Professional Documents

Culture Documents

Mobile Crane or Boom Truck Checklist Rev4 PDF

Mobile Crane or Boom Truck Checklist Rev4 PDF

Uploaded by

SMIYOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mobile Crane or Boom Truck Checklist Rev4 PDF

Mobile Crane or Boom Truck Checklist Rev4 PDF

Uploaded by

SMIYCopyright:

Available Formats

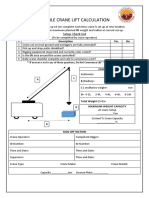

Inspection Checklist for a Mobile Crane or Boom Truck

1. Identification REFERENCE

Prime contractor: Site address: WCA 118

Contact person: Phone # Email: OHS 14.38(6)

Employer (crane owner): WCA 115(2)(e)

Contact person: Phone # Email: OHS 3.5

Crane operator: Phone #

Crane manufacturer: Crane model: Crane SN: OHS 14.3

Carrier manufacturer: Carrier model: Carrier LP #: OHS 14.3

Crane type: Hydraulic truck mounted Telescopic boom truck

Conventional crawler Rough terrain hydraulic Sign truck

Conventional truck mounted Carry deck Other:

Hydraulic crawler Articulating boom truck Other:

2. Documentation / Information Yes No REFERENCE

Crane annual inspection completed by P. Engineer, document and sticker available? OHS 14.71(1)

Combination Crane Truck (boom truck) has Stability Test Completed? Must have a OHS 4.8(2)(a)

Professional Engineer’s stamped/sealed document stating that unit has been tested as per OHS 14.(2)(1)

ANSI/SAE B30.22-2005 (J765) Stability Testing Requirements. This document will state if the ANSI/ASME

crane is safe to operate in all positions (360 degree) with the crane manufacturers supplied load B30.22-2005

chart or if the crane has a reduced capacity “Custom Load Chart” provided. See WorkSafe BC OHS 14.5(3)

Guideline G4.8 Rated Capacity of Truck-Mounted Cranes.

Crane operator qualifications, BC Association of Crane Safety certified (BC CraneSafe) or OHS 14.34(1)

Trades Qualified (Red-Seal) certified? OHS 14.34.1(a)

Crane manufacturer’s manual/operators manual available at the work site? OHS 14.12

Crane log book, start of shift crane inspection completed & signed? Checklist style? OHS 14.14(a)

OHS 4.9(2)(b)

Crane load chart is available for the boom, counterweight and outrigger/stabilizer position that OHS 4.8

the unit is set-up in? OHS 4.9

Crane set-up beside an excavation or on a concrete slab needs engineering? OHS 14.69(2)

Crane on a floating support has the rated capacity (barge & crane) determined by a P. Eng.? OHS 14.66(3)

Crane boom with vibratory extractor, drop hammer or dynamic compaction has a 1 month P. OHS 14.72(1)

Engineer’s boom inspection completed?

Crane boom driving piles with vibratory hammer has a 3 month P. Engineer’s boom inspection OHSR 14.72(2)

completed?

Obvious crane modification(s), structural (welding) repairs are certified by a P. Engineer? OHSR 14.15(2)

Radio Contact for overlapping cranes, tower crane, pump truck or mobile equipment? OHS 14.49(1)

Overhead power-lines considered? Procedure in place? OHS 14.52(1)

30M33 assurance in writing available? Guarding installed? OHS 19.25

Is a critical lift required? Tandem-lift, man-basket being used, lifts over power-lines, lifting a OHS 14.42

submerged load, 90% of crane capacity @ 50% boom length, load centre of gravity changing. OHS 14.42(1)

3. Set-up, Maintenance and Use Yes No REFERENCE

Safe lifting, the crane tasks are being carried out safely? Crane set-up and hoisting area is OHS 14.38(6)

flagged-off and all persons at this workplace regardless of their involvement in the hoisting OHS 14.40

duties are safe? OHS 14.41

OHS 14.44

The crane operator has full control of the equipment controls & is engage in no other duties. OHS 14.37.1

Revision #4, September 10, 2009, Doug Y.

