Professional Documents

Culture Documents

Rankshaft Deflections: Constructionalfeatures

Uploaded by

RABISH KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rankshaft Deflections: Constructionalfeatures

Uploaded by

RABISH KumarCopyright:

Available Formats

MEO Class I V - MEK

Diesel Engine

Con st r u ct ion a l Fe a t u r e s C ra nk sha ft de fle c t ions

Th e cr an k case align m en t is ch eck ed u sin g a dial gau ge. Th e gau ge is fi t t ed bet w een t h e adj acen t

w ebs, opposit e t h e cr an k pin at h alf of t h e diam et er fr om t h e sh aft cen t r e. Th e dial gau ge m easu r es

t h e cr an k w eb spr ead at differ en t an gu lar posit ion of t h e sh aft .

1. The fi rst m easurem ent is t aken wit h t he engine j ust beyond t he bot t om dead cent re posit ion

wit h t he gauge close t o t he side of t he connect ing rod. I t is usual t o set t he gauge t o zero at t his

posit ion.

2. The engine is rot at ed by t he t urning gear and st opped at each quart er from where gauge

readings are t aken. Opening of t he web is considered as posit ive and closing as negat ive.

3. The fi nal reading is t aken near bot t om dead cent re, wit h t he connect ing rod on t he opposit e side

of t he gauge t o t he fi rst reading. The fi rst and last readings are averaged t o use as an

approxim at ion for bot t om cent re posit ion.

4. The procedure is repeat ed for each unit and m easurem ent s are recorded.

A t y pical defl ect ion r epor t for m is giv en below w h er e t h e r eadin gs ar e r ecor ded.

Cr a n k sh a f t D e fl e ct io n Re p o r t :

MV -------------------

En gin e Ru n n in g Hou r s: ……………… Dat e: …………………… Place: ………………….

St an dar d Diam et er : ……. m m Cr an k case Tem per at u r e: ……… ( OC)

Tr im : Ev en Keel

Adj u st in g valu e at assem bly t im e: ……m m En gin e Room Tem per at u r e: ( OC)

List : 0 O

Max Allow an ce valu e: ……. m m

Seaw at er Tem per at u r e : ( OC) Scale : 1 / 1 0 0 m m

MEO Class I V - MEK

Diesel Engine

Con st r u ct ion a l Fe a t u r e s C ra nk sha ft de fle c t ions

Cr a n k Po sit io n 1 2 3 4 5 6 7

Bp ( bot t om por t )

P ( por t )

T ( TDC)

S ( st bd)

Bs ( bot t om St bd)

B = ( Bp+ Bs) / 2

P– S

T – B

Th e v er t ical an d h or izon t al defl ect ion r eadin gs ar e calcu lat ed. Th e m ax im u m defl ect ion valu e

sh ou ld n ot be m or e t h an t h e m ak er ’s r ecom m en dat ion .

A cu r v e is dr aw n w it h t h e valu es of t h e v er t ical m isalign m en t obt ain ed at each cr an k . St ar t in g

fr om on e en d t h e defl ect ion at each cr an k is pr ogr essiv ely added an d t h e poin t s ar e plot t ed.

I f t h e defl ect ion s ar e u n ifor m t h e cu r v e dr aw n t h r ou gh t h e poin t s w ill be sm oot h . Th e cu r v e is

allow ed t o dev iat e at each cr an k posit ion by an an gle pr opor t ion al t o t h e defl ect ion m easu r ed at

t h at cr an k . Th e cu r v e w ill display any u n equ al dev iat ion . Th e cu r v e is u sed t o isolat e t h e fau lt y

bear in g.

-5.2 -2.5 +8.0 +3.3 +7.5 +2.5

1 2 3 4 5 6 7

Deflection curve

Base line

Crankshaft deflections

Powered by TCPDF (www.tcpdf.org)

You might also like

- Lecture 42Document0 pagesLecture 42Kazim RazaNo ratings yet

- 110 Semiconductor Projects for the Home ConstructorFrom Everand110 Semiconductor Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- 20-32 Quantitative Prediction of Transformation Hardening in Steels PDFDocument13 pages20-32 Quantitative Prediction of Transformation Hardening in Steels PDFUlises Quintana CarhuanchoNo ratings yet

- Caiib With Ashok BFM Module A 1 - 3Document12 pagesCaiib With Ashok BFM Module A 1 - 3KiranNo ratings yet

- Basic Electronics Lab ManualDocument100 pagesBasic Electronics Lab Manualalkeshkhatri87% (15)

- Iecee Od-2025-B-2016Document21 pagesIecee Od-2025-B-2016krivitskiNo ratings yet

