Professional Documents

Culture Documents

Datasheet - Horno Viejo

Uploaded by

Desiree MolinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Datasheet - Horno Viejo

Uploaded by

Desiree MolinaCopyright:

Available Formats

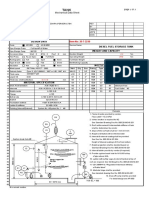

DATA SHEET FOR FURNACE

PLANT

UNIT EQUIPMENT FIRED HEATER TAG SERVICE

1 PROCESS DATA DRAWING RERUN COLUMN REBOILER

2 HEATER SECTION RADIANT SHOCK CONVECTION SOUTH WALL STACK NORTH WALL

3 FLUID

4 FLOW RATE

5 ALOWABLE

6 PRESSURE DROP

7 INLET CONDITIONS

8 LIQUID FLOW RATE 2 stacks with:

9 VAPUOR FLOW RATE 2" of 1:2:4 L:H:V ó

CORAL 80.

10 TEMPERATURE Dampers in stainless

11 PRESSURE steel

12 LIQUID DENSITY

13 OUTLET CONDITIONS

Q Q

14 LIQUID FLOW RATE

15 VAPOUR FLOW RATE Convection Wall: Radiant Unprotected wall:

16 TEMPERATURE 5" of 1:2:4 - L:H:V ó CORAL 80 5" - 1:2:4 L:H:V ó CORAL 80

y (CORAL 50 + CORAL 80). Anchor material: stainless steel.

17 PRESSURE Anchor material: stainless steel. Casing temperature: 200 °F.

18 LIQUID DENSITY Casing temperature: 170 °F. Casing thickness: 3/16".

19 Casing thickness: 3/16".

20 COMBUSTION DESIGN CONDITIONS

21 TYPE OF FUEL Fuel gas

22 EXCESS AIR EAST WALL WEAST WALL

23 CALCULATED HEAT N

24 RELEASE

25 GUARANTEED FUEL TEC

HO

26 EFFICIENCY (LHV)

27 FLUE GAS

28 TEMPERATURE

29 FLUE GAS QUANTITY

30 Radiant Protected wall: Radiant Floor:

31 MECHANICAL DESIGN CONDITIONS 5" - 1:2:4 L:H:V ó CORAL 80 5" - 1:2:4 L:H:V and 2.5" HDFB are reused.

Anchor material: stainless steel. Casing temperature: 200 °F.