Inspection Checklist for a Mobile Crane or Boom Truck

3. Set-up, Maintenance and Use Continued Yes No REFERENCE

Traffic control in place? OHS 18.2

Crane outriggers/stabilizers are set on appropriate cribbing for the soil or base? OHS 14.69(4)

Crane outrigger/stabilizer beams are marked to indicate correct extension is achieved? OHS 14.67(2)

Crane outrigger/stabilizer floats (pads) are secured to jacks? OHS 14.67(4)

Crane or carrier leveled for operation? OHS 14.66(1)

Crane anti-two-block functioning when used to hoist a man-basket? OHS 13.28(1)

Crane load cell (11 ton or greater capacity) or crane disengagement device functioning? OHS 14.64

OHS 14.36(2)

Crane operator knows the weight of the load being hoisted? OHS 14.36(1)

Boom angle indicator present and functioning? OHS 14.7

Crane hoist line inspected for broken wires, crushing and correct drum spooling? OHS 15.25

Fire extinguisher in crane cab? Minimum 10 BC rating? OHS 14.33

Crane horn (auditable warning device) functional? OHS 14.18

Crane controls are clearly marked for their function? OHS 14.28

Rigging Inspected for certification (WLL), broken wires or crushing? OHS 15.4(2)

OHS 15.5(1)

OHS 15.25

Chain sling(s) have been annually inspected & a record of the inspection (tag) is available. OHS 15.50

4. Crane Capacity Analysis

LOAD INFORMATION CRANE # 1 CRANE # 2

Load description:

Load length:

Load width/diameter:

Load height:

Hoisting up height:

Load weight:

Block or ball weight:

Rigging weight:

GROSS LOAD WEIGHT =

CRANE INFORMATION CRANE # 1 CRANE # 2

Crane make/size/model:

Crane boom length:

Crane jib length:

Crane counterweight:

Crane radius (furthest load distance):

Crane gross capacity:

Crane component deductions: (jib, load line, rooster)

Crane net capacity:

% OF CRANE CAPACITY =

(gross load weight / crane net cap X 100)

Maximum crane radius allowed (from load chart):

CSA - Z150-98, Safety Code on Mobile Cranes

ANSI/ASME - B30.22-2005, Safety Code on Articulating Boom Cranes

WorkSafe BC Guideline G4.8 Rated Capacity of Truck-Mounted Cranes

WorkSafe BC Guideline G14.34.1 Operator Certification

Revision #4, September 10, 2009, Doug Y.

You might also like

- DMF360 Tandem Lift With ForkliftDocument4 pagesDMF360 Tandem Lift With Forkliftreda mesbahNo ratings yet

- Lifting Plan: General Information: LP - 01 / Rev 00Document8 pagesLifting Plan: General Information: LP - 01 / Rev 00Ram BeesettiNo ratings yet

- Crane ChecklistDocument1 pageCrane Checklistsajin0% (1)

- Rigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Document3 pagesRigging Plan Worksheet: 4.0/3b07e011.pdf 1 (11/2006)Cleiciane FrancoNo ratings yet

- JSA For Crawler Crane Installation FormDocument3 pagesJSA For Crawler Crane Installation FormDaniel Prakoso50% (2)

- Combination-Bar Lifting Beam and Spreader BeamDocument1 pageCombination-Bar Lifting Beam and Spreader BeammaomontesNo ratings yet

- Mobile Crawler Crane ChecklistDocument2 pagesMobile Crawler Crane ChecklistJohn Kurong100% (5)

- Below The Hook Lifting HanesDocument26 pagesBelow The Hook Lifting HanesmaomontesNo ratings yet

- Crane InspectionDocument1 pageCrane InspectionMKhairulMD100% (1)

- Mobile Elevating Work Platforms: AUGUST 2014Document64 pagesMobile Elevating Work Platforms: AUGUST 2014Parmod RanaNo ratings yet

- A Lifting Plan Using ExcavatorDocument1 pageA Lifting Plan Using ExcavatorSyed Fawad ShahNo ratings yet

- N405 Crane - Lift Supervisor 20141Document9 pagesN405 Crane - Lift Supervisor 20141dsn_sarmaNo ratings yet

- Critical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectDocument1 pageCritical Lifting Plan 10T, 80% Capacity, One Side 10m: Al-Dur Ii Iwpp ProjectJianping KeNo ratings yet

- Crane Operator Daily Check ListDocument1 pageCrane Operator Daily Check ListMohamed Kasim Mohamed Ibrahim83% (6)