- Jeep WJ Service ManualDocument2,199 pagesJeep WJ Service ManualJairo Rodriguez A.100% (1)

- Auto Electronics Projects: An Introduction to Your Car Electrics with Useful and Proven Self-Buld ProjectsFrom EverandAuto Electronics Projects: An Introduction to Your Car Electrics with Useful and Proven Self-Buld ProjectsRating: 5 out of 5 stars5/5 (1)

- DC-DC Buck-Boost Converter by Bill Pray Mike Perry Course Section Lab T.A. Inseop Lee 5-4-99 Project Number 40Document17 pagesDC-DC Buck-Boost Converter by Bill Pray Mike Perry Course Section Lab T.A. Inseop Lee 5-4-99 Project Number 40Adithya ChandrasekaranNo ratings yet

- International Society for Rock Mechanics: List of Members 1980From EverandInternational Society for Rock Mechanics: List of Members 1980Rating: 3.5 out of 5 stars3.5/5 (2)

- ZFTLDocument2 pagesZFTLpavithramasiNo ratings yet

- 5.0"WVGA: Mitsubish I E Le Ctric Cor PDocument21 pages5.0"WVGA: Mitsubish I E Le Ctric Cor PEagle TouchNo ratings yet

- Study of Accelerating Torque Requirements of A Reciprocating CompDocument7 pagesStudy of Accelerating Torque Requirements of A Reciprocating CompannaNo ratings yet

- Praktica plc3 PDFDocument30 pagesPraktica plc3 PDFJoe GreenNo ratings yet

- Synte 5401B001 PDFDocument18 pagesSynte 5401B001 PDFMi CisneNo ratings yet

- Di'sruphve tecknoa vivg OLDocument7 pagesDi'sruphve tecknoa vivg OLAman ChauhanNo ratings yet

- Deconvolution Technique Application To Spectral Contour AnalysisDocument12 pagesDeconvolution Technique Application To Spectral Contour AnalysisYassine ZidNo ratings yet

- Deconvolution Technique Application To Spectral Contour AnalysisDocument12 pagesDeconvolution Technique Application To Spectral Contour AnalysisYassine ZidNo ratings yet

- Deconvolution Technique Application To Spectral Contour AnalysisDocument12 pagesDeconvolution Technique Application To Spectral Contour AnalysisYassine ZidNo ratings yet

- Optical Instrument and PrismDocument15 pagesOptical Instrument and Prismrajesh nayakNo ratings yet

- A Fortran Subroutine For The Numerical Solution of Systems of Nonlinear EquationsDocument12 pagesA Fortran Subroutine For The Numerical Solution of Systems of Nonlinear EquationsBoud ElhassanNo ratings yet

- 2022 Question Paper MMDDDocument5 pages2022 Question Paper MMDDKD GaMiNgNo ratings yet

- Frequency Temperature Behavior and Hysteresis of S-TCXOs Using New Shape GT Cut Quartz Crystal ResonatorsDocument8 pagesFrequency Temperature Behavior and Hysteresis of S-TCXOs Using New Shape GT Cut Quartz Crystal ResonatorsAnas HashmiNo ratings yet

- Cloud ComputingDocument3 pagesCloud Computingsyed saadNo ratings yet

- Adobe Scan 17-Mar-2024Document11 pagesAdobe Scan 17-Mar-2024s81924465No ratings yet

- DatasheetVS M72series GRDocument1 pageDatasheetVS M72series GRKSNo ratings yet

- 833Document13 pages833cleberNo ratings yet

- Design and Development of Quadrature Hybrid Coupler atDocument40 pagesDesign and Development of Quadrature Hybrid Coupler atBv Raj GopalNo ratings yet

- Feedback Controllers: Che 442 Process ControlDocument39 pagesFeedback Controllers: Che 442 Process ControlAhmadJaffarGulfarazNo ratings yet

- Engineering Physics Laboratory Manual: For B.E. I/II SemesterDocument28 pagesEngineering Physics Laboratory Manual: For B.E. I/II SemestersreejuslNo ratings yet

- Ubc - 1963 - A7 S2 S7Document90 pagesUbc - 1963 - A7 S2 S7BijuNo ratings yet

- 2 Complete Trusses Required ': (J 4 - 6 2 9 - I - I - A 1 3)Document1 page2 Complete Trusses Required ': (J 4 - 6 2 9 - I - I - A 1 3)Davidescu Elena IrinaNo ratings yet

- Application of energy-dissipation model to calculate flow near spinning discDocument8 pagesApplication of energy-dissipation model to calculate flow near spinning discHind AlnuaimiNo ratings yet

- Lecture Notes On Reciprocating Internal Combustion EnginesDocument102 pagesLecture Notes On Reciprocating Internal Combustion EnginesSamir KumarNo ratings yet

