Professional Documents

Culture Documents

Cottoninc Fulldocument-1

Uploaded by

Chaudhary UsmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cottoninc Fulldocument-1

Uploaded by

Chaudhary UsmanCopyright:

Available Formats

Volume 2, Issue 3, Summer 2002

100% Cotton Moisture Management

Cotton Incorporated, Cary, North Carolina

ABSTRACT

Moisture management often refers to the transport of both moisture vapor

and liquid away from the body. Moisture vapor can pass through openings

between fibers or yarns. In the case of cotton or other hydrophilic

fibers, the fiber can serve as a buffer by absorbing moisture vapor and

adding to the comfort properties of a fabric. This study is an example

of ongoing research and development at Cotton Incorporated related to

moisture management. Results indicate that it is possible to create a

whole spectrum of performance properties on 100% cotton for different

activities in a wide range of environments.

KEYWORDS: cotton, moisture, moisture vapor transmission, MVT, recreational performance

apparel, RVT

Moisture management often refers to the evaporation. There are very few, if any,

transport of both moisture vapor and liquid 100% cotton garments that are advertised as

away from the body. Moisture vapor can recreational performance apparel for athletic

pass through openings between fibers or activities. Consequently, research and

yarns. In the case of cotton or other development is ongoing at Cotton

hydrophilic fibers, the fiber can serve as a Incorporated to develop such garments to

buffer by absorbing moisture vapor and allow cotton to participate in this market.

adding to the comfort properties of a fabric.

Liquid water (or perspiration) must be For cotton fabrics and, therefore, garments

wicked into a fabric structure, and then to offer the performance desired for athletic

evaporate from the outside of the fabric. endeavors, innovation and enhancement of

the cotton fabric must take place.

There is much hype in the market about fast-

drying fabrics. In general, all flat or non- Innovation is today’s catch phrase. The

raised surface fabrics when saturated will consumer wants something different, and the

dry at the same rate, independent of fiber industry must respond. Innovation is also

type. Fabrics used in athletic and known by many other names such as high-

recreational end uses should have the ability tech, intelligent textiles, nano-technology,

to transport moisture to the fabric surface for and functional finishes.

Article Designation: Scholarly JTATM

Volume 2, Issue 3, Summer 2002

because of a combination of properties. For

Cotton fiber has perceived limitations with most end uses, natural cotton provides

regards to what is called recreational excellent thermophysiological and sensorial

performance apparel (RPA). Basically, comfort. Thermophysiological comfort is

cotton is not perceived as “high-tech” even complex and relates to the thermodynamics,

though it is one of the most chemically heat and moisture transfer of the human

reactive and versatile fibers. Perceived body and clothing. Sensorial comfort is a

technical issues on cotton, as may be seen in function of the feel of a fabric or garment

some of the advertisements for synthetics, against the skin and may include various

can be summarized as follows: sensations or descriptors such as clammy,

prickly, stiff, dry, etc. Ergonomic comfort is

• Too heavy when wet a function of the fit of a garment and may be

• Sags when wet due to the extra weight influenced by factors such as a tendency to

• Takes too long to dry stick to the skin.

• Sticks to the skin, restricting

movement Figure 1 shows the energy balance of the

• After the activity ends, the wearer human body when exposed to the

often feels cold environment (sunshine or lack of sunshine).

As the body produces heat during exercise,

These issues with cotton, as an active wear, which would otherwise cause the core

candidates are perceived by the trade press, temperature to rise above 37oC, the body

by the synthetic competition, and sometimes tries to regulate the temperature via

by the wearer. In some respects, garments perspiration and evaporative cooling.

made from synthetic fibers have similar Clothing can serve as a buffer in the

disadvantages when wet, such as in sticking moisture transfer process. For evaporative

to the skin and restricting movement. All cooling to occur, the moisture must transport

these issues with 100% cotton relate to through the fabric. In some places, the fabric

absorbent capacity of the basic cotton touches the skin, and in other places, it does

fabrics; most are often knit goods. not. For any garment to be comfortable

during exercise where liquid sweat is

The most important factor in determining produced, it must wick. Wicking simply

how much water (or perspiration) can be means the capillary movement of moisture

absorbed by a fabric is the fabric thickness. within a fabric structure. Cotton fabrics wick

The drying time is dependent mainly on how naturally. A certain amount of liquid

much water is absorbed by a fabric and, moisture or sweat will build up in any fabric

therefore, by the thickness of a fabric. A that wicks. Thicker fabrics, including

saturated terry towel will take a long time to traditional cotton fabrics, will absorb more

dry, not because it is cotton, but because it is liquid, and this will be roughly proportional

a thick fabric. Very thin cotton gauze, on the to their thickness. In some parts of the

other hand, has been shown to dry faster garment where there are openings, moisture

than a high-tech polyester fabric when equal vapor and heat can by-pass the fabric by

amounts of water are applied to both fabrics. going out the sleeve, neck, or pants leg.