- Crane Inspection Checklist 2Document1 pageCrane Inspection Checklist 2eslamNo ratings yet

- Lifting Plan FormDocument2 pagesLifting Plan FormezuanNo ratings yet

- Lifting Operation ChecklistDocument8 pagesLifting Operation ChecklistHein SiNo ratings yet

- Inspection Hiap CraneDocument2 pagesInspection Hiap CranePurwanroNo ratings yet

- Suspended Personnel Platform Check List PDFDocument1 pageSuspended Personnel Platform Check List PDFmark lester caluzaNo ratings yet

- Crane Mounted On Truck Inspection Report MH 12 FC8311Document12 pagesCrane Mounted On Truck Inspection Report MH 12 FC8311Safety DeptNo ratings yet

- B Lifting Plan Using LorryDocument1 pageB Lifting Plan Using LorrySyed Fawad ShahNo ratings yet

- Boom Truck Hiab Inspection ChecklistDocument9 pagesBoom Truck Hiab Inspection ChecklistPedro Antonio P. PaniaguaNo ratings yet

- Basic Lifting PlanDocument2 pagesBasic Lifting Planeslam100% (1)

- Work at HightDocument32 pagesWork at HightMY TEC SUPPORTNo ratings yet

- Pre Crane Lift ChecklistDocument1 pagePre Crane Lift ChecklistmiaicarbaNo ratings yet

- Excavator Pre-Use Inspection ChecklistDocument1 pageExcavator Pre-Use Inspection ChecklistFyan SaputraNo ratings yet

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- Checklist Inspection Tower CraneDocument2 pagesChecklist Inspection Tower CranemaomontesNo ratings yet

- Webbing Sling Safety Inspection Checklist Report PilotDocument1 pageWebbing Sling Safety Inspection Checklist Report PilotThirumaran MuthusamyNo ratings yet

- Pre Crane Lift ChecklistDocument1 pagePre Crane Lift Checklistg665013No ratings yet

- Lifting Plan SheetDocument2 pagesLifting Plan SheetAalam Irshad100% (1)

- Lifting Plan For Med Risk Rev 11 FinalDocument2 pagesLifting Plan For Med Risk Rev 11 FinalŠhiññ ŠóhäïNo ratings yet

- RA Hiab Crane TruckDocument8 pagesRA Hiab Crane TruckRichard Joseph67% (3)

- Ladder DesignDocument1 pageLadder DesignmaomontesNo ratings yet

- PTW Critical Lifting OperationDocument5 pagesPTW Critical Lifting Operationfikadu alemiNo ratings yet

- Crane Lifting Calculation SheetDocument1 pageCrane Lifting Calculation SheetAkbar Dawood100% (1)

- 737 Systems SchematicsDocument31 pages737 Systems SchematicsKhurram Naseem100% (5)

- Non Routine Lift Plan Check ListDocument2 pagesNon Routine Lift Plan Check Listmohamed atef0% (1)

- Load Chart Manual: Articulating Crane OperatorDocument9 pagesLoad Chart Manual: Articulating Crane OperatormaomontesNo ratings yet

- Lifting Plan For 62.07 RepairDocument6 pagesLifting Plan For 62.07 RepairLaith Salman100% (1)

- Pre-Start Checklist For Hydraulic (Mobile) Crane: Form: HDEC-HSE-CE-005 (E)Document3 pagesPre-Start Checklist For Hydraulic (Mobile) Crane: Form: HDEC-HSE-CE-005 (E)Nurma Rifah100% (4)

- OHDC Lifting ProcedureDocument12 pagesOHDC Lifting ProcedureHamid Ali100% (1)

- Indoor Air QualityDocument16 pagesIndoor Air QualityMichael Grant WhiteNo ratings yet

- Critical Lift Form - 16-3 - Final FillableDocument6 pagesCritical Lift Form - 16-3 - Final FillableKazim NawazNo ratings yet

- Economical Lifting Beams: Adjustable Spreader/Lifting Beam (ASLB16)Document11 pagesEconomical Lifting Beams: Adjustable Spreader/Lifting Beam (ASLB16)roopjayNo ratings yet

- Mobile CraneDocument2 pagesMobile CraneRashidi Rahman33% (3)

- PMF 015 HSE 151 v1 Lifting PlanDocument8 pagesPMF 015 HSE 151 v1 Lifting Plansikandar1234No ratings yet

