Professional Documents

Culture Documents

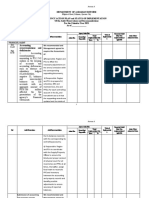

Corrective Actions Follow-Up Report: Vessel Name PMS Subject Marine Survey Inspected by ENG.: CAP.: Port Date Conclusion

Uploaded by

Eagle EyeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corrective Actions Follow-Up Report: Vessel Name PMS Subject Marine Survey Inspected by ENG.: CAP.: Port Date Conclusion

Uploaded by

Eagle EyeCopyright:

Available Formats

Petroleu

تقرير متابعة الجإراءات التصحيحية m Marine

Services

Corrective Actions follow-up Report Company

Vessel Name PMS 46

Subject Internal Seaway marine survey

Inspected by ENG.: CAP.: Stefan Luckau

Port Date 15.01.2019

Conclusion

No. Deficiency Issue Date Short Description of Deficiency or the required Action Corrective Action by Target Date Completed? Remarks

Level تاربخ الصإدار وصإف مختصإر للخلل أو الجإراء المطلوب /Implementation التاريخ هل إستكمل؟ ملحظات

Action المسئول عن الجإراء المستهدف

/ الجإراء التصإحيحى

التنفيذى

1 15.01.2019 Present Class period expires in May 2019. To All department

prepare Class renewal a 40-day-dry-docking of

the barge is planned. A list of the planned jobs is

attached. Renewal needs to be completed prior

chartering. Neither ballast water record book nor

oil record book are maintained. Certificates for

Insurance (hull and machinery as well as P & I)

were expired. Mr. Hassan declared valid

insurance certification will be presented on

15.01.2019 (this report will be updated

accordingly). Mr. Hassan also declared that a new

oil record book will be implemented and

maintained.

15.01.2019 Bridle recovery winch was dismantled. Therefore, Maintenance

2 it was not possible to lift and inspect main towing Dep.

arrangement (bridle was lowered to seabed) .

New Recovery winch to be installed. Towing

arrangement should be to re-inspected by SHL

after Class renewal. Installation of emergency

towing wire was partly improvised. The wire

hung partly in lose slings and was secured only by

Page 1 of 3 Revision No.: 01 09/2018 OPM 12-A2

Petroleu

تقرير متابعة الجإراءات التصحيحية m Marine

Services

Corrective Actions follow-up Report Company

textile ropes. Emergency towing wire to be

dismantled, cleaned and inspected and re-

installed to repaired holders. Messenger line

connection to the emergency wire was done only

by knots (no shackle). Messenger line only abt.

10 m long. Messenger line was worn.

Arrangement of Messenger line and floating ball

to be renewed.

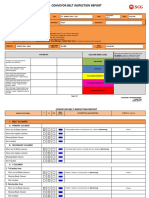

15.01.2019 Deck plating showed several heavy indents as All department

3 well as a lot of welding remnants from former

installations. Deck plating to be repaired and

cleaned properly. Nearly every hatch cover of the

ballast tank needs maintenance or repair

(gaskets, closing mechanism). All 4 Life buoys

with line and light need to be renewed, including

marking of barge name. Hand railing to be

completely renewed. Mast for day shapes to be

installed. Double bollard on starboard aft to be

repaired (and certified afterwards)

4 15.01.2019 Ballast tanks were not completely empty and not All department

measured gas free. Therefore, it was only

possible to inspect two tanks from above. So far

as visible tank internals showed only a moderate

amount of corrosion and no damage. Piping was

not visible. Tanks to be pressure tested during

Class renewal.

5 15.01.2019 Side shell with several, partly serious All department

indentations. Fender piping on both sides heavily

worn and partly destroyed (especially on port

side). Fender tires also heavily worn and to be

dismantled or renewed. Painting of draft marks

was gone especially at wet areas. Draft marking

not readable. Wet areas showed a huge amount

of marine growth. Side shell and bottom plating

Page 2 of 3 Revision No.: 01 09/2018 OPM 12-A2

Petroleu

تقرير متابعة الجإراءات التصحيحية m Marine

Services

Corrective Actions follow-up Report Company

to be detailed inspected during Class renewal.

Repair works to be done as demanded by class.

Reviewing of detailed class survey statements as

well as thickness measurement report by SHL is

highly recommended. Antifouling to be renewed.

6 15.01.2019 Pump room arrangement with 2 engines. One is Maintenance

driving ballast pump No. 1 and hydraulics for Dep.

anchor winch. The other one is driving ballast

pump. Both engines were Detroit Diesel two-

cylinder-engines. Both engines were running.

