Professional Documents

Culture Documents

Manual Tank 2016

Uploaded by

stiglatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Tank 2016

Uploaded by

stiglatCopyright:

Available Formats

TANK

User's Guide

Version 2016 (8.0)

Thursday, July 07,

2016

Copyright

Copyright © 1994-2016 Intergraph CAS, Inc. All Rights Reserved. Intergraph is part of Hexagon.

Including software, file formats, and audiovisual displays; may be used pursuant to applicable software license agreement; contains

confidential and proprietary information of Intergraph and/or third parties which is protected by copyright law, trade secret law, and

international treaty, and may not be provided or otherwise made available without proper authorization from Intergraph Corporation.

Contains RealDWG™ by Autodesk, Inc. Copyright © 1998-2015 Autodesk, Inc. All rights reserved.

Portions of the user interface copyright © 2012-2015 Telerik AD.

U.S. Government Restricted Rights Legend

Use, duplication, or disclosure by the government is subject to restrictions as set forth below. For civilian agencies: This was

developed at private expense and is "restricted computer software" submitted with restricted rights in accordance with

subparagraphs (a) through (d) of the Commercial Computer Software - Restricted Rights clause at 52.227-19 of the Federal

Acquisition Regulations ("FAR") and its successors, and is unpublished and all rights are reserved under the copyright laws of the

United States. For units of the Department of Defense ("DoD"): This is "commercial computer software" as defined at DFARS

252.227-7014 and the rights of the Government are as specified at DFARS 227.7202-3.

Unpublished - rights reserved under the copyright laws of the United States.

Intergraph Corporation

305 Intergraph Way

Madison, AL 35758

Documentation

Documentation shall mean, whether in electronic or printed form, User's Guides, Installation Guides, Reference Guides,

Administrator's Guides, Customization Guides, Programmer's Guides, Configuration Guides and Help Guides delivered with a

particular software product.

Other Documentation

Other Documentation shall mean, whether in electronic or printed form and delivered with software or on Intergraph Smart Support,

SharePoint, or box.net, any documentation related to work processes, workflows, and best practices that is provided by Intergraph

as guidance for using a software product.

Terms of Use

a. Use of a software product and Documentation is subject to the End User License Agreement ("EULA") delivered with the

software product unless the Licensee has a valid signed license for this software product with Intergraph Corporation. If the

Licensee has a valid signed license for this software product with Intergraph Corporation, the valid signed license shall take

precedence and govern the use of this software product and Documentation. Subject to the terms contained within the

applicable license agreement, Intergraph Corporation gives Licensee permission to print a reasonable number of copies of the

Documentation as defined in the applicable license agreement and delivered with the software product for Licensee's internal,

non-commercial use. The Documentation may not be printed for resale or redistribution.

b. For use of Documentation or Other Documentation where end user does not receive a EULA or does not have a valid license

agreement with Intergraph, Intergraph grants the Licensee a non-exclusive license to use the Documentation or Other

Documentation for Licensee’s internal non-commercial use. Intergraph Corporation gives Licensee permission to print a

reasonable number of copies of Other Documentation for Licensee’s internal, non-commercial use. The Other Documentation

may not be printed for resale or redistribution. This license contained in this subsection b) may be terminated at any time and

for any reason by Intergraph Corporation by giving written notice to Licensee.

Disclaimer of Warranties

Except for any express warranties as may be stated in the EULA or separate license or separate terms and conditions, Intergraph

Corporation disclaims any and all express or implied warranties including, but not limited to the implied warranties of merchantability

and fitness for a particular purpose and nothing stated in, or implied by, this document or its contents shall be considered or deemed

a modification or amendment of such disclaimer. Intergraph believes the information in this publication is accurate as of its

publication date.

The information and the software discussed in this document are subject to change without notice and are subject to applicable

technical product descriptions. Intergraph Corporation is not responsible for any error that may appear in this document.

The software, Documentation and Other Documentation discussed in this document are furnished under a license and may be used

or copied only in accordance with the terms of this license. THE USER OF THE SOFTWARE IS EXPECTED TO MAKE THE FINAL

EVALUATION AS TO THE USEFULNESS OF THE SOFTWARE IN HIS OWN ENVIRONMENT.

TANK User's Guide 2

Intergraph is not responsible for the accuracy of delivered data including, but not limited to, catalog, reference and symbol data.

Users should verify for themselves that the data is accurate and suitable for their project work.

Limitation of Damages

IN NO EVENT WILL INTERGRAPH CORPORATION BE LIABLE FOR ANY DIRECT, INDIRECT, CONSEQUENTIAL INCIDENTAL,

SPECIAL, OR PUNITIVE DAMAGES, INCLUDING BUT NOT LIMITED TO, LOSS OF USE OR PRODUCTION, LOSS OF

REVENUE OR PROFIT, LOSS OF DATA, OR CLAIMS OF THIRD PARTIES, EVEN IF INTERGRAPH CORPORATION HAS BEEN

ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

UNDER NO CIRCUMSTANCES SHALL INTERGRAPH CORPORATION’S LIABILITY EXCEED THE AMOUNT THAT

INTERGRAPH CORPORATION HAS BEEN PAID BY LICENSEE UNDER THIS AGREEMENT AT THE TIME THE CLAIM IS

MADE. EXCEPT WHERE PROHIBITED BY APPLICABLE LAW, NO CLAIM, REGARDLESS OF FORM, ARISING OUT OF OR IN

CONNECTION WITH THE SUBJECT MATTER OF THIS DOCUMENT MAY BE BROUGHT BY LICENSEE MORE THAN TWO (2)

YEARS AFTER THE EVENT GIVING RISE TO THE CAUSE OF ACTION HAS OCCURRED.

IF UNDER THE LAW RULED APPLICABLE ANY PART OF THIS SECTION IS INVALID, THEN INTERGRAPH LIMITS ITS

LIABILITY TO THE MAXIMUM EXTENT ALLOWED BY SAID LAW.

Export Controls

Intergraph Corporation’s software products and any third-party Software Products obtained from Intergraph Corporation, its

subsidiaries, or distributors (including any Documentation, Other Documentation or technical data related to these products) are

subject to the export control laws and regulations of the United States. Diversion contrary to U.S. law is prohibited. These Software

Products, and the direct product thereof, must not be exported or re-exported, directly or indirectly (including via remote access)

under the following circumstances:

a. To Cuba, Iran, North Korea, Sudan, or Syria, or any national of these countries.

b. To any person or entity listed on any U.S. government denial list, including but not limited to, the U.S. Department of Commerce

Denied Persons, Entities, and Unverified Lists, http://www.bis.doc.gov/complianceandenforcement/liststocheck.htm, the U.S.

Department of Treasury Specially Designated Nationals List, http://www.treas.gov/offices/enforcement/ofac/, and the U.S.

Department of State Debarred List, http://www.pmddtc.state.gov/compliance/debar.html.

c. To any entity when Licensee knows, or has reason to know, the end use of the Software Product is related to the design,

development, production, or use of missiles, chemical, biological, or nuclear weapons, or other un-safeguarded or sensitive

nuclear uses.

d. To any entity when Licensee knows, or has reason to know, that an illegal reshipment will take place.

