Professional Documents

Culture Documents

pr10 Elmes

Uploaded by

John StateOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

pr10 Elmes

Uploaded by

John StateCopyright:

Available Formats

Chapter 17

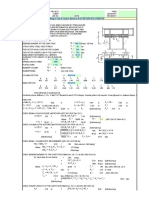

17-1 Given: F-1 Polyamide, b = 6 in, d = 2 in with n = 1750 rev/min, H nom = 2 hp, C = 9(12) =

108 in, velocity ratio = 0.5, K s = 1.25, n d = 1

V= d n / 12 = (2)(1750) / 12 = 916.3 ft/min

D = d / vel ratio = 2 / 0.5 = 4 in

D d 4 2

Eq. (17-1): d 2sin 1 2sin 1

3.123 rad

2C 2(108)

Table 17-2: t = 0.05 in, d min = 1.0 in, F a = 35 lbf/in, = 0.035 lbf/in3, f = 0.5

w = 12 bt = 12(0.035)6(0.05) = 0.126 lbf/ft

2 2

w V 0.126 916.3

(a) Eq. (e), p. 885: Fc 0.913 lbf Ans.

g 60 32.17 60

63 025H nom K s nd 63 025(2)(1.25)(1)

T 90.0 lbf · in

n 1750

2T 2(90.0)

F F1 a F2 90.0 lbf

d 2

Table 17-4: C p = 0.70

Eq. (17-12): (F 1 ) a = bF a C p C v = 6(35)(0.70)(1) = 147 lbf Ans.

F 2 = (F 1 ) a [(F 1 ) a F 2 ] = 147 90 = 57 lbf Ans.

Do not use Eq. (17-9) because we do not yet know f

F1 F2 147 57

Eq. (i), p. 886: Fi a

Fc 0.913 101.1 lbf Ans.

2 2

Using Eq. (17-7) solved for f ¢ (see step 8, p.888),

1 ( F1) a Fc 1 147 0.913

f ln ln 0.307

d F2 Fc 3.123 57 0.913

The friction is thus underdeveloped.

(b) The transmitted horsepower is, with F = (F 1 ) a F 2 = 90 lbf,

Chapter 17, Page 1/39

( F )V 90(916.3)

Eq. (j), p. 887: H 2.5 hp Ans.

33 000 33 000

H 2.5

nf s 1

H nom K s 2(1.25)

1 D d 1 4 2

Eq. (17-1): D 2sin 2sin 3.160 rad

2C 2(108)

Eq. (17-2): L = [4C2 (D d)2]1/2 + (D D + d d )/2

= [4(108)2 (4 2)2]1/2 + [4(3.160) + 2(3.123)]/2 = 225.4 in Ans.

3C 2 w 3(108 / 12)2 (0.126)

(c) Eq. (17-13): dip 0.151 in Ans.

2Fi 2(101.1)

Comment: The solution of the problem is finished; however, a note concerning the design

is presented here.

The friction is under-developed. Narrowing the belt width to 5 in (if size is available) will

increase f . The limit of narrowing is b min = 4.680 in, whence

w 0.0983 lbf/ft ( F1) a 114.7 lbf

Fc 0.713 lbf F2 24.7 lbf

T 90 lbf · in (same) f f 0.50

F ( F1) a F2 90 lbf dip 0.173 in

Fi 68.9 lbf

Longer life can be obtained with a 6-inch wide belt by reducing F i to attain f 0.50.