32 HEATER SECTION RADIANT SHOCK CONVECTION Casing temperature: 190 °F. Casing thickness: 3/16"

33 COIL DESIGN Casing thickness: 3/16". Radiant Arch:

34 DESIGN PRESSURE Lateral wall internal (W-E): firebrick 5" - 1:2:4 L:H:V ó CORAL 80.

Casing temperature: 190 °F

35 DESIGN FLUID

36 TEMPERATURE

37 CORROSION

38 ALLOWANCE TUBE # MATERIAL

39 HYDROSTATIC TEST RADIANT 22 A-106 GR B

SHOCK 8 A-106 GR B

40 PRESSURE

CONVECTION 36 A-106 GR B

41 WELDS HEAT

42 TREATMENT

43 % OF WELDS FULLY 17 18 19 20

44 RADIOGRAPHED 13 14 15 16

9 10 11 12

45 COIL ARRANGEMENT 5 6 7 8

46 # OF FLOW PASSES 1 2 3 4

CONVECTION TUBES

47 # OF TUBE PER ROW

48 # OF BARE TUBE

49 OVERALL TUBE

50 LENGHT

CONVECTION SUPPORT

51 EFFECTIVE TUBE

52 LENGHT

53 TUBES

54 ORIENTATION horizontal horizontal horizontal

55 MATERIAL

56 SPECIFICATION

57 OUTSIDE DIAMETER

58 WALL THICKNESS

59 MAX. TUBE WALL

60 TEMPERATURE

61 DESIGN BASIC FOR

API 530 API 530 API 530

62 TUBE THICKNESS TUBES RADIANT SUPPORT

63 RETURN BENDS OR PLUG-HEADERS

64 TYPE bend bend bend

65 LOCATION firebox firebox firebox MECHANICAL DESIGN CONDITIONS

66 MATERIAL BURNERS

67 SPECIFICATION HEATER SECTION RADIANT

68 NOMINAL RATING OR LOCATION End walls

69 SCHEDULE TYPE Natural draft, Low Nox, Horizontal Firing

70 TERMINALS REFERENCE MAKE AND TYPE John Zink - PSFR-18RM

71 TYPE flanged flanged FUEL TYPE Fuel gas

72 FLANGE TYPE AND NUMBER 4

WNRTJ WNRTJ

73 FACE HEAT RELEASED PER BURNER

74 OUTLET INLET MAXIMUM 10.03 MMBtu/h

MATERIAL

75 SPECIFICATION

NORMAL 8.02 MMBtu/h

76 SIZE NOMINAL MINIMUM 2.01 MMBtu/h

77 RATING TUBE SUPPORTS

78 # OF TERMINALS SECTION RADIANT RADIANT SHOCK CONVECTION

79 CROSSOVERS ENDS, TOP, BOTTOM,

intermediate intermed. intermed. intermediate

80 LOCATION INTERMEDIATE

81 PIPE MATERIAL MATERIAL A297 GrHK (note 2) A297 GrHK

82 PIPE SIZE THICKNESS

83 PIPE THICKNESS # OF SET 24 3

84 Notes: (note 1) the two last 4" tubes of each pass will be replaced by 6" sch40 tubes. Lower coils will be relocated accordingly as well as U-bends. The two last 4" U-bends will be replaced by 6" U-bends.

85 (note 2) All news supports will be 25/20 CrNi Gr HK40. In radiation section, new supports are provided for the new 6" tubes.Supports of 4" tubes will be all reused. buttom tube sheets in convection will not be

modified.

86

87 SPEACIALIST PROCESS

88 SPECIALIST MECHANICAL

89 SPECIALIST METALLURGICAL

90 Rev. Description Date Prd. Ckd. App. Rev. Description Date Prd. Ckd. App.

You might also like

- An Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesFrom EverandAn Introduction to Metallurgical Laboratory Techniques: Pergamon Series of Monographs in Laboratory TechniquesNo ratings yet

- Data Sheet For PSVDocument1 pageData Sheet For PSVBABILIN VNo ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- DELUGE VALVES DATASHEET Rev.01Document1 pageDELUGE VALVES DATASHEET Rev.01moodydoodyNo ratings yet

- Process Design Conditions: 842-PA-K17-3"-ES32EKFR-NIDocument2 pagesProcess Design Conditions: 842-PA-K17-3"-ES32EKFR-NITHOMASNo ratings yet

- Datasheet For Pressure TransmitterDocument8 pagesDatasheet For Pressure TransmitterVenkatesan ManikandanNo ratings yet

- ON-OFF Valves LTWDocument2 pagesON-OFF Valves LTWMeoNo ratings yet

- TD HE THE v2020.00Document43 pagesTD HE THE v2020.00Claudia BonocoreNo ratings yet

- Project Title: Detailed Engineering of Methanol Export Line To New Liquid JettyDocument2 pagesProject Title: Detailed Engineering of Methanol Export Line To New Liquid JettypavanNo ratings yet

- Datasheet For Level TransmitterDocument9 pagesDatasheet For Level TransmitterVenkatesan ManikandanNo ratings yet

- Boiler Calucation SheetDocument84 pagesBoiler Calucation Sheet9913489806No ratings yet

- Technical Specification - LT (DP Based)Document4 pagesTechnical Specification - LT (DP Based)ManodipPatilNo ratings yet

- PSV-1203 - 3632-I-DS-31001 WorkingDocument1 pagePSV-1203 - 3632-I-DS-31001 Workinganamaria ursuNo ratings yet