Electrical arrangement of both was improvised.

Exhaust of engine No. 2 was leaky. Exhaust was

clearly able to smell after starting the engine.

Wire of the quick closing valve was cut. At the

bilge as well as underneath the engines an

amount of abt. 10 cm oily water has been

detected. Electrical installation (especially lights)

was partly improvised. Manually operated

butterfly valves of the ballast water system were

in good shape. Housekeeping in the pump room

was generally poor. Both engines to be inspected

and mechanical maintained during class renewal.

Exhaust of engine No. 2 to be repaired. Quick

closing valve to be repaired. Electrical installation

to be inspected and repaired. Pump room to be

cleaned.

Prepared / checked by: …………………………………………… Date of last updating تاريخ أخر تحديث للتقرير

21-1-2019

Signature

Page 3 of 3 Revision No.: 01 09/2018 OPM 12-A2

You might also like

- NMLC Course TimetableDocument12 pagesNMLC Course TimetableEnong Mannie VasquezNo ratings yet

- Abandon Ship Drill ReportDocument6 pagesAbandon Ship Drill Reportmonica matualageNo ratings yet

- Report Part A Container Sample 1 - CompressedDocument22 pagesReport Part A Container Sample 1 - CompressedMohamed OmarNo ratings yet

- 4.D-017C Oil Spill Drill Report Rev 0Document3 pages4.D-017C Oil Spill Drill Report Rev 0Bataklanden MusicNo ratings yet

- F-REV-01a Minutes of The Meeting - Rev 0Document3 pagesF-REV-01a Minutes of The Meeting - Rev 0Kadesh Hanah McCarthyNo ratings yet

- Aapsi 2021Document29 pagesAapsi 2021Moda ArgonaNo ratings yet

- Shell Marine Terminal Inspection Report - MTP Batu Licin 23 Aug 19Document10 pagesShell Marine Terminal Inspection Report - MTP Batu Licin 23 Aug 19muh_akbar2451No ratings yet

- Presentation - Lenders VisitDocument5 pagesPresentation - Lenders VisitPTJ HSENo ratings yet

- Inspection at 150 Flight HoursDocument4 pagesInspection at 150 Flight HoursSiswadiNo ratings yet

- 1. GI01-04 三副交接班报告 THIRD OFFICER DUTY HAND OVER STATEMENTDocument4 pages1. GI01-04 三副交接班报告 THIRD OFFICER DUTY HAND OVER STATEMENTnewindonesiabagsNo ratings yet

- Miscellaneous Circular 2022 001 Rev 1 Preparation For Port State Control Inspections 1Document3 pagesMiscellaneous Circular 2022 001 Rev 1 Preparation For Port State Control Inspections 1ΑΝΝΑ ΒΛΑΣΣΟΠΟΥΛΟΥNo ratings yet

- Lifting & Rigging Procedure For PipingDocument13 pagesLifting & Rigging Procedure For PipingikramNo ratings yet

- Vos Challenge - ATR of OVID Inspection Updated On 16.08.2023 - Office Comments UpdatedDocument3 pagesVos Challenge - ATR of OVID Inspection Updated On 16.08.2023 - Office Comments UpdatedLUU QUANG HOANo ratings yet

- PSC Newsletter Issue 3 (2010)Document4 pagesPSC Newsletter Issue 3 (2010)santoshNo ratings yet

- USACE - Dam Inspection Guideline ChecklistDocument23 pagesUSACE - Dam Inspection Guideline ChecklistRaffaele MarinoNo ratings yet

- Jan 15,2020 CMR Covered For July 15,2019 To Dec 15,2019Document6 pagesJan 15,2020 CMR Covered For July 15,2019 To Dec 15,2019Romantic BeachNo ratings yet

- Sa 05-44Document3 pagesSa 05-44Shangril ChaitanyaNo ratings yet

- Operations Operations Operations Operations Manual Manual Manual ManualDocument6 pagesOperations Operations Operations Operations Manual Manual Manual ManualSarah BautistaNo ratings yet

- Trex 47221Document48 pagesTrex 47221OSDocs2012No ratings yet

- Checklist Audit Ism Kapal EngDocument11 pagesChecklist Audit Ism Kapal EngAji ArnowoNo ratings yet

- Chapter 15Document2 pagesChapter 15Al UcupNo ratings yet

- TO Amega West Services: A Carpenter CompanyDocument34 pagesTO Amega West Services: A Carpenter CompanyKamatchiNo ratings yet