Consequently, the drying time and energy

required to evaporate water from a wet To maximize comfort in recreational apparel

garment depends on the amount of water applications, the fabric must allow vapor

absorbed and not on the fiber type. and liquid to pass to the surface of the fabric

for evaporation. Too much absorbency (as

Various factors are known to influence the with thicker fabrics) has a negative aspect in

comfort of wearing apparel. Cotton is one of

the most comfortable apparel fabrics

Article Designation: Scholarly 1 JTATM

Volume 2, Issue 3, Summer 2002

Skin Contact

Heat Production

Aspects of Wear Comfort

Heat Transport

Moisture Transport

37°C Moisture Transport

Thermophysiological

Moisture Buffering Comfort

Convection Sensorial

Comfort

Ergonomic

Comfort

Ventilation

Figure 1. Energy Balance of the Human Body

that the fabric becomes heavy, takes too Fluoropolymers can provide useful

long to dry, and in cooler weather after the modifications to natural (untreated) cotton

activity ends, the wearer often feels cold. for certain end uses. Some of these products

are durable to multiple home launderings.

Moisture management can be defined in this Some will greatly reduce the absorbent

discussion as: capacity, which will reduce the drying time

of a fabric. However, techniques to maintain

“The controlled movement of wicking must be used if the apparel is

water vapor and liquid water designed for activities where high levels of

(perspiration) from the surface perspiration are a factor.

of the skin to the atmosphere

through a fabric.” Fluoropolymers can offer a wide range of

properties, such as:

A wide variety of chemistries and

technologies can be used to modify the • Water resistance

moisture management properties of cotton • Abrasion resistance

fabrics. Some of the chemistries, such as • Softness

fluoropolymers, can be applied to cotton • High durability

without altering the basic comfort-related • Permanence through regeneration

properties, such as moisture vapor transport, • Compatibility with other chemicals such

air permeability, and moisture regain. These as polyurethanes

chemistries include:

Figure 2 shows LAD fluoropolymers, which

• Fluoropolymers offer durability. LAD refers to the property

• Silicones of regeneration through laundering and air

• Waxes drying. Most fluoropolymers require that

• Coating treated fabrics be ironed or dried at elevated

• Laminations temperatures after laundering to return the

• Innovative technologies

Article Designation: Scholarly JTATM

Volume 2, Issue 3, Summer 2002

Figure 2. LAD Fluoropolymers Effect1

1. Oriented FC residues = good repellency.

2. Disorientation = poor repellency.

3. Ironing.

4. LAD effect.

5. Reorientation = repellency reactivation.

full benefits of the treatment to the fabric. porosity. At rest, a body will give off a

New chemistries do not require ironing for quarter of a cup (2 ounces, about 60 ml) of

performance after laundering, because they water vapor per hour at ambient conditions.

can renew with air-drying. Moderate exertion (walking, etc.) will

increase the amount to one pint (16 ounces,

MOISTURE VAPOR TRANSMISSION about 450 ml) per hour. The ASTM

RATE moisture vapor test (open cup test) is one of

a number of test methods for moisture vapor

Moisture vapor transmission rate (MVT) is transmission rate. In this test, fabric is

the speed or rate at which moisture vapor placed tightly over cups of water where the

moves through a fabric. It is typically water, the air above the water, and the room

determined by measuring the amount of environment are at the same temperature and

moisture vapor in grams that pass through pressure. The humidity of the room must be

1m2 of fabric in 24 hours with a specific controlled. The rate of water vapor that

driving force (e.g. humidity). MVT is passes through the fabric is determined by

primarily a function of fabric thickness and

Article Designation: Scholarly 1 JTATM

Volume 2, Issue 3, Summer 2002

Figure 3. Moisture Vapor Test – Open Cup Method

Figure 4. GATS (Gravimetric Absorbency Test System)

weighing the cups. Figure 3 shows the open fabric - Nike DRI-FIT T-shirt - was

cup apparatus. compared to five different cotton-blended T-

shirt fabrics and five 100% cotton T-shirt

The GATS (gravimetric absorbency test fabrics. The blends included

system) test apparatus is shown in Figure 4. cotton/polyester, cotton/nylon, and

A fabric sample is placed on a porous plate. cotton/polypropylene.

