Professional Documents

Culture Documents

Data Sheet For Spiral Heat Exchanger: Unit: Doc. Type: Progr: Rev. Sheet OF Date

Uploaded by

Desiree MolinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet For Spiral Heat Exchanger: Unit: Doc. Type: Progr: Rev. Sheet OF Date

Uploaded by

Desiree MolinaCopyright:

Available Formats

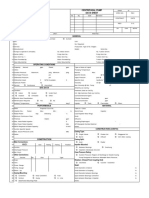

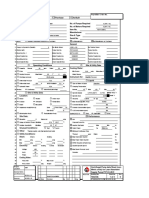

DATA SHEET FOR SPIRAL HEAT

EXCHANGER

PROJECT: UNIT: DOC. TYPE: PROGR: REV. 0 SHEET 1 OF 1 DATE:

Manufacturer Heat Exchanged, 10^6 Btu/h 1

Model No. Surface area per item, ft² 2

Customer MTD, Eff., °F 3

Plant Location Transfer rate, Btu/h-ft²-°F 4

Service Number items Parallel / Series 5

Basic design data

Pressure design code ASME Section VIII Div 1 Last Edition and Addenda Structural code 6

Code stamped yes no Flammable service yes No 7

Other specifications yes No 8

Fouling margin, % 9

Performance data - Hot side

IN OUT 10

Fluid name Temperature, °F 11

Total fluid entering, Ib/h Total Flow rate (liq./vap.), lb/h 12

Water/steam, lb/h Density (Liq./Vap.), lb / ft³ 13

Dew/Bubble/Pour/Freeze point,°F Viscosity (Liq./Vap.), CP 14

Latent heat, Btu/lb Therm. Cond. (Liq./Vap.), Btu / h ft °F 15

Inlet pressure psig psia Specific Heat (Liq./Vap.), Btu / lb°F 16

Pressure drop (allow./calc.), psi Nozzle velocity, ft/s 17

Max velocity (allow./calc.), ft/s Velocity between plates, ft/s 18

Strear Rate, S¯¹ Maximum velocity entrance area, ft/s 19

Performance data - Cold side

IN OUT 20

Fluid name Temperature, °F 21

Total fluid entering, Ib/h Total Flow rate (liq./vap.), lb/h 22

Water/steam, lb/h Density (Liq./Vap.), lb / ft³ 23

Dew/Bubble/Pour/Freeze point,°F Viscosity (Liq./Vap.), CP 24

Latent heat, Btu/lb Therm. Cond. (Liq./Vap.), Btu / h ft °F 25

Inlet pressure psig psia Specific Heat (Liq./Vap.), Btu / lb°F 26

Pressure drop (allow./calc.), psi Nozzle velocity, ft/s 27

Max velocity (allow./calc.), ft/s Velocity between plates, ft/s 28

Strear Rate, S¯¹ Maximum velocity entrance area, ft/s 29

Design, materials and construction

Hot side Cold side Nozzle list 30

Design name Nozzle Number Size Service Flanfe Rating Type 31

Test pressure, psig ID NPS Class 32

Design temperature, °F 33

Min. Design metal temperature, °F 34

Vacuum design metal temperature, °F 35

MAWP, psig 36

Corrosion allowance, inch 37

38

Coil 39

Cylinder Outside diameter, inch 40

Plate thickness, inch 41

Cylinder width, inch 42

Cylinder length, inch Mass of Unit: 43

Distance between plates, inch Empty, lb 44

Stud Arrangement Normal Operating, lb 45

Stud diameter, inch Filled with water, lb 46

Mechanical Cleaning required Yes No Lifting, lb 47

Covers, lb 48

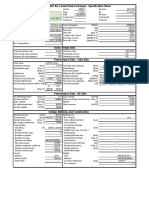

Design, materials and construction (continued)

Component Material Specification 49

Shell 50

Spiral Strip 51

Studs 52

Covers 53

Cover liner 54

Nozzles 55

Nozzle flanges 56

Stud bolts 57

Nuts 58

Supports 59

Name plate &fasteners 60

Gaskets 61

62

63

Fabrication, Inspection and Testing

64

Helium Leak Test required Yes No Surface Preparation 65

Post Weld Heat Treatment required Yes No Painting 66

Production Test required Yes No Insulation 67

Yes No 68

NDE requirements 69

70

71

Notes

1 72

2 73

3 74

4 75

5 76

6 77

7 78

8 79

83

Process Review Mechanical Review Metalurgical Review 84

DATE PREPARED BY REVIEWED BY 85

You might also like

- Data Sheet TEG-Gas Exchanger (E-5050)Document2 pagesData Sheet TEG-Gas Exchanger (E-5050)Elias EliasNo ratings yet

