Professional Documents

Culture Documents

Pipe Material Received: NO Item Material Description Quantity (PCS) Length (MTR) Remarks

Uploaded by

Alfian ImaduddinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipe Material Received: NO Item Material Description Quantity (PCS) Length (MTR) Remarks

Uploaded by

Alfian ImaduddinCopyright:

Available Formats

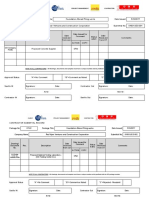

Form No : FR-AEC-01

Revision No : 0

Date : 21-Dec-2017

INSPECTION REPORT

PIPE MATERIAL RECEIVED

OFF LOADED DATE Report No. :

Start : Date: :

Finish : Shift :

Page :

RECEIVED AT LOCATION:

QUANTITY LENGTH

NO ITEM MATERIAL DESCRIPTION REMARKS

(Pcs) (Mtr)

TOTAL

Any items which are Over Delivered, Under (Short) Delivered, or Damaged shall be recorded on a separated Over, Short and Damage Report.

Legend : TOTAL

D : Dent NP : No Bevel Protector ND : No Damage

BD : Bevel Damage NEC : No End Cup Protection ACC : Accepted

SC : Scratch TI : Tail Rep : Repair

O : Ovality Mid : Midle (Body) Rej : Reject -

C : Contamination LE : Lead

Material Inspection by KHI Note :

Start :

Finish :

ATTACHMENTS : LIST INCOMING

PT. KHI Pipe Industries

Inspected by, Reviewed by, Witnessed/Reviewed by,

Name : : Muslich Name :: Muslich Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

Form No : FR-AEC-02

Revision No : 0

Date : 21-Dec-2017

INSPECTION REPORT

COATING MATERIAL RECEIVED

WO. NO. Report No.

Customer Page

Pipe Size Date

Project

Product Receiving Details Comment / Remarks

Product Name / Code: -

Manufacturer: -

Purchase Order No: -

Delivery Date: -

Delivery Order No: -

Quantity Order Received: -

Type of Packaging: -

Packaging Condition: Good Damage -

Certification Received: Yes No -

Order Completed: Yes No -

PT. KHI Testing Required: Yes No Date Sample Delivery to Laboratory: N/A

PT. KHI Test Report Received: Yes No Date Test Report Received: N/A

Product Batch Numbers Date of Manufacture Expire Date

Batch No :

Note : -

PT KHI Pipe Industries

Inspected by, Reviewed by, Reviewed/Witnessed by,

Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

Form No : FR-AEC-03

Revision No : 0

Date : 21-Dec-2017

INSPECTION REPORT

DAILY INSTRUMENT CALIBRATION

WO. NO. Report No.

Customer Date

Pipe Size Shift

Project Page

Instrument

I/D Time Target Results Variance Status Ref. Instrument

Type

Legend: Note : Variance Adjustable to ±5% of Target Value

Acc = Accepted R = Repair

DFT = Dry Film Thickness SPG = Surface Profile Gauge

HD = Holiday Detector SRT = Surface Roughness Tester

PT KHI Pipe Industries

Inspected by, Reviewed by, Witnessed/Reviewed by,

Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

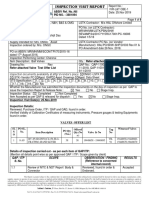

Form No : FR-AEC-04

Revision No :0

Date : 21-Dec-2017

INSPECTION REPORT

INCOMING PIPE

WO. NO. : Report No. :

Customer : Date :

Pipe Size : Shift :

Project : Page :

Salt

Length Surface

No Pipe No. Heat No. Visual Inspection Contamination

(Meter) Contamination

Test

No oil, grease,

Status Remarks

Acceptance Criteria - dirt and solid N/A

pollution

Frequency - Every pipe N/A

Name

EQUIPMENT

ID

Legend : ACC : Accepted Note : -

Hold : Hold for Cleaning or Repair

Reject : Reject

- : Blank

PT KHI Pipe Industries

Inspected by, Reviewed by, Witnessed/Reviewed by,

Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

Form No : FR-AEC-05

Revision No : 0

Date : 21-Dec-2017

INSPECTION REPORT

SURFACE PREPARATION

WO. NO. : Report No. :