Water (or other liquid) is fed to the sample,

and the sample is free to absorb without The results of testing on the GATS showed

pressure or restriction. The absorbency rate that the high-tech polyester was different

and absorbent capacity are measured. from the cotton and blended fabrics in two

Drying rates may be measured as well, but ways. The Nike DRI-FIT did wick quickly

this is not a standard part of the test method. and had a much lower absorbent capacity

In one series of tests run at Cotton than the cotton or blended fabrics. Because

Incorporated, a 100% polyester microfiber the synthetic fabric absorbed less water (due

Article Designation: Scholarly 1 JTATM

Volume 2, Issue 3, Summer 2002

to the thin construction and hydrophobic rate (water evaporated per unit time) for a

nature), the drying time was much less. Nike DRI-FIT fabric, the average values for

However, the drying rate was essentially the a series of five blends of cotton and

same for all fabrics. Cotton Incorporated is polyester, and the average values for a series

currently collecting data to demonstrate that of 100% cotton fabrics. There are significant

thin cotton fabrics can be constructed to differences in the fabric weights,

have greatly reduced drying time. For flat thicknesses, and absorbent capacities;

fabrics, drying time is a function of how however, there is not a difference in the

much water a fabric absorbs, which in turn drying rates, which were all 0.026 – 0.028

depends mainly on the thickness of the grams per minute.

fabric.

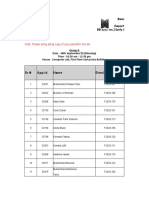

Table 1 shows the weight, thickness,

absorbent capacity, drying time, and drying

Table 1. Comparison of Typical T-shirt Fabrics for Active Wear

Test Nike DRI-FIT Blends 100% Cotton

(avg) (avg)

Fabric Weight 4.13 6.92 6.19

(oz/yd2)

Fabric Thickness 0.66 1.60 1.34

(mm)

Absorbent Capacity 2.77 6.09 4.71

(grams H2O on fabric)

Drying Time 99 236 180

(in minutes)

Drying Rate (g/min.) 0.028 0.026 0.026

MODIFYING COTTON FOR • A cool, pleasing hand

PERFORMANCE

Problems in the wet state must be minimized

Cotton naturally has excellent comfort by:

properties in the dry state. In order to match

the performance of the high-tech synthetics • Reducing the absorbent capacity

in terms of moisture management for • Maintaining the natural wicking

applications like recreational performance

fabrics, the absorbent capacity of cotton Reducing Absorbent Capacity and

must be reduced. This can be achieved by Maintaining Wicking

making thinner cotton fabrics and/or by

finishing techniques. Beneficial properties Cotton fabric’s absorbent capacity can be

must be maintained and include: reduced by making the fabric thinner by

using finer yarns and by making more open

• Comfort constructions. Absorbent capacity reduction

• Breathability can also be achieved by chemical

• Moisture vapor transport treatments. Resins, such as the common

• Softness wrinkle resist type chemistries, can reduce

Article Designation: Scholarly 1 JTATM

Volume 2, Issue 3, Summer 2002

the absorbent capacity of cotton on the order wick moisture away from the skin. This

of 15-20% or more. Resins reduce the method is obviously undesirable.

amount of water held inside the fiber.

Alternative methods to achieve recreational

Discontinuous water-repellent treatments performance apparel (RPA) on cotton can

can be applied on the side of the fabric that include:

will be worn next to the skin. These

applications create “wicking windows” that • Fiber treatments – intimate blends of

are areas of no treatment contained within or treated and untreated fibers in the

adjacent to areas of treatment. For example, same yarn.

leaving 50% of the surface area on the inside • Yarn treatments – mechanical blends

of the garment as natural absorbent cotton of treated and untreated yarns.

will allow the moisture to be wicked to the • Fabric treatments – printing.

outside of the garment. The untreated • Multi-layered fabrics – treated and

outside of the garment allows for wicking to untreated yarns.

the outside of the garment and provides • Crosslinking – resins.