- Planned Critical Lift Crane PermitDocument5 pagesPlanned Critical Lift Crane PermitsurnaikNo ratings yet

- Build A Microwave Transformer Homemade WelderDocument24 pagesBuild A Microwave Transformer Homemade Weldermarius_danila8736No ratings yet

- Steel ConnectionsDocument69 pagesSteel Connectionsmaomontes75% (4)

- Manlift ChecklistDocument1 pageManlift ChecklistFarid Brango0% (1)

- Wire Rope Wear, Abuse and Removal CriteriaDocument2 pagesWire Rope Wear, Abuse and Removal CriteriamaomontesNo ratings yet

- Lifting Plan Blank (PDF Library)Document4 pagesLifting Plan Blank (PDF Library)Alina UribeNo ratings yet

- Self Erecting Tower Crane Operators GuideDocument55 pagesSelf Erecting Tower Crane Operators Guidemaomontes100% (2)

- Lifting Plan and FarmDocument7 pagesLifting Plan and FarmAbid RehmanNo ratings yet

- Lifting PlanDocument10 pagesLifting PlanEko Kurniawan100% (4)

- Basic Lifting PlanDocument1 pageBasic Lifting PlanParashuram PatilNo ratings yet

- Boiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsDocument56 pagesBoiler Efficiency, Losses and Performance Optimization: Boiler Shutdown, Emergencies, ProtectionsPranav Sai100% (1)

- ISO Standards Collection - CranesDocument4 pagesISO Standards Collection - CranesJosé Rezende0% (1)

- Tower Cranes CommisioningDocument15 pagesTower Cranes Commisioningpammu18No ratings yet

- Ethane Deep Recovery Facility Project (Edrf) : Tie-In Package For Tip-0137Document63 pagesEthane Deep Recovery Facility Project (Edrf) : Tie-In Package For Tip-0137sarangpuneNo ratings yet

- 3 Green Lift Checklist FormDocument2 pages3 Green Lift Checklist FormHưng Hoàng DuyNo ratings yet

- Tower Crane Daily Inspection FormDocument1 pageTower Crane Daily Inspection FormZainul Hazwan83% (6)

- Tower Crane Inspection ChecklistDocument4 pagesTower Crane Inspection Checklistmailme_viju100% (1)

- DailyCranePre OpChecklist PDFDocument1 pageDailyCranePre OpChecklist PDFPablo Hidalgo ValenzuelaNo ratings yet

- Steam PDFDocument467 pagesSteam PDFRavi Bhaskar100% (1)

- Fire Standard ComparisionDocument59 pagesFire Standard ComparisionabmopalhvacNo ratings yet

- Osha 1910.27Document16 pagesOsha 1910.27maomontesNo ratings yet

- Crane Lifting Permit REVISION 01Document1 pageCrane Lifting Permit REVISION 01Aldrin100% (1)

- Form-067-Weekly Crane Inspection ChecklistDocument2 pagesForm-067-Weekly Crane Inspection Checklistshamroz khanNo ratings yet

- Rigging Up Checklist: Rig ModelDocument2 pagesRigging Up Checklist: Rig Model89simbuNo ratings yet

- Checklist For Lifting Plan: S/N Items YES NO RemarksDocument1 pageChecklist For Lifting Plan: S/N Items YES NO RemarksAndrianoNo ratings yet

- Lifting Plan For Erection of 2nd To 6th Rev.3Document11 pagesLifting Plan For Erection of 2nd To 6th Rev.3Rhannie GarciaNo ratings yet

- Flowchart Hpg1034Document1 pageFlowchart Hpg1034SharulNo ratings yet

- Employer Information: Crane Company DateDocument3 pagesEmployer Information: Crane Company DatekaniniuserNo ratings yet

- Astm A586 - 92Document4 pagesAstm A586 - 92maomontesNo ratings yet

- Safety Is Our First Priority: Optimal Lateral Lifting Solution For Molds and EquipmentsDocument4 pagesSafety Is Our First Priority: Optimal Lateral Lifting Solution For Molds and EquipmentsmaomontesNo ratings yet

- Channel Lifters P2 (4.5) : 1400 Lbs (635 KG)Document2 pagesChannel Lifters P2 (4.5) : 1400 Lbs (635 KG)maomontesNo ratings yet

