Professional Documents

Culture Documents

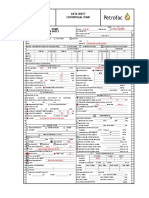

Column Spec Data Sheets - Coulson

Uploaded by

Ahmed YounisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Column Spec Data Sheets - Coulson

Uploaded by

Ahmed YounisCopyright:

Available Formats

992 CHEMICAL ENGINEERING

Equipment No. (Tag)

Column Tray data sheet ,,,, ,,,, Descript. (Func.)

•J (PROCEED)

Sheet No.

1

Operating Data TOP BOTTOM

OR TOP

2

AND BOTTOM

TOWER INSIDE DIAMETER (Inches) (mm) 3

TRAY SPACE (Inches) (mm) 4

TOTAL TRAYS IN SECTION 5

6

7

Internal Conditions at Tray Number

VAPOUR TO TRAY 8

RATE (lb/hr) (kg/hr) 9

3

DENSITY (lb/ft3) (kg/m ) 10

PRESSURE (psi) (kg/cm2) (Bar g) (Bar a) 11

TEMPERATURE (°F) (°C) 12

LIQUID FROM TRAY 13

RATE (lb/hr) (kg/m3) 14

DENSITY (lb/ft3) (kg/m3) 15

TEMPERATURE (°F) (°C) 16

VISCOSITY cP 17

NUMBER OF LIQUID FLOW PATHS 18

19

Technical/Mechanical Data 20

TOWER MANHOLE INSIDE DIAMETER (Inches) (mm) 21

TRAY MATERIAL 22

TRAY THICKNESS 23

CAP MATERIAL 24

HOLDDOWN MATERIAL 25

NUTS and BOLTS MATERIAL 26

SUPPORT RING MATERIAL 27

SUPPORT RING SIZE (Inches) (mm) 28

DOWNCOMER BOLT BAR THICKNESS (Inches) (mm) 29

30

CORROSION ALLOWANCE 31

TRAYS (Inches) (mm) 32

TOWER ATTACHMENTS (Inches) (mm) 33

TRAYS NUMBERED FROM TOP TO BOTTOM 34

TRAY MANWAY REMOVAL FROM 35

36

37

DATE OF ENQUIRY DATE OF ORDER 38

ORDER No. DRG. No. 39

MANUFACTURER 40

41

NOTES 42

(1) INTERNAL VAPOUR AND LIQUID LOADINGS AT THE LIMITING SECTIONS ARE REQUIRED TO ENSURE PROPER TRAY DESIGN. 43

DENSITIES ARE REQUIRED AT ACTUAL INSIDE TOWER CONDITIONS OF TEMPERATURE and PRESSURE. VISCOSITY IS NOT 44

REQUIRED UNLESS GREATER THAN 0.7 cp 45

46

(2) CROSS OUT DIMENSION UNITS WHICH DO NOT APPLY. TRAY SUPPLIER TO ADVISE. 47

REMARKS 48

49

50

51

52

53

54

55

56

57

Prepared 3 6 58

Checked 2 5 59

Approved 1 4 60

Date Engineering Process REV By Appr. Date REV By Appr. Date 61

Service Company Address 62

Equipment No. 63

Project No. 64

You might also like

- Modelos Folhas de Especificação, Coulson Richardsons ChemicalDocument12 pagesModelos Folhas de Especificação, Coulson Richardsons ChemicalEmmyli SantosNo ratings yet

- Belt Conveyor. Technical Data SheetDocument1 pageBelt Conveyor. Technical Data SheetCarmen FloresNo ratings yet

- WHITE Operating ManualDocument32 pagesWHITE Operating ManualJaime Asis LopezNo ratings yet

- Centrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si UnitsDocument15 pagesCentrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si Unitsf09aiNo ratings yet

- Startup Formate - TBDocument1 pageStartup Formate - TBashishvaidNo ratings yet

- De Nora Water Technologies Karabiga: Milano - ItalyDocument1 pageDe Nora Water Technologies Karabiga: Milano - ItalyÇağlar EbeperiNo ratings yet