- Att. 5-1 RAPID-P028B-CMI-MEC-TDS-1450-0402 - 0Document6 pagesAtt. 5-1 RAPID-P028B-CMI-MEC-TDS-1450-0402 - 0Ranjith Kumar100% (1)

- DS 26-101 - IsO 16812 Shell and Tube Heat Exchangers API 660 - 0900a8668013a8feDocument1 pageDS 26-101 - IsO 16812 Shell and Tube Heat Exchangers API 660 - 0900a8668013a8feFernando RomeroNo ratings yet

- Ac-8 DSDocument2 pagesAc-8 DSOwais AhmedNo ratings yet

- Customer Project No. by Project Tag Checked Location Date Revision ServiceDocument3 pagesCustomer Project No. by Project Tag Checked Location Date Revision ServiceAdministrador de ContratoNo ratings yet

- Heat Exchanger Sizing AC-6050 #1Document2 pagesHeat Exchanger Sizing AC-6050 #1Luis Enrique Leyva OvalleNo ratings yet

- Design Data SheetDocument1 pageDesign Data Sheetdriller27No ratings yet

- Operating Conditions Units Max Norm Min: FCI Steam Trap Specification SheetDocument3 pagesOperating Conditions Units Max Norm Min: FCI Steam Trap Specification SheetHayder HusseinNo ratings yet

- Hojas de Datos Planta de GasDocument23 pagesHojas de Datos Planta de GasCarlos RinconNo ratings yet

- Heat Exchanger Rating SheetDocument2 pagesHeat Exchanger Rating SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- Customer Project No. by Project Tag Checked Location Date Revision ServiceDocument3 pagesCustomer Project No. by Project Tag Checked Location Date Revision ServiceAdministrador de ContratoNo ratings yet

- T 9 HxspecenglishDocument1 pageT 9 Hxspecenglishkinjalpatel12345No ratings yet

- General: Centrifugal Pump Data SheetDocument3 pagesGeneral: Centrifugal Pump Data Sheetfaraujodff10No ratings yet

- Heat Exchanger Specification Sheet: Btu / H ft2 °FDocument1 pageHeat Exchanger Specification Sheet: Btu / H ft2 °FDesiree MolinaNo ratings yet

- PPIS-660-IT-Y-003 - A - Anexo 12. Bombas Embarque y Cooldown - Constante C AjustadaDocument19 pagesPPIS-660-IT-Y-003 - A - Anexo 12. Bombas Embarque y Cooldown - Constante C AjustadaAnonymous S9qBDVkyNo ratings yet

- PVRV Data Sheet PDFDocument1 pagePVRV Data Sheet PDFharshkumar patelNo ratings yet

- Reem Takrouri PDF - Results PDFDocument5 pagesReem Takrouri PDF - Results PDFريم تكروريNo ratings yet

- Plate Heat ExchangerDocument1 pagePlate Heat ExchangerDavid Muñoz CastroNo ratings yet

- Orifice Plate DatasheetDocument29 pagesOrifice Plate DatasheetshayabajNo ratings yet

- Kadant MikeSoucy 032018 110Document53 pagesKadant MikeSoucy 032018 110Reinaldo RamirezNo ratings yet

- BTÑ HTDS - H 10Document1 pageBTÑ HTDS - H 10Juan Pablo Sanchez MelgarejoNo ratings yet

- Aircooled Heat Exchanger Process Data SheetDocument2 pagesAircooled Heat Exchanger Process Data SheetamitkrayNo ratings yet

- Plate Heat Exchanger Data SheetDocument2 pagesPlate Heat Exchanger Data SheetZUCEL ARLLETTE MAJUS CASTANEDANo ratings yet

- By Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetDocument12 pagesBy Todd Harvey at 10:31 Am, Sep 30, 2013: API 661 Air-Cooled Heat Exchanger - Specification SheetPackage RotaryNo ratings yet