Prob. 17-8 develops an equation we can use here

( F Fc ) exp( f ) Fc

F1

exp( f ) 1

F2 F1 F

F1 F2

Fi Fc

2

1 F1 Fc

f ln

d F2 Fc

3C 2 w

dip

2Fi

which in this case, d = 3.123 rad, exp(f ) = exp[0.5(3.123)] = 4.766, w = 0.126 lbf/ft,

F = 90.0 lbf, F c = 0.913 lbf, and gives

Chapter 17, Page 2/39

0.913 90 4.766 0.913

F1 114.8 lbf

4.766 1

F 2 = 114.8 90 = 24.8 lbf

F i = (114.8 + 24.8)/ 2 0.913 = 68.9 lbf

1 114.8 0.913

f ln 0.50

3.123 24.8 0.913

2

3 108 / 12 0.126

dip 0.222 in

2(68.9)

So, reducing F i from 101.1 lbf to 68.9 lbf will bring the undeveloped friction up to 0.50,

with a corresponding dip of 0.222 in. Having reduced F 1 and F 2 , the endurance of the

belt is improved. Power, service factor and design factor have remained intact.

______________________________________________________________________________

17-2 Double the dimensions of Prob. 17-1.

In Prob. 17-1, F-1 Polyamide was used with a thickness of 0.05 in. With what is available

in Table 17-2 we will select the Polyamide A-2 belt with a thickness of 0.11 in. Also, let

b = 12 in, d = 4 in with n = 1750 rev/min, H nom = 2 hp, C = 18(12) = 216 in, velocity

ratio = 0.5, K s = 1.25, n d = 1.

V= d n / 12 = (4)(1750) / 12 = 1833 ft/min

D = d / vel ratio = 4 / 0.5 = 8 in

D d 8 4

Eq. (17-1): d 2sin 1 2sin 1

3.123 rad

2C 2(216)

Table 17-2: t = 0.11 in, d min = 2.4 in, F a = 60 lbf/in, = 0.037 lbf/in3, f = 0.8

w = 12 bt = 12(0.037)12(0.11) = 0.586 lbf/ft

2 2

w V 0.586 1833

(a) Eq. (e), p. 885: Fc 17.0 lbf Ans.

g 60 32.17 60

63 025H nom K s nd 63 025(2)(1.25)(1)

T 90.0 lbf · in

n 1750

2T 2(90.0)

F F1 a F2 45.0 lbf

d 4

Table 17-4: C p = 0.73

Chapter 17, Page 3/39

Design variable: Belt width.

Use a method of trials. Initially, choose b = 6 in

dn (48)(380)

V 4775 ft/min

12 12

w 12 bt 12(0.042)(6)(0.13) 0.393 lbf/ft

wV 2 0.393(4775 / 60) 2

Fc 77.4 lbf

g 32.17

63 025H nom K s nd 63 025(60)(1.1)(1)

T 10 946 lbf · in

n 380

2T 2(10 946)

F 456.1 lbf

d 48

F1 ( F1) a bFaC pCv 6(100)(1)(1) 600 lbf

F2 F1 F 600 456.1 143.9 lbf

Transmitted power H

F (V ) 456.1(4775)

H 66 hp

33 000 33 000

F1 F2 600 143.9

Fi Fc 77.4 294.6 lbf

2 2

1 F Fc 1 600 77.4

f ln 1 ln 0.656

d F2 Fc 143.9 77.4

Eq. (17-2): L = [4(192)2 (48 48)2]1/2 + [48( ) + 48( )] / 2 = 534.8 in

Friction is not fully developed, so b min is just a little smaller than 6 in (5.7 in). Not having

a figure of merit, we choose the most narrow belt available (6 in). We can improve the

design by reducing the initial tension, which reduces F 1 and F 2 , thereby increasing belt

life (see the result of Prob. 17-8). This will bring f to 0.80

F Fc exp f Fc

F1

exp f 1

exp f exp(0.80 ) 12.345

Therefore

(456.177.4)(12.345) 77.4

F1 573.7 lbf

12.345 1

F2 F1 F 573.7 456.1 117.6 lbf

F1 F2 573.7 117.6

Fi Fc 77.4 268.3 lbf

2 2

These are small reductions since f is close to f , but improvements nevertheless.

Chapter 17, Page 5/39

Hd Ha

4.36

1.25H nom

4.36

H nom 3.49 hp Ans.