- Pic 1 SL2 N/A Tc1A N2 Secondary Barrier: Tag #Revision #Document NºDocument2 pagesPic 1 SL2 N/A Tc1A N2 Secondary Barrier: Tag #Revision #Document NºRanchojiNo ratings yet

- Drum PDSDocument1 pageDrum PDScavidan20055No ratings yet

- RITA - Tanque Cilindrico - Alcalinos Diluidos - SPI - David - LongDocument27 pagesRITA - Tanque Cilindrico - Alcalinos Diluidos - SPI - David - LongRoberto Gomez R.No ratings yet

- Diesel Tank DSDocument1 pageDiesel Tank DSNurcahyo Djati W0% (1)

- Burner DatasheetDocument6 pagesBurner DatasheetHafiz Muhammad AbubakarNo ratings yet

- 2055 Ed 2FGGF7 B1 9Document1 page2055 Ed 2FGGF7 B1 9amirNo ratings yet

- Data Sheet For Pressure TransmitterDocument2 pagesData Sheet For Pressure TransmitterDavinder Singh BhattiNo ratings yet

- Design Conditions Units Min Nor MaxDocument2 pagesDesign Conditions Units Min Nor MaxJay RathodNo ratings yet

- ChE 301 PartII Lecture IVDocument45 pagesChE 301 PartII Lecture IVMahmudur Rahman RiadNo ratings yet

- Co2 PDFDocument1 pageCo2 PDFahmedomar_953724702No ratings yet

- Datasheet For Level TransmitterDocument11 pagesDatasheet For Level TransmitterEliyanto E BudiartoNo ratings yet

- TD HE S&T v2020.00Document29 pagesTD HE S&T v2020.00Claudia BonocoreNo ratings yet

- Heat Transfer LabDocument56 pagesHeat Transfer LabTej RockersNo ratings yet

- Transmisores de Presión y TemperaturaDocument6 pagesTransmisores de Presión y TemperaturaCh LoNo ratings yet

- Data Sheet Flanged End Globe ValveDocument1 pageData Sheet Flanged End Globe ValveIbad Alam100% (1)

- Vacuum CondensersDocument12 pagesVacuum CondensersErick EspinosaNo ratings yet

- 6-Pressure Safety ValveDocument1 page6-Pressure Safety ValveFari NazariNo ratings yet

- NitrogenDocument1 pageNitrogensurendharNo ratings yet

- L-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECDocument1 pageL-CV-155-VA-24XX01 Nitrogen: ASME Sec VIII Div 1+ PED97/23/ECevrim77No ratings yet

- Data Sheet & Katologe Ballvalve - New AsiaDocument62 pagesData Sheet & Katologe Ballvalve - New AsiaYulfikaenis MachroniNo ratings yet

- Cartridge Filter DatasheetDocument5 pagesCartridge Filter DatasheetSuaib VCSNo ratings yet

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- Lab 2 (Ii) HeDocument8 pagesLab 2 (Ii) HeSchaieraNo ratings yet

- Data Sheet Residue Gas Scrubber (V-1110)Document2 pagesData Sheet Residue Gas Scrubber (V-1110)Elias EliasNo ratings yet

- Design Conditions Units Min Nor MaxDocument2 pagesDesign Conditions Units Min Nor MaxJay RathodNo ratings yet

- Chiller Data SheetDocument3 pagesChiller Data SheetMoriyasuNguyenNo ratings yet

- PG Pressure GaugeDocument2 pagesPG Pressure GaugeAr RahmanNo ratings yet

- 0ZSIRLS001 SAMWONG SERA Contacteur de Niv Data SheetDocument1 page0ZSIRLS001 SAMWONG SERA Contacteur de Niv Data Sheetjean-marie BOGUYNo ratings yet

- Temperature SwitchDocument1 pageTemperature SwitchHafiz Muhammad AbubakarNo ratings yet

- ACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgDocument2 pagesACFrOgBo1iGqwe3hPVDeso7MlgDOoxXORvOyEPoZX7JH5P r8f w5kQHxIeABvtbWmHyzF8fls6khF BW 5H54Qnr8eSv2XIP8cFF1tq7Bcevn9Kl6UNUgaqVsIwYNgbaccour bilelNo ratings yet