evaporative cooling effects. Discontinuous, • Garment treatments – printing.

durable water-repellent applications can be

achieved by treating fibers, yarns, fabrics, or The general concept of moisture

garments. management for 100% cotton RPA is shown

in Figure 5. Liquid moisture will be wicked

For applications where moderate to heavy away from the skin via the untreated,

perspiration is likely to occur, the entire absorbent areas to the outside of the fabric

fabric could be water-repellent treated. where it can evaporate. The absorbent

However, if it is, it will not absorb the liquid capacity of the cotton is much reduced;

moisture. Without the garment absorbing or therefore, the drying time of the fabric is

wicking, evaporative cooling is greatly significantly reduced. This effect can be

reduced, and the garment is perceived as achieved by any of the alternative methods

very hot. Also, fully treated fabric will not listed above.

Figure 5. Concept: 100% Cotton RPA

Article Designation: Scholarly 1 JTATM

Volume 2, Issue 3, Summer 2002

Print applications of durable water repellents Table 2 shows the results for seven replicate

(on the side to be worn next to the skin) are samples, which were rather consistent. In

one technique. Another is yarn treatments this case, the FC was printed in a striped

where treated and untreated yarns are plaited pattern on one side of the fabric with about

to achieve the effect. The overall concept 50% coverage, and as planned, the FC did

will have the following results: not penetrate the full thickness of the fabric.

The absorbent capacity (in this case wet

o 40-90% of the cotton fabric next to pickup) was substantially reduced by almost

the skin is treated and remains dry. 50%.

o 10-60% of the cotton fabric next to The test method used for Tables 2 (no

the skin is untreated, absorbent, and laundering) and 3 (one laundering) was the

wicks moisture away into the Cotton Incorporated Gross Absorbency Test.

outside of the fabric for evaporation This test measures the absorbent capacity of

and cooling. fabric samples by placing them on a

“uniformly saturated fabric” with a readily

o The outside of the fabric is untreated available water supply. In this test, the

and absorbent. “uniformly saturated fabric” is in a

horizontal position and is maintained in the

o The chemistry and process saturated state by being in direct contact

technology required is simple and with a fine-pore sponge, which is mostly

widely available. immersed in a tray of water. The exact

details of this test can be obtained by

• The chemistry is durable to home contacting the Cotton Incorporated Textile

laundering. Chemistry Research Department.

In one test series, 100% cotton fabric was

printed with durable fluorocarbons (FC).

Table 2: Comparisons of % Wet Pickup for FC Printed vs. Unprinted 100% Cotton

(no laundering)

Gross Absorbency Test

500

% Water WPU

400

300

200

100

0

#1 #2 #3 #4 #5 #6 #7

FC printed (no HL) untreated ctrl. (no HL)

Article Designation: Scholarly 1 JTATM

Volume 2, Issue 3, Summer 2002

This same test was performed after one chemistry is durable to more than 50 home

home laundering. The FC that was chosen launderings. Table 3 gives the comparison

can be crosslinked to cotton and becomes for the seven replicates of treated and

very durable to laundering. The untreated samples after one home

manufacturer's data indicates that the laundering.

Table 3: Comparison of % Wet Pickup for FC Printed vs.

Unprinted 100% Cotton (After One Home Laundering)

Gross Absorbency Test

500

% Water WPU

400

300

200

100

0

#1 #2 #3 #4 #5 #6 #7

FC printed (1 HL) untreated ctrl. (1 HL)

Drying Rates ambient weights rather than bone-dry

weights. The fabric samples were cut and

Drying rates were determined for a Nike weighed after conditioning for about four

DRI-FIT polyester fabric and a 100% cotton hours in the conditioned environment. The

fabric printed with a FC. The rate of drying fabrics were then wet-out with just water in

for each is shown in Table 4. the rotary drum machine and extracted for

two minutes. The samples were then placed

The fabrics were saturated with water and in plastic bags and immediately brought to

extracted in a laboratory garment the conditioned lab and reweighed; whereas,

washing/dyeing machine (rotary drum). The the initial percent water on fabric was

data shows that the percent water on the calculated, using the ambient fabric weight

polyester fabric was just over 50% (50.6%), as the basis.

and the cotton fabric yielded just over 30%

(30.5%). Both fabrics were allowed to air The cotton fabric can feel dry to the touch

dry in a conditioned laboratory (74oF and when it contains a significant amount of

53% RH). Both the cotton and the polyester moisture because of its hydrophilic nature.

fabric’s dry or basis weights were based on Cotton’s normal regain is 6-8%. However,

Article Designation: Scholarly 1 JTATM

Volume 2, Issue 3, Summer 2002

the polyester fabric can feel damp or Because of cotton’s higher natural regain, a

clammy when it contains only a few percent cotton fabric can feel dry when it contains as

moisture because of its very low moisture much as 15% moisture. However, just a few

regain of about 0.5 percent. In this example, percent moisture on a polyester fabric can

the cotton can be expected to feel dry after make it feel clammy and uncomfortable.