- Handbook of Steel Construction: 9 Edition, 3 Revised Printing 2007 RevisionsDocument16 pagesHandbook of Steel Construction: 9 Edition, 3 Revised Printing 2007 RevisionsmaomontesNo ratings yet

- Yoke Rigging HardwareDocument128 pagesYoke Rigging HardwaremaomontesNo ratings yet

- Load Attaching Points On Loads in Nuclear Power PlantsDocument59 pagesLoad Attaching Points On Loads in Nuclear Power PlantsmaomontesNo ratings yet

- G&s Chassis Product-GuideDocument24 pagesG&s Chassis Product-GuidemaomontesNo ratings yet

- Astm A36-04Document4 pagesAstm A36-04dai.nhNo ratings yet

- Lift It Twin-Path Slings PIBDocument6 pagesLift It Twin-Path Slings PIBmaomontesNo ratings yet

- OSHA - Cranes and Derricks PDFDocument32 pagesOSHA - Cranes and Derricks PDFmaomontesNo ratings yet

- Errata ASME BTH-1 2005 - PDFDocument1 pageErrata ASME BTH-1 2005 - PDFmaomontesNo ratings yet

- Transyt 15 User GuideDocument546 pagesTransyt 15 User GuideLuis VilchesNo ratings yet

- Viking Johnson MaxiFit MaxiXtra Couplings End CapsDocument1 pageViking Johnson MaxiFit MaxiXtra Couplings End CapsjimmyNo ratings yet

- PDFDocument3 pagesPDFAlexNo ratings yet

- Sd7201gcpe1q ManualDocument4 pagesSd7201gcpe1q Manualmarc pandalesNo ratings yet

- On-Load Tap-Changers: Selection GuideDocument8 pagesOn-Load Tap-Changers: Selection GuideRey ArthurNo ratings yet

- Hazard Analysis: Total Flooding Extinguishing SystemDocument14 pagesHazard Analysis: Total Flooding Extinguishing SystemJose Antonio LaraNo ratings yet

- Comprehensive Mobility Plan For Pune 2015Document22 pagesComprehensive Mobility Plan For Pune 2015rgadgiNo ratings yet

- Woodtech Pu ExteriorDocument2 pagesWoodtech Pu ExteriorSathish SathishNo ratings yet

- Gamification For The Purpose of Eliciting Requirements A Systematic Literature Review PDFDocument21 pagesGamification For The Purpose of Eliciting Requirements A Systematic Literature Review PDFadnan naseemNo ratings yet

- Treinamento Sap Apo Planejamento de FornecimentoDocument103 pagesTreinamento Sap Apo Planejamento de FornecimentoAntoniniNo ratings yet

- PNDDocument1 pagePNDbilalNo ratings yet

- Calibracion MtuDocument272 pagesCalibracion MtuJoséNo ratings yet

- Fittings For Glass 2012Document532 pagesFittings For Glass 2012transinovNo ratings yet

- Sigmapro18A Ext. Bass Shelf, Medium Power, Low F3: Box PropertiesDocument10 pagesSigmapro18A Ext. Bass Shelf, Medium Power, Low F3: Box PropertiesAdrian SalaNo ratings yet

- LBK-System Overview enDocument8 pagesLBK-System Overview enFabio AguiarNo ratings yet

- Jorc Coal Exploration Procedure PDFDocument24 pagesJorc Coal Exploration Procedure PDFRico SalimNo ratings yet

- MS40A Opretion ManaualDocument128 pagesMS40A Opretion ManaualzNo ratings yet

- Technical Terms Chapter 80Document5 pagesTechnical Terms Chapter 80thena MartinNo ratings yet

- Caleffi Autofeed Backflow Valve Combination BrochureDocument4 pagesCaleffi Autofeed Backflow Valve Combination Brochuree-ComfortUSANo ratings yet

- Mapping The Scienti Fic Research On Open Data: A Bibliometric ReviewDocument12 pagesMapping The Scienti Fic Research On Open Data: A Bibliometric ReviewJunaid AfzalNo ratings yet

- Polyfuse: The BasicsDocument4 pagesPolyfuse: The BasicsDianne Claudinne MapanooNo ratings yet

- Chapter 3 - MATERIAL HANDLING PDFDocument10 pagesChapter 3 - MATERIAL HANDLING PDFShiverrania 29080% (2)