Customer : Date :

Pipe Size : Shift :

Project : Page :

Ambient Conditions, Preheat

Pipe Length Temp. Surface Profile Salt

Blast

No Heat No. Elapsed Time Contamination

Dew Cleanliness Press 'O'

No (M) Pipe RH Visual Test

Point film

Pipe surface temperature All minor defect

No Flash rusting, like burrs and Status Remarks

after blasting shall be 3⁰C 50-100 Max. 2 µg/cm²

Acceptance Criteria RH<85% max 4

above dew point minimum &

Sa. 2½ spalters and

µm (Max. 20 mg/m2)

hrs irregularities shall

RH Max 85% be removed

At start up and once every 4 Once

Frequency Every pipe

hrs

Every pipe Every end

per shift

1 pipe per shift

Name

EQUIPMENT

ID

Legend : ACC : ACCEPTED Note : -

REP : REPAIR

REJ : REJECTED

- : BLANK

PT KHI Pipe Industries

Inspected by, Reviewed by, Witnessed / Reviewed by,

Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

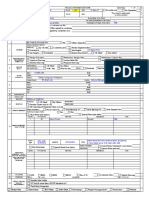

Form No : FR-AEC-05A

Revision No :0

Date : 21-Dec-2017

INSPECTION REPORT

SURFACE PREPARATION

WO. NO. : Report No. :

Customer : Date :

Pipe Size : Shift :

Project : Page :

٠ Ambient Conditions, Preheat Temperature & Cleanliness

Item Criteria Frequency Results

Compressed Air Test

Time

Pipe Number

o

Dew Point ( C)

% RH

(Relative Humidity)

Pipe Temperature (oC)

Elapsed time between

blasting & coating

Blast Cleanliness

٠ Surface Profile

Item Criteria Frequency Results

Pipe Number

Profile

(Grit type comparator)

Profile (by Press 'O' film)

Item Criteria Frequency Results

Pipe Number

Profile

(Grit type comparator)

Profile (by Press 'O' film)

Item Criteria Frequency Results

Pipe Number

Profile

(Grit type comparator)

Profile (by Press 'O' film)

٠ Salt Contamination Test

Item Criteria Frequency Results

Pipe Number

Salt Contamination

PT. KHI Pipe Industries

Inspected by, Reviewed by, Witnessed / Reviewed by,

Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

Form No : FR-AEC-05B

Revision No :0

Date: : 21-Dec-2017

INSPECTION REPORT

SURFACE PREPARATION

WO. No. : PQT Report No :

Customer : Date: :

Pipe Size : Shift :

Project : Page No :

Equipment Name/ID :

> Dust Test (clear tape As per ISO 8502-3)

Pipe No. Acceptance Criteria Frequency Result

Dust Test Record N/A

Pipe No. Acceptance Criteria Frequency Result

Dust Test Record N/A

Pipe No. Acceptance Criteria Frequency Result

Dust Test Record N/A

Pipe No. Acceptance Criteria Frequency Result

Dust Test Record N/A

Pipe No. Acceptance Criteria Frequency Result

Dust Test Record N/A

PT KHI Pipe Industries

Inspected by, Reviewed by, Reviewed/Witnessed by,

Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

Form No : FR-AEC-06

Revision No :0

Date : 21-Dec-2017

INSPECTION REPORT

COATING PRIMER APPLICATION

WO. NO. : Report No. :

Customer : Date :

Pipe Size : Shift :

Project : Page :

Pipe Dry Film Thickness

Length Visual

No Pipe No. Surface Temp.

(M) X1 X2 X3 X4 X5 X6 Appearance

(°C)

Covered entire

Between 30°C Average

Acceptance Criteria 20 µm surface area and Status Remarks

and 50°C (µm) free from runs,

sags.

