Professional Documents

Culture Documents

Anemometer Calibration at Different Air Temperatures and Air Pressures - 2018 PDF

Anemometer Calibration at Different Air Temperatures and Air Pressures - 2018 PDF

Uploaded by

Big FloresOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Anemometer Calibration at Different Air Temperatures and Air Pressures - 2018 PDF

Anemometer Calibration at Different Air Temperatures and Air Pressures - 2018 PDF

Uploaded by

Big FloresCopyright:

Available Formats

Anemometer calibration at different

air temperatures and air pressures

Deutsche WindGuard Wind Tunnel Services GmbH

Oldenburger Str. 65

26316 Varel

Germany

Project No.: VT180259

Report No.: VT180259_01_Rev0

Report Date: 2018-03-02

VT180259_01_Rev0

Anemometer calibration at different air temperatures and air pressures

Company: Deutsche WindGuard

Wind Tunnel Services GmbH

Oldenburger Straße 65

26316 Varel

Germany

Telephone: +49 4451 95 15 0

Fax: +49 4451 95 15 29

E-Mail: D.Westermann@windguard.de

Project No.: VT180255

Report No.: VT180255_01_Rev0

Date of Report: 2018-03-02

Busche P., Dipl. Ing.

Authors:

May C., B. Eng.

Roß A., M. Sc.

Suhr J., M. Sc.

Westermann H., B. Sc.

Approved by: Dipl.-Phy. D. Westermann

Anemometer calibration at different air temperatures and air pressures Page 2 of 16

VT180259_01_Rev0

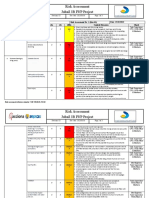

Revision History

Revision No. Date Status Amendment

Rev0 02.03.2018 1st issue

Note: The last revision replaces all previous versions of the report.

Anemometer calibration at different air temperatures and air pressures Page 3 of 16

VT180259_01_Rev0

Contents

1 Introduction 5

2 Former investigations on temperature induced effects onto the

anemometer output 6

3 Technical description of the variable air density wind tunnel 8

3.1 Measuring system 10

4 Calibration procedure 10

4.1 Calibration procedure for varying air temperatures 11

4.2 Calibration procedure for varying air pressures 11

5 Measurement uncertainty 12

6 Sample results 12

6.1 Calibration results for varying air temperatures 13

6.2 Calibration results for varying air pressures/air densities 14

7 Conclusion 15

8 References 16

Disclaimer:

We hereby state, that the results in this report are based upon generally acknowledged and state-of-the-art

methods and have been neutrally conducted to the best of our knowledge and belief. No guarantee, however, is

given and no responsibility is accepted by Deutsche WindGuard Wind Tunnel Services GmbH for the correctness

of the derived results. The work presented in this report complies with the present day valid standards and

guidelines and the corresponding quality management system of Deutsche WindGuard. Any partial duplication

of this report is allowed only with written permission of Deutsche WindGuard Wind Tunnel Services GmbH. The

results of the following report refer to the investigated test objects only.

This report covers 16 pages.

Anemometer calibration at different air temperatures and air pressures Page 4 of 16

VT180259_01_Rev0

1 Introduction

An anemometer calibration is typically performed in a wind tunnel at a constant, pre-

vailing air temperature and atmospheric pressure. This calibration is the basis for the

wind speed measurements at meteorological met masts and therefore for the site as-

sessment for potential wind farms. As the environmental parameters can influence the

performance of the anemometer, an adequate anemometer for the specific site has to be

chosen. Furthermore it is important to have a measure of the environmental influence

on an accurate site assessment and wind turbine control.

Anemometers are assigned into different accuracy classes. In the latest IEC 61400-12-1

standard [1] there are different influence parameters which have to be investigated dur-

ing the anemometer classification. The different classes cover different operational

ranges of these influence parameters. Among these parameters are the air temperature

and the air density.

In the IEC 61400-12-1 [1], it is assumed that a change in air temperature only influences

the bearing friction. Higher air temperatures decrease the friction and therefore in-

crease the rotational speed and vice versa.

