Professional Documents

Culture Documents

RR Wa R1 0 PDF

RR Wa R1 0 PDF

Uploaded by

Shoppingpak comOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RR Wa R1 0 PDF

RR Wa R1 0 PDF

Uploaded by

Shoppingpak comCopyright:

Available Formats

Olaer Fawcett Christie

13 Boola Place

Cromer 2099 NSW

Tel: (02) 9981 6888

Fax: (02) 9981 6144

Hydraulic Accumulators – Rules and Regulations

Introduction All Pressure vessel inspections shall be carried out by

a competent person, such as a Boiler inspector or

This document is a summary of OH&S requirements Company that specializes in Pressure vessel

relating to hydraulic accumulators. Hydraulic inspections.

accumulators are pressure vessels and as such

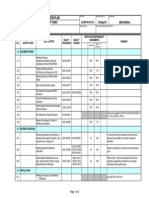

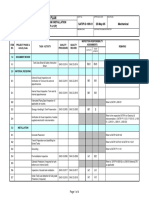

require statutory regulation. Nominal Inspection Periods (AS3788)

Commissioning

1. Design Registration

Extended

1st Year

External

Nominal

P = design pressure

Pressure Equipment with Hazard Levels A, B, C and V = vessel volume

D shall be design registered with WorkSafe WA.

Design registration is a process of having the design

rd Oil Service

verified by 3 party and then registering this design

with WorkSafe WA. Acceptable pressure vessel PV < 100 MPa·L N N - - -

designs in WA are specified in AS1200. Designs PV = 100-200 MPa·L Y N - - -

accepted in AS1200 are: AS1210, ASME Viii and PV > 200 MPa·L Y Y 2 12 12

PD5500. Chemical Service Y Y 2 4 12

Imported equipment shall be design registered. Relating above table to Olaer standard oil service

units rated to 345Bar.

Older equipment should also be design registered.

- 1 & 2.5ltr units are not subject to inspections

2. Plant Registration - 4ltr units are subject to commissioning

inspection.

Hydraulic Accumulators with Hazard Levels A, B and - 10ltr and above are subject to internal and

C (as specified in AS4343) shall be registered as external inspection.

plant with WorkSafe WA. Person responsible for plant

registration is the owner of the equipment. All accumulators used with chemicals that are

corrosive or flammable are to be inspected on regular

Plant registration involves filling out the relevant basis. The inspector can grant an extended period for

application form, signing a compliance statement that internal inspections if he feels that there is no ground

the plant is safe to operate, and payment of for expecting any corrosion problem after he has done

registration fee (payable annually). the first internal inspection.

For further info please visit: References

http://www.worksafe.wa.gov.au

AS4343, AS3788, AS1200, OH&S Regulations 1996

3. In-Service Inspection

As a risk control measure employer must ensure that

pressure equipment is inspected in accordance with

AS3788-2001.

Each owner is responsible for ensuring that the extent

and frequency of inspection is appropriate and

adequate for the continued safe and economic

operation of the pressure equipment. This may

require seeking of expert outside advice.

DISCLAIMER: The information provided in this presentation should be used as a guide only. Olaer Fawcett Christie do not accept

any responsibility with regard to the accuracy of the content or any legal ramifications which could arise from using of this

document. It is the responsibility of the end user to make sure they comply with their local OH&S state requirements.

R&R WA R1.0

You might also like

- QMIS LBE Rev Mech Final OldDocument683 pagesQMIS LBE Rev Mech Final Oldh_aldhwyain100% (9)

- SOW - Internal Corrosion Monitoring.Document8 pagesSOW - Internal Corrosion Monitoring.Chukwuma Emmanuel Onwufuju50% (2)

- Tower Light Almeer 101Document2 pagesTower Light Almeer 101groshan20No ratings yet

- FAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansFrom EverandFAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansRating: 5 out of 5 stars5/5 (2)