- (API 610-10th) Centrifugal Pump - SI UnitsDocument15 pages(API 610-10th) Centrifugal Pump - SI UnitsArieWBNo ratings yet

- Spec SheetDocument7 pagesSpec SheetPatricia MirandaNo ratings yet

- Main Af Form 1458 Daily Steam Plant Operating LogDocument2 pagesMain Af Form 1458 Daily Steam Plant Operating LogRitche Lim BragaisNo ratings yet

- (API 610-10th) Centrifugal Pump - SI Units PDFDocument2 pages(API 610-10th) Centrifugal Pump - SI Units PDFParaschiv AlexandruNo ratings yet

- (API 610-10th) Centrifugal Pump - SI UnitsDocument2 pages(API 610-10th) Centrifugal Pump - SI UnitsParaschiv AlexandruNo ratings yet

- DX170W-5 Spec Sheet - Ver04Document33 pagesDX170W-5 Spec Sheet - Ver04AbdelrahmanNo ratings yet

- 02809MCR - Freightliner - NmaldonadoDocument11 pages02809MCR - Freightliner - NmaldonadoruthNo ratings yet

- Data Sheet For Spiral Heat Exchanger: Unit: Doc. Type: Progr: Rev. Sheet OF DateDocument1 pageData Sheet For Spiral Heat Exchanger: Unit: Doc. Type: Progr: Rev. Sheet OF DateDesiree MolinaNo ratings yet

- DSH in 621 3Document13 pagesDSH in 621 3Procurement PardisanNo ratings yet

- Aip Cy 2021Document2 pagesAip Cy 2021Narmen Pestola EchinNo ratings yet

- Publication, 81-170-00003. S Indicate Groups Pertaining To Police VehiclesDocument1,050 pagesPublication, 81-170-00003. S Indicate Groups Pertaining To Police VehiclesChristopher VizcarraNo ratings yet

- Preliminary Packing List (Format)Document1 pagePreliminary Packing List (Format)salman KhanNo ratings yet

- Data SheetDocument1 pageData SheetStephen BeasleyNo ratings yet

- Valve Accessory Design Data SheetDocument4 pagesValve Accessory Design Data SheetAzrul Ikhwan AzharNo ratings yet

- Schematic Compeletion - AzhDocument15 pagesSchematic Compeletion - AzhHamid Reza BabaeiNo ratings yet

- Traffic Engineering With BGP and Level3 PDFDocument29 pagesTraffic Engineering With BGP and Level3 PDFSamuel TedesqueNo ratings yet

- Optibelt Drive Calculation FormDocument1 pageOptibelt Drive Calculation FormChrionny AlumediNo ratings yet

- GeneralDocument1 pageGeneralamirNo ratings yet

- Transmission SectionDocument376 pagesTransmission Sectionjhon greigNo ratings yet

- User Man Eng Af01gt v5 r2Document80 pagesUser Man Eng Af01gt v5 r2l1f3b00kNo ratings yet

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- Corrosion Coupon Data SheetDocument3 pagesCorrosion Coupon Data SheetKaluoji50% (2)

- Corrosion Coupon Data SheetDocument3 pagesCorrosion Coupon Data SheetĐiệnBiênNhâmNo ratings yet

- Corrosion Coupon Data SheetDocument3 pagesCorrosion Coupon Data SheetĐiệnBiênNhâmNo ratings yet

- 6143-MAR-EU-1030 - R0 (1) Approved MAR For Rubber Grommet-Pioneer HardwareDocument63 pages6143-MAR-EU-1030 - R0 (1) Approved MAR For Rubber Grommet-Pioneer HardwareNAVANEETHNo ratings yet

- DL220-5 Spec Sheet 150901Document23 pagesDL220-5 Spec Sheet 150901Abdelrahman100% (1)

- Handheld Intelligent Inkjet Printer User ManualDocument10 pagesHandheld Intelligent Inkjet Printer User ManualWalter BassumNo ratings yet