In the IEC standard [1] are no further suggestions on how to evaluate a variation in air

density. The air density is a function of air temperature and air pressure. To investigate

the influence of a variation in air density, either the air temperature or the pressure can

be altered. It is difficult to distinguish between the influence of changing air temperature

and density if temperature variation is used to adjust the air density during the calibra-

tion. If both parameters, air temperature and air pressure, can be altered independently

the most precise results will be obtained.

In standard wind tunnels air temperature and pressure can usually not be set deliber-

ately. Therefore the impact of these environmental conditions cannot be estimated reli-

ably. A special research wind tunnel of “Göttinger” layout has been developed with the

ability to vary the ambient tunnel pressure and temperature independently.

This document describes a measurement methodology for calibration of cup anemome-

ters, propeller anemometers and sonic anemometers in the variable air density wind

tunnel of WindGuard Wind Tunnel Services. The calibration result is the indicated wind

speed of the anemometer at different temperatures and/or different air pressure. The

calibration results can be used to estimate the uncertainty for wind sensors at very low

or high temperatures and/or at high altitudes (lower temperatures in combination with

lower density). The results are also essential for the classification of anemometers ac-

cording to IEC [1].

In the second chapter, former investigations on the influence of changing air tempera-

ture onto the bearing friction of cup anemometers are presented. In the third chapter, a

technical description of the variable air density wind tunnel will be given, followed by

the anemometer calibration procedure for varying air temperatures and air pressures.

In the fourth chapter the uncertainty calculation is presented. In the end sample results

for two different, commonly used and similar shaped cup anemometers with a frequen-

cy output are presented with a final conclusion.

Anemometer calibration at different air temperatures and air pressures Page 5 of 16

VT180259_01_Rev0

2 Former investigations on temperature induced effects onto the an-

emometer output

Former investigations ([2], [3]) on temperature induced impacts on wind speed meas-

urements with cup anemometers were performed by flywheel experiments in a climate

chamber.

Figure 1 and Figure 2 illustrate the experimental set-up for the investigation of the bear-

ing friction in a climate chamber with a flywheel test. The procedure assumes that the

air resistance of the rotational disc is known. Still, a drag coefficient determined in 1934

by W. G. Cochran [4] is used, as there are no new reliable values for this coefficient. In

the scope of a bachelor thesis [3] the flywheel test was done for different discs as well as

for different surface roughness values. The results showed the possibility of quite high

deviations.

Figure 2: Experimental set-up for a flywheel test in a climate

Figure 1: Experimental set-up for a fly- chamber at WindGuard Wind Tunnel Services.

wheel test in a climate chamber, conduct-

ed by RISØ for the Characterisation and

Classification of the RISØ P2546 Cup Ane-

mometer in 2004 [2].

A similar procedure was used during the classification of the Thies First Class anemome-

ter in 2003 to calculate the influence of varying air pressures and air temperatures [5]. A

foil heater was used to solely increase the temperature of the bearing shaft, see Figure 3.

To decrease the temperature of the bearing shaft a cooling device was constructed, see

Figure 4.

Anemometer calibration at different air temperatures and air pressures Page 6 of 16

VT180259_01_Rev0

Figure 3: Experimental set-up for producing hot Figure 4: Experimental set-up for producing cold

temperatures through a foil heater. Not represent- temperatures through the cooling device. Not rep-

ed is the necessary thermal insulation. resented is the necessary thermal insulation.

Both procedures work with the idealized assumption that a change in air temperature

only influences the bearing friction. Other possible temperature induced effects, like dis-

tortion of the rotor or changes of the aerodynamic properties are not considered. Wind

tunnel tests with changing air temperature on the other hand also assess these effects

and should therefore estimate the anemometer performance in a more realistic way.