Frequency Every pipe 1 per shift Every pipe

NAME

EQUIPMENT

ID

Legend : ACC : ACCEPTED Note : -

REP : REPAIR

REJ : REJECTED

- : BLANK

PT KHI Pipe Industries

Inspected by, Reviewed by, Witnessed / Reviewed by,

Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

Form No : FR-AEC-07

Revision No. : 0

Date : 21-Dec-2017

INSPECTION REPORT

COATING APPLICATION

WO. NO. : Report No. :

Customer : Date :

Pipe Size : Shift :

Project : Page :

Equip. Name/ID :

Application Of Asphalt Enamel Temp. Of Heating

Temperature (°C) Kettles (°C)

Length Time Visual

No Pipe No. Visual Primer

(M) (WIB) Dew Asphalt

Pipe Asphalt Quenching 1 2 3

Point

Status Remarks

Within 4 hrs, shall Pipe temp shall be at

Manufacturer's Continous &

Acceptance Criteria be tuch dry & free least 3⁰C above dew

recommendation

Max. 65°C 200-240°C Free Defect

contamination point

1 pipe per

Frequency Every pipe Once per shift Every pipe 1 per shift

shift

Legend : NOTE : -

ACC : ACCEPTED

REP : REPAIR

REJ : REJECTED

- : BLANK

PT KHI Pipe Industries

Inspected by, Reviewed by, Whitnessed / Reviewed by,

Name: Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

Form No : FR-AEC-08

Revision No. :0

Date : 21-Dec-2017

INSPECTION REPORT

PLACEMENT AND DISTRIBUTION OF WRAPPING

WO. NO. : Report No. :

Customer : Date :

Pipe Size : Shift :

Project : Page :

Equip. Name/ID :

Innerwrap Outerwrap

Length

No Pipe No.

(M) Overlap (mm) Visual Inspection Overlap (mm) Visual Inspection

Status

Acceptance Criteria Min 25 mm Neat, & Smooth Min 25 mm Neat, & Smooth

Frequency 1 per day 1 per day

PT KHI Pipe Industries

Inspected by, Reviewed by, Witnessed/Reviewed by,

Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

Form No : FR-AEC-09

Revision No. :0

Date : 21-Dec-2017

INSPECTION REPORT

COATING REPAIR

WO. NO. : Report No. :

Customer : Date :

Pipe Size : Shift :

Project : Page :

Thickness (mm)

Heat Length Holiday Detection Visual

NO. Pipe No. Defect Description (location, Area, Etc) Status Remarks

Number (Meter) at 20 kV X1 X2 X3 X4 X5 AVG Appearance

NAME

EQUIPMENT

ID

Legend : PT KHI Pipe Industries

ACC : ACCEPTED REJ : REJECTED Inspected by, Reviewed by, Whitnessed / Reviewed by,

REP : REPAIR - : BLANK

Note:

1. The record shall be complete,clear and accurate,

no alteration

2. Repair in strict accordance with related techincal documents Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

Form No : FR-AEC-10

Revision No. :0

Date : 21-Dec-2017

INSPECTION REPORT

FINAL COATING

WO. NO. : Report No. :

Customer : Date :

Pipe Size : Shift :

Project : Page :

Weight Total Coating Thickness Cutback

Length Visual

No. Pipe No. Heat No. (Pipe+AEC ) (mm) Holiday Distribution of Innerwrap (mm)

(M) Appearance

(Kg) End (1) Middle End (2) Test at 20 E1 E2

Average kV Completely embadded within No wringkling, pinholes, Status REMARKS

Acceptance Criteria Min. 4 mm the middle 50% of the enamel 150 - 160 mm voids, lamination dry wrap

thickness & separate from each and blemish

Frequency Every pipe 3 location (at 12,3,6 and 9 o'clock) Every pipe Once per shift Every pipe Every pipe

Name

Equipment

ID

Legend : ACC : ACCEPTED - : BLANK PT KHI Pipe Industries

REP : REPAIR Inspected by, Reviewed by, Whitnessed / Reviewed by,

REJ : REJECTED

Note: 1. The record shall be complete,clear and accurate, No Alternation

2. Inspection in strict accordance with related techincal document

3. Indicate the reason for rejection

Cc.: 1. QA Departement 2.Client Rep. 3. File Name : Name : Name :

Form No : FR-AEC-11

Revision No. :0

Date : 21-Dec-2017

INSPECTION REPORT

ADHESION TEST

WO. NO. : Report No. :

Customer : Date :

Pipe Size : Shift :

Project : Page :

:

Equip. Name/Id :

Result of Testing

Production Date :

Testing Date :

Acceptance Criteria :

Continuity Coating Thickness

Length

Testing Pipe No. Heat No. Result of Adhesion Remarks

(Mtr)