Any questions regarding export or re-export of these Software Products should be addressed to Intergraph Corporation’s Export

Compliance Department, Huntsville, Alabama 35894, USA.

Trademarks

Intergraph, the Intergraph logo, Intergraph Smart, PDS, SmartPlant, SmartMarine, FrameWorks, I-Sketch, IntelliShip, Isogen,

SmartSketch, SPOOLGEN, SupportManager, and SupportModeler are trademarks or registered trademarks of Intergraph

Corporation or its subsidiaries in the United States and other countries. Microsoft and Windows are registered trademarks of

Microsoft Corporation. MicroStation is a registered trademark of Bentley Systems, Inc. Other brands and product names are

trademarks of their respective owners.

TANK User's Guide 3

Contents

What's New in TANK 2016 .......................................................................................................................... 7

Introduction ................................................................................................................................................ 10

Program Capabilities ............................................................................................................................. 10

TANK Input............................................................................................................................................ 12

TANK Interface ........................................................................................................................................... 13

File Tab ................................................................................................................................................. 14

Home Tab ............................................................................................................................................. 14

File Panel ........................................................................................................................................ 15

Edit Panel ....................................................................................................................................... 15

Title Page Panel ............................................................................................................................. 16

Input Panel ..................................................................................................................................... 16

Scratchpad Panel ........................................................................................................................... 72

Analyze Panel ................................................................................................................................. 75

Units Panel ..................................................................................................................................... 77

2D Plot Panel .................................................................................................................................. 77

Tools Tab .............................................................................................................................................. 78

Configuration .................................................................................................................................. 78

Create a New Units File.................................................................................................................. 84

Material Database Editor ................................................................................................................ 86

Diagnostics Tab .................................................................................................................................... 94

CRC Check ..................................................................................................................................... 95

Program Scanner ........................................................................................................................... 95

Error Review ................................................................................................................................... 96

ESL Tab ................................................................................................................................................ 97

Access Registry Details through the ESL....................................................................................... 98

Help Tab.............................................................................................................................................. 100

Build a Tank ............................................................................................................................................. 102

Input Data............................................................................................................................................ 102

Starting TANK ............................................................................................................................... 103

Define the Tank Data.................................................................................................................... 103

Define the Shell Courses .............................................................................................................. 104

Define the Roof Specifications ..................................................................................................... 105

Check the Input for Errors ................................................................................................................... 106

Complete the Error Check Phase ................................................................................................. 107

Analyze the Tank ................................................................................................................................ 108

TANK Program Files..................................................................................................................... 108

Solution Overview ......................................................................................................................... 109

Generate Output Reports .................................................................................................................... 111

Use the Output Processor ............................................................................................................ 111

PDF Header .................................................................................................................................. 113

Report List Tab ............................................................................................................................. 113

TANK User's Guide 4

Contents

Options Tab .................................................................................................................................. 123

View the Graphics Output ................................................................................................................... 124

3D View ........................................................................................................................................ 125

2D View ........................................................................................................................................ 127

Examples .................................................................................................................................................. 133

Example Problem APP_K ................................................................................................................... 133

Example Problem O_WC .................................................................................................................... 133

Example Problem A_WC .................................................................................................................... 133

Example Problem KOCZWARA .......................................................................................................... 134

Example Problem B&Y ....................................................................................................................... 134

Example Problem SSTEST1............................................................................................................... 134

Example Problem TEST1 ................................................................................................................... 134

Example Problem SSC1 ..................................................................................................................... 134

Example Problem APP_P ................................................................................................................... 134

Example Problem EXTERN01 ............................................................................................................ 134

Example Problem SEIS01 .................................................................................................................. 135

Appendix A - Program File List .............................................................................................................. 136

Main Set .............................................................................................................................................. 136

Help & Error Processing Set ............................................................................................................... 137

English Text Set .................................................................................................................................. 138

API Data Set ....................................................................................................................................... 138

Examples Data Set ............................................................................................................................. 139

Appendix B - Standard Units Systems .................................................................................................. 140

Appendix C - List of Materials ................................................................................................................ 143

* ASTM Standards .............................................................................................................................. 143

* CSA Standards ................................................................................................................................. 144

* National Standards ........................................................................................................................... 144

* ISO 630 ............................................................................................................................................. 144

* Stainless Steels (Temperature Dependent) ..................................................................................... 144

* Duplex Stainless Steels (Temperature Dependent) ......................................................................... 145

* Unknown For API-653 ...................................................................................................................... 145

Appendix D - Default Configuration Directives .................................................................................... 146

Appendix E - Selected References ........................................................................................................ 147

Appendix F - Revision History ............................................................................................................... 148

Version 7.00 Changes (12/14) ............................................................................................................ 148

Version 6.00 Changes (12/13) ............................................................................................................ 149

Version 5.00 Changes (4/13) .............................................................................................................. 149

Version 4.00 Changes (3/12) .............................................................................................................. 150

Version 3.30 Changes (9/10) .............................................................................................................. 150

Version 3.20 Changes (9/09) .............................................................................................................. 150

Version 3.10 Changes (9/08) .............................................................................................................. 150

TANK User's Guide 5

Contents

Version 3.00 Changes (11/07) ............................................................................................................ 150

Version 2.55 Changes (10/05) ............................................................................................................ 151

Version 2.50 Changes (3/04) .............................................................................................................. 151

Version 2.40 Changes (7/02) .............................................................................................................. 151

Version 2.30 Changes (2/02) .............................................................................................................. 151

Version 2.20 Changes (9/00) .............................................................................................................. 152

Version 2.10 Changes (5/00) .............................................................................................................. 152

Version 1.60 / 2.00 Changes (1/99) .................................................................................................... 152

Version 1.51 Changes (9/97) .............................................................................................................. 153

Version 1.50 Changes (5/97) .............................................................................................................. 153

Version 1.40 Changes (9/96) .............................................................................................................. 154

Version 1.31 Changes (2/96) .............................................................................................................. 154

Version 1.30 Changes (8/95) .............................................................................................................. 154

Version 1.20 Changes (11/94) ............................................................................................................ 155

Version 1.10 Changes (6/94) .............................................................................................................. 155

Index ......................................................................................................................................................... 157

TANK User's Guide 6

What's New in TANK 2016

The latest TANK release delivers a number of significant new and extended capabilities in

response to current market requirements, as well as direct feedback from the growing TANK

community. The following changes have been made to TANK.

TANK 2016 (Version 8.00.00.0000)

Code Updates

Updated the software to support API 620, 12th Edition, Addendum 1 (November 2014).

(CR-TX-10640, CR-TX-16131, CR-TX-16486, CR-TX-16775)

Updated the software to support API 650, 12th Edition, Addendum 2 (January 2016).

(CR-TX-16464)

Updated the software to support API 653, 5th Edition (November 2014)

Updated the software to support API 2000, 7th Edition (March 2014)

Configuration

Enhanced TANK to compress and archive files. The software compresses input, output, and

intermediate files into a zip file when you close a file, create a new file when another file is

opened, or save an open file under a new fame. TANK now saves and compresses files

under the new .tk file extension. This new functionality is enabled by default, but it can be

disabled by selecting Do Not Compress the Input Files on the Configuration dialog.