Anemometer calibration at different air temperatures and air pressures Page 7 of 16

VT180259_01_Rev0

3 Technical description of the variable air density wind tunnel

The variable air density wind tunnel of WindGuard Wind Tunnel Services has a closed-

circuit design with a circular return flow. The wind tunnel is characterized by a particu-

larly homogeneous flow at low turbulence level (<0.5 %). The wind tunnel is conceived

mainly for investigation of anemometers at different total air pressure and air tempera-

tures. The limits for the ambient conditions are given by the IEC 61400-12-1 [1]. On this

basis, the following design criteria were laid out:

• Flow speed in the empty test section:

o currently up to 16 m/s,

o planned extension up to 25 m/s

• Air temperature range: -20 °C – +40 °C

• Air density range: 0.9 kg/m³ – 1.35 kg/m³

• Air pressure: 600 hPa – 1100 hPa

Based on these criteria and constraints, a suitable wind tunnel design is the closed-

circuit configuration tunnel with a closed test section. A 0.8 m long test section with a

cross sectional area of 0.5 m x 0.5 m was chosen. This provides an acceptable blockage

ratio for the intended anemometer testing at different air densities. The tunnel has a

contraction ratio of 3.3:1.

Figure 5 and Figure 6 show a photo of the variable air density wind tunnel at the Wind-

Guard headquarters.

Figure 5: Photo of the variable air density wind tunnel during the installation.

Anemometer calibration at different air temperatures and air pressures Page 8 of 16

VT180259_01_Rev0

Figure 6: Photo of the variable air density wind tunnel of WindGuard Wind Tunnel Services.

The wind tunnel itself is comprised of a sheet metal construction with a closed test sec-

tion that is hermetically sealed, thus enabling a variation of internal air pressure. Fur-

thermore, the whole wind tunnel is placed in an isolated and temperature controlled

chamber.

To achieve a high-quality flow, the settling chamber consists of a special honey-

comb/screen arrangement of five screens and one honeycomb. Calculations were per-

formed in order to determine the size of individual wind-tunnel components, the pres-

sure variation and flow speed in different sections of the tunnel. These calculations were

based on well proven values of diffuser angles, contraction ratios and pressure drop co-

efficients. Consequently, a fan unit was chosen to compensate the pressure loss and pro-

duce the desired wind speed at the test section.

Anemometer calibration at different air temperatures and air pressures Page 9 of 16

VT180259_01_Rev0

3.1 Measuring system

In Figure 7 the measuring system is illustrated schematically. Two pitot static tubes de-

liver the reference flow speed. Furthermore, the air temperature and the humidity are

monitored within the wind tunnel and also in the climatized room.

Pos. Sensor

1 Pitot static tube

2 Pitot static tube

3 El. Barometer

4 Pressure transducer

5 Pressure transducer

6 El. Thermometer

7 El. Humidity

8 El. Thermometer

9 El. Humidity

10 Test item

11 Data acquisition sytem

Figure 7: Schematic of the measurement setup.

4 Calibration procedure

To reduce the measurement uncertainties, first the anemometer has to be calibrated at

normal ambient conditions in an accredited wind tunnel of WindGuard Wind Tunnel

Services. Subsequently a measurement in the variable air density wind tunnel is per-

formed at nearly the same temperature and pressure prevailing during the first meas-

urement. The anemometer itself serves as a transfer standard. With both calibrations

done, a transfer factor for measurements in the variable air density wind tunnel can be

determined.

The advantage of this procedure is that blockage effects are negligible. Only the uncer-

tainties due to repeatability (type ‘A’) and the uncertainty of the basic calibration remain

and have to be taken into account.

For this report, the following calibration procedure is used. However, this is not a stand-

ardized procedure.

During the calibration in the variable air density wind tunnel, the anemometer output is

measured for flow speeds between 4 m/s and 15.5 m/s. For each measurement point

adequate time is allowed to generate stable flow conditions. After this settling time, the

flow speed is kept constant for a sampling interval of at least 30 s. The sampling fre-

quency is at least 4 Hz. To cover rising and falling flow speeds the following sequence is

chosen: 4, 8, 12, 15.5, 14, 10, 6 m/s.

Anemometer calibration at different air temperatures and air pressures Page 10 of 16

VT180259_01_Rev0

4.1 Calibration procedure for varying air temperatures

After determining the transfer factor for the anemometer under investigation, the air

temperature is decreased down to -20 °C and a calibration run is done. The air tempera-

ture is then increased in 5 °C steps up to the maximum air temperature of 40 °C, while

the air pressure is kept constant. At each temperature the calibration is done as de-

scribed above. To decrease the type ‘A’ uncertainty, the minimum duration of the sam-

pling interval is 30 s. For each calibration run a linear regression analysis is performed,

resulting in a calibration function with slope and offset for one particular air tempera-

ture.

