ansar HayatNo ratings yet

- Test BB 2510 Phase DiagramDocument2 pagesTest BB 2510 Phase Diagramafnene1No ratings yet

- BooksDocument1 pageBooksafnene1No ratings yet

- StainlessSteels PDFDocument129 pagesStainlessSteels PDFsantu_23100% (2)

- Cold Work PercentageDocument1 pageCold Work Percentageafnene1No ratings yet

- Experiment 1Document2 pagesExperiment 1afnene1No ratings yet

- Experiment 1Document2 pagesExperiment 1afnene1No ratings yet

- 4 PDFDocument6 pages4 PDFafnene1No ratings yet

- Design of ExperimentDocument2 pagesDesign of Experimentafnene1No ratings yet

- Duplex Stainless SteelDocument231 pagesDuplex Stainless Steelponnivalavans_994423No ratings yet

- This documentDocument44 pagesThis documentTran Thanh HaoNo ratings yet

- Ellingham DiagramsDocument4 pagesEllingham DiagramsSumit KumarNo ratings yet

- Tutorial Chap 3-1-2020Document17 pagesTutorial Chap 3-1-2020afnene1No ratings yet

- 5-Cold Working BrassDocument4 pages5-Cold Working BrassAhmed MagedNo ratings yet

- MTDocument2 pagesMTafnene1No ratings yet

- Radiographic TestingDocument47 pagesRadiographic TestingsmrndrdasNo ratings yet

- Radiography Test Inspection Free NDT Sample ProcedureDocument4 pagesRadiography Test Inspection Free NDT Sample ProcedureAjay KumarNo ratings yet

- Experiment 3Document2 pagesExperiment 3afnene1No ratings yet

- Radio GraphicDocument58 pagesRadio GraphicApex AesNo ratings yet

- Experiment 5: Hardening of Duplex Stainless SteelDocument1 pageExperiment 5: Hardening of Duplex Stainless Steelafnene1No ratings yet

- ExperimentsDocument2 pagesExperimentsafnene1No ratings yet

- Fractography SteelDocument42 pagesFractography SteelRebeccaNandaNo ratings yet

- Module 6 MCQDocument68 pagesModule 6 MCQlipibhaiNo ratings yet

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument6 pagesAmerican Fastener - ASTM, SAE, and ISO Grade MarkingsmameeranNo ratings yet

- Engineering Cost Estimate for Pneumatic Conveying System BuildingDocument1 pageEngineering Cost Estimate for Pneumatic Conveying System BuildingDaniyal Khursheed0% (1)

- Zamil Brochure DT PDFDocument8 pagesZamil Brochure DT PDFDjamila HaddiNo ratings yet

- Boiler Materials For USC Plants IJPGC 2000Document22 pagesBoiler Materials For USC Plants IJPGC 2000pawanumarji1100% (1)

- WPQ 양식 김정균 (DSHI Rev.0)Document5 pagesWPQ 양식 김정균 (DSHI Rev.0)이훈No ratings yet

- Material Selection Guide PDFDocument1 pageMaterial Selection Guide PDFYanuarAshariNo ratings yet

- Which Material Is Used For Connecting Rod.Document3 pagesWhich Material Is Used For Connecting Rod.MECHA ENGINEEERINGNo ratings yet

- Is 513 StandardsDocument18 pagesIs 513 StandardsEr Abhijeet Kamble0% (1)

- Astm A193Document2 pagesAstm A193Saju Thomas AlexanderNo ratings yet

- Bolts - ASTM F3125Document4 pagesBolts - ASTM F3125rahuljoagNo ratings yet

- Title Proposal JournalizingDocument13 pagesTitle Proposal JournalizingMark TepaceNo ratings yet

- Pickling HandbookDocument32 pagesPickling HandbookPradeepNo ratings yet

- Hofmann BrochureDocument88 pagesHofmann BrochureJorge VillalobosNo ratings yet

- BME301 - Material Engineering Notes - 2023 - 24Document15 pagesBME301 - Material Engineering Notes - 2023 - 24kec.abhishek463No ratings yet

- Tabel Elektroda LasDocument162 pagesTabel Elektroda LasNaufal Dzaky M ANo ratings yet

- Project Report (Arc Weldinng)Document63 pagesProject Report (Arc Weldinng)Somasekhar Koushik Ayalasomayajula100% (1)

- Annexure I - Scope & Specification For Construction of Rock Silo-D - Rev 0Document121 pagesAnnexure I - Scope & Specification For Construction of Rock Silo-D - Rev 0Ayan MajumderNo ratings yet

- Characterization Study and Fabrication of Aluminium Bronze Wheel Rim For AutomobileDocument2 pagesCharacterization Study and Fabrication of Aluminium Bronze Wheel Rim For AutomobileTanzir MusaNo ratings yet

- Material Data Sheet: Material Number Country DesignationsDocument21 pagesMaterial Data Sheet: Material Number Country DesignationsSan ReyNo ratings yet

- MDSReport 1039818470Document154 pagesMDSReport 1039818470javier ortizNo ratings yet

- Niobium and Heat Affected Zone MythologyDocument42 pagesNiobium and Heat Affected Zone MythologyLayzza TardinNo ratings yet

- DR008 - Earthing of PipingDocument3 pagesDR008 - Earthing of PipingMadhan RajNo ratings yet

- Hand Tools Test 121 PDFDocument22 pagesHand Tools Test 121 PDFDeca BernabéNo ratings yet

- Astm A965x 2021aDocument7 pagesAstm A965x 2021aamitNo ratings yet

- Combined Laboratory Mill & Press: CentaurusDocument5 pagesCombined Laboratory Mill & Press: CentaurusSunil T V SuniNo ratings yet

- 20-SDMS-01 REV. 02: Saudi Electricity CompanyDocument39 pages20-SDMS-01 REV. 02: Saudi Electricity CompanyMendu Prashanth100% (1)

- Safety & Reliability in Ammonia Synthesis ConvertersDocument12 pagesSafety & Reliability in Ammonia Synthesis ConvertersGaurav GuptaNo ratings yet