60 minutes; whereas, the polyester may still

feel damp or clammy after 90 minutes.

Table 4: Drying Rate of 100% Cotton FC Printed Fabric versus Polyester

Wetted and Extracted

Fabric (74°F (23°C) andin Unimac

53% Washing

Relative Machine and

Humidity)

Air Dried

60

% Water on Fabric

50

40

30

20

10

0

0 15 30 45 60 75 90 105 120

Time in min.

printed cotton yellow Nike Polyester

CONCLUSIONS

o A wide range of performance

With some of the techniques that are being characteristics can be achieved using

developed, it will be possible to create a existing chemistries and available mill

whole spectrum of performance properties equipment.

on 100% cotton for different activities in a

wide range of environments. From this It is possible to create a whole range of

study, the following can be derived: performance characteristics for different

activities or environments in 100% cotton. A

o 100% cotton fabrics can be produced creative marketing program based on this

with reduced absorbent capacity. concept can provide an incentive at retail

with emphasis on innovation.

o Reducing absorbent capacity while

maintaining wicking is critical.

o Various methods can be used to

manufacture recreational performance

apparel from 100% cotton.

Article Designation: Scholarly 1 JTATM

Volume 2, Issue 3, Summer 2002

References

1

Stefan Thumm, “LAD Fluorocarbon

Technology for High-Tech Sportswear,”

International Textile Bulletin, January 2000,

p. 60

CONTACT INFORMATION:

Michelle Wallace

Cotton Incorporated

World Headquarters

6399 Weston Parkway

Cary, North Carolina 27513

Tel. (919) 678-2220

Fax. (919) 678-2230

Article Designation: Scholarly 1 JTATM

Volume 2, Issue 3, Summer 2002

You might also like

- Aldehydes and Ketones I NucleophIlic Addition To The Carbonyl GroupDocument41 pagesAldehydes and Ketones I NucleophIlic Addition To The Carbonyl GroupDenisse BadiolaNo ratings yet

- Water Proof Fabrics: Types of Fabrics Methods of Making WaterproofDocument33 pagesWater Proof Fabrics: Types of Fabrics Methods of Making WaterproofSoumita GoswamiNo ratings yet

- Modern technology of acid slurry, surfactants, soapsDocument6 pagesModern technology of acid slurry, surfactants, soapsDinesh KumarNo ratings yet

- 14 Building Materials used in constructionDocument10 pages14 Building Materials used in constructionM ShahidNo ratings yet

- High-Performance Sports TextilesDocument4 pagesHigh-Performance Sports Textilesila03100% (1)

- Thermal Comfort: Government College of Engineering and Textile Technology, SeramporeDocument25 pagesThermal Comfort: Government College of Engineering and Textile Technology, SeramporePURNIMA RANJITNo ratings yet

- Lecture 7 and 8Document129 pagesLecture 7 and 8M Salman NaeemNo ratings yet

- Basics Sports TextilesDocument49 pagesBasics Sports Textiles20MT31 - NAAVENDHAN SNo ratings yet

- STDS'M&SDocument8 pagesSTDS'M&SSazid Rahman100% (1)

- Smart FabricsDocument16 pagesSmart FabricsVenkatesh Malpani100% (1)

- Introduction To Waterproof Breathable Membrane TechnologyDocument9 pagesIntroduction To Waterproof Breathable Membrane TechnologyIrmantas Saulius100% (3)

- Moisture Management Fabric PerformanceDocument8 pagesMoisture Management Fabric PerformanceMohammed Atiqul Hoque Chowdhury100% (1)

- Industrial Good SuppliersDocument8 pagesIndustrial Good Suppliersumesh kumarNo ratings yet