- Gi400 LCDDocument44 pagesGi400 LCDJavier Flores CortesNo ratings yet

- 910-0046 Rev-T RED ENG RED Command Protocol Reference GuideDocument61 pages910-0046 Rev-T RED ENG RED Command Protocol Reference GuideIlja MasikNo ratings yet

- INDIA06 7 RChopra IndiaDocument14 pagesINDIA06 7 RChopra IndiaalexalgyNo ratings yet

- TR Template AugustDocument16 pagesTR Template AugustMohamed ZakiNo ratings yet

- P-3C "Orion" Dangerous Waters™ OWTOP: (Orion Warrior Training and Operating Procedures)Document52 pagesP-3C "Orion" Dangerous Waters™ OWTOP: (Orion Warrior Training and Operating Procedures)pepeNo ratings yet

- Model Document No: Modification of User Service Data Sheet 2016.06.24 J.G - Han D.K. JiDocument27 pagesModel Document No: Modification of User Service Data Sheet 2016.06.24 J.G - Han D.K. JiAbdelrahmanNo ratings yet

- SWC Mec DTS P001abDocument9 pagesSWC Mec DTS P001abAlonso1593No ratings yet

- Centrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorDocument2 pagesCentrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorJuan José Grajeda AguayoNo ratings yet

- For Dim CRP 059 15 48 HR CheckDocument8 pagesFor Dim CRP 059 15 48 HR CheckJhony GomezNo ratings yet

- Mixer Data SheetDocument2 pagesMixer Data SheetBenedick Jayson MartiNo ratings yet

- EPC-1A Hot Tappings Post-Site-Visit Master 23nov2020Document1 pageEPC-1A Hot Tappings Post-Site-Visit Master 23nov2020Joseley D'souzaNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- 2-Vertical Separator PDFDocument1 page2-Vertical Separator PDFSudarshan GopalNo ratings yet

- Pro Iii Evo: Manual (EN)Document47 pagesPro Iii Evo: Manual (EN)Jef FerreiraNo ratings yet

- ARC01016-Building Data SheetDocument12 pagesARC01016-Building Data SheetCamilo CastilloNo ratings yet

- Piping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaDocument3 pagesPiping Pressure Drop and Pump Design Calculation Sheet: PT Ca Ltex Pacific IndonesiaElias EliasNo ratings yet

- 5691 CPP Me DS 0001 0 PDFDocument17 pages5691 CPP Me DS 0001 0 PDFĐiệnBiênNhâmNo ratings yet

- Process Design QuestionaryDocument30 pagesProcess Design QuestionaryNguyen Anh TungNo ratings yet

- ED1801 Ventilation Fan WOKDocument46 pagesED1801 Ventilation Fan WOKJOHAN VILCHEZNo ratings yet

- Code Manual For Hitachi Service Report FormDocument37 pagesCode Manual For Hitachi Service Report FormYoga SugiNo ratings yet

- Compaq Prover - Rev - ABDocument1 pageCompaq Prover - Rev - ABPsa Metering RU II DumaiNo ratings yet

- Apron FeederDocument8 pagesApron FeederBruce QuareNo ratings yet

- Exact Eco Check Instruction ManualDocument20 pagesExact Eco Check Instruction ManualNikita PuertoNo ratings yet

- Company Catalogue: Power of Applied IntelligenceDocument11 pagesCompany Catalogue: Power of Applied IntelligenceHamza ArifNo ratings yet

- Typical Pump P&IDDocument1 pageTypical Pump P&IDAhmed YounisNo ratings yet

- Air Cooled Heat Exchanger Layout 2Document1 pageAir Cooled Heat Exchanger Layout 2Ahmed YounisNo ratings yet

- Error Vs Thermometer ReadingDocument3 pagesError Vs Thermometer ReadingAhmed YounisNo ratings yet

- Ethyl Acetate Productions by Conventional and Reactive Distillation Processes Using Aspen Plus PDFDocument12 pagesEthyl Acetate Productions by Conventional and Reactive Distillation Processes Using Aspen Plus PDFAhmed YounisNo ratings yet