4.2 Calibration procedure for varying air pressures

The calibration procedure for varying air pressures is done similar to varying tempera-

tures. After the measurement for the determination of the transfer factor, the air pres-

sure is increased in 50 hPa steps from 700 hPa up to 1100 hPa. To cover an air density of

about 0.8 kg/m³ to 1.4 kg/m³, the measurements for different air pressures is done at a

fixed air temperature of 10 °C. For each calibration run with variable ambient pressure a

linear regression analysis is performed, resulting in a calibration function with slope and

offset for each particular ambient air pressure.

It is possible to conduct surveys in any combination of pressure and temperature within

the parameter range as describes in Chapter 3.

Anemometer calibration at different air temperatures and air pressures Page 11 of 16

VT180259_01_Rev0

5 Measurement uncertainty

The measurement uncertainty 𝑈𝐷𝑈𝑇 for the procedure described in Chapter 4 is a com-

bination of the measurement uncertainty of the device under test (DUT) 𝑈𝑊𝑇 and of the

standard error calculated from the 𝑛 > 10 measurement repetitions.

𝜎 2 0.5

𝑈𝐷𝑈𝑇 = (𝑈𝑊𝑇 2 + ( 𝑛) ) ; 𝑘=1

√

Where:

Measurement uncertainty from the standard calibration of the device under

𝑈𝑊𝑇 :

test

𝜎: Standard deviation of the measurement

𝑛: Amount of measurement repetition

The measurement uncertainty 𝑈𝑊𝑇 from the calibration in the accredited wind tunnel of

the device under test amounts to 0.05 m/s (k=2).

The sample results presented in Chapter 6 show relative changes for varying air tem-

peratures and air pressures, therefore only type ‘A’ uncertainties are relevant. However,

the uncertainty calculation must be applied if absolute calibrations at a certain air tem-

perature and air pressure are performed.

6 Sample results

To illustrate the influence of air temperature and air pressure, some calibration results

will be illustrated in this section.

Two different, commonly used and similar shaped cup anemometers with a frequency

output from two different manufacturers were tested. Both anemometers contain roller

bearings which support the spindle. To compare the results for both anemometers a ra-

tio was calculated. This ratio represents the relation between measured wind speed (if

the anemometer is not calibrated for different air temperature and air pressure) and the

real wind speed. The ratio k is calculated as follows:

𝑓(𝑇,𝑝) ⁄𝑣(𝑇,𝑝)

𝑘(𝑇,𝑝) =

𝑓(20°𝐶,1000 ℎ𝑃𝑎) ⁄𝑣(20°𝐶,1000 ℎ𝑃𝑎)

Where:

Frequency output at wind speed v(T,p) for a certain air temperature T and

f(T,p):

pressure p

Frequency output at wind speed v(20°C,1000 hPa) for measurements at 20 °C air

f(20°C,1000 hPa):

temperature and 1000 hPa air pressure

Anemometer calibration at different air temperatures and air pressures Page 12 of 16

VT180259_01_Rev0

6.1 Calibration results for varying air temperatures

In Figure 8 the ratio for different air temperatures is illustrated.

Figure 8: Ratio 𝑘 for anemometer A and B at varying air temperatures and wind speeds and at constant air

pressure.

The dashed lines with a triangular marker show the results for anemometer A at differ-

ent wind speeds, the solid lines with a circular marker for anemometer B. As described

above, the ratio is calculated by normalizing to the results at 20 °C. The influence of var-

ying temperatures for both anemometers is quite different. Anemometer A has a de-

creasing ratio for decreasing temperatures whereas anemometer B has the opposite

characteristic. Furthermore the influence of varying the air temperature is stronger at

lower wind speeds.

If the basic calibration established at 20 °C is applied, anemometer A would undervalue

the wind speed at low temperatures. Anemometer B on the other hand would indicate a

too high wind speed at low temperatures. Air temperatures above 20 °C would lead to

opposing results. Hence, the influence on anemometer B is stronger and would result in

a slightly undervalued wind speed.