(CR-TX-8905, CR-TX-8906, CR-TX-8907, CR-TX-10596, CR-TX-10908)

Updated TANK by allowing the default structural database selection to display in Structural

Database. Previously, when you selected a default structural database on the

Configuration dialog, the software required you to reselect that database option on the

Supported Cone Roof Data tab. The software has been updated, and the default database

option selected on the Configuration dialog automatically displays in Structural Database

on the Supported Cone Roof Data tab. (CR-TX-10413)

Productivity

Enhanced TANK to allow you to lock files. You can now lock a file by selecting Lock the

Current Input File on the Tools tab. When the file is opened, a message displays indicating

the file is read-only and cannot by saved or analyzed. If the file needs to be modified, you

can unlock it by selecting Unlock the Current Input File on the Tools tab. This

enhancement reduces the chance of users making accidental changes to files.

(CR-TX-10470)

Updated TANK by creating new options for users to select a material or edit material

properties. New Database and Edit/View Properties options were added to the material

selection fields throughout the software. When you select Database, the updated Material

Selection dialog box displays. When you select Edit/View Properties, the Material

Properties dialog displays. (CR-TX-12902)

Updated TANK by adding the ability to display insulation on the 3D model. New Insulation

options were added to the right-click menu that allow you to choose how insulation displays

on the 2D and 3D models. (CR-TX-16447)

TANK User's Guide 7

What's New in TANK 2016

Updated TANK by adding a .vue file exporter utility. Users can now select Export to VUE

Format on the Tools tab to open the VUE File Exporter utility. This utility allows users to

convert their TANK .tk files into .vue files. Users can then open and review the TANK model

in SmartPlant Review. (CR-TX-16502, CR-TX-16501, CR-TX-16843)

Updated TANK by removing the functionality to append reports. The Append Reports icon

has been removed and all references to it removed from the documentation. (CR-TX-12270)

Enhanced TANK by integrating the TKerck.exe program into the TANK program. As a result

of this enhancement, the time needed to analyze a file has been greatly reduced.

(CR-TX-16064)

Analysis

Updated TANK to allow you to edit the value for Maximum Allowable Tensile Stress.

Previously, Maximum Allowable Tensile Stress did not display on the input, the value was

only defined in the material database. The interface has been enhanced and you can now

edit the value on the Material Properties dialog or the General Tank Data tab. This

enhancement grants you more control over the value that is calculated for Maximum

Allowable Compressive Stress for API 620. (CR-TX-10652)

Updated TANK to only require you enter a value for Minimum Yield Strength of Bottom

Plate once. Previously, the software required you to enter the value on the Seismic Data,

Grillage Review, and Appendix M - Cycle Life tabs. The software has been updated to

contain Minimum Yield Strength of Bottom Plate only on the General Tank Data tab, and

the software uses the value in all necessary calculations. (CR-TX-10896)

Enhanced the Nozzle Stiffness Data tab to support API 620 radial nozzle inputs. When you

select 620 in API Design Code on the General Tank Data tab, the API 620 Specific Data

section on the Nozzle Stiffness Data tab populates with inputs that are used to perform

nozzle area replacement analysis. (CR-TX-9529, CR-TX-10144)

Enhanced the Nozzle Stiffness Data tab in TANK to allow you to determine the nozzle

outer diameter based on pipe properties specified in the Seamless Pipe Selection dialog

box. When you click the ellipses in Nozzle Outer Diameter, the Seamless Pipe Selection

dialog box displays, where you can select piping properties for the nozzle, such as Pipe

Schedule and Nominal Pipe Diameter from various piping databases. The value for

Nozzle Outer Diameter is then automatically calculated based on your selections.

(CR-TX-10274, TR-TX-10562)

Updated TANK to include a check box to allow users to include the insulation thickness and

density in the roof weight analysis. When you select Is the Roof Insulated on the General

Roof Specs tab, the software uses the insulation data from the Tank Data tab to account for

the weight of the insulated roof. Roof insulation calculations are only performed for tanks

analyzed per API 620. (CR-TX-16167)

Updated TANK by adding the ability to plot and analyze nozzles on the roof of a tank. Two

new options, Is Nozzle on Roof and Distance from the Center were added to allow users

to plot and analyze nozzles on the roof of a tank. Users can plot nozzles on the 3D model for

both API 650 and API 620 tanks, but nozzle analysis is only performed for tanks designed

per API 620. (CR-TX-16444)

Output Reports

Updated TANK to allow a seismic importance factor greater than 1.5. Previously, if the value

in Importance Factor on the Seismic Data tab was greater than 1.5, the software

TANK User's Guide 8

What's New in TANK 2016

encountered a fatal error upon analysis. The software now display a warning on the Error

Checker .LOG File report if the seismic importance factor is greater than 1.5, but allows the

analysis to continue. (CR-TX-12837)

Updated TANK to display a warning message on output reports when certain code rules are

violated. According to API 650, a nozzle that is subjected to external loads must be located

within a specified region of a tank. The software now displays a warning message on the

Nozzle Flexibility & Load Results report when API 650 code rules are violated for nozzle

placement. (CR-TX-10877)

For a complete TANK revision history, see Appendix F - Revision History (on page 148).

TANK User's Guide 9

SECTION 1

Introduction

TANK is a software tool for the design and analysis of large storage tanks using the API-620,

API-650, and API-653 design codes. TANK incorporates interactive dialogs for user input, input

validation to avoid run time errors, and extensive diagnostics to assist in problem resolution.

This manual provides detailed instructions for the configuration and operation of the program.

Additionally, cell-specific help for guidance and information can be launched by pressing F1. For

installation information, refer to the TANK Installation Guide.

Program Capabilities

TANK incorporates the major considerations of API-650 Section 5 and several of the

Appendices. These include:

Shell course thickness and fluid height computations according to either the variable point

method or the one foot method.

Wind girder computations for the top and up to five intermediate girders.

Minimum metal temperature reporting.

Shell course thickness and fluid height computations according to Appendix A.

Seismic computations according to Appendix E.

Internal pressure considerations according to Appendix F.

Grillage computations according to Appendix I.

Material modifications due to temperature according to Appendix M.

Cycle Life computations according to Appendix M.

TANK User's Guide 10

Introduction

Nozzle flexibilities and limiting loads according to Appendix P, including the limiting load

interaction diagrams.

Stainless Steel considerations according to Appendix S.

External pressure computations according to Appendix V.

Duplex Stainless Steel considerations according to Appendix X.

An alternate nozzle stiffness calculation routine according to PVP-1279.

Tank sizing/costing scratch-pad.

A Material Database editor.

TANK also incorporates the following considerations from API-620:

Shell course thickness computations according to Section 5.10.

Maximum compressive stress calculations according to Section 5.5.

Roof analysis according to Section 5.10.

Analysis of nozzles on the roof of a tank.

Vacuum analysis.

TANK also incorporates the following considerations from API-653:

Material modifications according to Section 2.3.

Shell Settlement evaluation according to Appendix B.

Retiring thicknesses and remaining corrosion allowance.