- MC02-1-07 - HydrantDocument2 pagesMC02-1-07 - HydrantBAHARUDIN BURAHNo ratings yet

- Later ReleasedDocument2 pagesLater ReleasedJuvelyn LugatimanNo ratings yet

- VIQ Bulletin From 1 To 17Document39 pagesVIQ Bulletin From 1 To 17Cristel_DCNo ratings yet

- Issue 1 Inspectors Newsletter 4Document4 pagesIssue 1 Inspectors Newsletter 4DeepakNo ratings yet

- L2 Risk Assessment Leakage HVAC Ducting Rectification - PlanDocument5 pagesL2 Risk Assessment Leakage HVAC Ducting Rectification - PlanHaris Risdiana100% (2)

- Weekly 1/G1J06 OkDocument9 pagesWeekly 1/G1J06 OkWisnu NugrahaNo ratings yet

- MSI Pulse Volume1 2018Document8 pagesMSI Pulse Volume1 2018DeepakNo ratings yet

- April 2019 Monthly Progress ReportDocument1 pageApril 2019 Monthly Progress ReportJazzie ZabalaNo ratings yet

- M40105 - Air Conditioning, Air Curtain Unit Ver 2.0Document2 pagesM40105 - Air Conditioning, Air Curtain Unit Ver 2.0Samawi Muhammad0% (1)

- Crw-F-23a Map - Master r01Document9 pagesCrw-F-23a Map - Master r01GAMERS HUBNo ratings yet

- Environmental Aspects & Impacts Register 2023Document7 pagesEnvironmental Aspects & Impacts Register 2023Tamara Johnson-PariagNo ratings yet

- Risk Assessment KURA WEST XINGDocument14 pagesRisk Assessment KURA WEST XINGMamuka ShaorshadzeNo ratings yet

- 10-06-2019 11 02 59 - Khac Phuc Khuyen Cao Cua FAADocument7 pages10-06-2019 11 02 59 - Khac Phuc Khuyen Cao Cua FAAhungphanNo ratings yet

- Annex 3-1 Pro-Forma Proponent Compliance Monitoring Report (CMR) Semi-Annual Module 5 of SMRDocument7 pagesAnnex 3-1 Pro-Forma Proponent Compliance Monitoring Report (CMR) Semi-Annual Module 5 of SMRAngge JavierNo ratings yet

- Jib Crane Inspection Report 04-1005198 - J1610644 - NQ5643 - PDFDocument3 pagesJib Crane Inspection Report 04-1005198 - J1610644 - NQ5643 - PDFAnonymous N2Se0bYNo ratings yet

- Trip and Alarm Change Procedure: Suez Oil CompanyDocument5 pagesTrip and Alarm Change Procedure: Suez Oil Companyeng20072007No ratings yet

- TRA For ScaffoldingDocument3 pagesTRA For Scaffoldingaparna_losariNo ratings yet

- 2021 PSC Case Study - Tokyo MoU, Paris MoU, USCGDocument23 pages2021 PSC Case Study - Tokyo MoU, Paris MoU, USCGCharalampos Chatzivasileiou100% (1)

- Safeguard - January 2022Document15 pagesSafeguard - January 2022ishaqNo ratings yet

- PPC Corrective and Preventive Action PDFDocument5 pagesPPC Corrective and Preventive Action PDFRajesh RoutrayNo ratings yet

- Manuel LO2.2 EWATCH-Contingency PlanDocument11 pagesManuel LO2.2 EWATCH-Contingency PlanAngelo ZarrudoNo ratings yet

- Thai Maintenance - Moe Rev.06Document118 pagesThai Maintenance - Moe Rev.06MikeNo ratings yet

- Risk Assessment For Installation of Water Supply PipeDocument18 pagesRisk Assessment For Installation of Water Supply PipeAnandu Ashokan89% (27)

- Checklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Condensate Extraction PumpsDocument1 pageChecklists Title: Checklist For Preventive Maintenance of Equipments TG & Bop Maintenance Department Condensate Extraction Pumpsjp mishraNo ratings yet

- VT 551Document108 pagesVT 551Mohamed HarbNo ratings yet

- ER Responsibility Matrix (RACI) (PDFDrive)Document27 pagesER Responsibility Matrix (RACI) (PDFDrive)le thanhNo ratings yet

- 1.0 ResponsibilitiesDocument10 pages1.0 ResponsibilitiesHasan Cosalev100% (1)