- Dip Assignment-4Document7 pagesDip Assignment-4Hari Natha ReddyNo ratings yet

- Neuromorphic Engineering II: Grading PolicyDocument6 pagesNeuromorphic Engineering II: Grading PolicyEliasA.TiongkiaoNo ratings yet

- Assessor Check List PDFDocument2 pagesAssessor Check List PDFOmPrakashChouhanNo ratings yet

- DAA QBDocument23 pagesDAA QBVarad PatilNo ratings yet

- Marine HoseDocument9 pagesMarine HosemtajikNo ratings yet

- Qprop UsermanualDocument11 pagesQprop UsermanualMuhammad AamirNo ratings yet

- Crypto LabDocument7 pagesCrypto LabRiza Fahmy100% (1)

- Executive Summary: 2.1 Project SiteDocument17 pagesExecutive Summary: 2.1 Project SiteFirdaus JahanNo ratings yet

- Triple resonance pulse transformer circuit patent detailsDocument4 pagesTriple resonance pulse transformer circuit patent detailsharishkumarsinghNo ratings yet

- Asynchronous Transfer Mode (ATM) : - ReferencesDocument19 pagesAsynchronous Transfer Mode (ATM) : - Referencesanoop.egNo ratings yet

- SMP1012X Series - Installation Guide: OverviewDocument4 pagesSMP1012X Series - Installation Guide: OverviewenriquealugovNo ratings yet

- JF STEFFE Rheology Book Resumen 2019Document364 pagesJF STEFFE Rheology Book Resumen 2019Centzon TotochtinNo ratings yet

- Tektronix 576Document251 pagesTektronix 576Allme0% (1)

- Lotus ManualDocument998 pagesLotus ManualArielNo ratings yet

- Secondary Mathematics KitDocument137 pagesSecondary Mathematics KitlallamayandNo ratings yet

- JUNOS Juniper EX Cheat SheetDocument5 pagesJUNOS Juniper EX Cheat SheetWerner ViljoenNo ratings yet

- 00579Document3 pages00579imman46920No ratings yet

- Alineamiento de Ejes Buques Vía Strain GageDocument9 pagesAlineamiento de Ejes Buques Vía Strain GageMario Alejandro Sime OdarNo ratings yet

- ICERA2020 Prof - DienNP ContentsDocument8 pagesICERA2020 Prof - DienNP ContentsEd snowdenNo ratings yet

- Chopper & SCRDocument11 pagesChopper & SCRSudipta DebnathNo ratings yet

- 1975 - Longo - Monte Carlo Calculation of Photon-Initiated Electromagnetic Showers in Lead GlassDocument25 pages1975 - Longo - Monte Carlo Calculation of Photon-Initiated Electromagnetic Showers in Lead GlassMartonSandesNo ratings yet

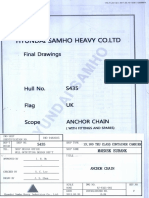

- Draft ConversationDocument2 pagesDraft ConversationRABISH KumarNo ratings yet

- O-39 Anchor ChainDocument3 pagesO-39 Anchor ChainRABISH KumarNo ratings yet

- DLP 5Document55 pagesDLP 5RABISH KumarNo ratings yet

- O-38 Anchor PDFDocument5 pagesO-38 Anchor PDFRABISH KumarNo ratings yet

- O-38 Anchor PDFDocument5 pagesO-38 Anchor PDFRABISH KumarNo ratings yet

- Safety and Construction of ShipsDocument10 pagesSafety and Construction of ShipsRABISH KumarNo ratings yet

- Naval DiagramsDocument2 pagesNaval Diagramsvenkatesh BNNo ratings yet

- Safety CollDocument10 pagesSafety CollMuhammed SabeehNo ratings yet

- Safety and Construction of ShipsDocument10 pagesSafety and Construction of ShipsRABISH KumarNo ratings yet

- ElectricalDocument33 pagesElectricalRABISH KumarNo ratings yet

- Electrical Oral: Question BankDocument33 pagesElectrical Oral: Question BankRABISH KumarNo ratings yet

- MMD Oral QuestionsDocument24 pagesMMD Oral QuestionsIndraSenaNo ratings yet

- Electrical Oral 1Document26 pagesElectrical Oral 1RABISH KumarNo ratings yet

- Marine Electrical Knowledge Questions & AnswersDocument16 pagesMarine Electrical Knowledge Questions & AnswerssivaNo ratings yet

- Marine Centrifugal Pumps GuideDocument4 pagesMarine Centrifugal Pumps GuideRABISH KumarNo ratings yet