- Unit 60% Load After Boiler Light Up Before HP-LP Bypass Charging Before Turbine Rolling After Unit Synchronisa TionDocument1 pageUnit 60% Load After Boiler Light Up Before HP-LP Bypass Charging Before Turbine Rolling After Unit Synchronisa TionIskerNo ratings yet

- Datasheet - Boiler-Superheater-EconomizerDocument1 pageDatasheet - Boiler-Superheater-EconomizerDesiree MolinaNo ratings yet

- Verifical Turbine Pump PDFDocument1 pageVerifical Turbine Pump PDFnecio77No ratings yet

- Hoja de Datos de BombaDocument5 pagesHoja de Datos de Bombaluis zambranoNo ratings yet

- Heater DatasheetDocument3 pagesHeater DatasheetReza Muhammad100% (1)

- Loadsheet Demin Water Pump PU-1202 ABDocument13 pagesLoadsheet Demin Water Pump PU-1202 ABGunturMudaAliAkbarNo ratings yet

- 001.17056.000028-AK008-01 1st Stage PreheaterDocument5 pages001.17056.000028-AK008-01 1st Stage PreheaterQuy RomNo ratings yet

- Damper Datasheet FormDocument1 pageDamper Datasheet FormharishcsharmaNo ratings yet

- ARNU42GTMC4Document2 pagesARNU42GTMC4jaimegutierrezlinganNo ratings yet

- ERSA010-DSM-001 Rev.0 DS Boquillas RociadorasDocument1 pageERSA010-DSM-001 Rev.0 DS Boquillas RociadorasAdrian Andres Quilodran MirandaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-105.edr Printed: 24/01/2023 at 4:39:51 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Tema Style HX DatasheetDocument1 pageTema Style HX Datasheet404FileNotFoundNo ratings yet

- LNG Booster Pump DatasheetDocument7 pagesLNG Booster Pump DatasheetsswahyudiNo ratings yet

- Datasheet For Chart Recorder - IfbDocument9 pagesDatasheet For Chart Recorder - Ifbfathan fathullahNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)Document5 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)bubbles82No ratings yet

- Gerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinDocument4 pagesGerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinGerencia Rigar Colombia SASNo ratings yet

- Standard Operating Procedure FOR HP HeaterDocument6 pagesStandard Operating Procedure FOR HP HeatersambhuNo ratings yet

- Obj124808-Gassification Plant EquipmentDocument34 pagesObj124808-Gassification Plant EquipmentR GikiswantoNo ratings yet

- IPS-C-PM-215-Equipment Record CardDocument1 pageIPS-C-PM-215-Equipment Record Cardseguridadyambiente641No ratings yet

- Technical Bid Tabulation: Vendor Description SpecificationDocument8 pagesTechnical Bid Tabulation: Vendor Description SpecificationGunturMudaAliAkbarNo ratings yet

- G. Pumps and DriversDocument14 pagesG. Pumps and DriversJithinNo ratings yet

- D04-V-E809 Instrument Air ReceiverDocument2 pagesD04-V-E809 Instrument Air Receiverpragnesh82011No ratings yet

- Perú Corp. S.A. Perú Corp. S.A.: BASKET FILTER FCC-31200/31205Document4 pagesPerú Corp. S.A. Perú Corp. S.A.: BASKET FILTER FCC-31200/31205William ChipanaNo ratings yet

- Hojas de Datos Ejercicio ExtraDocument1 pageHojas de Datos Ejercicio ExtraJohnny Ramos DíazNo ratings yet

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Document5 pages18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaNo ratings yet

- TI DatasheetsDocument8 pagesTI Datasheetspatilrohan4444No ratings yet

- 3808-E128-M-DS-100-005 Hoja de Datos de Un FlareDocument5 pages3808-E128-M-DS-100-005 Hoja de Datos de Un FlareDesiree MolinaNo ratings yet

- ARNU36GTNC4Document2 pagesARNU36GTNC4Edgard Chara CarhuayoNo ratings yet

- 80 KW Water-Cooler ratavljiviDS (6364)Document1 page80 KW Water-Cooler ratavljiviDS (6364)Jelena VuleticNo ratings yet

- Pulsation Damper Specification Form: Accumulator Type Fluids/medium Further InformationDocument1 pagePulsation Damper Specification Form: Accumulator Type Fluids/medium Further InformationsanthoshkumarplNo ratings yet