At 20 KV Min. 4 mm

Adhesion

Testing

Note : -

PT. KHI Pipe Industries

Inspected by, Reviewed by, Witnessed / Reviewed by,

Name : Name : Name :

Cc.: 1. QA Departement 2.Client Rep. 3. File

You might also like

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument2 pagesCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Incoming Raw Material Insp. Report JKDocument1 pageIncoming Raw Material Insp. Report JKAmit RaiNo ratings yet

- QAR-QD#419-2 Single PartsDocument2 pagesQAR-QD#419-2 Single PartsIrwanto ManafNo ratings yet

- 8D FormatDocument6 pages8D FormatGeorge SubaNo ratings yet

- N-17765-STANTEC-SEDE-CS-0101 - Wall Thickness Calc-Mtr Fttngs - R.0Document8 pagesN-17765-STANTEC-SEDE-CS-0101 - Wall Thickness Calc-Mtr Fttngs - R.0Noor AnterNo ratings yet

- Structural Inspection Report SummaryDocument1 pageStructural Inspection Report SummarytalhaNo ratings yet

- Inspection Test Plan For Fabrication PDF FreeDocument4 pagesInspection Test Plan For Fabrication PDF Freesam paulNo ratings yet

- Contractor Submittal RecordDocument172 pagesContractor Submittal RecordErwin ObenzaNo ratings yet

- Fit-Up Inspection Report: Project Name Form No.: Rev-0Document2 pagesFit-Up Inspection Report: Project Name Form No.: Rev-0sallehinyusoffNo ratings yet

- Quality Control Form ProjectDocument1 pageQuality Control Form ProjectashwinNo ratings yet

- Fm-qcd-08 Inspection ReportDocument1 pageFm-qcd-08 Inspection Reportapi-3832465No ratings yet

- Contractor Submittal RecordDocument101 pagesContractor Submittal RecordErwin ObenzaNo ratings yet

- QAR-QD#419-24 Edmo Jack Cylinder GPDocument2 pagesQAR-QD#419-24 Edmo Jack Cylinder GPIrwanto ManafNo ratings yet

- IMSB-AR-CL-001 BrickworkDocument1 pageIMSB-AR-CL-001 BrickworkShan THALANo ratings yet

- Form Punjas PDFDocument3 pagesForm Punjas PDFocktoperryphNo ratings yet

- Slawinski Datasheet enDocument10 pagesSlawinski Datasheet enahmed mohamedNo ratings yet

- Returned parts list for A321 aircraftDocument1 pageReturned parts list for A321 aircraftPhạm Hà TiếnNo ratings yet

- D8C26-0319-01JASAIMPIANDocument1 pageD8C26-0319-01JASAIMPIANAnonymous lv8SNRyNo ratings yet

- Material Traceability Inspection ReportDocument32 pagesMaterial Traceability Inspection ReportBalmiki SinghNo ratings yet

- QAR-QD#419-21 Boom Cylinder GPDocument2 pagesQAR-QD#419-21 Boom Cylinder GPIrwanto ManafNo ratings yet

- Itp Structural SteelDocument2 pagesItp Structural SteelSahad VarambankallanNo ratings yet

- Pipe fit-up inspection formDocument1 pagePipe fit-up inspection formrashid ahmadiNo ratings yet

- Snag 5Document1 pageSnag 5mkalidas2006No ratings yet

- Material Inspection SheetDocument3 pagesMaterial Inspection Sheetrahid iqubalNo ratings yet

- Checklist-EDC TANKDocument14 pagesChecklist-EDC TANKPartheeban SkpNo ratings yet

- DPT ReportDocument1 pageDPT ReportSaqlain MalikNo ratings yet

- QAR-QD#419-15 Feed Cylinder GPDocument8 pagesQAR-QD#419-15 Feed Cylinder GPIrwanto ManafNo ratings yet

- 7.5.5 - 05 Material Return Slip - DoneDocument1 page7.5.5 - 05 Material Return Slip - DoneSONIYANo ratings yet

- Install Beacon ChecklistDocument1 pageInstall Beacon ChecklistZulfequar R. Ali Khan100% (1)

