Professional Documents

Culture Documents

Calibration Only Spectris Solaris: MEDRAD, Inc. 2007

Uploaded by

brianOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calibration Only Spectris Solaris: MEDRAD, Inc. 2007

Uploaded by

brianCopyright:

Available Formats

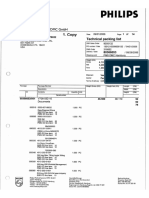

05/31/2007 at 16:47:36.

VIEWED/PRINTED:

Calibration Only

Spectris Solaris

©

MEDRAD, Inc. 2007

Prior to use, you are responsible to confirm this copy's revision is the latest released.

This copy of 205254 Rev A is valid as of May-30-2007 at 11:06:00.

This calibration procedure is confidential, proprietary information of MEDRAD, Inc.

It is provided to trained employees of our customers for the sole purpose of

enabling such employees to service customer-owned MEDRAD injectors. This

information may not be shared with third parties or used to service injectors other

than as specified herein. Further restrictions on the disclosure and use of this

information is provided in the Service Training Agreement executed by the

customer and trained biomed at the time of training. Please refer to that

agreement or contact MEDRAD, Inc. if you have any questions about the

information provided in this package.

205254 Rev. A Page 1 of 8

This calibration procedure is confidential, proprietary information of MEDRAD, Inc. It is provided to trained employees of our customers for

the sole purpose of enabling such employee to service customer-owned MEDRAD injectors. This information may not be shared with third

parties or used to service injectors other than as specified herein. Further restrictions on the disclosure and use of this information is

provided in the Service Training Agreement executed by the customer and trained biomed at the time of training. Please refer to that

agreement or contact MEDRAD, Inc. if you have any questions about the information provided in this package.

TABLE OF CONTENTS

05/31/2007 at 16:47:36.

1. SCOPE .................................................................. 3

VIEWED/PRINTED:

2. AUDIENCE ............................................................ 3

3. EQUIPMENT.......................................................... 3

4. DOCUMENTATION ............................................... 4

5. CALIBRATION ....................................................... 4

6. PRESSURE CHECK.............................................. 5

7. SYSTEM LEAKAGE TEST .................................... 6

8. FINAL PREPARATION .......................................... 8

Prior to use, you are responsible to confirm this copy's revision is the latest released.

This copy of 205254 Rev A is valid as of May-30-2007 at 11:06:00.

205254 Rev. A Page 2 of 8

This calibration procedure is confidential, proprietary information of MEDRAD, Inc. It is provided to trained employees of our customers for

the sole purpose of enabling such employee to service customer-owned MEDRAD injectors. This information may not be shared with third

parties or used to service injectors other than as specified herein. Further restrictions on the disclosure and use of this information is

provided in the Service Training Agreement executed by the customer and trained biomed at the time of training. Please refer to that

agreement or contact MEDRAD, Inc. if you have any questions about the information provided in this package.

1. SCOPE

1.1 This document outlines the steps required to update, calibrate,

and verify proper performance of the Spectris Solaris MR

Injector System.

05/31/2007 at 16:47:36.

2. AUDIENCE

VIEWED/PRINTED:

2.1 This Preventive Maintenance Procedure is to be performed by

MEDRAD Trained Field Service Representatives and/or Dealer

Representatives.

3. EQUIPMENT

3.1 General Hand Tools

3.2 Leakage Test Box (Fixture No. 1-0-01), Bender Leakage Tester

or NeTech LGK 601 Electrical Leakage Analyzer – Equipment

Number 11153

3.3 Digital Pressure Gauge Assembly – 89301-00-AM-02

3.4 Stellant 200 ml Test Syringe – 3009672

Prior to use, you are responsible to confirm this copy's revision is the latest released.

3.5 PFS 100 Syringe Adapter Kit – 3008169 (If Available)

3.6 PFS 150 Syringe Adapter Kit – 3009580 (If Available)

3.7 DMM (3.5 Digit) True RMS, Tektronix TX1 or equivalent

This copy of 205254 Rev A is valid as of May-30-2007 at 11:06:00.