- 4638 16635 1 PBDocument5 pages4638 16635 1 PBAhmed YounisNo ratings yet

- Typical Centrifugal Compressor P&IDDocument1 pageTypical Centrifugal Compressor P&IDAhmed YounisNo ratings yet

- Steam ReformingDocument131 pagesSteam ReformingAhmed YounisNo ratings yet

- MCE 3601-Lab 1Document1 pageMCE 3601-Lab 1Ahmed YounisNo ratings yet

- Report With ConclusionDocument30 pagesReport With ConclusionAhmed YounisNo ratings yet

- 101-Article Text-171-1-10-20140518 PDFDocument11 pages101-Article Text-171-1-10-20140518 PDFDessy Alfu LaylaNo ratings yet

- Activity II Report Format PDFDocument1 pageActivity II Report Format PDFAhmed YounisNo ratings yet

- Article PDFDocument40 pagesArticle PDFAhmed YounisNo ratings yet

- Executive Summary: Design ReportDocument3 pagesExecutive Summary: Design ReportAhmed YounisNo ratings yet

- Net Flow ProfileDocument3 pagesNet Flow ProfileAhmed YounisNo ratings yet

- Methanol From GlycerolDocument2 pagesMethanol From GlycerolAhmed YounisNo ratings yet

- 101-Article Text-171-1-10-20140518 PDFDocument11 pages101-Article Text-171-1-10-20140518 PDFDessy Alfu LaylaNo ratings yet

- Soap Manufacturing PDFDocument6 pagesSoap Manufacturing PDFAhmed YounisNo ratings yet

- Clinker Production Caliculation ProgramDocument3 pagesClinker Production Caliculation ProgramAhmed YounisNo ratings yet

- Distance From Addis Ababa (Capital), KM Installed Clinker Capacity (TPD) Operation CommencementDocument21 pagesDistance From Addis Ababa (Capital), KM Installed Clinker Capacity (TPD) Operation CommencementDuabelasyusufNo ratings yet

- Assignment - Final Project - Draft1Document22 pagesAssignment - Final Project - Draft1Ahmed YounisNo ratings yet

- Chap 3 VDZ Activity Report 09-12Document19 pagesChap 3 VDZ Activity Report 09-12Ahmed YounisNo ratings yet

- Solid Process SamplingDocument23 pagesSolid Process SamplingAhmed YounisNo ratings yet

- 0 Basics Facts About ClinkerDocument1 page0 Basics Facts About ClinkerAhmed Younis100% (1)

- F Sheet CementDocument1 pageF Sheet CementAhmed YounisNo ratings yet

- Crude Column With Heat Train and Naphtha SplitterDocument1 pageCrude Column With Heat Train and Naphtha SplitterAhmed YounisNo ratings yet

- White CementDocument5 pagesWhite CementAhmed Younis100% (1)

- Sat Jan 20 00:29:43 2018 Case: E:/Aspentech 8/aspen Hysys V7.2/Cases/Refining Tutorial - HSC Flowsheet: Atmos Tower (Col1)Document1 pageSat Jan 20 00:29:43 2018 Case: E:/Aspentech 8/aspen Hysys V7.2/Cases/Refining Tutorial - HSC Flowsheet: Atmos Tower (Col1)Ahmed YounisNo ratings yet

- Hysys PrintDocument1 pageHysys PrintAhmed YounisNo ratings yet

- MS in Accounting Sep 1997 - Sep 2001: E-MailDocument2 pagesMS in Accounting Sep 1997 - Sep 2001: E-MailAhmed YounisNo ratings yet

- Instructions HMG 47-48Document2 pagesInstructions HMG 47-48arindamdhar2004No ratings yet

- Centrifugal PumpsDocument0 pagesCentrifugal PumpsAbsar MamunNo ratings yet

- Daikin Individual Control Systems Technical Data BookDocument37 pagesDaikin Individual Control Systems Technical Data BooktonylyfNo ratings yet

- BAC Open Cooling Towers BaltimoreDocument8 pagesBAC Open Cooling Towers Baltimorekimran80No ratings yet