- Major Process Equipment Maintenance and RepairFrom EverandMajor Process Equipment Maintenance and RepairRating: 4 out of 5 stars4/5 (4)

- Notarial Law Violation CASESDocument5 pagesNotarial Law Violation CASESMai ReamicoNo ratings yet

- Recommended WPCE Service and Certification ScheduleDocument3 pagesRecommended WPCE Service and Certification ScheduleMehdi SoltaniNo ratings yet

- Hydrostatic Test Procedure: Salalah Ammonia ProjectDocument6 pagesHydrostatic Test Procedure: Salalah Ammonia ProjectAbdelkhak KhallaNo ratings yet

- SATIP-X-400-01 Rev 5Document3 pagesSATIP-X-400-01 Rev 5aamirapiNo ratings yet

- Rfi TrackingDocument42 pagesRfi Trackinganand100% (2)

- Saic N 2031Document4 pagesSaic N 2031aamirapi100% (1)

- Asme BPVC.: Information For ManufacturersDocument2 pagesAsme BPVC.: Information For ManufacturersHaziqNo ratings yet

- 1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFDocument4 pages1 SATIP-W-011-01 Welding of On-Plot Piping - Rev1 PDFWIZKHALIFANo ratings yet

- AGN 014 - Marine Alternators: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesDocument5 pagesAGN 014 - Marine Alternators: Application Guidance Notes: Technical Information From Cummins Generator TechnologiesariwibowoNo ratings yet

- Pre Comm FormatDocument75 pagesPre Comm FormatHaleem Ur Rashid Bangash100% (1)

- Machine Test ProcedureDocument69 pagesMachine Test ProcedurekbldamNo ratings yet

- Yoke 2016Document12 pagesYoke 2016WalterNo ratings yet

- This Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncDocument10 pagesThis Document Contains Proprietary Data and Shall Not Be Reproduced or Disclosed Without The Permission of ALSTOM Power IncJKKNo ratings yet

- 1 SATIP-W-017-01 Welding of API Tanks-Rev 1Document4 pages1 SATIP-W-017-01 Welding of API Tanks-Rev 1khalid764No ratings yet

- HvacDocument104 pagesHvaclamping_apNo ratings yet

- 1 SATIP-D-109-01 Shop Fab Storage Tank PDFDocument4 pages1 SATIP-D-109-01 Shop Fab Storage Tank PDFJithuJohnNo ratings yet

- SH-Testing and Commissioning of DOAS - AHU Unit-Clin 3Document24 pagesSH-Testing and Commissioning of DOAS - AHU Unit-Clin 3Ali ElHelfawyNo ratings yet

- Hiller Annual Fire Protection Systems 3 Year Inspections Agreement Tower 1Document6 pagesHiller Annual Fire Protection Systems 3 Year Inspections Agreement Tower 1Kyle JamesNo ratings yet

- 3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommDocument10 pages3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommNishit KhuntNo ratings yet

- Satr H 1003Document1 pageSatr H 1003Moghal AliNo ratings yet

- 6.JGPD-IsF-T-SH-SA-1444-RTR Pipe Installation & Lamination of Pipe End JointDocument23 pages6.JGPD-IsF-T-SH-SA-1444-RTR Pipe Installation & Lamination of Pipe End JointPangky AbasoloNo ratings yet

- Pse10 0029Document8 pagesPse10 0029Daoued HaouesNo ratings yet

- Type Approval: Offshore Container Lifting OperationDocument28 pagesType Approval: Offshore Container Lifting OperationregisreginhoNo ratings yet

- HSB Pressure Points 2017 MayDocument6 pagesHSB Pressure Points 2017 MayzaheerNo ratings yet

- Certificado Siemens 115Document3 pagesCertificado Siemens 115Iñaki EseberriNo ratings yet

- STD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureDocument27 pagesSTD PIP VECQ1001 2009 Vessel Shop Qualification ProcedureNikunj KNo ratings yet

- Generator Manual 1Document392 pagesGenerator Manual 1Gopal Radhakrishnan100% (5)