Corroded hydrotest case

Shell thickness evaluations using individual joint efficiencies and “L” locations

Bottom Plate minimum thickness determinations

Hydrotest heights

TANK can also design or analyze a supported cone roof according to the procedures outlined in

Brownell & Young. TANK also incorporates venting computations from API-2000.

TANK relies extensively on data specified in the API codes. This includes the material data from

Table 5.2, and digitized data from Appendix P. Other data tables have also been incorporated

into the program where necessary.

Every effort is made to ensure that TANK is up to date with the current codes.

TANK User's Guide 11

Introduction

TANK Input

The first step in the design or analysis of a tank is to generate an input file, which describes the

characteristics of the tank. Each tank requires an input file with a unique job name for each

configuration to be studied. All of the tank particulars and descriptive information are stored in

this input file. The input file name consists of the job name as the prefix, followed by a .tki

extension.

Start the input process by selecting File > New or File > Open (and browsing to select an

existing TANK file) and then choosing any option from the Input panel.

TANK separates the input data into logical categories. Each category addresses a specific code

requirement on design task. You must enter tank input data using the General Tank Data

command to save the tank input file. For more information on tank input data commands, see

the Input Panel section in the TANK User's Guide.

As with most software programs, there is an option to save the current state of the input data to

a file. With TANK, you can save the input by using File > Save, or by clicking Save . Save

your input frequently during any extended editing session. When you begin an analysis the

software also saves the data automatically, but it is always best to save the data yourself too.

When you are finished defining the input for your vessel, use the Analyze panel to verify and/or

analyze the job.

For more information, review the other TANK commands in the TANK User's Guide, and then

see Build a Tank (on page 102).

TANK User's Guide 12

SECTION 2

TANK Interface

The main TANK window has a quick access toolbar in the top left corner (indicated with a red 1

in the picture below), which you can customize with the commands that you use the most.

Directly below the quick access toolbar is a series of ribbons (indicated with a red 2) and panels.

Each ribbon tab contains different panels related to that ribbon. For example, on the Home Tab

(on page 14), you can complete commands related to files using the File Panel (on page 15)

(indicated with a red 3), perform edits to tank data using the Edit Panel (on page 15) (indicated

with a red 4), specify title information for the job using the Title Page Panel (on page 16)

(indicated with a red 5), input tank data using the Input Panel (on page 16) (indicated with a red

6), and more.

The TANK panel commands primarily relate to input options, along with some commands for

output review (both text and graphics). The other TANK tabs include commands for software

tools, diagnostic utilities (such as the Material Database Editor), ESL review, and help options.

In This Section

File Tab .......................................................................................... 14

Home Tab ...................................................................................... 14

Tools Tab ....................................................................................... 78

Diagnostics Tab ............................................................................. 94

ESL Tab ......................................................................................... 97

Help Tab ........................................................................................ 100

TANK User's Guide 13

TANK Interface

File Tab

Controls general operations of TANK files.

The File tab contains the following commands:

Open - Opens an existing TANK (.tki) file.

Recent - Displays recently-opened files and folder. Select a file to open.

Save - Saves the open .tki file.

Save As - Saves the open .tki file with a new name.

Print Setup - Selects a printer and printer options.

Preview/Print - Previews and prints the graphics in the open file.

Help - Displays help, getting started, contact information, and version

number for TANK.

System Folder - Opens the System folder in Windows Explorer.

Backup Folder - Opens the Backup folder in Windows Explorer. The

software saves a backup of your TANK files upon analysis.

Exit - Closes the software.

Home Tab

Displays the most commonly-used commands in TANK. The software displays with the Home

tab active by default.

The Home tab contains the following panels:

Panel Description

File Provides file management commands, such as Open, Save,

and Print. For more information, see File Panel (on page 15).

Edit Provides commands for basic editing tasks in TANK. For more

information, see Edit Panel (on page 15).

Title Page Provides commands that let you add descriptive information

about the tank to your job. For more information, see Title Page

Panel (on page 16).

TANK User's Guide 14

TANK Interface

Input Provides commands to add input data to a tank. For more

information, see Input Panel (on page 16).

Scratchpad Provides scratchpads for your tank, where you can compute

data that you later enter in the tank input boxes. For more

information, see Scratchpad Panel (on page 72).

Analyze Provides commands for analyzing the tank. For more

information, see Analyze Panel (on page 75).

Units Provides commands for changing units used in the tank job. For

more information, see Units Panel (on page 77).

2D Plot Provides commands for plotting out various tank details using

the graphics processor in 2D View. For more information, see

2D Plot Panel (on page 77) and View the Graphics Output (on

page 124).

File Panel

The Home > File panel consists of the standard program options for creating new TANK jobs,

opening existing jobs, and saving jobs.

The commands associated with this panel include:

New - Creates a new TANK (.tki) file.

Open - Opens an existing TANK file.

Save - Saves the TANK file.

System Folder - Opens the system folder for TANK. Log files, report header information,

and other software information is saved in this folder.

Edit Panel

The Home > Edit panel includes commands that let you perform common editing tasks to your

tank data.

The commands associated with this panel include:

Cut - Cuts selected elements from the document and pastes them to the Clipboard. The

selected elements replace the previous contents of the Clipboard.

Copy - Copies selected elements to the Clipboard. The selected elements replace the

previous contents of the Clipboard.

TANK User's Guide 15

TANK Interface

Paste - Inserts the Clipboard contents into the file. The command is not available if the

Clipboard is empty.

Title Page Panel

The Home > Title Page panel provides commands that let you describe the tank being studied.

The commands associated with this panel include:

Title Page - Displays the Title Page dialog box. Enter a text description. Use of this dialog

box is optional, but is highly recommended.

Default Title Page - Restores the default title page, located in the file TITLE.HED.

The title page can contain 60 lines of 75 characters. You can scroll down to view any additional

lines. Use standard editing functions to enter information in this dialog box.

Input Panel

The Home > Input panel contains all of the input commands necessary to define a TANK job.

Each command defines a type of data.

The commands associated with this panel include:

General Tank Data - Opens the General Tank Data dialog box. Data must be provided on

this dialog box for every tank analyzed. This information consists of the diameter, the

number of courses, the course height, course thickness, course material, fluid depth, fluid

specific gravity, temperature, pressure, external loads, and the needed code. For more

information, see General Tank Data (on page 17).

Seismic Data Specifications - Opens the Seismic Data Specifications dialog box, where

you can describe the seismic parameters associated with the tank location. The

computations that use this data are found in API-650 Appendix E or API-620 Appendix L.

This is dialog box is an optional input, depending on the tank. For more information, see

Seismic Data Specifications (on page 31).

Nozzle Stiffness - Opens the Nozzle Stiffness dialog box, which allows you to specify up

to fifteen low nozzles on the tank. The computations that use this data are found in API-650

Appendix P. This dialog box is an optional input, depending on the tank. For more

information, see Nozzle Stiffnesses (on page 33).

External Pressure - Opens the Appendix V External Pressure dialog box, where you can

enter data that determines the external pressure capacity of the tank. For more information,

see External Pressure (on page 43).

Inspection Data - Opens the API-653 Service Measurement Data dialog box. For more

information, see Inspection Data (on page 44).