- TEMA StandardsFAQ 2020Document11 pagesTEMA StandardsFAQ 2020liNo ratings yet

- BFP - Part 1Document1 pageBFP - Part 1nejatihosseinNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)Document4 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)bubbles82No ratings yet

- Datasheet Rev 1Document7 pagesDatasheet Rev 1Tauasi TauasisNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-102 - 1.edr Printed: 24/01/2023 at 8:20:10 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Datasheet - Horno ViejoDocument2 pagesDatasheet - Horno ViejoDesiree MolinaNo ratings yet

- Process Data Sheet Vessels: Plant: TAG Project: Unit: Doc. Type: Progr: Rev. Sheet OF DateDocument1 pageProcess Data Sheet Vessels: Plant: TAG Project: Unit: Doc. Type: Progr: Rev. Sheet OF DateDesiree MolinaNo ratings yet

- Heat Exchanger Specification Sheet: Btu / H ft2 °FDocument1 pageHeat Exchanger Specification Sheet: Btu / H ft2 °FDesiree MolinaNo ratings yet

- Cooling Tower CalculationsDocument4 pagesCooling Tower CalculationsDesiree MolinaNo ratings yet

- Datasheet - Boiler-Superheater-EconomizerDocument1 pageDatasheet - Boiler-Superheater-EconomizerDesiree MolinaNo ratings yet

- PRV Sizing - XLSMDocument11 pagesPRV Sizing - XLSMDesiree MolinaNo ratings yet

- Analizador de AzufreDocument10 pagesAnalizador de AzufreDesiree MolinaNo ratings yet

- Impact of American PetroleumDocument111 pagesImpact of American PetroleumDesiree MolinaNo ratings yet

- Hysys RVP Method: Reid Vapour Pressure Methods in HYSYSDocument3 pagesHysys RVP Method: Reid Vapour Pressure Methods in HYSYSDesiree MolinaNo ratings yet

- Aspen Tech Compressor Modeling in AspenDocument16 pagesAspen Tech Compressor Modeling in AspenDesiree MolinaNo ratings yet

- Aspen HYSYS DYNAMICS Training Course PDFDocument23 pagesAspen HYSYS DYNAMICS Training Course PDFendosporaNo ratings yet

- Comparacion Entre ASTM D7169 y TBPDocument28 pagesComparacion Entre ASTM D7169 y TBPDesiree Molina100% (1)

- Useful Tips For A Successful HAZOP Study: Process Hazard Analysis TechniquesDocument10 pagesUseful Tips For A Successful HAZOP Study: Process Hazard Analysis TechniquesDesiree MolinaNo ratings yet

- Vacuum Pump-Lifting WaterDocument2 pagesVacuum Pump-Lifting WaterDesiree MolinaNo ratings yet

- Line Sizing Example Juan PDocument16 pagesLine Sizing Example Juan PDesiree MolinaNo ratings yet

- Line Sizing: Liquid Phase CaseDocument13 pagesLine Sizing: Liquid Phase CaseDesiree MolinaNo ratings yet

- Aspen Tech Compressor Modeling in AspenDocument16 pagesAspen Tech Compressor Modeling in AspenDesiree MolinaNo ratings yet

- Process Simulation With ASPEN PlusDocument1 pageProcess Simulation With ASPEN PlusDesiree MolinaNo ratings yet

- Liquid Control Valve SizingDocument9 pagesLiquid Control Valve SizingDesiree MolinaNo ratings yet

- Beyond Predicting Failures For Reliable Assets - Learn MoreDocument77 pagesBeyond Predicting Failures For Reliable Assets - Learn MoreDesiree MolinaNo ratings yet

- Valve Guide For The Pulp Paper Industry 97.01 01 PDFDocument24 pagesValve Guide For The Pulp Paper Industry 97.01 01 PDFRido P SitompulNo ratings yet

- Journal of Semipermeable Membrane andDocument8 pagesJournal of Semipermeable Membrane andMichael Bryan PrajogoNo ratings yet

- TDS - Paper WS - Niklakett - Medium - PlusDocument1 pageTDS - Paper WS - Niklakett - Medium - PlusSundar MoorthiNo ratings yet

- Ferrous and Non Ferrous MetalsDocument4 pagesFerrous and Non Ferrous MetalsLyka Balacdao100% (1)