- DLP 1Document47 pagesDLP 1RABISH KumarNo ratings yet

- CoverDocument1 pageCoverRABISH KumarNo ratings yet

- Distance Learning ProgramDocument9 pagesDistance Learning ProgramRABISH KumarNo ratings yet

- Distance Learning ProgramDocument37 pagesDistance Learning ProgramRABISH KumarNo ratings yet

- Class IV A Exemption-1Document5 pagesClass IV A Exemption-1RABISH KumarNo ratings yet

- Cylinder Liner Gauging 1Document5 pagesCylinder Liner Gauging 1RABISH Kumar100% (1)

- Bajaj Platina 125 Spare Parts CatalogueDocument67 pagesBajaj Platina 125 Spare Parts CataloguemuheetNo ratings yet

- 01 RT-flex 4 Course A OverviewDocument116 pages01 RT-flex 4 Course A OverviewRachit Sharma100% (2)

- Fault-codes-DM1 - Issue-6-1-11 (1) - Split - 22Document1 pageFault-codes-DM1 - Issue-6-1-11 (1) - Split - 22TAMSNo ratings yet

- Technical Training Guide v1.2 Key Systems OverviewDocument157 pagesTechnical Training Guide v1.2 Key Systems OverviewGogu Ilie0% (1)

- 2004-2007 Renault Modus Fuse Box DiagramDocument9 pages2004-2007 Renault Modus Fuse Box DiagramVieru AndreiNo ratings yet

- Chapter 5Document100 pagesChapter 5Duffoo91No ratings yet

- LCV Crde ManualDocument85 pagesLCV Crde ManualVickyNo ratings yet

- GT 650Document210 pagesGT 650Szabolcs MártonNo ratings yet

- 3JPF 1994Document81 pages3JPF 1994flavianosenaNo ratings yet

- The Effects of Intake Plenum Volume On The Performance of A Small Naturally Aspirated Restricted EngineDocument7 pagesThe Effects of Intake Plenum Volume On The Performance of A Small Naturally Aspirated Restricted EnginePaulo Wey CostaNo ratings yet

- Ez Pedaler ManualDocument20 pagesEz Pedaler ManualNadine M Albu100% (1)

- Pulsar N-160 BS6 - SPCDocument78 pagesPulsar N-160 BS6 - SPCrefaccionariabajaj.camp267% (3)

- 2017 Cannondale Tech - Oliver PDFDocument99 pages2017 Cannondale Tech - Oliver PDFPreeti TaraNo ratings yet

- Mokka X Owners Manual August 2016Document245 pagesMokka X Owners Manual August 2016Leon ČepleNo ratings yet

- Perkins 804C-33 ManualDocument25 pagesPerkins 804C-33 ManualIbrahim Awad50% (2)

- Catalogo Diferencial MB ReduzidoDocument9 pagesCatalogo Diferencial MB ReduzidoGuilherme AvilaNo ratings yet

- Lb361 List PartsDocument7 pagesLb361 List PartsJorge Luis BriceñoNo ratings yet

- FRPP Cam SpecsDocument1 pageFRPP Cam SpecsDan GriggsNo ratings yet

- 0192 IP PracticeExamDocument32 pages0192 IP PracticeExamlisahunNo ratings yet

- Turbo ChargersDocument24 pagesTurbo ChargersTanyaNo ratings yet

- Auto ClutchDocument26 pagesAuto ClutchKritisundar GarnayakNo ratings yet

- PKZ4975 Manual PDFDocument12 pagesPKZ4975 Manual PDFDarren-Edward O'NeillNo ratings yet

- Jeep Wiring DiagramsDocument172 pagesJeep Wiring Diagramsmnlwood255887% (91)

- C783 - Intake Manifold 1 Temperature-Abnormal Rate of ChangeDocument4 pagesC783 - Intake Manifold 1 Temperature-Abnormal Rate of ChangeLucas CamposNo ratings yet

- Expt 3 Study of Energy Recovered Using Regenerative BrakingDocument10 pagesExpt 3 Study of Energy Recovered Using Regenerative BrakingYash BhangaleNo ratings yet

- Service Manual: Downloaded From Manuals Search EngineDocument208 pagesService Manual: Downloaded From Manuals Search Engineisaac_luna_1No ratings yet

- 10 RH90C Swing SystemDocument29 pages10 RH90C Swing SystemOrlando Barboza VasquezNo ratings yet

- Workshop Manual Aub Bby BBZ BkyDocument253 pagesWorkshop Manual Aub Bby BBZ Bkylefteris8450% (2)

- Jeep Parts Catalog CompleteDocument70 pagesJeep Parts Catalog Completelenakost50% (2)

- kUBOTAv2003tb PDFDocument112 pageskUBOTAv2003tb PDFBobCavNo ratings yet