1.25

______________________________________________________________________________

17-19 Given: H nom = 60 hp, n = 400 rev/min, K s = 1.4, d = D = 26 in on 12 ft centers.

Design task: specify V-belt and number of strands (belts). Tentative decision: Use D360

belts.

Table 17-11: L p = 360 + 3.3 = 363.3 in

Eq. (17-16b):

2

C 0.25 363.3 (26 26) 363.3 (26 26) 2(26 26) 2

2 2

140.8 in (nearly 144 in)

d , D , exp[0.5123 ] 5.0,

dn (26)(400)

V 2722.7 ft/min

12 12

Table 17-13: For = 180°, K 1 = 1

Table 17-14: For D360, K 2 = 1.10

Table 17-12: H tab = 16.94 hp by interpolation

Thus, H a = K 1 K 2 H tab = 1(1.1)(16.94) = 18.63 hp / belt

Eq. (17-19): H d = H nom K s n d = 60(1.4)(1) = 84 hp

Number of belts, N b

Hd 84

Nb 4.51

Ha 18.63

Round up to five belts. It is left to the reader to repeat the above for belts such as C360

and E360.

Chapter 17, Page 21/39

63 025H a 63 025(18.63)

Fa 225.8 lbf/belt

n(d / 2) 400(26 / 2)

( Fa )d 225.8(26)

Ta 2935 lbf · in/belt

2 2

Eq. (17-21):

2 2

V 2722.7

Fc 3.498 3.498 25.9 lbf/belt

1000 1000

At fully developed friction, Eq. (17-9) gives

T exp( f ) 1 2935 5 1

Fi 169.3 lbf/belt

d exp( f ) 1 26 5 1

2 exp( f ) 2(5)

Eq. (17-10): F1 Fc Fi 25.9 169.3 308.1 lbf/belt

exp( f ) 1 5 1

F2 F1 Fa 308.1 225.8 82.3 lbf/belt

H a Nb 18.63 5

nf s 1.109 Ans.

Hd 84

Life From Table 17-16,

Kb 5 680

T1 T2 F1 308.1 526.6 lbf

d 26

Eq. (17-27):

b b 1

K K 9

NP 5.28 10 passes

T1 T2

9

Thus, N P > 10 passes Ans.

N P Lp 109 (363.3)

Eq. (17-28): t

720V 720(2722.7)

Thus, t > 185 320 h Ans.

______________________________________________________________________________

17-20 Preliminaries: D 60 in, 14-in wide rim, H nom = 50 hp, n = 875 rev/min, K s = 1.2,

n d = 1.1, m G = 875/170 = 5.147, d 60 / 5.147 11.65 in

(a) From Table 17-9, an 11-in sheave exceeds C-section minimum diameter and

precludes D- and E-section V-belts.

Decision: Use d = 11 in, C270 belts

Chapter 17, Page 22/39

Decision #4: Choose C = 30.0 in.

______________________________________________________________________________

17-28 Follow the decision set outlined in Prob. 17-27 solution. We will form two tables, the

first for a 15 000 h life goal, and a second for a 50 000 h life goal. The comparison is

useful.

Function: H nom = 50 hp at n = 1800 rev/min, n pump = 900 rev/min, m G = 1800/900 = 2,

K s = 1.2, life = 15 000 h, then repeat with life = 50 000 h

Design factor: n d = 1.1

Sprockets: N 1 = 19 teeth, N 2 = 38 teeth

Table 17-22 (post extreme):

1.5 1.5

N1 19

K1 1.18

17 17

Table 17-23: K 2 = 1, 1.7, 2.5, 3.3, 3.9, 4.6, 6.0

Decision variables for 15 000 h life goal:

K s nd H nom 1.2(1.1)(50) 55.9

H tab (1)

K1K 2 1.18K 2 K2

K1K 2 H tab 1.18K 2 H tab

nf s 0.0197 K 2 H tab

K s H nom 1.2(50)

Form a table for a 15 000 h life goal using these equations.