3.8 PC with Swift (201844 latest version) Software

3.9 Security Key – 403004189

3.10 Pot Calibration Slug – 3009644

3.11 Service Ethernet Cable – 3004687

3.12 Electro Static Dissipation Equipment

3.13 Protective Gloves

205254 Rev. A Page 3 of 8

This calibration procedure is confidential, proprietary information of MEDRAD, Inc. It is provided to trained employees of our customers for

the sole purpose of enabling such employee to service customer-owned MEDRAD injectors. This information may not be shared with third

parties or used to service injectors other than as specified herein. Further restrictions on the disclosure and use of this information is

provided in the Service Training Agreement executed by the customer and trained biomed at the time of training. Please refer to that

agreement or contact MEDRAD, Inc. if you have any questions about the information provided in this package.

4. DOCUMENTATION

4.1 APPLICABLE DOCUMENTS

4.1.1 Bender Box Equipment Configuration – No. 97057-00-SV-01

(MEBV only)

05/31/2007 at 16:47:36.

4.2 REFERENCE DOCUMENTS

VIEWED/PRINTED:

4.2.1 Spectris Solaris Service Manual – No. 200880

4.2.2 Field Service Report (FSR) – No. 92056, 88026, or appropriate

for the location of unit

4.2.3 Field ESD Policy – No. 89057-00-PP-01

4.2.4 Service Call Procedure – No. 94057-00-FI-01

4.2.5 SWIFT Operation Manual – No. 201610

5. CALIBRATION

5.1 Connect PC to CRU. Apply power. Verify that the Control

Room Unit sounds a tone, and when the Safety Screen

appears, activate the Swift program on the PC. NOTE: If the

Prior to use, you are responsible to confirm this copy's revision is the latest released.

Swift program on the PC had been activated already, click the

icon “connect to the injector”.

5.2 Recalibrate the Touch Screen.

This copy of 205254 Rev A is valid as of May-30-2007 at 11:06:00.

5.3 Press Flow Rate. With a pencil point, touch all four corners of

the number 2 and verify that the key activates. Recalibrate

Touch Screen, if needed.

5.4 Enter the following parameters:

• Phase 1, Syringe A, 10.0 ml/second Flow, 15 ml Volume

• Phase 1, Syringe B, 10.0 ml/second Flow, 15 ml Volume

• Phase 2, Syringe A, 5.0 ml/second Flow, 5 ml Volume

• Phase 2, Syringe B, 5.0 ml/second Flow, 5 ml Volume

205254 Rev. A Page 4 of 8

This calibration procedure is confidential, proprietary information of MEDRAD, Inc. It is provided to trained employees of our customers for

the sole purpose of enabling such employee to service customer-owned MEDRAD injectors. This information may not be shared with third

parties or used to service injectors other than as specified herein. Further restrictions on the disclosure and use of this information is

provided in the Service Training Agreement executed by the customer and trained biomed at the time of training. Please refer to that

agreement or contact MEDRAD, Inc. if you have any questions about the information provided in this package.

5.5 Connect a 65 ml and 115 ml syringe. Set plunger to 60 ml and

100 ml marks on the syringe respectively.

5.6 Arm the injector.

5.7 Inject using the start switch.

5.8 Verify that the arm lights stop flashing when the plungers are

05/31/2007 at 16:47:36.

moving.

VIEWED/PRINTED:

5.9 Verify that A and B syringe injects 20 ml and that the plungers

are now on 40 ml (A syringe) and 80 ml (B syringe) marks on

the syringe.

5.10 Go to the History Screen and open the latest file. Verify that the

Total Contrast = 20 ml, Total Flush = 20 ml and pressure limit

indication is NO.

