Professional Documents

Culture Documents

Floor Mats and Frames

Uploaded by

Anonymous QPuuIv4Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Floor Mats and Frames

Uploaded by

Anonymous QPuuIv4Copyright:

Available Formats

SECTION 12695

FLOOR MATS AND FRAMES

PART 1 - GENERAL

1.1 SECTION INCLUDES

A. Floor entrance mats and frames as shown on Drawings and as herein specified.

1.2 REFERENCES

A. SAUDI ARABIAN STANDARDS ORGANIZATION (SASO)

SASO 903/1994 Determination of thickness of pile above the

backing.

SASO 904/1994 Determination of number of tufts and/or loops per

unit length and per unit area

SASO 906/1994 Determination of mass of effective pile per unit area

that can be shorn away from the backing.

SASO 909/1994 Determination of mass of total pile yarn per unit

area.

SASO 910/1994 Determination of measured surface pile density and

measured pile fiber volume ratio.

SASO 79/1998 Aluminum and aluminum alloys for building

purposes – Part 1: Rods/Bars, tubes and profiles.

SASO 80/1977 Testing methods for aluminum and aluminum alloy

products for building purposes Part 1: Sheets,

strips, bars and structural sections.

1.3 SUBMITTALS

A. Submit shop drawings indicating dimensions, installation construction details.

B. Submit product data indicating mat characteristics, component dimensions,

recessed frame and details.

C. Submit 2 samples 600 x 600 mm in size illustrating pattern, color, finish and edging.

1.4 OPERATION AND MAINTENANCE DATA

A. Submit maintenance data including cleaning instructions and stain removal

procedures.

500-Bed Hospitals for M.O.H.

12695 -1 Floor Mats and Frames

PART 2 - PRODUCTS

2.1 MATERIALS

A. Entrance Mats:

1. Mat Construction: Mats shall be suitable for recessed installation,

constructed of an extruded anodized aluminum frame and modular

aluminum rails each having carpet tread inserts and vinyl filler at the

borders.

2. Perimeter Frame: Manufactured aluminum extrusions, alloy 6063-T52 in

accordance with ASTM B 209. Frame shall have a clear anodized finish.

3. Rails: Manufactured from aluminum extrusions, alloy 6063-T52 in

accordance with ASTM B 209 and shall be continuously hinge connected to

permit roll-back for cleaning. Rails shall have a continuous co-extruded PVC

cushions. Rails shall have a clear anodized finish.

4. Tread Surface: Carpet, colorfast, solution dyed 100% nylon pile fusion

bonded to a rigid 2-ply vinyl backing. Carpet fiber shall contain an anti-

microbial additive and shall be treated with an anti-soiling agent to reduce

soiling. Carpet shall have a one inch matching vinyl filler border on all

edges. Color of carpet and vinyl filler shall be as approved by the Engineer.

B. Fasteners and Fixing Devices: As recommended by the manufacturer and

approved by the Engineer.

PART 3 - EXECUTION

3.1 EXAMINATION

A. Verify that floor openings are ready to receive work.

B. Verify field measurements are as shown on shop drawings.

C. Beginning of installation means acceptance of existing conditions.

3.2 PREPARATION

A. Verify size of floor recess before cutting mats.

B. Vacuum clean floor recess.

3.3 INSTALLATION

A. Install mats in floor recess flush with finish floor after final cleaning of finish flooring.

500-Bed Hospitals for M.O.H.

12695 -2 Floor Mats and Frames

3.4 TOLERANCES

A. Maximum Allowable Gap between Recessed Frame and Mat: 6 mm.

END OF SECTION

500-Bed Hospitals for M.O.H.