- NES 838 Part2Document42 pagesNES 838 Part2QTESNo ratings yet

- Applications of Solar Energy PDFDocument42 pagesApplications of Solar Energy PDFpallav guptaNo ratings yet

- HW 5 SolDocument20 pagesHW 5 SolKhoa Le TienNo ratings yet

- Simplified Model For Evaluating Soil Liquefaction Potential Using CPTUDocument8 pagesSimplified Model For Evaluating Soil Liquefaction Potential Using CPTUIbrahim SuryaNo ratings yet

- E6 SAS 14 Example Sheet 2 SolutionsDocument8 pagesE6 SAS 14 Example Sheet 2 Solutionstamucha.fx.derivNo ratings yet

- Telescope Equations: Useful Formulas For Exploring The Night Sky Randy CulpDocument97 pagesTelescope Equations: Useful Formulas For Exploring The Night Sky Randy CulparitmeticsNo ratings yet

- 2500 Busbar CalculationDocument4 pages2500 Busbar CalculationPramod B.Wankhade100% (1)

- Sensors: A New Approach For Improving Reliability of Personal Navigation Devices Under Harsh GNSS Signal ConditionsDocument21 pagesSensors: A New Approach For Improving Reliability of Personal Navigation Devices Under Harsh GNSS Signal ConditionsRuddy EspejoNo ratings yet

- La Teoria SintergiaDocument17 pagesLa Teoria SintergiaCarlos CárdenasNo ratings yet

- The Pore-Pressure Coefficients A and B: A (Ao, - AU,) ) Est Mentally B Are Given. BDocument5 pagesThe Pore-Pressure Coefficients A and B: A (Ao, - AU,) ) Est Mentally B Are Given. BdaveNo ratings yet

- Anti Sweat HeatersDocument2 pagesAnti Sweat HeatersbreavmacNo ratings yet

- To Estimate The Charge Induced On Each One of The Two Identical Styrofoam BallsDocument15 pagesTo Estimate The Charge Induced On Each One of The Two Identical Styrofoam Ballskiran ViratNo ratings yet

- The Klein-Gordon EquationDocument22 pagesThe Klein-Gordon EquationAnderson CalistroNo ratings yet

- Solid Works EMS TutorialsDocument353 pagesSolid Works EMS TutorialsAnonymous sAmJfcV100% (1)

- Timoshenko Beam ElementDocument11 pagesTimoshenko Beam ElementMahmoud M.S. DwaikatNo ratings yet

- Electronique - Audio - Microphone Valve PreampDocument7 pagesElectronique - Audio - Microphone Valve PreampkoukihamedNo ratings yet

- Chemical Engineering Past Present and FutureDocument2 pagesChemical Engineering Past Present and FutureArinjayKumarNo ratings yet

- Chemical Physics: Manish Chopra, Niharendu ChoudhuryDocument11 pagesChemical Physics: Manish Chopra, Niharendu ChoudhuryasdikaNo ratings yet

- Divided Wall Column 496Document6 pagesDivided Wall Column 496GeorgeNo ratings yet

- 69kV and Above Oil Immersed Transformer Instruction ManualDocument30 pages69kV and Above Oil Immersed Transformer Instruction ManualYaser MajeedNo ratings yet

- Spwla 2014 HHHDocument12 pagesSpwla 2014 HHHclimaco20No ratings yet

- PipephaseDocument32 pagesPipephaseZadeh NormanNo ratings yet

- Room Air Conditioner System Modeling: Acrc Tr-60 July 1994Document97 pagesRoom Air Conditioner System Modeling: Acrc Tr-60 July 1994eyob feshaNo ratings yet

- Learn CBSE: To Measure Diameter of A Given Wire Using Screw GaugeDocument4 pagesLearn CBSE: To Measure Diameter of A Given Wire Using Screw GaugeSuman SamantaNo ratings yet

- AudiV6TDI MechanicsDocument15 pagesAudiV6TDI Mechanicsmarc4266No ratings yet

- Fluids Secondaires PDFDocument11 pagesFluids Secondaires PDFmohand_mindietaNo ratings yet