K2 H' tab Chain # H tab nf s Lub

1 55.90 120 21.6 0.423 C'

1.7 32.90 120 21.6 0.923 C'

2.5 22.40 120 21.6 1.064 C'

3.3 16.90 120 21.6 1.404 C'

3.9 14.30 80 15.6 1.106 C'

4.6 12.20 60 12.4 1.126 C'

6 9.32 60 12.4 1.416 C'

There are 4 possibilities where n f s ≥ 1.1

Decision variables for 50 000 h life goal

From Eq. (17-40), the power-life tradeoff is:

Chapter 17, Page 32/39

( H tab ) 2.515 000 ( H tab ) 2.5 50 000

1/ 2.5

15 000

H tab ( H tab ) 2.5 0.618 H tab

50 000

Substituting from (1),

55.9 34.5

H tab 0.618

K2 K2

The H notation is only necessary because we constructed the first table, which we

normally would not do.

K1K 2 H tab K1K 2 (0.618H tab )

nf s 0.618[(0.0197) K 2 H tab ]

K s H nom K s H nom

0.0122 K 2 H tab

Form a table for a 50 000 h life goal.

K2 H'' tab Chain # H tab nf s Lub

1 34.50 120 21.6 0.264 C'

1.7 20.30 120 21.6 0.448 C'

2.5 13.80 120 21.6 0.656 C'

3.3 10.50 120 21.6 0.870 C'

3.9 8.85 120 21.6 1.028 C'

4.6 7.60 120 21.6 1.210 C'

6 5.80 80 15.6 1.140 C'

There are two possibilities in the second table with n f s ≥ 1.1. (The tables allow for the

identification of a longer life of the outcomes.) We need a figure of merit to help with

the choice; costs of sprockets and chains are thus needed, but is more information than

we have.

Decision #1: #80 Chain (smaller installation) Ans.

n f s = 0.0122K 2 H tab = 0.0122(8.0)(15.6) = 1.14 O.K.

Decision #2: 8-Strand, No. 80 Ans.

Decision #3: Type C Lubrication Ans.

Decision #4: p = 1.0 in, C is in midrange of 40 pitches

Chapter 17, Page 33/39

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- 8-Bolted Stiffened End Plate DesignDocument6 pages8-Bolted Stiffened End Plate DesignlucianduNo ratings yet

- Section 15Document58 pagesSection 15Ya Hoo100% (1)

- Aluminum Beam Design Capacity AnalysisDocument5 pagesAluminum Beam Design Capacity AnalysisBoopathi YoganathanNo ratings yet

- The Design Is Adequate.: 6 OD × 0.375 WALLDocument3 pagesThe Design Is Adequate.: 6 OD × 0.375 WALLGreatNo ratings yet

- Seismic Design For Ordinary Concentrically Braced Frames Based On IBC 06 & AISC 341-05Document5 pagesSeismic Design For Ordinary Concentrically Braced Frames Based On IBC 06 & AISC 341-05xuankhoi doanvanNo ratings yet

- How To Answer A Problematic Question??? Key Points: Topic + I R A C 1) Topic / Scope of DiscussionDocument5 pagesHow To Answer A Problematic Question??? Key Points: Topic + I R A C 1) Topic / Scope of Discussionsyahiir syauqii100% (2)

- Sacred SpaceDocument440 pagesSacred SpaceAbdiel Cervantes HernandezNo ratings yet

- Bolted Moment ConnectionDocument9 pagesBolted Moment ConnectionAmey Gudigar100% (1)

- Comparative Essay: The Sense of Closure in The Endings of A Streetcar Named Desire and Things Fall Apart - Google DocsDocument3 pagesComparative Essay: The Sense of Closure in The Endings of A Streetcar Named Desire and Things Fall Apart - Google DocsLucileNo ratings yet