12695 -3 Floor Mats and Frames

You might also like

- Section 12090 UpholsteryDocument4 pagesSection 12090 UpholsteryMØhãmmed ØwięsNo ratings yet

- Compresor Kaeser CSD100 PDFDocument133 pagesCompresor Kaeser CSD100 PDFjars0318095083% (6)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- DR ApichitDocument139 pagesDR ApichitMuh. Yousuf KhanNo ratings yet

- 08 44 13 Glazed Aluminium Curtain Wal &Document28 pages08 44 13 Glazed Aluminium Curtain Wal &M Refaat FathNo ratings yet

- Exocad Prosthetic Components Libraries enDocument22 pagesExocad Prosthetic Components Libraries enAlex BushNo ratings yet

- Technical Specification: 40' X 8' X 8'6" ISO 1AA TYPE Steel Dry Cargo ContainerDocument15 pagesTechnical Specification: 40' X 8' X 8'6" ISO 1AA TYPE Steel Dry Cargo ContainerAnonymous i6ohyRNo ratings yet

- Arlanxeo NBR Product PortofolioDocument8 pagesArlanxeo NBR Product PortofolioErwin ErwinNo ratings yet

- Carbon Black Fundamentals 041206Document8 pagesCarbon Black Fundamentals 041206gems_gce074325No ratings yet

- Oki C9650 ServiceDocument246 pagesOki C9650 ServicewilbingNo ratings yet

- 09 5100 BSD-Suspended Acoustical CeilingsDocument4 pages09 5100 BSD-Suspended Acoustical CeilingsSivaram KottaliNo ratings yet

- Fiber Cement BoardDocument4 pagesFiber Cement Boardfrozenfatty139956100% (1)

- ITCC in Riyadh Residential Complex J10-13300 12484 - 1 Floor Mats and FramesDocument2 pagesITCC in Riyadh Residential Complex J10-13300 12484 - 1 Floor Mats and FramesuddinnadeemNo ratings yet

- Part 1 General 1.01 SummaryDocument5 pagesPart 1 General 1.01 Summaryআফজাল -উল ইসলাম নূরNo ratings yet

- Specifications: Stair Treads and Nosings - 05 55 00Document4 pagesSpecifications: Stair Treads and Nosings - 05 55 00rheriNo ratings yet

- TS US Gabion, GalMac Jan19Document8 pagesTS US Gabion, GalMac Jan19johnnee98No ratings yet

- Composite Panel SpecificationDocument6 pagesComposite Panel SpecificationracvilleNo ratings yet

- SECTION 09510 Acoustical Ceilings Part 1-General General RequirementsDocument8 pagesSECTION 09510 Acoustical Ceilings Part 1-General General RequirementsIm Chinith100% (1)

- Section 09514Document7 pagesSection 09514motaz alzoubiNo ratings yet

- T350 Series: Product Standards and Guide SpecificationsDocument1 pageT350 Series: Product Standards and Guide SpecificationsMyrah MirandaNo ratings yet

- De635 Suggested SpecificationDocument2 pagesDe635 Suggested Specificationqpuc198No ratings yet

- 03 24 00solDocument4 pages03 24 00solmp4 ghad mp4No ratings yet

- Specifications: Louvers - 08 91 00Document14 pagesSpecifications: Louvers - 08 91 00Persephone KylaNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilinguddinnadeemNo ratings yet

- Unit Masonry AssembliesDocument13 pagesUnit Masonry AssembliesHusen ZahranNo ratings yet

- Section 09100 Metal Framing SystemDocument5 pagesSection 09100 Metal Framing Systemestimasi100% (1)

- Section 077100 - Roof SpecialtiesDocument6 pagesSection 077100 - Roof SpecialtiesWENDING HUNo ratings yet

- SECTION 03 51 13 Cementitious Wood Fiber DecksDocument6 pagesSECTION 03 51 13 Cementitious Wood Fiber DecksJuanPaoloYbañezNo ratings yet

- SF - Glass-Fiber-Reinforced Concrete (GFRC)Document6 pagesSF - Glass-Fiber-Reinforced Concrete (GFRC)SunilNo ratings yet

- 09 28 13 Cement Board CeilingsDocument6 pages09 28 13 Cement Board CeilingsWagih NabihNo ratings yet

- Architextures - Barrisol Stretch Ceilings SpecDocument4 pagesArchitextures - Barrisol Stretch Ceilings SpecMohammed Abdul BaseerNo ratings yet

- Section 230713 - Duct InsulationDocument7 pagesSection 230713 - Duct Insulationmattar2007No ratings yet

- 09 51 00asiDocument17 pages09 51 00asiAngelica Dela CruzNo ratings yet

- AAB 089119 Fixed Louvers (Incl Catladders)Document5 pagesAAB 089119 Fixed Louvers (Incl Catladders)Tewodros TeferaNo ratings yet