TANK User's Guide 16

TANK Interface

Roof Specification - Opens the Roof Specification Parameters dialog box, where you

can enter roof descriptive parameters. The computations that use this data are found in

API-650 Appendix F and in the text by Brownell & Young. This dialog box is an optional

input, depending on the tank. For more information, see Roof Specifications (on page 48).

Grillage Review - Opens the Grillage Review dialog box, where you can specify the

grillage parameters. The specifics of this computation are found in API-650 Appendix I,

Section I.7. This dialog box is an optional input, depending on the tank. For more

information, see Grillage Review (on page 67).

Cycle Life - Opens the Appendix M Cycle Life Data specification used in the procedures

outlined in API-650 Appendix M to determine the allowed number of “fill-empty” cycles the

tank can undergo without a detailed stress analysis. This dialog is an optional input,

depending on the tank. For more information, see Cycle Life (on page 68).

Shell Settlement - Opens the Shell Settlement Data dialog box used in the procedures

outlined in API-653 Appendix B to determine the maximum and allowed out-of-plane

settlement of the tank shell. This dialog box is an optional input, depending on the tank. For

more information, see Shell Settlement (on page 69).

Venting Requirements - Opens the API-2000 Venting Data dialog box used to determine

the necessary venting for in-breathing, out-breathing, and fire. For more information, see

Venting Requirements (on page 70).

General Tank Data

Home tab: Input > General Tank Data

Lets you define details about the basic characteristics of the tank.

The Tank Data tab specifies the overall characteristics of the tank. For each input cell, a

descriptive comment defines the expected input. Where applicable, the expected units

display to the right of the input cell. For more information, see Tank Data Tab (on page 18).

The Shell Courses tab displays a grid where the height, thickness, corrosion allowance,

material name, material design stress, and material test stress can be specified for each

shell course. The material and its properties specified on this tab are used as default values

for all of the shell courses. You can use the options on this tab to change the material, if

necessary, on a course-by-course basis. For more information, see Shell Courses Tab (on

page 25).

The Wind Details tab defines detailed wind parameters specific to ASCE #7. If these times

are not defined, TANK uses the recommended API 650 defaults. For more information, see

Wind Details Tab (on page 27).

The Anchor Bolt and Gusset Details tab defines the data necessary for the software to

design anchorage, if necessary. API-650 Section 5.12 defines a number of different cases

which must be evaluated (depending on the tank), and may result in the design of required

anchorage. For more information, see Anchor Bolt and Gusset Details Tab (on page 28).

TANK User's Guide 17

TANK Interface

Tank Data Tab

The Tank Data tab specifies the overall characteristics of the tank. For each input cell, a

descriptive comment defines the expected input. Where applicable, the expected units display to

the right of the input cell.

API Design Code

Defines whether API 650, API 620, or API 653 rules are applied to the current job file. Select

the entry from the list. Based on the design code that you select, the software displays

different fields in other sections of the TANK input.

API 650 and API 620 are intended for the design of new tanks and can be

implemented in either design or analysis modes. Because API 653 is intended for the

analysis of existing tanks, it can only be used in analysis mode.

Design Method

Specifies the preferred method of evaluating the shell course thickness requirements. You

can choose: Variable Point, One Foot, or Appendix A. The Design Method also

determines which method is used to compute the allowed fluid heights.

Run Objective

Specifies whether the software should analyze the tank based on your input, or design the

necessary parameters to satisfy the API code.

The setting of this option affects all computations following the shell

TANK User's Guide 18

TANK Interface

course thickness evaluation, as described below:

If you select Design, subsequent calculations for wind girders, seismic, and internal

pressure use the larger of the design or test thicknesses.

If you select Analyze, subsequent calculations use the user-specified course

thicknesses. The computed thicknesses for the design and test cases are reported

for information purposes only. A message is included in the output report when

Analyze is selected.

Design Temperature

Defines the design temperature in the indicated units.

API-650 limits the design temperature to 200 F / 93 C. If the design temperature

exceeds this limit but is less than 500F / 260 C, then the rules of Appendix M are

applied.

Design temperatures that exceed of 500 F / 260 C can cause a fatal error.

If the design temperature value changes, the software automatically implements a

routine to interpolate the data from API-650 Table P-1. The software inserts the

resulting values of modulus and expansion coefficient into the Nozzle dialog box.

API-620 limits the design temperature to 250F / 121C.

Design Pressure at Top

Defines the design pressure in the indicated units.

API-650, Appendix F, limits the design pressure to 2.5 psi / 17.2 kPa.

API-620, Section 5.3, limits the design pressure to 15 psi / 103.4 kPa.

Tank Nominal Diameter [D]

Defines the diameter of the tank.

According to API-650, the software assumes the tank diameter is the centerline

diameter of the bottom shell course plates.

Tank Shell Height [HTK]

Defines the total height of the tank shell. This value should be the sum of the individual

course heights, and is used in the wind load computations.

Design Liquid Level [H]

Defines the height of the design liquid level. This is the height from the tank bottom to the

top of the shell, or to the bottom of any overflow device.

Bottom Plate Thickness [Tb]

Defines the thickness of the bottom plate.

Liquid Specific Gravity [G]

Defines the specific gravity of the fluid.

This value is used only in the Design case. The software automatically uses a

specific gravity of 1.0 for the Hydrotest case.

Weight of Attachments/Structures

TANK User's Guide 19

TANK Interface

Defines the total weight of the attachments and structures on the roof and shell which

should be considered to resist uplift and in the maximum allowed pressure computation.

Distance Down to Top Wind Girder

Defines the distance from the top of the tank shell to the location of the top wind girder.

If the top wind girder is at the top of the shell, type 0.

If the top wind girder is below the top of the tank, such as for a walk-way, type the actual

distance.

If you specify a value of greater than 0.01, the software shows the wind girder

on the 3D model. The software displays intermediate wind girders, when applicable,

after analysis on the model and in the Wind, Material, Thickness & Weights report.

Joint Efficiency (API 620, API 650 App A or 653 [E]

According to Appendix A.3.4, the joint efficiency should be either 0.85 or 0.70. API-653

Section 2.3.3 also uses this value of joint efficiency. No other computations use this value,

so the default of 1.0 can be left alone for variable point and one foot API-650 calculations.

According to API-620, the joint efficiency ranges from 0.35 to 1.0. Use Table 5-2 to

determine the appropriate joint efficiency value for your tank design.

API-653 2nd Edition provides Table 2-1 for weld joint efficiencies if the original E value is

unknown. This table is reproduced as follows:

Standard Edition & Joint Type Joint Efficiency Applicability or

Year E Limits

API-650 7th & Later Butt 1.00 Basic Standard

(1980-Presen Butt 0.85 Appendix A - Spot

t) RT

Butt 0.70 Appendix A - No RT

1st - 6th Butt 0.85 Basic Standard

(1961-1978) Butt 1.00 Appendices D&G

API-12C 14th & 15th Butt 0.85

(1957-1958)

3rd-13th Lap (a) 0.75 3/8 inch max t

(1940-1956)

Butt (c) 0.85

1st & 2nd Lap (a) 0.70 7/16 inch max t

(1936-1939)

Lap (b) 0.50 + k/5 1/4 inch max t

Butt (c) 0.85

TANK User's Guide 20

TANK Interface

Standard Edition & Joint Type Joint Efficiency Applicability or

Year E Limits

Unknow Lap (a) 0.70 7/16 inch max t

n

Lap (b) 0.50 + k/5 1/4 inch max t

Butt (c) 0.85

Lap (d) 0.35

(a) Full double lap welded.