- 578 07 - Chapter 2Document44 pages578 07 - Chapter 2priyaNo ratings yet

- FEI1020Document5 pagesFEI1020priyaNo ratings yet

- Moisture Management 2023Document3 pagesMoisture Management 2023samiasherif73No ratings yet

- Moisturemanagement 161123172751Document141 pagesMoisturemanagement 161123172751aqsa imranNo ratings yet

- OnofreiDocument14 pagesOnofreiVinoth DhanamNo ratings yet

- Moisture ManagementDocument5 pagesMoisture ManagementSombis2011No ratings yet

- Comfort and Thermo Physiological Characteristics of Multilayered Fabrics For Medical TextilesDocument16 pagesComfort and Thermo Physiological Characteristics of Multilayered Fabrics For Medical TextilesIra TryNo ratings yet

- Moisture Management PropertiesDocument11 pagesMoisture Management Propertiesaqsa imranNo ratings yet

- Thermal Properties of Egyptian Stretched Knitted FabricsDocument4 pagesThermal Properties of Egyptian Stretched Knitted FabricsaymanNo ratings yet

- SportswearDocument5 pagesSportswearsashahodgeNo ratings yet

- Moisture 2Document15 pagesMoisture 2RH NiloyNo ratings yet

- 03.2 The Wool Fibre and Its Applications NotesDocument34 pages03.2 The Wool Fibre and Its Applications Notesatwijukye raymondNo ratings yet

- MoistureManagement eDocument7 pagesMoistureManagement esoumen biswasNo ratings yet

- Characteristics of Knitted Structures Produced by Engineered Polyester Yarns and Their Blends in Terms of Thermal ComfortDocument10 pagesCharacteristics of Knitted Structures Produced by Engineered Polyester Yarns and Their Blends in Terms of Thermal ComfortMuqarab Hassan 0140No ratings yet

- Comfort Characteristics Required For SportswearDocument3 pagesComfort Characteristics Required For SportswearKamakshi AggarwalNo ratings yet

- SportwearDocument17 pagesSportwearSaurav UjjainNo ratings yet

- An Innovative Process of Producing Garments With Functional and Fashion Aspects TTDocument9 pagesAn Innovative Process of Producing Garments With Functional and Fashion Aspects TTMitesh ShahNo ratings yet

- Moisture Transmission PrintDocument49 pagesMoisture Transmission PrintMusical Black DiaryNo ratings yet

- CLOTHTECHDocument56 pagesCLOTHTECHMohammad RazibNo ratings yet

- Journal Moisture ManagementDocument9 pagesJournal Moisture ManagementDiar HifdiNo ratings yet

- Moisture Transmission Through Textiles 1Document11 pagesMoisture Transmission Through Textiles 1Ahmad SamerNo ratings yet

- CLOTHTECHDocument54 pagesCLOTHTECHDewan Ajuad Hossain RifatNo ratings yet

- Influence of tuck stitch placement on thermal comfort of layered knitsDocument11 pagesInfluence of tuck stitch placement on thermal comfort of layered knitssrini_kalmulaNo ratings yet

- Intelligent Fabric: Inspired by Pine ConesDocument7 pagesIntelligent Fabric: Inspired by Pine ConesvijishanNo ratings yet

- 577 6.4.3onofireDocument13 pages577 6.4.3onofirepriyaNo ratings yet

- Moisture Vapor Permeability and Thermal Wear ComfortDocument24 pagesMoisture Vapor Permeability and Thermal Wear ComforthawNo ratings yet

- Evaluation of Thermal and Moisture ManagDocument9 pagesEvaluation of Thermal and Moisture ManagDibyendu DattaNo ratings yet

- DenimDocument11 pagesDenimJ.SathishNo ratings yet

- Special Garment ProtectionDocument11 pagesSpecial Garment Protectionjack omeNo ratings yet

- Smart and Technical Textiles: The Future of Fibres & FabricsDocument15 pagesSmart and Technical Textiles: The Future of Fibres & Fabricsaqsa imranNo ratings yet

- Comfort Properties of Bi-Layer Knitted Fabrics - Knitting & Hosiery - Features - The ITJ PDFDocument12 pagesComfort Properties of Bi-Layer Knitted Fabrics - Knitting & Hosiery - Features - The ITJ PDFAhmad SamerNo ratings yet

- Polartec Delta Fact SheetDocument2 pagesPolartec Delta Fact SheetAaronNo ratings yet