- Section 321443 - Porous Unit Paving: Part 1 - GeneralDocument7 pagesSection 321443 - Porous Unit Paving: Part 1 - Generalery achjariNo ratings yet

- Bill UnpricedDocument4 pagesBill UnpricedAmile Michael ShawonNo ratings yet

- Specification For FRP Weir and Scum BafflesDocument4 pagesSpecification For FRP Weir and Scum BafflesTS WongNo ratings yet

- Astm D1669Document3 pagesAstm D1669Donnabel CaleNo ratings yet

- Covered Walkways SpecificationsDocument5 pagesCovered Walkways SpecificationsErnesto LopezNo ratings yet

- Plot A 007: Curtain Wall and Glazed AssembliesDocument6 pagesPlot A 007: Curtain Wall and Glazed AssembliesRACHED ABBOUDNo ratings yet

- Section 10200 Louvers and VentsDocument3 pagesSection 10200 Louvers and VentsMØhãmmed ØwięsNo ratings yet

- Vol 2 Sec 05 MasonryDocument21 pagesVol 2 Sec 05 MasonryAdamNo ratings yet

- Gypsum Wallboard (Hard Metric Sizes) : Standard Specification ForDocument3 pagesGypsum Wallboard (Hard Metric Sizes) : Standard Specification Forkoushik15No ratings yet

- Part 1 - General: SECTION 15060 Hangers, Supports and Piping SpecialtiesDocument11 pagesPart 1 - General: SECTION 15060 Hangers, Supports and Piping SpecialtiesahmadNo ratings yet

- Asm XDocument6 pagesAsm XAlijihad2001aoNo ratings yet

- SPC Occ 221423 MeDocument4 pagesSPC Occ 221423 Metarekhisham1234No ratings yet

- V6JN5 3part CsiDocument3 pagesV6JN5 3part CsiWahyu Candra WardanaNo ratings yet

- AAB 092813 Calcium Silicate Board CeilingDocument7 pagesAAB 092813 Calcium Silicate Board CeilingTewodros TeferaNo ratings yet

- SECTION 07 72 00 Roof AccessoriesDocument8 pagesSECTION 07 72 00 Roof AccessoriesJuanPaoloYbañezNo ratings yet

- 440 SbceilingsDocument2 pages440 Sbceilingsscribdatapinky.comNo ratings yet

- ITS Installation & Civil Specification & Guidelines-05Document14 pagesITS Installation & Civil Specification & Guidelines-05N V Sumanth VallabhaneniNo ratings yet

- 03 48 00clcDocument5 pages03 48 00clcAira LauzonNo ratings yet

- Acoustic Louver SpecificationDocument2 pagesAcoustic Louver Specificationsameeh kadourahNo ratings yet

- Specifications Alphasorb Barrier Fabric Wrapped Acoustic PanelsDocument3 pagesSpecifications Alphasorb Barrier Fabric Wrapped Acoustic PanelsThabaswini SNo ratings yet

- SECTION 09515 Matal Ceiling SystemsDocument4 pagesSECTION 09515 Matal Ceiling SystemsIm ChinithNo ratings yet

- General Directorate 02835-1 Chain Link FencesDocument6 pagesGeneral Directorate 02835-1 Chain Link Fencesmotaz alzoubiNo ratings yet

- 04200Document9 pages04200uddinnadeemNo ratings yet

- Preparation of Test Panels For Accelerated and Outdoor Weathering of Bituminous CoatingsDocument3 pagesPreparation of Test Panels For Accelerated and Outdoor Weathering of Bituminous CoatingsMohammad YaseenNo ratings yet

- Section 067300 - Composite DeckingDocument4 pagesSection 067300 - Composite DeckingWENDING HUNo ratings yet

- SECTION 03 55 11 Gypsum Concrete Floor DecksDocument5 pagesSECTION 03 55 11 Gypsum Concrete Floor DecksJuanPaoloYbañezNo ratings yet

- Section 03210 Epoxy Coated Concrete ReinforcementDocument7 pagesSection 03210 Epoxy Coated Concrete ReinforcementgulzamanNo ratings yet