6. PRESSURE CHECK

6.1 Fill both syringes with water and install both onto head. Install

the pressure gauge assembly onto syringe A and remove any

air bubbles.

6.2 Connect PC to CRU.

Prior to use, you are responsible to confirm this copy's revision is the latest released.

6.3 Cycle CRU power and at safety screen activate the Swift

program.

6.4 Run the program “Scripts/Monitor/Pressure (static)” and select

This copy of 205254 Rev A is valid as of May-30-2007 at 11:06:00.

Syringe A; Strain Gauge 1 (Primary) and Strain Gauge 2

(Redundant).”

NOTE: 1 mVDC = 1 PSI.

6.5 Set DVM to DC millivolts, set pressure module to PSI and rotate

the “zero” adjustment until the DVM reads 0 mVDC. Close the

flow control valve.

6.6 Press “Start” on the PC screen. (Do not press the Enable key)

Using the A Forward Load key pressurize the system to the

following pressures on the digital gauge and press the Check for

Air key after achieving each pressure +/- 1 psi. Refer to the

Swift Op Manual, if needed.

• 75 PSI acceptable PC reading

205254 Rev. A Page 5 of 8

This calibration procedure is confidential, proprietary information of MEDRAD, Inc. It is provided to trained employees of our customers for

the sole purpose of enabling such employee to service customer-owned MEDRAD injectors. This information may not be shared with third

parties or used to service injectors other than as specified herein. Further restrictions on the disclosure and use of this information is

provided in the Service Training Agreement executed by the customer and trained biomed at the time of training. Please refer to that

agreement or contact MEDRAD, Inc. if you have any questions about the information provided in this package.

• A side 35.5 –114.5 PSI; B side 37.5 –112.5 PSI

• 175 PSI acceptable PC reading

• A side 139.5 –210.5 PSI; B side 132.5 –217.5 PSI

• 250 PSI acceptable PC reading

• A side 214 –286 PSI; B side 209 –291 PSI

05/31/2007 at 16:47:36.

6.7 Using the Load key, reverse plunger A to remove the pressure

VIEWED/PRINTED:

in the syringe.

6.8 Move the pressure assembly to the B syringe and redo Steps

12.1 to 12.7 substituting the B syringe for the A syringe.

6.9 Verify that the PC readout is within the acceptable ranges for all

pressure transducers for each reading.

6.10 Retract both pistons and remove the pressure gauge assembly.

Remove and discard the syringe.

7. SYSTEM LEAKAGE TEST

NOTE: Leakage checks cannot be performed on units that are

hard wired to a power source. Leakage checks for the injector

must then be performed per hospital requirements. Place “N/A”

Prior to use, you are responsible to confirm this copy's revision is the latest released.

in the corresponding line in Section 13 of the PMP checklist if

leakage is tested as part of scanner system.

NOTE: If unit is equipped with a Continuous Battery Charger,

Section 13 must also be performed on the power cord attached

This copy of 205254 Rev A is valid as of May-30-2007 at 11:06:00.

to the Continuous Battery Charger.

7.1 Perform this step only if the Bender Box is required. Test

leakage according to 97057-00-SV-01.

7.2 MEDRAD LEAKAGE BOX

7.2.1 Connect the CRU power cord to the leakage box. Inspect

power cord condition. Plug the leakage box into the power

source

7.2.2 Leakage box set-up: Set DMM to the lowest millivolt AC range

and connect to the points labeled Meter. With a test lead,

jumper Ground to Probe on the leakage box.

205254 Rev. A Page 6 of 8

This calibration procedure is confidential, proprietary information of MEDRAD, Inc. It is provided to trained employees of our customers for

the sole purpose of enabling such employee to service customer-owned MEDRAD injectors. This information may not be shared with third

parties or used to service injectors other than as specified herein. Further restrictions on the disclosure and use of this information is

provided in the Service Training Agreement executed by the customer and trained biomed at the time of training. Please refer to that

agreement or contact MEDRAD, Inc. if you have any questions about the information provided in this package.