- Itr CoatingDocument4 pagesItr Coatingcsc EXPERTISENo ratings yet

- PDF Inspection Test Plan For Fabrication - CompressDocument4 pagesPDF Inspection Test Plan For Fabrication - Compressridwan maulanaNo ratings yet

- CO#01 - Wilcon Naic WarehouseDocument9 pagesCO#01 - Wilcon Naic WarehouseMinh HoangNo ratings yet

- Iw-02 Lime Stucco Waterproof Finish Rev 02 Final PDFDocument115 pagesIw-02 Lime Stucco Waterproof Finish Rev 02 Final PDFlinga2014No ratings yet

- Tins Gen Chklist M 012 r00 Hvac Test ReportDocument2 pagesTins Gen Chklist M 012 r00 Hvac Test ReportachusanachuNo ratings yet

- Inspection report for 15 pcs CAP 28Document1 pageInspection report for 15 pcs CAP 28Jovianto PrisilaNo ratings yet

- Delivery Receipt TemplateDocument1 pageDelivery Receipt Templatejaguirre_03No ratings yet

- Inspection Report: CPP-RM-PO-0180Document4 pagesInspection Report: CPP-RM-PO-0180ANIL PLAMOOTTIL0% (1)

- Form Welding Summary and Material Traceability Record - Piping TuhupDocument6 pagesForm Welding Summary and Material Traceability Record - Piping TuhupYuwantoniAlNo ratings yet

- IVR-HAL-ONGC-L&T-CBE-003-Dt 25-11 - 019Document6 pagesIVR-HAL-ONGC-L&T-CBE-003-Dt 25-11 - 019Harish GundaNo ratings yet

- Maintenance Process Traceability CardDocument1 pageMaintenance Process Traceability Cardmohamed hamedNo ratings yet

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- YLF-PM-077 Material Receiving ReportDocument1 pageYLF-PM-077 Material Receiving ReportMark Joey DavidNo ratings yet

- F-008 Dye Penetrant Test ReportDocument1 pageF-008 Dye Penetrant Test ReportEshwarNo ratings yet

- Remulla Warehouse GDSDocument14 pagesRemulla Warehouse GDSMinh HoangNo ratings yet

- QAR-QD#419-14 Grapple Cylinder GPDocument6 pagesQAR-QD#419-14 Grapple Cylinder GPIrwanto ManafNo ratings yet

- Sample CHB Laying MethodologyDocument10 pagesSample CHB Laying Methodologykrcandinato23No ratings yet

- Ecn Record Internal & External Tracking SheetDocument1 pageEcn Record Internal & External Tracking SheetParveen KumarNo ratings yet

- Initial Inspection Report-CONTROLEDDocument1 pageInitial Inspection Report-CONTROLEDAmal RajNo ratings yet

- FMEA Procedure K-PosDocument111 pagesFMEA Procedure K-PosFábio GonçalvesNo ratings yet

- YLF-PM-060 Inspection Request - Curtain Wall, Window Shutter InstallationDocument4 pagesYLF-PM-060 Inspection Request - Curtain Wall, Window Shutter InstallationMark Joey DavidNo ratings yet

- GS QCF 320Document1 pageGS QCF 320SivaramkumarNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Liquid Penetrant Inspection Report: Industrial Proforma FormDocument1 pageLiquid Penetrant Inspection Report: Industrial Proforma FormJohn DolanNo ratings yet

- Surveillance ReportDocument1 pageSurveillance ReportYuzuan OthmanNo ratings yet

- Field Inspection Report: Pile FabricationDocument2 pagesField Inspection Report: Pile FabricationZEC LIMITEDNo ratings yet

- RPLC Signal ListDocument12 pagesRPLC Signal ListproteccionesNo ratings yet

- Hydrotest ReportDocument1 pageHydrotest Reportshamon shajahanNo ratings yet

- Master - BOMDocument1 pageMaster - BOMdarkamhimuraNo ratings yet

- CLEARANCE RUDDER (S) - DikonversiDocument8 pagesCLEARANCE RUDDER (S) - DikonversiNoveta FernaldinatanNo ratings yet

- Iso 11126-10Document1 pageIso 11126-10Alfian Imaduddin50% (2)

- Latestcswip3 160825063830Document437 pagesLatestcswip3 160825063830Lely AsriNo ratings yet