- Oil Leak Test ProcedureDocument5 pagesOil Leak Test ProcedurekumaraguruNo ratings yet

- Occidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-ADocument45 pagesOccidental of Oman, Inc. Engineering Services Contract For Oman North OXY CONTRACT NO. SWL-CA-2013-24000039693-ASakthikumar ChandrasekaranNo ratings yet

- Air Dryer - Tangguh PJDocument64 pagesAir Dryer - Tangguh PJRanu JanuarNo ratings yet

- Hydrostatic and Settlement Tests ProcedureDocument12 pagesHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- SATIP-K-001-08 - Air Filtration Devices and Grease FilterDocument2 pagesSATIP-K-001-08 - Air Filtration Devices and Grease Filterimrankhan22No ratings yet

- Air Cooled Water Chiller-SpecsDocument9 pagesAir Cooled Water Chiller-SpecsShrikant SomvanshiNo ratings yet

- 758930-PVD-Q-X-XXX-PRO-0007 Hydrostatic Test Procedure Rev ADocument12 pages758930-PVD-Q-X-XXX-PRO-0007 Hydrostatic Test Procedure Rev ATran Van Nhut LinhNo ratings yet

- Manual 53ehov 14060014Document32 pagesManual 53ehov 14060014Sharatchandra RaoNo ratings yet

- Procedure For Tin - inDocument13 pagesProcedure For Tin - inAdil IjazNo ratings yet

- PRES-E-04 Electrical Equipment - Oil & TransformerDocument2 pagesPRES-E-04 Electrical Equipment - Oil & TransformersalamlinNo ratings yet

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDocument18 pages4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNo ratings yet

- QC CV SampleDocument11 pagesQC CV SampleSikander NawazNo ratings yet

- Satip K 001 03Document1 pageSatip K 001 03Dusngi MoNo ratings yet

- SatipDocument5 pagesSatipMuhammad Abdul Kadher100% (3)

- Pgcil-Latest Testing FormatDocument149 pagesPgcil-Latest Testing FormatVeeranki Bharath80% (5)

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument2 pagesAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- 1 SATIP-N-110-01 Castable Refractory InstallationDocument2 pages1 SATIP-N-110-01 Castable Refractory Installationsonalisabir100% (1)

- Honing Procedure: Doc. No.: - Job No.: 26071Document10 pagesHoning Procedure: Doc. No.: - Job No.: 26071Muhammad GaneshaNo ratings yet

- GTGB - Start Up - Ric8955863 Rev 0.1Document44 pagesGTGB - Start Up - Ric8955863 Rev 0.1Mohamed El Amine BouazzaNo ratings yet

- EN-769-PL-1823 - Rev A - Lifting & Rigging PlanDocument19 pagesEN-769-PL-1823 - Rev A - Lifting & Rigging PlanSkinhead TvNo ratings yet

- Saic N 2034Document4 pagesSaic N 2034aamirapiNo ratings yet

- Document Submittal From Contractor: Method of Statements For RTR PipingDocument11 pagesDocument Submittal From Contractor: Method of Statements For RTR PipingAbdul raheem syed100% (1)

- Ec 1811338 EcDocument25 pagesEc 1811338 EcChuck AnsphilNo ratings yet

- DDDDocument7 pagesDDDmohd as shahiddin jafriNo ratings yet

- 26 Saic A 2009Document5 pages26 Saic A 2009Naveed ShahNo ratings yet

- Baudouin Marine ProductGuide Watermark-4Document33 pagesBaudouin Marine ProductGuide Watermark-4ugur8ayNo ratings yet

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Chapter 1-3 SummaryDocument10 pagesChapter 1-3 SummaryLovely Jane Raut CabiltoNo ratings yet

- HR 2617Document8 pagesHR 2617National JournalNo ratings yet

- Polymer Rubber Corporation vs. SalamudingDocument13 pagesPolymer Rubber Corporation vs. Salamudingpoiuytrewq9115No ratings yet