7.2.3 NOTE: For the following leakage tests, measured millivolts is

equal to microAmps (mVAC = µAmps).

7.2.4 Set Ground to Open, Line to Normal. Apply power. Leakage

must be less than 100 mVAC. Record value.

7.2.5 Set Line to Reverse. Leakage must be less then 100 mVAC.

Record value.

05/31/2007 at 16:47:36.

VIEWED/PRINTED:

7.2.6 Set ground to closed.

7.2.7 Disconnect the test lead from the probe jack on the leakage box

and touch any metal part on the head with test lead, ensure the

leakage is less than 10 mVAC. Record the leakage value.

7.2.8 Remove power. Remove the leakage box power cord from the

outlet. Reconnect the CRU power cord and secure.

7.3 NETECH ELECTRICAL SAFETY ANALYZER

7.3.1 Inspect power cord condition. Connect the power cord to the

leakage box. Plug the leakage box into the appropriate power

source.

7.3.2 Leakage Box Set-Up

Prior to use, you are responsible to confirm this copy's revision is the latest released.

7.3.3 Plug unit into the NeTech Electrical Safety Analyzer and the

NeTech Electrical Safety Analyzer into the AC supply.

7.3.4 Set the Mode switch to case leakage.

This copy of 205254 Rev A is valid as of May-30-2007 at 11:06:00.

7.3.5 Set the load selector switch to 601.

7.3.6 Set Outlet to NORMAL. Apply power. Press the Ground switch

to OPEN. Leakage must be less than 100 mVAC for voltages

less than 130VAC (300mVAC with AC voltage greater than

131VAC). Record the leakage value.

7.3.7 Release the Ground switch.

7.3.8 LINE to REVERSE. Press the Ground switch to OPEN.

Leakage must be less than 100 mVAC for voltages less than

130VAC (300mVAC with AC voltage greater than 131VAC).

Record the leakage value.

7.3.9 Release the Ground switch.

205254 Rev. A Page 7 of 8

This calibration procedure is confidential, proprietary information of MEDRAD, Inc. It is provided to trained employees of our customers for

the sole purpose of enabling such employee to service customer-owned MEDRAD injectors. This information may not be shared with third

parties or used to service injectors other than as specified herein. Further restrictions on the disclosure and use of this information is

provided in the Service Training Agreement executed by the customer and trained biomed at the time of training. Please refer to that

agreement or contact MEDRAD, Inc. if you have any questions about the information provided in this package.

7.3.10 Connect a test lead to the Case Ground jack on the NeTech

Electrical Safety Analyzer. Touch any metal part on the head

with test lead. Ensure the leakage is less than 10 mVAC.

Record the leakage value.

7.3.11 Remove the leakage test box from unit. Reconnect unit to AC

supply.

05/31/2007 at 16:47:36.

VIEWED/PRINTED:

8. FINAL PREPARATION

8.1 Clean the area around the injector and sink of all spilled water.

Ensure syringes used during the PM are removed from the

injector and disposed properly. Discard all disposable materials

used while performing this PM. Place all linens used during

calibration in the soiled linen receptacle.

8.2 Apply DCU power.

8.3 Record the software versions from the safety screen on the

PMP checklist.

8.4 Connect with Swift and run the program “Scripts/Clear/Flight

recorder.

8.5 Press Continue. Reset the calibration reminder to next

Prior to use, you are responsible to confirm this copy's revision is the latest released.

calibration due date on the calibration reminder screen.

8.6 Remove power.

8.7 Ensure that all covers are in place and all hardware is present

and secure.

This copy of 205254 Rev A is valid as of May-30-2007 at 11:06:00.

8.8 Ensure that all surfaces are clean.

8.9 Ensure that screws on the SRU have a yellow coating.

8.10 Remove the old Calibration Label and install a completed

Calibration Label.