- Visual Comparative Guide Degrees of CleanlinessDocument1 pageVisual Comparative Guide Degrees of CleanlinessAhmad GhafouriNo ratings yet

- Milling Machine ReportDocument7 pagesMilling Machine ReportAlex HdezNo ratings yet

- Corrosion - Wikipedia, The Free EncyclopediaDocument14 pagesCorrosion - Wikipedia, The Free EncyclopediaSanthosh Reddy BNo ratings yet

- 04 - D - Merril Crowe Con CCD DFDocument2 pages04 - D - Merril Crowe Con CCD DFAnonymous rBcspMzPNo ratings yet

- Frequently Asked Questions (FAQ) About Hot-Dip Galvanized Reinforcing BarsDocument6 pagesFrequently Asked Questions (FAQ) About Hot-Dip Galvanized Reinforcing Barsali tahaNo ratings yet

- G.A. Bom, Isometric Views, Parts and Assemblies 6 Cylinder "Elbow" Steam EngineDocument1 pageG.A. Bom, Isometric Views, Parts and Assemblies 6 Cylinder "Elbow" Steam EngineErrol NietoNo ratings yet

- MCQ - Unit 5 Advanced Manufacturing MethodDocument3 pagesMCQ - Unit 5 Advanced Manufacturing MethodDipak naikNo ratings yet

- 24th Annual International Pittsburgh Coal 2007 WixDocument10 pages24th Annual International Pittsburgh Coal 2007 WixAmauche OgeNo ratings yet

- Mapúa University: Shop Practice No. 4 KnurlingDocument8 pagesMapúa University: Shop Practice No. 4 KnurlingmarisonNo ratings yet

- Tapflex Flier 083116BDocument2 pagesTapflex Flier 083116BGerardo JM PalaciosNo ratings yet

- Btlgtco Questions & Answers - Clyde DmelloDocument15 pagesBtlgtco Questions & Answers - Clyde DmelloKennen LasradoNo ratings yet

- Handbook of Heterogeneous Catalysis, G. Ertl, H. Közinger, J. WeitkampDocument40 pagesHandbook of Heterogeneous Catalysis, G. Ertl, H. Közinger, J. WeitkampFederico BogettiNo ratings yet

- The Importance of Welding Electrode FluxDocument105 pagesThe Importance of Welding Electrode FluxAnnamalai Ram JGCNo ratings yet

- AMERICAN Pipe Manual Linings and Coatings 5 24 21Document15 pagesAMERICAN Pipe Manual Linings and Coatings 5 24 21Ludi D. LunarNo ratings yet

- Sly Venturi ScrubberDocument2 pagesSly Venturi Scrubberzguy360No ratings yet

- PVC and WPC Wood Plastic Panel Production Line en PDFDocument1 pagePVC and WPC Wood Plastic Panel Production Line en PDFMihaiNo ratings yet

- PPG - Pull-Off Test Report FormatDocument1 pagePPG - Pull-Off Test Report FormatErin Williams100% (1)

- Australian Wood Review June 2020Document84 pagesAustralian Wood Review June 2020Jimmytron Gallegos100% (1)

- Ceiling GypsumCeiling 20190514Document11 pagesCeiling GypsumCeiling 20190514BeatrizLlamasNo ratings yet

- Engineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureDocument11 pagesEngineering Standards Manual ISD 341-2: Chapter 13, Welding & Joining Volume 2, Welding Fabrication ProcedureJaveed A. Khan100% (1)

- 2287DCh1 PDFDocument126 pages2287DCh1 PDFdiegomilitojNo ratings yet

- Jed-739 008 GDocument5 pagesJed-739 008 GPaulo Henrique NascimentoNo ratings yet

- Data Sheet: Mild Steel ElectrodesDocument1 pageData Sheet: Mild Steel ElectrodeschepurthiNo ratings yet

- Croda Coatings Product Overview EuropeDocument4 pagesCroda Coatings Product Overview Europemanox007100% (1)

- AWS B2 1 1 004 2013 SWPS GMAW ShortDocument22 pagesAWS B2 1 1 004 2013 SWPS GMAW Shortreza acbariNo ratings yet

- Presented By:-: Akshay Ts DTDM 6 SEM Roll No - 04Document23 pagesPresented By:-: Akshay Ts DTDM 6 SEM Roll No - 04Deepak RameshNo ratings yet