- Legal Counselling defined in broad and narrow sensesDocument5 pagesLegal Counselling defined in broad and narrow sensesRegie Rey AgustinNo ratings yet

- Employee Evaluation Form SummaryDocument3 pagesEmployee Evaluation Form SummaryRahmatur RizalNo ratings yet

- Aluminum DesignDocument8 pagesAluminum Designxhq08100% (1)

- Fixed Bolted JointDocument16 pagesFixed Bolted JointPartth VachhaniNo ratings yet

- PROGRAMMING 11 - Q1 - W2 - Mod2 PDFDocument13 pagesPROGRAMMING 11 - Q1 - W2 - Mod2 PDFDianne Brucal - MatibagNo ratings yet

- The Design Is Adequate.: F y U UDocument6 pagesThe Design Is Adequate.: F y U UIndustry Standard Structural DesignNo ratings yet

- SHCT 167 Reeves - English Evangelicals and Tudor Obedience, C. 1527-1570 2013 PDFDocument222 pagesSHCT 167 Reeves - English Evangelicals and Tudor Obedience, C. 1527-1570 2013 PDFL'uomo della Rinascitá100% (1)

- BELT DRIVE DESIGN CALCULATIONSDocument33 pagesBELT DRIVE DESIGN CALCULATIONSJUAN SANTIAGO VILLEGAS CENTENO100% (1)

- The Design Is Adequate.: Ksi, (345 Mpa) Kips, (120.1 KN) FT, (10.06 M) FT, (2.74 M)Document3 pagesThe Design Is Adequate.: Ksi, (345 Mpa) Kips, (120.1 KN) FT, (10.06 M) FT, (2.74 M)Ridho ZiskaNo ratings yet

- Shiglay SM ch17Document33 pagesShiglay SM ch17Muhammad WaqasNo ratings yet

- ECH 158B hw1Document5 pagesECH 158B hw1Trường Tùng LýNo ratings yet

- Flexible Power Belts Design ProblemsDocument56 pagesFlexible Power Belts Design ProblemsSecret SecretNo ratings yet

- Differential equations model temperature to maximize component BDocument4 pagesDifferential equations model temperature to maximize component BPaola KasandraNo ratings yet

- Timber Textbook CHP 7Document48 pagesTimber Textbook CHP 7Kevin LowNo ratings yet

- Screw jack column and component designDocument5 pagesScrew jack column and component designLhance BabacNo ratings yet

- SteelDesign: Plate GirderDocument32 pagesSteelDesign: Plate GirderTalha Noor SiddiquiNo ratings yet

- Kelompok 5 Heat Exchanger ColdDocument3 pagesKelompok 5 Heat Exchanger ColdJangan ada yangNo ratings yet

- DB Per Octave Slopes PDFDocument4 pagesDB Per Octave Slopes PDFVikas JawariaNo ratings yet

- Ejercicios Diseño Mecanico ShigleyDocument6 pagesEjercicios Diseño Mecanico ShigleyBrajack RhNo ratings yet

- Chapter 10 Solutions PDFDocument42 pagesChapter 10 Solutions PDFyavercanNo ratings yet

- EL5123 F11 Midtermsolution NewDocument11 pagesEL5123 F11 Midtermsolution Newsf121596No ratings yet

- Wa0010 PDFDocument8 pagesWa0010 PDFrahmaNo ratings yet

- Wa0010 PDFDocument8 pagesWa0010 PDFAnita PuspitasariNo ratings yet

- 3 Coulombs LawDocument14 pages3 Coulombs LawFe Simon CagumbayNo ratings yet

- Calculation of Restrained Pipe Length at TR-02 (Ch-14+426) - 1.2mDocument2 pagesCalculation of Restrained Pipe Length at TR-02 (Ch-14+426) - 1.2mSaifur RahmanNo ratings yet

- Coulomb's Law & Electric FieldDocument24 pagesCoulomb's Law & Electric FieldJohn RivasNo ratings yet