- Presentation On Thermal Comfort and Resistance: Submitted To: Prof. Prakash Khude Submitted By: Mohd MushahidDocument14 pagesPresentation On Thermal Comfort and Resistance: Submitted To: Prof. Prakash Khude Submitted By: Mohd Mushahidaslam khanNo ratings yet

- Comfort properties of bi-layer knitted fabricsDocument22 pagesComfort properties of bi-layer knitted fabricsDorin VladNo ratings yet

- Factors Affecting Thermal Insulation Properties of GarmentDocument7 pagesFactors Affecting Thermal Insulation Properties of GarmentravikantNo ratings yet

- Thermal Comfort and Resistance PresentationDocument14 pagesThermal Comfort and Resistance Presentationaslam khanNo ratings yet

- Thermal comfort properties of Kevlar and Kevlar/wool fabricsDocument10 pagesThermal comfort properties of Kevlar and Kevlar/wool fabricsSamuel VanoostenNo ratings yet

- Effect of Different Mercerization Techniques On Tactile Comfort of Cotton FabricDocument6 pagesEffect of Different Mercerization Techniques On Tactile Comfort of Cotton FabricAhmad ButtNo ratings yet

- Achieving Comfort in Intimate ApparelDocument28 pagesAchieving Comfort in Intimate Apparelaqsa imranNo ratings yet

- Study of Bedding Fabrics and Their Influence On Thermal Comfort and Sleep Ijariie15793Document6 pagesStudy of Bedding Fabrics and Their Influence On Thermal Comfort and Sleep Ijariie15793Kriptun KNo ratings yet

- Water - Proof Breathable FabricDocument29 pagesWater - Proof Breathable FabricKryptonNo ratings yet

- Development An Effective Quick Fabric Relaxation MDocument10 pagesDevelopment An Effective Quick Fabric Relaxation MMohammed Tanjil Morshed remonNo ratings yet

- New Microsoft PowerPoint Presentation2Document37 pagesNew Microsoft PowerPoint Presentation2M Salman NaeemNo ratings yet

- Research Article: Effect of Fibers and Weave Designs On The Thermo-Physiological Comfort of Summer Scarf FabricDocument8 pagesResearch Article: Effect of Fibers and Weave Designs On The Thermo-Physiological Comfort of Summer Scarf FabricMuqarab Hassan 0140No ratings yet

- SynopsisDocument31 pagesSynopsisRajesh DwivediNo ratings yet

- Moisture Properties of Raised 3-Thread Fleece Fabric Knitted with Different Face and Fleecy YarnsDocument12 pagesMoisture Properties of Raised 3-Thread Fleece Fabric Knitted with Different Face and Fleecy YarnsShahin ghasemi nezhadNo ratings yet

- Breathable GarmentsDocument7 pagesBreathable Garmentsmarikaki12No ratings yet

- Smart TextilesDocument36 pagesSmart TextilesFaizan ShaikhNo ratings yet

- BBA. (Hons.) Early Admissions Orientation Schedule - Fall 2020 2Document7 pagesBBA. (Hons.) Early Admissions Orientation Schedule - Fall 2020 2Chaudhary UsmanNo ratings yet

- Hostel Admission & Registration FormDocument3 pagesHostel Admission & Registration FormChaudhary UsmanNo ratings yet

- Department of Economics Sample Admission TestDocument3 pagesDepartment of Economics Sample Admission TestChaudhary UsmanNo ratings yet

- Punjab Boards 11th Class Chemistry Book English Medium 6368075084588991190 PDFDocument583 pagesPunjab Boards 11th Class Chemistry Book English Medium 6368075084588991190 PDFGulshairNo ratings yet

- Pre-Feasibility Study: Rice Husking & Polishing UnitDocument28 pagesPre-Feasibility Study: Rice Husking & Polishing UnitVIRTU 8 HR & IT LLPNo ratings yet

- Cottoninc Fulldocument-1Document11 pagesCottoninc Fulldocument-1Chaudhary UsmanNo ratings yet

- Punjab Boards 11th Class Biology Book English Medium 6368073082448619590 PDFDocument455 pagesPunjab Boards 11th Class Biology Book English Medium 6368073082448619590 PDFNnc Saud KhanNo ratings yet

- Punjab Boards 11th Class Biology Book English Medium 6368073082448619590 PDFDocument455 pagesPunjab Boards 11th Class Biology Book English Medium 6368073082448619590 PDFNnc Saud KhanNo ratings yet