(b) Full fillet weld with at least 25% intermittent full fillet opposite side:

k = percent of intermittent weld expressed in decimal form.

(c) Single butt-welded joints with a back-up bar were permitted from the

years of 1936 to 1940 and 1948 to 1954.

(d) Single lap welded only.

Wind Velocity

Defines the wind velocity acting on the tank. You should follow Section 5.9.7.1a. The

standard is a 120 mile per hour (53.6 m/sec) wind but may be increased to account for

additional tank height, wind gust, internal pressure, or open-top tanks.

Several configuration settings control how the wind pressure is computed and applied to the

tank. These configuration settings are as follows:

Roof Projection in Wind Moment - Turns on and off wind loads on the roof.

10% Plus 5psf in Wind Moment - Defines the basic wind moment definition according

to Section 5.9.7.

Section 5.11 Wind Pressure - Defines the wind pressure to be used for Section 5.11

stability.

Internal Pressure Combination Factor [Fp]

Defines the ratio of the normal operating pressure to the design pressure. The value of Fp is

used in Appendix R and Section 5.11 of the API 650 Code.

The minimum value of Fp is 0.4. Values lower than 0.4 are automatically set to 0.4.

The maximum value of Fp is 1.0. Values higher than 1 are automatically set to 1.

If your tank has zero internal design pressure, enter a value of 0.4 for Fp.

Default Shell Course Material

Defines the default material name for all individual shell courses.

Click the ellipsis to the right of the box to display the Database option or View

Properties option.

Click Database to display the Material Selection Dialog Box (on page 25) dialog box.

TANK User's Guide 21

TANK Interface

From the dialog box, you can select any valid material from the active database. Click Tools

> Configuration > Database Definitions (on page 83) to select or change the active

material database file.

Click View Properties to display the Material Properties Dialog Box (on page 23) dialog

box. The material data specified on the dialog box pertains to the entire tank. If the material

varies over the shell courses, you must specify the change on the Shell Courses Tab (on

page 25).

Number of Shell Courses

Defines the number of shell courses in the tank. Use this box to check the shell course input

and control the shell course generation, if necessary.

Insulation Thickness

Defines the thickness of the insulation on the tank shell. The insulation is assumed to extend

from the bottom of course #1 to the top of the last (top) course.

Insulation Density

Defines the density of the tank insulation.

Plate Length

Defines the length of the plate for the tank.

The software uses this input for the 3D plot only.

Course Offset

Defines the offset distance of the weld between the plates.

The software uses this input for the 3D plot only.

The following graphic explains the course offset in relation to the plate length.

Include Annular Base Plate Details

Defines whether the tank has an annular base ring. If the tank does not have an annular

base ring, do not select this check box.

Include Wind Moment in Appendix F.4.2 Calculations

Defines whether a wind moment term is included. As of API-650 9th Edition, the equation for

TANK User's Guide 22

TANK Interface

the maximum allowed pressure in Section F.4.2 includes a wind moment term. A later code

interpretation makes the use of this wind moment term optional.

To include the wind moment term, select this check box. Clear this check box to ignore the

wind moment term (as in the 8th Edition).

Minimum Yield Strength of Bottom Plate

Defines the minimum yield strength of the bottom plate.

External Pressure Combination Factor [Fpe]

Defines the ratio of the normal operating external pressure to the design external pressure.

The value of Fpe is used in Appendix R and Section 5.11 of the API 650 Code.

The minimum value of Fpe is 0.4. Values lower than 0.4 are automatically set to 0.4.

The maximum value of Fpe is 1.0. Values higher than 1 are automatically set to 1.

If your tank has zero external design pressure, enter 0.4 for Fpe.

Entire Shell Course Evaluation

Defines whether the shell thickness calculation is for the entire shell course according to

API-653 Section 4.3.3.1. This selection uses equation 4.3.3.1.a, which deducts one foot

from the fluid height.

This deduction only occurs if the one-foot method is in use.

The software only displays this box when you select 653 in the API Design Code box at

the top of the Tank Data tab.

Local Area of Shell Only

Specifies whether the shell thickness calculation is for a local area of the shell course,

according to API-653 Section 4.3.3.1. This selection uses equation 4.3.3.1.b, which does not

deduct one foot from the fluid height.

The software only displays this box when you select 653 in the API Design Code

box at the top of the Tank Data tab.

Material Properties Dialog Box

The Material Properties dialog box (shown below) displays property specifications for the

selected material. The default values for each material property are taken from the material's

corresponding standard and are compiled in the material database.

The properties for each material can be modified, although doing so only changes the properties

locally. Changing the material properties does not modify the database.

TANK User's Guide 23

TANK Interface

For a list of the materials and their corresponding standards, see Appendix C (see "Appendix C -

List of Materials" on page 143).

Material Name

Type the name of the material. The software contains a database of materials taken from

various standards.

A list of the available materials and their corresponding standards can be found in Appendix

C (see "Appendix C - List of Materials" on page 143).

Design Stress [Sd or Sts]

Type the yield stress for the material at the operating temperature.

Hydro Test Stress [St]

Type the allowable stress to use during the hydro test condition.

Minimum Yield Strength

Enter the yield stress as a function of temperature.

Minimum Tensile Stress

Type the tensile strength designated in the material specification.

Maximum Allowable Tensile Stress

Type the maximum allowable tensile stress of the material.

Maximum Thickness

Type the thickness limit for which the stresses apply.

Material Grade

Type the grade of the material. This specification is taken from the material's corresponding

standard.

Material Group

Type the group of the material. This specification is taken from the material's corresponding

standard.

TANK User's Guide 24

TANK Interface

Material Selection Dialog Box

Displays materials and material properties. Select the needed material. To modify material

properties, click the ellipsis in the material selection field. Then, select Edit Properties.

Material Search String - Type part of the material name to search against.

Find Next Matl - Click to go to the next matching material name available.

Cancel - Exit the dialog box without selecting a material.

Click Tools > Configuration > Database Definitions (on page 83) to select or

change the active material database file.

Shell Courses Tab

The material and its properties that are specified on the Tank Data tab display as the default

values for the shell courses on the Shell Courses tab. The Shell Courses tab displays a grid

where the height, thickness, corrosion allowance, material name, material design stress, and

material test stress can be specified for each shell course.

The design and test stress values for the specified material are normally acquired from the

Material Database. Initially, all courses acquire the same material, as specified on the Tank

Data tab. However, as necessary, specific shell courses may be assigned a different

material, or the material for specific courses may be manually modified by the user. If any

modifications are made to the default material on the Tank Data tab, all the shell courses

subsequently reacquire the default material specifications.

For carbon steels from Table 3-2, the software fills in the Sd and St values. For stainless

steels, the value used for Sd is unknown until run-time. Therefore, for stainless materials,

the allowable versus temperature table displays in the right-most grid columns of this dialog.