- Timber TableDocument29 pagesTimber Tableye548599No ratings yet

- Anchor Bolt Design For Shear and TensionDocument2 pagesAnchor Bolt Design For Shear and Tensionk.m.ariful islamNo ratings yet

- Ebook Digital Signal Processing Using Matlab 3Rd Edition Schilling Solutions Manual Full Chapter PDFDocument67 pagesEbook Digital Signal Processing Using Matlab 3Rd Edition Schilling Solutions Manual Full Chapter PDFconnielopezpmdrzqcjbn100% (8)

- MomentConnection 1aDocument1 pageMomentConnection 1aKrishnaNo ratings yet

- CBE 442 Practice Problems SolnDocument15 pagesCBE 442 Practice Problems SolnElliotNo ratings yet

- Solutions To Assignment 1Document5 pagesSolutions To Assignment 1billy bobNo ratings yet

- Exam1 SolutionsDocument6 pagesExam1 SolutionsAriel GamboaNo ratings yet

- Bsep SMFDocument8 pagesBsep SMFcurlyjockeyNo ratings yet

- Last Name, First CHE426:: F C V C V C F + F F CDocument6 pagesLast Name, First CHE426:: F C V C V C F + F F Clợi trầnNo ratings yet

- Unit # 04 (Part-Ii) : Exercise - IDocument21 pagesUnit # 04 (Part-Ii) : Exercise - IDeborshi ChakrabartiNo ratings yet

- Dphe KecapDocument19 pagesDphe KecapMatthew BramastaNo ratings yet

- Welding Design ProblemsDocument41 pagesWelding Design ProblemsMark EstepaNo ratings yet

- Heat Transfer Equipment DesignDocument7 pagesHeat Transfer Equipment DesignBhawani Pratap Singh PanwarNo ratings yet

- Aits 1819 FT II Jeem SolDocument15 pagesAits 1819 FT II Jeem SolScribd nowNo ratings yet

- Pre Heater Design CalculationsDocument4 pagesPre Heater Design CalculationsFahad KhokharNo ratings yet

- T-104 To NA-101 - HannaDocument6 pagesT-104 To NA-101 - HannaEUNICE ANGELA LASCONIANo ratings yet

- Kelompok 1 Anggota Proyek Pertukaran Panas Benzena-ToluenaDocument5 pagesKelompok 1 Anggota Proyek Pertukaran Panas Benzena-ToluenaDewi AnggreniNo ratings yet

- Perpindahan Panas: Tugas 3 (Double PipeDocument4 pagesPerpindahan Panas: Tugas 3 (Double Pipeiim252575% (4)

- Aluminum I WF CapacityDocument14 pagesAluminum I WF CapacityjohnlaihungNo ratings yet

- 9 - Wellbore Flow PerformanceDocument23 pages9 - Wellbore Flow PerformanceGadhoumiWalidNo ratings yet

- Ae2235 Exercises Lecture 6Document6 pagesAe2235 Exercises Lecture 6Sarieta SarrahNo ratings yet

- DAPP (B) - CaseDocument5 pagesDAPP (B) - Case시우민SeohyunNo ratings yet

- Footing Diameter CalculationDocument3 pagesFooting Diameter CalculationAakar ConsultantsNo ratings yet

- 01 ProblemsDocument10 pages01 ProblemsKhin OoNo ratings yet

- ENGG 2310 Assignment 2 SolutionsDocument6 pagesENGG 2310 Assignment 2 SolutionscraticNo ratings yet

- Ayudantía 3 03-04-2023 Solución + Pauta P1Document16 pagesAyudantía 3 03-04-2023 Solución + Pauta P1Francisco Javier EspañaNo ratings yet

- Bearing Capacity Calculation: Description of StrataDocument8 pagesBearing Capacity Calculation: Description of StrataDadi YashwantNo ratings yet