- RPR 210 Semester Test 2 2022 (Memo)Document5 pagesRPR 210 Semester Test 2 2022 (Memo)Akshar SewlallNo ratings yet

- Firestone Tire & Rubber Company of The Philippines vs. Court of AppealsDocument10 pagesFirestone Tire & Rubber Company of The Philippines vs. Court of AppealsJayson FranciscoNo ratings yet

- Sirius Timer Relay ManualDocument28 pagesSirius Timer Relay ManualVinoth MahendranNo ratings yet

- Commons Library Analysis of The Corporate Insolvency and Governance Bill (HC 2019-21)Document51 pagesCommons Library Analysis of The Corporate Insolvency and Governance Bill (HC 2019-21)marsela gaxhaNo ratings yet

- Legal Medicine: Second Year-M1Document311 pagesLegal Medicine: Second Year-M1rapturereadyNo ratings yet

- Utahns For Alternatives To The Death Penalty: Position PaperDocument6 pagesUtahns For Alternatives To The Death Penalty: Position Paperhrhr99No ratings yet

- 15 Defensor-Santiago v. GuingonaDocument3 pages15 Defensor-Santiago v. GuingonaMarl Dela ROsaNo ratings yet

- Bengzon v. Senate Blue Ribbon Committee - DigestDocument3 pagesBengzon v. Senate Blue Ribbon Committee - DigestMarbeluz AnnNo ratings yet

- People Vs ManaloDocument4 pagesPeople Vs Manalosabrina gayoNo ratings yet

- Mock TrialDocument27 pagesMock TrialRochel TualeNo ratings yet

- Raunaq Dash - Internship Offer LetterDocument2 pagesRaunaq Dash - Internship Offer LetterRaunaq DashNo ratings yet

- Aarhus U ClaimantDocument75 pagesAarhus U ClaimantVishal MandalNo ratings yet

- The Practitioner's Guide To Civil LitigationDocument306 pagesThe Practitioner's Guide To Civil LitigationValentinedavisNo ratings yet

- Economic Citizenship Programme - GrenadaDocument3 pagesEconomic Citizenship Programme - GrenadaCITIZENSHIP AND RESIDENCY PROGRAMMES WORLDWIDENo ratings yet

- Sy-Quia Vs Sheriff - Paguio (d2017)Document1 pageSy-Quia Vs Sheriff - Paguio (d2017)CzarPaguioNo ratings yet

- United States v. Curtiss-WrightDocument1 pageUnited States v. Curtiss-WrightcrlstinaaaNo ratings yet

- Beneficial Owner DisclaimerDocument1 pageBeneficial Owner DisclaimerJULIO MEJIANo ratings yet

- People v. Oco 412 Scra 190 PDFDocument22 pagesPeople v. Oco 412 Scra 190 PDFVen Xtian TellesNo ratings yet

- Arigo, Magallona Case DigestsDocument6 pagesArigo, Magallona Case DigestsBlaise VENo ratings yet

- Ltia Forms 1-7 2023.docx 20240229 102918 0000Document31 pagesLtia Forms 1-7 2023.docx 20240229 102918 0000thompsoncaroline619No ratings yet

- Notice For Submission of DocumentsDocument1 pageNotice For Submission of Documentsامین ثانیNo ratings yet

- Notary Public HandbookDocument17 pagesNotary Public HandbookBull LANo ratings yet

- Laws of The Game Resumed - ®MR - JM - RC - 2015-2016 PDFDocument23 pagesLaws of The Game Resumed - ®MR - JM - RC - 2015-2016 PDFIlidio RodriguesNo ratings yet

- KartaDocument17 pagesKartaAnshul SinghNo ratings yet

- Bacungan V CA Deheza-Inamarga V AlanoDocument2 pagesBacungan V CA Deheza-Inamarga V AlanoCarol AugustNo ratings yet

- Auditing Trs by IcapDocument53 pagesAuditing Trs by IcapArif AliNo ratings yet