For stainless materials, the value of Sd (on this dialog) is shown as zero. The actual value

used in the calculations is reported in the output.

Height

Defines the height for the current shell course in the specified units. The sum of all shell

course heights should equal the tank shell height entered previously.

If it is constant, the shell course height does not need to be specified for any course

after the first course.

TANK User's Guide 25

TANK Interface

If this cell is left blank, the software duplicates the shell course height to all required

courses.

Thickness

Specifies the thickness for the current shell course. If the purpose of this job is to design the

shell course thickness, then enter a good starting value (see API-650 5.6.1.1). If this cell is

left blank for the first course, the software sets the thickness according to API-650 Table

5.6.1.1.

If it is constant, the shell course height does not need to be specified for any course

after the first course.

If this cell is left blank, the software duplicates the shell course height to all required

courses.

Corrosion Allowance

Defines the corrosion allowance to be considered in the thickness evaluations for shell

course.

If it is constant, the shell course height does not need to be specified for any course

after the first course.

If this cell is left blank, the software duplicates the shell course height to all required

courses.

Material

Displays the material name that you selected for the shell course on the Tank Data tab.

To edit or view the material properties for the selected shell course, click the ellipsis to

the right of the box. Then, select Edit Properties to open the Material Properties Dialog

Box (on page 23) dialog box.

To change the material for the selected shell course, click the ellipsis to the right of the

blank box. Then, select Database to open the Material Selection Dialog Box (on page 25)

dialog box, from which you can click to select a new material.

Design Stress, Sd

Represents the allowable design stress, referred to as Sd in the API code. This value is

automatically registered by the software if the material was selected from the database.

If necessary, the value of design allowable stress obtained from the database may be

overridden by typing in a different value.

For stainless steels, this value is displayed as zero, since a temperature versus

allowable table is used instead.

Hydro Test Stress, St

Represents the allowable test stress, referred to as St in the API code. This value is

automatically registered by the software if the material was selected from the database.

If necessary, the value of test allowable stress obtained from the database may be

overridden by typing in a different value.

SSD1 through SSD5

TANK User's Guide 26

TANK Interface

Represents the allowable stress for a stainless steel according to API-650 Appendix S,

Table S-2. These values are used during the computation phase of the solution to determine

the actual Sd value.

For stainless steels, these values are interpolated during the solution phase. For this

reason, the value of Sd (at the left) is displayed as 0.

Wind Details Tab

Provides options for defining detailed wind parameters specific to ASCE #7.

If these values are not defined, TANK uses the recommended API 650 defaults.

Velocity pressure exposure coefficient (Kz)

Specifies the velocity pressure coefficient as defined by ASCE #7. If left blank, the value

defaults to 1.04.

Topographic Factor (Kzt)

Defines the wind speed up factor for hills. This value should be 1.0 (the default) except for

those structures on isolated hills or escarpments.

Wind Directionality Factor (Kd)

Defines the wind directionality factor. API 650 recommends a value of 0.95, the default for

this option.

Importance Factor (I)

Specifies the wind importance factor as defined by ASCE #7. If left blank, the value defaults

to 1.0.

Gust Effect Factor (Gh)

Specifies the wind gust factor as defined by ASCE #7. If left blank, the value defaults to

0.85.

User defined Wind Pressure vs. Elevation

Defines whether you want to enter wind pressure and "To" Height (elevation) values.

"To" Height

Defines the elevation.

Pressure

Defines the pressure.

TANK User's Guide 27

TANK Interface

Anchor Bolt and Gusset Details Tab

The Anchor Bolt and Gusset Details tab contains the following information:

Anchor Bolt Data

Gusset and Top Plate Input (Anchor Chairs)

Anchor Bolt Data

Anchor Bolt Diameter (optional) (d)

Defines the bolt diameter of an existing anchorage. This is an optional value.

Threads per Unit Length

The software can either evaluate a user-specified design or design an anchorage according

to API-650 Section 5.12. In order to size the anchor bolts, the thread pitch is necessary. The

pitch is the reciprocal of the parameter known as threads per inch.

Type the threads per inch in the appropriate units. This is a required entry used in the event

that the software must design an anchorage. Typical threads per inch for various size UNC

bolts are listed in the following table:

Basic Major Diameter Threads per Inch

(in)

0.5000 13

0.6250 11

0.7500 10

TANK User's Guide 28

TANK Interface

Basic Major Diameter Threads per Inch

(in)

0.8750 9

1.0000 8

1.1250 7

1.2500 7

1.3750 6

1.5000 6

1.7500 5

2.0000 4.5

2.2500 4.5

2.5000 4

2.7500 4

3.0000 4

3.2500 4

3.5000 4

3.7500 4

4.0000 4

Number of Anchor Bolts (optional)

Defines the number of anchor bolts for evaluation of an existing anchorage. If the software

redesigns the anchorage, the number of bolts will be a multiple of the bolt increment

specified in the configuration.

Bolt Yield Stress

Defines the yield stress of the anchor bolts for use in Section 5.12. This is a required entry

that is used in the event that the software must design an anchorage.

Bolt Offset from Mean Tank Diameter

Defines the offset from the mean tank diameter to the anchor bolt circle. This value must be

greater than zero for bolt circles outside the tank. If this value is left blank, an offset of 0.0 is

used.

The software internally multiplies this value by 2.0 before adding it to the tank

TANK User's Guide 29

TANK Interface

diameter value.

Anchor Bolt Corrosion Allowance

Defines the value of the corrosion allowance to be considered when sizing the anchor bolts.

Previous versions of API-650, Section F.7.4, required a corrosion allowance of at

least 0.25 inches.

Gusset and Top Plate Input (Anchor Chairs)

Evaluate Anchor Chair Assembly?

Activates anchor chair assembly inputs so you can specify details for this anchor bolt.

If you select this check box, then the software activates the inputs below this section of

the dialog box. Selecting this checkbox lets you evaluate the chair assembly using

standards from the AISI document, Steel Plate Engineering Data, Volume 1: Steel

Tanks for Liquid Storage (Revised Edition 1992).

If you clear this check box, the software disables anchor chair assembly inputs and

does not evaluate the anchor bolt assembly.

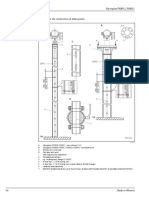

Height of Gussets (hg)

Defines the height of the gussets.

Refer to the figure on the right side of the dialog box for a diagram explaining the value of

[hg].

Gusset Plate Thickness

Enter the gusset plate thickness.

Refer to the figure on the right side of the dialog box for the value of [j].

Distance between Gussets (g)

Defines the distance between gussets.

Refer to the figure on the right side of the dialog box for the value of [g].

Width at top of Gussets (twdt)

Defines the width at the top of the gussets.

Refer to the figure on the right side of the dialog box for the value of [twdt].

Width at base of Gussets (bwdt)

Defines the width at the base of the gussets.

Refer to the figure on the right side of the dialog box for the value of [bwdt].

Top Plate Thickness (c)

Defines the top plate thickness.

Refer to the figure on the right side of the dialog box for the value of [c].

Top Plate Circumferential Width (a)

Defines the top plate circumferential width.

Refer to the figure on the right side of the dialog box for the value of [a].