- Punjab Boards 11th Class Chemistry Book English Medium 6368075084588991190 PDFDocument583 pagesPunjab Boards 11th Class Chemistry Book English Medium 6368075084588991190 PDFGulshairNo ratings yet

- Modern Ginning and Pressing UnitDocument8 pagesModern Ginning and Pressing UnitHiteshGondalia100% (3)

- Mark Twain QuotesDocument1 pageMark Twain QuotesBen ChongNo ratings yet

- CottonDocument20 pagesCottonTariqNo ratings yet

- Pharmacognosy: History and ScopeDocument29 pagesPharmacognosy: History and ScopeHarry ShahNo ratings yet

- Fiber Reinforced Composite in Dentistry PDFDocument13 pagesFiber Reinforced Composite in Dentistry PDFDrg Sri Pandu UtamiNo ratings yet

- Conventional Vs Synthetic OilDocument2 pagesConventional Vs Synthetic Oilsembalap29No ratings yet

- EZ Mulz 1475 TDS 1Document2 pagesEZ Mulz 1475 TDS 1Dinesh babuNo ratings yet

- Clariant - Additives For Bio Polymers FNL 6-26-08Document4 pagesClariant - Additives For Bio Polymers FNL 6-26-08henriknNo ratings yet

- Fire Classification-PrelimDocument6 pagesFire Classification-PrelimLevy DaceraNo ratings yet

- Cell Wall Synthesis Inhibitors (CompleteDocument44 pagesCell Wall Synthesis Inhibitors (CompletegrayNo ratings yet

- Past and Present Perspectives On - Lactamases Antimicrobial Agents and Chemotherapy-2018-Bush-e01076-18.FullDocument20 pagesPast and Present Perspectives On - Lactamases Antimicrobial Agents and Chemotherapy-2018-Bush-e01076-18.FullPatricio Suazo SotoNo ratings yet

- Synthesis of Soap DetergentDocument4 pagesSynthesis of Soap DetergentHarvey Mher RarangNo ratings yet

- Natural Polymeric Biomaterials: Properties and ProcessingDocument6 pagesNatural Polymeric Biomaterials: Properties and ProcessingAndres Felipe Rojas RodriguezNo ratings yet

- PCOG LEC - Assignment 5 (Volatile Oils)Document4 pagesPCOG LEC - Assignment 5 (Volatile Oils)sadburgerNo ratings yet

- (Tt305) Advcned Yarn Manufacutring: Unit - VDocument1 page(Tt305) Advcned Yarn Manufacutring: Unit - VAnonymous fhTeZJtNo ratings yet

- C1079PE Heavy Duty Pneumatic Pumps Series 400200Document2 pagesC1079PE Heavy Duty Pneumatic Pumps Series 400200Angelica Dragulescu100% (1)

- Chemical Spinning Methods - Wet, Dry & MeltDocument5 pagesChemical Spinning Methods - Wet, Dry & MeltGolam SarwarNo ratings yet

- Kingspan IRW Maintenance Manual NADocument9 pagesKingspan IRW Maintenance Manual NAEddie MunsonNo ratings yet

- Hori 2018Document5 pagesHori 2018Mellya RizkiNo ratings yet

- EP0338486A2Document12 pagesEP0338486A2Gemblung01No ratings yet

- A Handbook of Applied Biopolymer Technology: Synthesis, Degradation and ApplicationsDocument500 pagesA Handbook of Applied Biopolymer Technology: Synthesis, Degradation and ApplicationsRizvana HreditaNo ratings yet

- Nugent 13Document2 pagesNugent 13ari wiliamNo ratings yet

- Pratley Adjustable Gland LeafletDocument2 pagesPratley Adjustable Gland LeafletAndy Kong KingNo ratings yet

- Organotin CompoundDocument10 pagesOrganotin CompoundAtsar Leswara NinditaNo ratings yet

- Aspirin and SoapDocument4 pagesAspirin and SoapyeeeyyyNo ratings yet

- Nonwovens For Medical TextilesDocument11 pagesNonwovens For Medical TextilesaswinipranavNo ratings yet

- Ganzo Firebird CatalogueDocument16 pagesGanzo Firebird CatalogueElSuperbeastoNo ratings yet

- BMC V - Unit-3 - FinishesDocument14 pagesBMC V - Unit-3 - FinishesniviNo ratings yet