- SI 120-02 Amdt. 2 Auditing and Surveillance Procedures of AiDocument61 pagesSI 120-02 Amdt. 2 Auditing and Surveillance Procedures of AiDjunatiara FadaNo ratings yet

- Application For Waiver of Pressure Test: Appendix 2Document1 pageApplication For Waiver of Pressure Test: Appendix 2Natarajan MurugesanNo ratings yet

- Harwinder Singh Gill: CertificationsDocument1 pageHarwinder Singh Gill: CertificationsIssac JohnNo ratings yet

- MSD 252 Safety Inspection FormDocument11 pagesMSD 252 Safety Inspection FormNitin GoyalNo ratings yet

- SEL HSE P 004 Attachment 1 Generic Envrionmental Aspects Register Rev03Document8 pagesSEL HSE P 004 Attachment 1 Generic Envrionmental Aspects Register Rev03tyoNo ratings yet

- 16-022 PSC DeficienciesDocument3 pages16-022 PSC Deficiencieskristi lakNo ratings yet

- Ummary Flowchart: Pollution PreventionDocument2 pagesUmmary Flowchart: Pollution Preventionedward snowden100% (1)

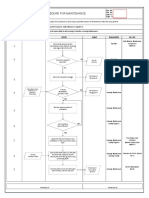

- Procedure For MaintenanceDocument2 pagesProcedure For MaintenanceAnmol ChetriNo ratings yet

- Repair and Maintenance ProcedureDocument5 pagesRepair and Maintenance Proceduremacky PanuelosNo ratings yet

- Mohamed Farag Saber: Acad Training & ConsultingDocument1 pageMohamed Farag Saber: Acad Training & ConsultingEagle EyeNo ratings yet

- ProfileDocument1 pageProfileEagle EyeNo ratings yet

- Nurminen JussiDocument40 pagesNurminen JussiEagle EyeNo ratings yet

- White and Gold Elegant Completion Certificate PDFDocument1 pageWhite and Gold Elegant Completion Certificate PDFEagle EyeNo ratings yet

- GenconDocument7 pagesGenconvi leNo ratings yet

- Egypt Energy MonitorDocument1 pageEgypt Energy MonitorEagle EyeNo ratings yet

- Check List - Q1Document1 pageCheck List - Q1Eagle EyeNo ratings yet

- HLO - Helicopter Landing Officer UKDocument3 pagesHLO - Helicopter Landing Officer UKEagle EyeNo ratings yet

- Mission Report Tunis December2013Document13 pagesMission Report Tunis December2013Eagle EyeNo ratings yet

- En-Ar Translation (202302116)Document5 pagesEn-Ar Translation (202302116)Eagle EyeNo ratings yet

- #101 - Oilfield HSE Inspection HandbookDocument30 pages#101 - Oilfield HSE Inspection HandbookEagle EyeNo ratings yet

- AWB007 - Accommodation Work Barge PDFDocument2 pagesAWB007 - Accommodation Work Barge PDFEagle Eye0% (1)

- 2022-2023 HandbookDocument10 pages2022-2023 HandbookEagle EyeNo ratings yet

- Egypt Country Strategic Plan 20182023 1Document37 pagesEgypt Country Strategic Plan 20182023 1Eagle EyeNo ratings yet

- Ultra-Deep Water Port Feasibility Study: November 2018Document122 pagesUltra-Deep Water Port Feasibility Study: November 2018Eagle EyeNo ratings yet

- Cswip 3.1Document1 pageCswip 3.1Eagle EyeNo ratings yet

- Gantt Chart LDocument8 pagesGantt Chart LAshok PuttaparthyNo ratings yet

- Human Resource PhilosophyDocument2 pagesHuman Resource PhilosophyEagle EyeNo ratings yet

- Asd Wei Gang Tuo 10 PDFDocument2 pagesAsd Wei Gang Tuo 10 PDFEagle EyeNo ratings yet

- Gecf Secretariat Employment Application Form: Position DepartmentDocument4 pagesGecf Secretariat Employment Application Form: Position DepartmentEagle EyeNo ratings yet

- 08 KPI ToolsDocument9 pages08 KPI ToolsEagle EyeNo ratings yet

- 1Document2 pages1Eagle EyeNo ratings yet

- AbcsDocument2 pagesAbcsEagle EyeNo ratings yet

- Allianz Intrepid - Investigation ReportDocument11 pagesAllianz Intrepid - Investigation ReportHSE PULAI ANo ratings yet