- Datasheet For Restriction OrificeDocument1 pageDatasheet For Restriction OrificeRajesh Rajesh67% (3)

- Datasheet - Boiler-Superheater-EconomizerDocument1 pageDatasheet - Boiler-Superheater-EconomizerDesiree MolinaNo ratings yet

- Fernández-Seara 2010 IJR R22 Substitutes Condensation CuNi Turbo CDocument10 pagesFernández-Seara 2010 IJR R22 Substitutes Condensation CuNi Turbo CJose Iglesias PradoNo ratings yet

- Level ControllerDocument1 pageLevel Controllerkhasim15No ratings yet

- HNVW2A 30Hp 4 30K 380x50HzDocument1 pageHNVW2A 30Hp 4 30K 380x50HzBernad OrlandoNo ratings yet

- Actuated Ball Valve 357 D - BDKDocument4 pagesActuated Ball Valve 357 D - BDKfarhanakhtar ansariNo ratings yet

- AC Service Training-Behr India Ltd.Document68 pagesAC Service Training-Behr India Ltd.jag18718No ratings yet

- IN DataSheetForInstrumentsDocument8 pagesIN DataSheetForInstrumentssparkletsharjahNo ratings yet

- TRBA-TSRTSF SPMDocument53 pagesTRBA-TSRTSF SPMBeto CastañedaNo ratings yet

- Heat Exchanger Specification SheetDocument2 pagesHeat Exchanger Specification SheetDycka Anugerah PuryantoroNo ratings yet

- General: Crude Oil Crude Oil - 219 219Document1 pageGeneral: Crude Oil Crude Oil - 219 219amirNo ratings yet

- Data Sheet TEG Contactor (V-1100)Document2 pagesData Sheet TEG Contactor (V-1100)Elias EliasNo ratings yet

- Pump CalcDocument5 pagesPump CalcpavanNo ratings yet

- KELEN HB 07 eDocument40 pagesKELEN HB 07 enhblinh100% (2)

- 7854-Hds-2e2301 Rev 8Document3 pages7854-Hds-2e2301 Rev 8SonNguyenNo ratings yet

- Datasheet For Hopper (D-3103)Document1 pageDatasheet For Hopper (D-3103)Joe GrosirNo ratings yet

- Heat Exchanger Specification Sheet: Btu / H ft2 °FDocument1 pageHeat Exchanger Specification Sheet: Btu / H ft2 °FDesiree MolinaNo ratings yet

- Datasheet - Boiler-Superheater-EconomizerDocument1 pageDatasheet - Boiler-Superheater-EconomizerDesiree MolinaNo ratings yet

- Project Cost Estimating Guide - PracticeDocument58 pagesProject Cost Estimating Guide - PracticeMurat Syzdykov100% (5)

- Analizador de AzufreDocument10 pagesAnalizador de AzufreDesiree MolinaNo ratings yet

- Process Data Sheet Vessels: Plant: TAG Project: Unit: Doc. Type: Progr: Rev. Sheet OF DateDocument1 pageProcess Data Sheet Vessels: Plant: TAG Project: Unit: Doc. Type: Progr: Rev. Sheet OF DateDesiree MolinaNo ratings yet

- Data Sheet For Spiral Heat Exchanger: Unit: Doc. Type: Progr: Rev. Sheet OF DateDocument1 pageData Sheet For Spiral Heat Exchanger: Unit: Doc. Type: Progr: Rev. Sheet OF DateDesiree MolinaNo ratings yet

- Cooling Tower CalculationsDocument4 pagesCooling Tower CalculationsDesiree MolinaNo ratings yet

- Astm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your AdvertisementDocument25 pagesAstm Crude Oils: Здесь Могла Быть Ваша Реклама Place For Your Advertisementsachyn7No ratings yet