- SECTION 03200 Concrete ReinforcementDocument8 pagesSECTION 03200 Concrete ReinforcementSuranga ManuNo ratings yet

- Section 12484 Floor Mats and Frames PartDocument3 pagesSection 12484 Floor Mats and Frames PartjacksondcplNo ratings yet

- 05 10 00 Metal DeckingDocument5 pages05 10 00 Metal DeckingKiran D AnvekarNo ratings yet

- 05 31 00milDocument7 pages05 31 00milJerico NamucoNo ratings yet

- Interior Partition Wire MeshDocument9 pagesInterior Partition Wire MeshKağan ZorluoğluNo ratings yet

- GAD - Gallaf - After TBC Revc PDFDocument58 pagesGAD - Gallaf - After TBC Revc PDFDaniel DuongNo ratings yet

- Asdip ConcreteDocument3 pagesAsdip ConcreteRomani Noel S. Chavez Jr.No ratings yet

- Recycling 03 00059 v3Document15 pagesRecycling 03 00059 v3mojtaba nNo ratings yet

- Desmodur VL PDFDocument3 pagesDesmodur VL PDFsriatul2006No ratings yet

- Tornillo SinfinDocument96 pagesTornillo SinfintonniuccioNo ratings yet

- Sample Installation Standard of BTS PDFDocument10 pagesSample Installation Standard of BTS PDFJufriadi Baginda Naposo HrpNo ratings yet

- DFG 60BLKJ InstructionsDocument2 pagesDFG 60BLKJ Instructionsvikas_ojha54706No ratings yet

- Lpgtech KatalogDocument16 pagesLpgtech KatalogAvram VukasovićNo ratings yet

- Abb - Fuses - Ato Katalog - Eng Lo-Res 09.2015Document56 pagesAbb - Fuses - Ato Katalog - Eng Lo-Res 09.2015Edwin QuispeNo ratings yet

- TDS LF-370Document2 pagesTDS LF-370ofershochetNo ratings yet

- MSDS N9514 PDFDocument9 pagesMSDS N9514 PDFrikiNo ratings yet

- 5-Pdvsa34 Rp5 PolymersDocument80 pages5-Pdvsa34 Rp5 PolymersFranklin RevillNo ratings yet

- 22pa058 TechnicalDocument14 pages22pa058 TechnicalMica BisaresNo ratings yet

- Compact Type Electronically Controlled Pattern Sewing Machines For Extra Thick MaterialDocument66 pagesCompact Type Electronically Controlled Pattern Sewing Machines For Extra Thick MaterialBill JiangNo ratings yet

- Housekeeping Practical WorkbookDocument30 pagesHousekeeping Practical WorkbookDebra-Dreana Marshall-Stuart100% (2)

- Plomo 2Document14 pagesPlomo 2Octavio ContrerasNo ratings yet

- NGC3+Low Voltage+Switchgear,+Withdrawable+TypeDocument8 pagesNGC3+Low Voltage+Switchgear,+Withdrawable+TypedmugalloyNo ratings yet

- Presentation On Sintech Make Pumps For Sugar IndustryDocument21 pagesPresentation On Sintech Make Pumps For Sugar IndustrysahildhingraNo ratings yet

- BUJIAS Spark Plug External FlashoverDocument2 pagesBUJIAS Spark Plug External Flashoverjorge antonio guillenNo ratings yet

- 15055Document10 pages15055Waleed Abd El-HamiedNo ratings yet

- SELECTION Radiator Valve DIN 42560 Type A - ENG PDFDocument2 pagesSELECTION Radiator Valve DIN 42560 Type A - ENG PDFSiniša PerčićNo ratings yet

- Ra-11 RNSDocument64 pagesRa-11 RNSArif AnsariNo ratings yet

- 7601 - Crystallin Silica PDFDocument6 pages7601 - Crystallin Silica PDFAmalia NurbandiniNo ratings yet

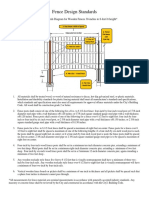

- Fence Design Standards: Structural Standards Diagram For Wooden Fences 30-Inches To 8-Feet in HeightDocument1 pageFence Design Standards: Structural Standards Diagram For Wooden Fences 30-Inches To 8-Feet in Heightmy mp3No ratings yet