205254 Rev. A Page 8 of 8

You might also like

- Samsung Heavy Crane ManualDocument132 pagesSamsung Heavy Crane ManualAndrewNo ratings yet

- Daewoo PUMA 6HS CNC Lathe Instruction ManuallDocument29 pagesDaewoo PUMA 6HS CNC Lathe Instruction Manuallsunhuynh100% (2)

- GEHC Service Manual CARESCAPE MV100 Vital Signs Monitor 2011Document178 pagesGEHC Service Manual CARESCAPE MV100 Vital Signs Monitor 2011patolin_123No ratings yet

- ProteusXRaSM21 PDFDocument562 pagesProteusXRaSM21 PDFРухулла АгакеримовNo ratings yet

- Drager Medibus Instructions For Use PDFDocument16 pagesDrager Medibus Instructions For Use PDFbprzNo ratings yet

- Multimobil 25Document12 pagesMultimobil 25dody100% (1)

- REGIUS SIGMA - Service Manual (A1P6YG220B - 110707 - Fix)Document178 pagesREGIUS SIGMA - Service Manual (A1P6YG220B - 110707 - Fix)Rejie GrabadorNo ratings yet

- Datex-Ohmeda Aespire 7900 Anaesthesia Machine - User Reference Manual 1 PDFDocument88 pagesDatex-Ohmeda Aespire 7900 Anaesthesia Machine - User Reference Manual 1 PDFDaniel Roberto Chacon MatuNo ratings yet

- Shimadzu MOBILEART - Eco - TanDocument8 pagesShimadzu MOBILEART - Eco - TanRASHID AMANNo ratings yet

- Service Manual REV1.4 (Pancorp) - EnglishDocument120 pagesService Manual REV1.4 (Pancorp) - EnglishMary TrujilloNo ratings yet

- (PAPAYA 3D) Technical Manual Eng Ver 1.5-Appendix - CE 2460Document88 pages(PAPAYA 3D) Technical Manual Eng Ver 1.5-Appendix - CE 2460Marko SalarNo ratings yet

- Manual Cardiocap 5Document227 pagesManual Cardiocap 5Alejandro Barrera Torres0% (1)

- Instrument Cluster and Fault Codes PDFDocument28 pagesInstrument Cluster and Fault Codes PDFDavid QuinNo ratings yet

- Loqelmelp P L P 'Ééü: Downloaded From Manuals Search EngineDocument32 pagesLoqelmelp P L P 'Ééü: Downloaded From Manuals Search EngineIii xxxxxNo ratings yet

- CR Mammography Solution CR 30-Xm - Service ManualDocument68 pagesCR Mammography Solution CR 30-Xm - Service ManualEDGAR WILSON CRUZNo ratings yet

- Hamcb SwordDocument101 pagesHamcb SwordNaseh Ya NasehNo ratings yet

- Mercury 332 User's ManualDocument95 pagesMercury 332 User's ManualManuel Vivero DiéguezNo ratings yet

- BSM3000 SM-F PDFDocument200 pagesBSM3000 SM-F PDFYAMILE DIAZ FERRAN100% (1)

- Alluramonoplaneinstructionforuseeng PDFDocument398 pagesAlluramonoplaneinstructionforuseeng PDFFRANCISCO PINEDONo ratings yet

- Scio Four Family Gas Measurement ModulesDocument6 pagesScio Four Family Gas Measurement Moduleschuong hoNo ratings yet

- MD902 Tech DescDocument74 pagesMD902 Tech DescHuda LestraNo ratings yet

- Acuson Nx3 Acuson Nx3 Elite Diagnostic Ultrasound System Instructions For UseDocument370 pagesAcuson Nx3 Acuson Nx3 Elite Diagnostic Ultrasound System Instructions For UseAzeertyNo ratings yet

- Vita Troubleshooting GuideDocument84 pagesVita Troubleshooting GuideIranildo Barbosa100% (1)