- Quick Start Guide: PRV2SIZE 101: Introduction To Pressure Management Sizing SoftwareDocument34 pagesQuick Start Guide: PRV2SIZE 101: Introduction To Pressure Management Sizing SoftwareRaditya RaditNo ratings yet

- Crude Tower Simulation-HYSYS v8.6 PDFDocument62 pagesCrude Tower Simulation-HYSYS v8.6 PDFrawadNo ratings yet

- Rating Tables As Per ASME B-16.5Document2 pagesRating Tables As Per ASME B-16.5Desiree MolinaNo ratings yet

- Simple Dew Point Control AspenPlus v10Document44 pagesSimple Dew Point Control AspenPlus v10SpicyNo ratings yet

- PRV Sizing - XLSMDocument11 pagesPRV Sizing - XLSMDesiree MolinaNo ratings yet

- Aspen HYSYS DYNAMICS Training Course PDFDocument23 pagesAspen HYSYS DYNAMICS Training Course PDFendosporaNo ratings yet

- Crude Tower Simulation-HYSYS v8.6 PDFDocument62 pagesCrude Tower Simulation-HYSYS v8.6 PDFrawadNo ratings yet

- Aspen Tech Compressor Modeling in AspenDocument16 pagesAspen Tech Compressor Modeling in AspenDesiree MolinaNo ratings yet

- Hysys RVP Method: Reid Vapour Pressure Methods in HYSYSDocument3 pagesHysys RVP Method: Reid Vapour Pressure Methods in HYSYSDesiree MolinaNo ratings yet

- Informacion PDFDocument4 pagesInformacion PDFgraciela areinamoNo ratings yet

- Line Sizing Example Juan PDocument16 pagesLine Sizing Example Juan PDesiree MolinaNo ratings yet

- Comparacion Entre ASTM D7169 y TBPDocument28 pagesComparacion Entre ASTM D7169 y TBPDesiree Molina100% (1)

- Impact of American PetroleumDocument111 pagesImpact of American PetroleumDesiree MolinaNo ratings yet

- Comparacion Entre ASTM D7169 y TBPDocument28 pagesComparacion Entre ASTM D7169 y TBPDesiree Molina100% (1)

- Shimadzu Simulated Distillation Gas Chromatograph System: Printed in Japan 3655-102211-40AITDocument8 pagesShimadzu Simulated Distillation Gas Chromatograph System: Printed in Japan 3655-102211-40AITAnish KarthikeyanNo ratings yet

- API TDB CompleteDocument1,316 pagesAPI TDB CompleteDũng ĐỗNo ratings yet

- Column Hydraulics and Internals ProjectDocument11 pagesColumn Hydraulics and Internals ProjectAdham AbusalehiNo ratings yet

- Crude Tower Simulation Using Aspen HYSYSDocument32 pagesCrude Tower Simulation Using Aspen HYSYSTouhid Islam100% (2)

- Simulation Chem Eng Gil Ivan Copia-A+Document537 pagesSimulation Chem Eng Gil Ivan Copia-A+Dahiyana Cristancho100% (3)

- Line Sizing: Liquid Phase CaseDocument13 pagesLine Sizing: Liquid Phase CaseDesiree MolinaNo ratings yet

- Aspen Tech Compressor Modeling in AspenDocument16 pagesAspen Tech Compressor Modeling in AspenDesiree MolinaNo ratings yet

- Edexcel IGCSE Physics: Chapter-4 Momentum Study QuestionDocument2 pagesEdexcel IGCSE Physics: Chapter-4 Momentum Study QuestionMahbub KhanNo ratings yet

- Ngineering ATA: Temperature & Altitude Effects On FansDocument3 pagesNgineering ATA: Temperature & Altitude Effects On FansMohamed TahounNo ratings yet

- CSC 211 ManualDocument48 pagesCSC 211 Manualsgshekar30No ratings yet

- Name: - Yr. & Sec: - DateDocument3 pagesName: - Yr. & Sec: - DateJhasper ManagyoNo ratings yet

- Technical Audit Report (Sample)Document4 pagesTechnical Audit Report (Sample)रविन्द्र मरघड़ेNo ratings yet