- Applying Thin Film Coatings to ConcreteDocument10 pagesApplying Thin Film Coatings to ConcreteAlfian ImaduddinNo ratings yet

- Bar Chart Time Schedule SPAM Kampar Project Rev.0.0Document1 pageBar Chart Time Schedule SPAM Kampar Project Rev.0.0Alfian ImaduddinNo ratings yet

- List Acceptance Criteria For Mechanical Test (03032017)Document7 pagesList Acceptance Criteria For Mechanical Test (03032017)Alfian Imaduddin100% (1)

- KHI Pipe Marking ProcedureDocument12 pagesKHI Pipe Marking ProcedureAlfian ImaduddinNo ratings yet

- Handling Procedure PDFDocument13 pagesHandling Procedure PDFAlfian ImaduddinNo ratings yet

- Report PQT Elnusa PDFDocument40 pagesReport PQT Elnusa PDFAlfian ImaduddinNo ratings yet

- Matriks Spesifikasi Rev.1 (Issued Februari 2017)Document8 pagesMatriks Spesifikasi Rev.1 (Issued Februari 2017)Alfian ImaduddinNo ratings yet

- Astm A53-A53m 2018Document23 pagesAstm A53-A53m 2018Lewis M. Nixon100% (4)

- Applying Thin Film Coatings to ConcreteDocument10 pagesApplying Thin Film Coatings to ConcreteAlfian ImaduddinNo ratings yet

- ASTM D2240 Standard Test Method For Rubber Property Durometer Hardness PDFDocument15 pagesASTM D2240 Standard Test Method For Rubber Property Durometer Hardness PDFAlfian Imaduddin0% (1)

- 1043-BD-MA-TRD-0003 - TRD For Steel Pipe Pile Supply - Rev. ADocument20 pages1043-BD-MA-TRD-0003 - TRD For Steel Pipe Pile Supply - Rev. AAlfian ImaduddinNo ratings yet

- Handling Procedure PDFDocument13 pagesHandling Procedure PDFAlfian ImaduddinNo ratings yet

- 1043-BD-MA-TRD-0003 - TRD For Steel Pipe Pile Supply - Rev. ADocument20 pages1043-BD-MA-TRD-0003 - TRD For Steel Pipe Pile Supply - Rev. AAlfian ImaduddinNo ratings yet

- Progress 6 Desember 2019 Rev.1Document1 pageProgress 6 Desember 2019 Rev.1Alfian ImaduddinNo ratings yet

- 9754-MAR-DWG-0206 - A Pile MakeupDocument5 pages9754-MAR-DWG-0206 - A Pile MakeupAlfian ImaduddinNo ratings yet

- Khi ProcedureDocument12 pagesKhi ProcedureAlfian ImaduddinNo ratings yet

- 1043-BD-MA-TRD-0003 - TRD For Steel Pipe Pile Supply - Rev. ADocument20 pages1043-BD-MA-TRD-0003 - TRD For Steel Pipe Pile Supply - Rev. AAlfian ImaduddinNo ratings yet

- Final Inspection Report Swarna - BrantasDocument50 pagesFinal Inspection Report Swarna - BrantasAlfian ImaduddinNo ratings yet

- Astm A6 PDFDocument59 pagesAstm A6 PDFAlexi SanjinésNo ratings yet

- Overview of Pipeline Coatings) PDFDocument7 pagesOverview of Pipeline Coatings) PDFTamer Hesham AhmedNo ratings yet

- Ansi Awwa c203Document40 pagesAnsi Awwa c203Meredith Hebert100% (1)

- List Pipa Surat JalanDocument1 pageList Pipa Surat JalanAlfian ImaduddinNo ratings yet

- Astm A6 PDFDocument59 pagesAstm A6 PDFAlexi SanjinésNo ratings yet

- Determining The Inclusion Content of Steel: Standard Test Methods ForDocument19 pagesDetermining The Inclusion Content of Steel: Standard Test Methods ForAnonymous NRlowQUcn100% (3)

- Plain Bars KWTDocument1 pagePlain Bars KWTAlfian ImaduddinNo ratings yet

- RFQ Pt. Khi Pipe IndustriesDocument6 pagesRFQ Pt. Khi Pipe IndustriesAlfian ImaduddinNo ratings yet