- NX - Installation Planning 3.0Document38 pagesNX - Installation Planning 3.0manelNo ratings yet

- Affinity Service Manual Rev7Document235 pagesAffinity Service Manual Rev7Ákos Lengyel100% (1)

- CAC-ENG-STD-014 Instrumentation Standard For Canada PDFDocument14 pagesCAC-ENG-STD-014 Instrumentation Standard For Canada PDFAksheyNo ratings yet

- GE Healthcare CARESCAPE Monitor B450 Service Manual: Software Version 2 Hardware Version B450-01Document244 pagesGE Healthcare CARESCAPE Monitor B450 Service Manual: Software Version 2 Hardware Version B450-01Guillermo Alberto CampetellaNo ratings yet

- Illume Na PartsDocument365 pagesIllume Na Partslaszlo1231No ratings yet

- Automatic Irrigation System Using Microcontroller Main DocumentDocument39 pagesAutomatic Irrigation System Using Microcontroller Main Documentmyhomenet119188180% (15)

- Service Manual Alpha RTDocument216 pagesService Manual Alpha RTRubén Cadima Barrientos100% (1)

- Erbe ICC-200 - Instruction ManualDocument8 pagesErbe ICC-200 - Instruction ManualFrancisco AvilaNo ratings yet

- Canon TX-10 TonometroDocument5 pagesCanon TX-10 TonometroSERGIO2000BA0% (1)

- System, DICOM Configuration CSTD US34-NX3.805.01 US34-102.843.01Document63 pagesSystem, DICOM Configuration CSTD US34-NX3.805.01 US34-102.843.01Ezzeddin AliNo ratings yet

- Vista-120 Installation ManualDocument176 pagesVista-120 Installation Manualkaserta13No ratings yet

- Emax 2 Plus System: User'S ManualDocument60 pagesEmax 2 Plus System: User'S ManualSerkan ÖztürkNo ratings yet

- AM5000 anesthesia module service manualDocument34 pagesAM5000 anesthesia module service manualluisNo ratings yet

- Medrad VistronDocument4 pagesMedrad VistronEC VegaNo ratings yet

- CR-IR 363 Service Manual: Control SheetDocument6 pagesCR-IR 363 Service Manual: Control SheethoudaNo ratings yet

- Neuromuscular Transmission Module, E-Nmt: Service ManualDocument34 pagesNeuromuscular Transmission Module, E-Nmt: Service ManualAlexandra JanicNo ratings yet

- Service ManualDocument116 pagesService ManualrenatozimermannNo ratings yet

- Bird VIP Gold, Stering - Service ManualDocument184 pagesBird VIP Gold, Stering - Service ManualPatricia ReyesNo ratings yet

- Installation: Previous ModelDocument121 pagesInstallation: Previous ModelNikolay PenevNo ratings yet

- AR-B1551NP Manual: 1. Setting Up The SystemDocument3 pagesAR-B1551NP Manual: 1. Setting Up The Systemdido fidoNo ratings yet

- User Manual Intensive Care Unit Heated Cradle Amplatm 2085Document117 pagesUser Manual Intensive Care Unit Heated Cradle Amplatm 2085طارق الخرزيNo ratings yet

- MGA21324 - DefiMonitor XD - GB - JDocument102 pagesMGA21324 - DefiMonitor XD - GB - JJulio Benancio ZuluagaNo ratings yet

- GE Dash 3000,4000 V4 Monitor - User ManualDocument478 pagesGE Dash 3000,4000 V4 Monitor - User ManualLogicLife50% (2)

- Vio 3 ServiceDocument84 pagesVio 3 ServiceAngeloNo ratings yet

- Vista 120 S Patient Monitoring Solution: 305 MM (12") TFT Color Touchscreen Medibus/Medubus-X ConnectivityDocument14 pagesVista 120 S Patient Monitoring Solution: 305 MM (12") TFT Color Touchscreen Medibus/Medubus-X ConnectivitydiegolimanaNo ratings yet