- Charged Rotating Black Hole MetricDocument21 pagesCharged Rotating Black Hole MetricFrancisco Tello OrtizNo ratings yet

- Aerodynamics Review Set BDocument8 pagesAerodynamics Review Set BReem RodriguezNo ratings yet

- EC2272 Formulario 3Document1 pageEC2272 Formulario 3AngelNo ratings yet

- Tunnel Face Stability PDFDocument208 pagesTunnel Face Stability PDFnumspyNo ratings yet

- The Brothers KaramazovDocument8 pagesThe Brothers KaramazovAnonymous sao1siUbNo ratings yet

- ACCFA V CUGCO Case DigestDocument2 pagesACCFA V CUGCO Case DigestLoren yNo ratings yet

- 21st Century Literature Grade 11 21st Century Literature Grade 11 21st Century Literature Grade 11 CompressDocument75 pages21st Century Literature Grade 11 21st Century Literature Grade 11 21st Century Literature Grade 11 Compressdesly jane sianoNo ratings yet

- Verbal and Nonverbal Communication - Business Communication Skills For ManagersDocument7 pagesVerbal and Nonverbal Communication - Business Communication Skills For ManagersCINDY BALANONNo ratings yet

- Getting Started With The NIST Cybersecurity Framework:: A Quick Start GuideDocument3 pagesGetting Started With The NIST Cybersecurity Framework:: A Quick Start GuidejohnNo ratings yet

- En 14490 After CEN Enquiry (Soil Nailing)Document59 pagesEn 14490 After CEN Enquiry (Soil Nailing)Abraham FIgueroa ARevaloNo ratings yet

- Chapter 32Document22 pagesChapter 32Clifford BacsarzaNo ratings yet

- Robert FrostDocument8 pagesRobert FrostARIESGA, NICOLE FRANCINE M.No ratings yet

- F&P Level IndicatorsDocument23 pagesF&P Level IndicatorsBen100% (1)

- MethotrexateDocument9 pagesMethotrexateHuỳnh Ngọc SángNo ratings yet

- AFM Shark-EN 60 - 2017-05-21 - FinalDocument104 pagesAFM Shark-EN 60 - 2017-05-21 - FinalLance Montgomery BoyleNo ratings yet

- UNIT 6 - LESSON 1 - PART 3 - Pronunciation and SpeakingDocument4 pagesUNIT 6 - LESSON 1 - PART 3 - Pronunciation and SpeakingLê Thị HạnhNo ratings yet

- Impala Job Application 2Document3 pagesImpala Job Application 2EXXARO MATLANo ratings yet

- Multiple-Choice-Questions My Mother at Sixty SixDocument2 pagesMultiple-Choice-Questions My Mother at Sixty SixDubai SheikhNo ratings yet

- Work Written: Student - I - Gabriela BocănețDocument14 pagesWork Written: Student - I - Gabriela BocănețEscu NykuNo ratings yet

- LAMPE Harald Ignatius HubertusDocument100 pagesLAMPE Harald Ignatius HubertusSumaya NoorNo ratings yet

- Gr.8 Ch.5 Chapter Review AnswerDocument10 pagesGr.8 Ch.5 Chapter Review Answerson GokuNo ratings yet

- Clsi Document c28 A2Document2 pagesClsi Document c28 A2Kristine Marie Pateño0% (1)

- Online: ExistDocument16 pagesOnline: Existjyjc_admNo ratings yet

- Short Analysis of Geoffrey Hill Septemper SongDocument2 pagesShort Analysis of Geoffrey Hill Septemper SongAnwar SahebNo ratings yet

- DevStat8e 16 04Document28 pagesDevStat8e 16 04SaadiShahwanNo ratings yet

- A. Two Subsequences: Codeforces Round #751 (Div. 2)Document4 pagesA. Two Subsequences: Codeforces Round #751 (Div. 2)Trần Nhật KhánhNo ratings yet