- Shop Drawing Pt. CPM - Khi (Spam Umbulan) Rev.2Document1 pageShop Drawing Pt. CPM - Khi (Spam Umbulan) Rev.2Alfian ImaduddinNo ratings yet

- M 200Document3 pagesM 200Rafael Capunpon VallejosNo ratings yet

- Opening SpeechDocument1 pageOpening SpeechTaniușa SavaNo ratings yet

- CS Risk and Crisis Management FinalDocument62 pagesCS Risk and Crisis Management FinaldangermanNo ratings yet

- The Electrooculogram (EOG)Document34 pagesThe Electrooculogram (EOG)Prasidha PrabhuNo ratings yet

- HN E-Catalog CableDocument36 pagesHN E-Catalog CableMin Min AungNo ratings yet

- The Federal Environmental Protection Authority: May 2004 Addis Ababa EthiopiaDocument44 pagesThe Federal Environmental Protection Authority: May 2004 Addis Ababa Ethiopiayared0% (1)

- Group 3Document11 pagesGroup 3Sharp MIER TVNo ratings yet

- Technical Data Sheet PDFDocument2 pagesTechnical Data Sheet PDFLuis VilelaNo ratings yet

- 0972 June 2021 QP 41 Cie Igcse Physics - Pdfquestion7Document2 pages0972 June 2021 QP 41 Cie Igcse Physics - Pdfquestion7Kareem YouakimNo ratings yet

- GCS Guilford County Schools 2020 Staff Manual Omits Obesity From CDC Covid WarningsDocument26 pagesGCS Guilford County Schools 2020 Staff Manual Omits Obesity From CDC Covid WarningscitizenwellsNo ratings yet

- Laporan FaalDocument25 pagesLaporan FaalAgnes NathaniaNo ratings yet

- Preserving Food Drying Fruits and VegetablesDocument12 pagesPreserving Food Drying Fruits and Vegetablespdxpharris100% (1)

- Wazaif Totaky Home Remedies Receiver Software Powervu Key-1Document18 pagesWazaif Totaky Home Remedies Receiver Software Powervu Key-1Habib MohammedNo ratings yet

- Boiler Feedwater ControlDocument14 pagesBoiler Feedwater ControlJonas PeraterNo ratings yet

- ZinkPower Batam - Company BrochureDocument6 pagesZinkPower Batam - Company BrochureansarALLAAHNo ratings yet

- Dissertation - December 2022Document71 pagesDissertation - December 2022Musasa TinasheNo ratings yet

- Animals Pets Board GameDocument1 pageAnimals Pets Board GameOlga ZasNo ratings yet

- Maximize muscle gains with reverse pyramid trainingDocument8 pagesMaximize muscle gains with reverse pyramid trainingMusadiq Ahmed100% (1)

- 1-Well Completion I PDFDocument20 pages1-Well Completion I PDFHomam MohammadNo ratings yet

- India TodayDocument76 pagesIndia TodaySanket RaveendraNo ratings yet

- Help to Buy ISA GuideDocument4 pagesHelp to Buy ISA GuidefsdesdsNo ratings yet

- A Study On Satisfaction Level of Employees With Special Reference Textile IndustryDocument12 pagesA Study On Satisfaction Level of Employees With Special Reference Textile Industrysai kiran bade100% (1)

- Kshitija's ResumeDocument1 pageKshitija's ResumeNavinNo ratings yet

- Ecl7000 enDocument2 pagesEcl7000 ensuchaya tupyangNo ratings yet

- 2requirements Permit PDFDocument1 page2requirements Permit PDFHazel CorralNo ratings yet

- Hyperfunctional Voice DisordersDocument11 pagesHyperfunctional Voice DisordersJam PNo ratings yet

- Duconmix CRP 400Document2 pagesDuconmix CRP 400FounTech612No ratings yet

- Income Tax BasicsDocument48 pagesIncome Tax BasicsAzad Singh BajariaNo ratings yet

- Chapter 5 Integumentary Study GuideDocument3 pagesChapter 5 Integumentary Study GuideSuperjunior8No ratings yet

- CHEMDocument20 pagesCHEMValli RamalingamNo ratings yet