- Service Manual M9000Document48 pagesService Manual M9000Zulma BonillaNo ratings yet

- Zoll M Series Defibrillator Manual PDFDocument111 pagesZoll M Series Defibrillator Manual PDFAhmad TanveerNo ratings yet

- GE Imaging Parts List (CT Mammo RAD R&F US LUNAR)Document31 pagesGE Imaging Parts List (CT Mammo RAD R&F US LUNAR)deng mayNo ratings yet

- Cares. DV5700 Dicom PDFDocument40 pagesCares. DV5700 Dicom PDFLuis Fernando Garcia SNo ratings yet

- Units Catalogue OriginalDocument76 pagesUnits Catalogue Originalroberto.a100% (1)

- Chapter 5 DiagnosticsDocument16 pagesChapter 5 DiagnosticsArturo Jimenez Terrero100% (1)

- Manual Versamed Ivent 201 (Ingles) PDFDocument310 pagesManual Versamed Ivent 201 (Ingles) PDFjulherasec100% (1)

- Mammomat 1000 NovaDocument138 pagesMammomat 1000 NovaAngelo CorleoneNo ratings yet

- GE MAC 500 Serv EngDocument54 pagesGE MAC 500 Serv EngJuan Esteban Castro LopezNo ratings yet

- Service Manual: VIO 100 C VIO 50 CDocument42 pagesService Manual: VIO 100 C VIO 50 CSerginho HenriqueNo ratings yet

- Wolf HD Endocam - User ManualDocument56 pagesWolf HD Endocam - User ManualAhmed 771000303No ratings yet

- Document Information For:: 5339157TST 5339157TSTDocument19 pagesDocument Information For:: 5339157TST 5339157TSTMkrtich AltunyanNo ratings yet

- FONA XDC Service & Installation Manual - GB Rev 7 - 17755 PDFDocument48 pagesFONA XDC Service & Installation Manual - GB Rev 7 - 17755 PDFLUIS NUÑEZNo ratings yet

- GN Ts User Manual REV - 07Document196 pagesGN Ts User Manual REV - 07Reuel TacayNo ratings yet

- Thales Electron User ManualDocument32 pagesThales Electron User ManualВадім Русинчук100% (1)

- OrthophosPlusCephMaintenance PDFDocument30 pagesOrthophosPlusCephMaintenance PDFIii xxxxxNo ratings yet

- X-VIEW 2D PAN Technical InfoDocument9 pagesX-VIEW 2D PAN Technical InfohassaniNo ratings yet

- IBIS Controller 4.7 User ManualDocument87 pagesIBIS Controller 4.7 User ManualLuis Darío Alvarez ToscanoNo ratings yet

- Manual Sopladores IrDocument50 pagesManual Sopladores IrAnonymous tFhBRsNo ratings yet

- GE Advantx-E Boot-Up Process To AppsDocument2 pagesGE Advantx-E Boot-Up Process To AppsbrianNo ratings yet

- PDF Created With Fineprint Pdffactory Trial VersionDocument14 pagesPDF Created With Fineprint Pdffactory Trial VersionbrianNo ratings yet

- GE Notes PDFDocument3 pagesGE Notes PDFbrianNo ratings yet

- P500 Tower Cable SupportDocument2 pagesP500 Tower Cable SupportbrianNo ratings yet

- GE Notes PDFDocument3 pagesGE Notes PDFbrianNo ratings yet

- Field Documents RevisionsDocument4 pagesField Documents RevisionsbrianNo ratings yet

- Manual Vistron 95403 T 140Document116 pagesManual Vistron 95403 T 140brian100% (1)

- GE Notes PDFDocument3 pagesGE Notes PDFbrianNo ratings yet

- Hospira Plum A+ TSMDocument183 pagesHospira Plum A+ TSMbrianNo ratings yet

- ACR ClinicalTestingInstructionsDocument8 pagesACR ClinicalTestingInstructionsbrianNo ratings yet