- Neha JNPTDocument14 pagesNeha JNPTGaurav SinghNo ratings yet

- Nav WarnDocument7 pagesNav WarnPolaris BridgemanNo ratings yet

- Titanic Script With Name'sDocument5 pagesTitanic Script With Name'ssulNo ratings yet

- Ship Structural Design NotesDocument115 pagesShip Structural Design NotesMohamed100% (3)

- Rules For The Classification Naval Ships Part A - Classification and Surveys - Chapter 1 Al 5 - NR 483.A1 DT R01 E - 2011-11Document114 pagesRules For The Classification Naval Ships Part A - Classification and Surveys - Chapter 1 Al 5 - NR 483.A1 DT R01 E - 2011-11Marlon Alejandro Arboleda TapiaNo ratings yet

- Cruise IndustryDocument72 pagesCruise IndustrySheena Harrien100% (1)

- 5 Law 5102 MARITIME LIENSDocument25 pages5 Law 5102 MARITIME LIENSzin minNo ratings yet

- 53ft Traditional Narrow Boat For SaleDocument2 pages53ft Traditional Narrow Boat For SaleDominic Miles100% (1)

- Top 10 Master Mariner November 2010Document1 pageTop 10 Master Mariner November 2010Coolbuster.NetNo ratings yet

- Cap 6 - Apostolos Papanikolaou (Auth.) - Ship Design - Methodologies of Preliminary Design-Springer Netherlands (2014)Document9 pagesCap 6 - Apostolos Papanikolaou (Auth.) - Ship Design - Methodologies of Preliminary Design-Springer Netherlands (2014)Barbara OliveiraNo ratings yet

- Unit 4. The Lateral - Modified Lateral Marks Region A - B Features and Function and All MarksDocument8 pagesUnit 4. The Lateral - Modified Lateral Marks Region A - B Features and Function and All MarksZuri MpowerNo ratings yet

- 1 03 Ottobre 2015 Model Course On Advanced Training For Chemical Tanker Cargo Operations Secretariat PDFDocument149 pages1 03 Ottobre 2015 Model Course On Advanced Training For Chemical Tanker Cargo Operations Secretariat PDFbharatheeeyuduNo ratings yet

- USVDocument5 pagesUSVÖmer Faruk ÇinkoNo ratings yet

- Crew Change and SeaVaxDocument5 pagesCrew Change and SeaVaxKarthikeyan JagadeesanNo ratings yet

- Important Features of Muster List On ShipDocument4 pagesImportant Features of Muster List On ShipGiorgi Kandelaki100% (1)

- Port OperationsDocument15 pagesPort OperationsEkom AkonjomNo ratings yet

- G.S.C.C. Annual Report 2021-2022Document78 pagesG.S.C.C. Annual Report 2021-2022nikoulisNo ratings yet

- ISAS Insights: Economic Impact of Terrorism On The Southeast Asian RegionDocument10 pagesISAS Insights: Economic Impact of Terrorism On The Southeast Asian Regionazrulazlan89No ratings yet

- Pintail Duckboat Build LogDocument18 pagesPintail Duckboat Build LogecalzoNo ratings yet

- Apply Medical First Aid On Board ShipDocument22 pagesApply Medical First Aid On Board ShipAzka ChannelNo ratings yet

- Curriculum Vitae: I. Personal InformationDocument1 pageCurriculum Vitae: I. Personal InformationMichael MillenniumNo ratings yet

- 10 Simple Things That Make Seafarers Happy On Board ShipsDocument17 pages10 Simple Things That Make Seafarers Happy On Board ShipsvdevivNo ratings yet

- RsiDocument13 pagesRsiNicolòDallaCostaNo ratings yet

- Accreditation of Domestic Shipping Enterprises or Entities MC 2006 003 Central OfficeDocument15 pagesAccreditation of Domestic Shipping Enterprises or Entities MC 2006 003 Central OfficeKristal TagleNo ratings yet

- Introduction To The MSC GroupDocument60 pagesIntroduction To The MSC GroupElena SovaNo ratings yet

- Guide To Oil Spill Exercise Planning PDFDocument36 pagesGuide To Oil Spill Exercise Planning PDFYao WeiNo ratings yet

- John Deere Narrow Tractors 5400n 5500n Operators Manual Omlv62124Document23 pagesJohn Deere Narrow Tractors 5400n 5500n Operators Manual Omlv62124alexrichard010998ojr100% (121)

- Fifteen Thousand Miles On The AmazonDocument565 pagesFifteen Thousand Miles On The AmazonMarkNo ratings yet