- 12 ElectrostaticsDocument24 pages12 ElectrostaticsTanvi ShahNo ratings yet

- Origin of The UniverseDocument44 pagesOrigin of The UniverseLuis PazNo ratings yet

- LUCB1XBLDocument2 pagesLUCB1XBLAlex Ruben Alvarez GallardoNo ratings yet

- Outdoor Air Switches Selection and Application: 8.25 Thru 800 KV Max. Voltage 600 Thru 5000 Amperes Bulletin 2.3.1-1FDocument18 pagesOutdoor Air Switches Selection and Application: 8.25 Thru 800 KV Max. Voltage 600 Thru 5000 Amperes Bulletin 2.3.1-1FannymagoNo ratings yet

- Per Unit (P.u.) System: Decimal Fractions of Chosen Base ValuesDocument12 pagesPer Unit (P.u.) System: Decimal Fractions of Chosen Base Valuessubbu2051No ratings yet

- Classical Electrodynamics: Review of ElectrostaticsDocument16 pagesClassical Electrodynamics: Review of ElectrostaticsBaby SileshiNo ratings yet

- Hydrodynamic Design and Analysis of A Swirling Flow GeneratorDocument16 pagesHydrodynamic Design and Analysis of A Swirling Flow Generatorrone2000No ratings yet

- Read and Measure Temperature COTDocument57 pagesRead and Measure Temperature COTCyril Lyn Natividad Credo91% (11)

- GeneralPhysics1 Q2 Module-2 Gravity v5Document25 pagesGeneralPhysics1 Q2 Module-2 Gravity v5rexilldatorNo ratings yet

- 3NE13342 Datasheet enDocument4 pages3NE13342 Datasheet enWilber SánchezNo ratings yet

- Ace2 Inverter: User ManualDocument85 pagesAce2 Inverter: User ManualAdam Schwemlein100% (1)

- Three Phase Energy Meter - Counter Type: FeaturesDocument6 pagesThree Phase Energy Meter - Counter Type: FeaturesAbhinandan JainNo ratings yet

- Flux Mag 53 enDocument18 pagesFlux Mag 53 enЛадо КиладзеNo ratings yet

- EIE321 Module 2Document65 pagesEIE321 Module 2Opeyemi OrugunNo ratings yet

- Handout No. 11 (Capacitance II) by Odon M. Sanchez C. (Spring Semester 2017)Document4 pagesHandout No. 11 (Capacitance II) by Odon M. Sanchez C. (Spring Semester 2017)AMC PureNo ratings yet

- Active Operation of Hydrogen Fuelling Stations To Support Renewable IntegrationDocument6 pagesActive Operation of Hydrogen Fuelling Stations To Support Renewable IntegrationDiego CamachoNo ratings yet

- Chapter 4Document34 pagesChapter 4Ahmad TahirNo ratings yet

- 1.intro Electrical SafetyMicrosoft PowerPoint - PPT 1 Introduction To Electrical Safety 1 OshaDocument22 pages1.intro Electrical SafetyMicrosoft PowerPoint - PPT 1 Introduction To Electrical Safety 1 OshaMohd MuzaniNo ratings yet

- RDE12Document1 pageRDE12Galih SpotifyNo ratings yet

- 2 Cylinders ContactDocument20 pages2 Cylinders ContactGuliguli GuliNo ratings yet

- Fundamentals of Automotive Electricity & ElectronicsDocument83 pagesFundamentals of Automotive Electricity & ElectronicsJohnny Ym100% (1)

- Janitza Manual Prophi 7 GBDocument35 pagesJanitza Manual Prophi 7 GBJose TroscaNo ratings yet

- Fluid Chapter 3Document31 pagesFluid Chapter 3ALNo ratings yet

- Chapter 7 - Gas Steam MediumDocument21 pagesChapter 7 - Gas Steam MediumAdugna Gosa100% (1)

- Audi Obd 2 Trouble CodesDocument1 pageAudi Obd 2 Trouble CodesJames100% (47)