Top Plate Radial Width (b)

TANK User's Guide 30

TANK Interface

Defines the top plate radial width.

Refer to the figure on the right side of the dialog box for the value of [b].

Corrosion Allowance on Chairs (Ca)

Defines the corrosion allowance needed for anchor chairs. API 650 specifies that the

corrosion allowance specified on a tank does not apply to external attachments, such as

chairs, unless they are specified separately.

Allowable Tensile Stress of Plates (S)

Defines the allowable tensile stress of plates.

Seismic Data Specifications

Home tab: Input > Seismic Data Specifications

Allows you to specify seismic (earthquake) parameters. This dialog box is optional for tank input.

The Seismic Data dialog box contains the following input fields:

Minimum Yield Strength of Weld Material

Defines the minimum yield strength of the weld material.

Seismic Use Group

Specifies the Seismic Use Group for the tank. See API-650 Section E.3.1 for details on the

various SUG categories. Valid entries for this field are 1, 2, or 3 (corresponding to SUG

groups I, II, and III).

Friction Factor

Specifies the friction factor used to determine tank sliding in API-650 Section E.7.6. API

limits the maximum value of this friction factor to 0.4.

Importance Factor

Specifies the API importance factor for seismic analysis. Usually, this value is 1.0, unless

TANK User's Guide 31

TANK Interface

specified otherwise by the purchaser. API recommends that this value not exceed 1.5.

Table E.5 - Importance Factor (I) and Seismic Use Group Classification

Seismic Use Group I

I 1.0

II 1.25

III 1.5

Initial Anchorage Type

Defines the initial anchorage type as either Self or Mechanical (bolts).

Even if you specify a self-anchored tank, the requirements of the Code may be

such that anchor bolts are required. In this instance, the software will design bolting.

Earthquake Type

Defines the earthquake type as either Mapped or Site Specific. For more information about

earthquake types, refer to API-650 Sections E.4.2 and E.4.3.

Site Class

Defines the seismic site class according to Section E.4.6. Valid choices are A through F,

where F represents soils that require site-specific evaluations.

Spectral Acceleration Adjustment Coefficient (K)

Defines the spectral acceleration adjustment coefficient (K). This coefficient is used to adjust

the spectral acceleration from 5% to 0.5% damping. If no value is specified, the coefficient

defaults to 1.5.

Scaling Factor (Q)

Defines the scaling factor from the maximum considered earthquake (MCE) to the design

level spectral accelerations. The value of Q is 2/3 for ASCE #7.

Transitional Period (TL)

Defines the regional-dependent transition period for longer period ground motion, in

seconds. Unless otherwise specified, Transitional Period is taken as the mapped value

found in ASCE #7.

Mapped Max Earthquake Short Period (Ss)

Defines Ss, which is the mapped maximum considered earthquake, 5% damped, spectral

response acceleration parameter at short periods (0.2s), %g.

Mapped Max Earthquake 1-sec. Period (S1)

Defines S1, which is the mapped maximum considered earthquake, 5% damped, spectral

response acceleration parameter at a period of one second, %g.

Mapped Max Earthquake 0-sec. Period (S0)

Defines S0, which is the mapped maximum considered earthquake, 5% damped, spectral

response acceleration parameter at a period of zero seconds (peak ground acceleration for

a rigid structure), %g.

TANK User's Guide 32

TANK Interface

Peak Ground Acceleration for Non-ASCE (Sp)

Defines SP, which is the design level peak ground acceleration parameter for sites not

addressed by ASCE methods.

Design Acceleration Parameter at Short Periods for ASCE Methods (Sds)

Defines SDS, which is the design, 5% damped, spectral response acceleration parameter at

short periods (T = 0.2 seconds) based on ASCE 7 methods, %g.

Spectral Acceleration Parameter at Zero Period (Sa0*)

Defines Sa0*, which is the 5% damped, design spectral response acceleration parameter at

zero period based on site-specific procedures, %g.

Spectral Acceleration Parameter at Any Period (Sa*)

Defines Sa*, which is the 5% damped, design spectral response acceleration parameter at

any period based on site-specific procedures, %g.

Nozzle Stiffnesses

Home tab: Input > Nozzle Stiffness

TANK User's Guide 33

TANK Interface

Allows you to specify up to fifteen low tank nozzles. The data specification can include external

piping loads from a pipe stress analysis, if available.

When you select 650 as the API Design Code in General Tank Data (on page 17), the

software uses the data acquired from this dialog box to implement the rules of API 650,

Appendix P.

When you select 620 as the API Design Code in General Tank Data (on page 17), an

additional API 620 Specific Data section displays, and the the software uses the data

acquired from this dialog box to implement the rules of API 620.

When the tank temperature value in General Tank Data (on page 17) is changed, the

software updates the Modulus of Elasticity and Expansion Coefficient values

automatically. These values are obtained by interpolating the data provided in Table P-1 of

API 650.

If you check Use PVP-1279, TANK uses an alternate method to compute the nozzle

stiffnesses. This alternate procedure is detailed in PVP-1279 and is valid for smaller tanks.

Nozzle Designation / Number

Defines a descriptive tag or number of the current nozzle. This cell is restricted to four

characters and can contain letters and/or digits. Example entries for this cell are:

NZ1 NA0A

NZ2 PGLG

TANK User's Guide 34

TANK Interface

NZ3

Nozzle Height above Bottom Plate

Defines the height of the nozzle centerline above the bottom plate.

Nozzle Outer Diameter

Defines the outer diameter of the nozzle.

Delta Temperature

Defines the difference between the normal operating temperature and the installation

temperature.

Modulus of Elasticity

Defines the modulus of elasticity. These values should be taken from API-650 Table P-1,

reproduced as follows:

Design Temp (deg F) Modulus (psi) Thermal Expansion (in/in/deg F)

70 29.5E6 -

200 28.8E6 6.67E-6

300 28.3E6 6.87E-6

400 27.7E6 7.07E-6

500 27.3E6 7.25E-6

The value of elastic modulus is automatically defined by the software when you change the

design temperature on the general spreadsheet. You can change this value, if necessary.

If the bottom shell course is specified as Stainless Steel, then the modulus value for Table

P-1 is not used. Instead, the modulus value is obtained from Table S-6:

Design Temp (deg F) Modulus (psi)

100. 28.0E6

200. 27.4E6

300. 26.6E6

400. 26.1E6

500. 25.2E6

Expansion Coefficient

Defines the value of the thermal expansion coefficient. These values should be taken from

API-650 Table P-1and are reproduced as follows:

TANK User's Guide 35

TANK Interface

Design Temp (deg F) Modulus (psi) Thermal Expansion (in/in/deg F)

70. 29.5E6 -

200. 28.8E6 6.67E-6

300. 28.3E6 6.87E-6

400. 27.7E6 7.07E-6

500. 27.3E6 7.25E-6

Design Temp (deg C) Modulus (MPa) Thermal Expansion (mm/mm/deg C)

20. 203000 -

90. 199000 12.0

150. 195000 12.4

200. 191000 12.7

260. 188000 13.1

The value of expansion coefficient is automatically defined by the software (using internal,

English, units) when you change the design temperature on the general spreadsheet. You

can change this value, if necessary.