- DUK E101 E - SPMDocument15 pagesDUK E101 E - SPMbrianNo ratings yet

- 2138247r15 PDFDocument1,112 pages2138247r15 PDFbrian0% (1)

- Hospira Plum A+ TSMDocument183 pagesHospira Plum A+ TSMbrianNo ratings yet

- Eleva PLDocument6 pagesEleva PLbrianNo ratings yet

- Eleva PLDocument14 pagesEleva PLbrianNo ratings yet

- Solid State Drives & StartersDocument18 pagesSolid State Drives & StartersFlo MircaNo ratings yet

- SF100 User ManualDocument32 pagesSF100 User ManualHerdy LiowNo ratings yet

- Cessna Emergency Rescue Access and Fire Fighting Procedures - CitationDocument66 pagesCessna Emergency Rescue Access and Fire Fighting Procedures - CitationMaurice FiechterNo ratings yet

- Eh Ria452Document60 pagesEh Ria452Julistio Anggo Trizki CahyoNo ratings yet

- Letourneau University Lab #17: Avtc2441 Airframe Electrical LabDocument10 pagesLetourneau University Lab #17: Avtc2441 Airframe Electrical LabSantiago Blanco MarconiNo ratings yet

- Edp70 PDFDocument65 pagesEdp70 PDFValentinNo ratings yet

- Comfortpoint Open: Cpo-Vav2A (Unitary Controller)Document4 pagesComfortpoint Open: Cpo-Vav2A (Unitary Controller)MikeNo ratings yet

- DPS - 2000B 48 8Document38 pagesDPS - 2000B 48 8Marco MatteucciNo ratings yet

- 116 UserDocument4 pages116 UserMohamed Yahya100% (1)

- Handbook UPS PDFDocument52 pagesHandbook UPS PDFJoni EfwanNo ratings yet

- Plate SwitchesDocument3 pagesPlate Switchesandrewmwamba1No ratings yet

- Ryobi 1801 Router Operator's ManualDocument20 pagesRyobi 1801 Router Operator's ManualJeremy BaverNo ratings yet

- DX200 - YewDocument37 pagesDX200 - YewLuís Gustavo SantiniNo ratings yet

- REHS4499 Testing The Refrigerant Compressor Protection ModuleDocument5 pagesREHS4499 Testing The Refrigerant Compressor Protection ModuleJuan Carlos Galarza CastilloNo ratings yet

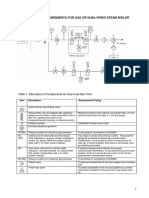

- Gas Train Requirements For Gas or Dual Fired Steam Boiler PDFDocument2 pagesGas Train Requirements For Gas or Dual Fired Steam Boiler PDFringo limNo ratings yet

- Ecu SS40 (Ess-2200)Document2 pagesEcu SS40 (Ess-2200)pubudu inrajithNo ratings yet

- Fda L5MDocument1 pageFda L5MCode JonNo ratings yet

- CPS1000E User Manual enDocument16 pagesCPS1000E User Manual enAdriano ManciniNo ratings yet

- Mikro Overcurrent Relay Mk234a - ManualDocument4 pagesMikro Overcurrent Relay Mk234a - Manualkomiks0609No ratings yet

- GS-KB55S Operating InstuctionsDocument8 pagesGS-KB55S Operating InstuctionsPiero CaprettiNo ratings yet

- 1 PartsDocument68 pages1 PartsBappaditya AdhikaryNo ratings yet

- PRKRvQCOM CAFC20140915 AppellantBriefDocument211 pagesPRKRvQCOM CAFC20140915 AppellantBriefDaniel RavicherNo ratings yet

- Scissor Lift ManualDocument30 pagesScissor Lift Manualvalmiki briseñoNo ratings yet