Anemometer calibration at different air temperatures and air pressures Page 13 of 16

VT180259_01_Rev0

6.2 Calibration results for varying air pressures/air densities

In Figure 9 the ratio for different air densities and wind speeds is illustrated. The differ-

ent air densities are obtained by varying the air pressure at a constant air temperature

of 10 °C.

Figure 9: Ratio 𝑘 for anemometer A and B at varying air density and wind speeds and at constant air tem-

perature.

The dashed lines with a triangular marker show the results for anemometer A and the

lines with a circular marker for anemometer B. As described, the ratio is calculated by

normalizing to the results at 1000 hPa, corresponding to an air density of about 1.23

kg/m³. The influence of varying densities for both anemometers is almost similar. Both

anemometers have a decreasing ratio for decreasing pressure. The influence is again

stronger for lower wind speeds.

If the basic calibration established at 1000 hPa is applied, both would undervalue the

wind speed at low densities and pressure respectively. The pressure can be assigned to

an altitude above sea level with the so called barometric formula. A pressure of about

950 hPa, which corresponds to 1.16 kg/m³ in Figure 9, correlates to a height of about

500 m. Starting at moderate heights of about 500 m, the pressure difference would al-

ready influence the output of the anemometers.

Anemometer calibration at different air temperatures and air pressures Page 14 of 16

VT180259_01_Rev0

7 Conclusion

The results presented in Chapter 5 clearly verify the influence of varying air tempera-

ture and air pressure on the cup anemometer performance. For the two tested cup ane-

mometers, the influence is more pronounced at low wind speeds. While the results for

varying air pressures are similar between the tested anemometers, the results for vary-

ing air temperatures are opposing. This demonstrates that a change in air temperature

can have other effects than just an increase in bearing friction. Therefore it is not suffi-

cient to evaluate the influence of varying temperature with the flywheel method. It is

necessary to perform tests in which the whole anemometer is exposed to different tem-

peratures.

Additionally, the results demonstrate the importance to consider air pressure as a pri-

mary influencing variable on cup anemometer measurements, rather than air density.

Moreover, as the air density is dependent on air temperature and air pressure, the influ-

ence of the air density and air temperature on cup anemometer measurements can be

very different. None of these aspects are covered in IEC 61400-12-1 [1].

If cup anemometers are used in subarctic climate regions or in higher altitudes, a stand-

ard calibration can lead to an under or over estimation of the wind speed. The magni-

tude may be in the order of several percent in wind speed, which is an even greater de-

viation in wind power.

Also the use of anemometers for the wind turbine control in these regions may result in

a delayed start of power production, especially as the influence of air pressure and tem-

perature is the highest for low wind speeds.

A correction procedure to adjust the indicated wind speed seems feasible. The correc-

tion algorithm may be developed considering air pressure, air temperature and wind

speed. This correction function has to be individually developed for each anemometer

type. Further discussion is needed on how to assess the impact of the air pressure and

air temperature correction upon the associated uncertainty due to anemometer class

number according to [1].

Anemometer calibration at different air temperatures and air pressures Page 15 of 16

VT180259_01_Rev0

8 References

[1] IEC 61400-12-1, Edition 2.0, Wind energy generation systems – Part 12-1: Power

performance measurements of electricity producing wind turbines, IEC TC/SC 88,

2017

[2] T. Friis Pedersen, Characterisation and Classification of RISØ P2546 Cup Anemom-

eter, Risø-R-1364(ed. 2)(EN), March 2004

[3] P. Purucker, Untersuchung des thermischen Einflusses der Lagerreibung auf das

Kalibrierergebnis von Schalensternanemometern, Bachelorarbeit, WindGuard

Wind Tunnel Services GmbH, 2016

[4] W. G. Cochran, The flow due to a rotating disc, Mathematical Proceedings of the

Cambridge Philosophical Society, Vol. 30(3), pp. 365-375, 1934

[5] D. Westermann, Investigation and Classification of the Anemometer Thies First

Class, WindGuard AK03 002, April 2003

[6] J.-Å. Dahlberg, J. Gustavsson, G. Ronsten, T. F. Pedersen, U. Schmidt Paulsen D.

Westermann, CLASSCUP - Development of a standardised cup anemometer suited

to wind energy applications, June 2001

[7] C. May, Windkanaluntersuchungen zum Einfluss von Lufttemperatur und Luft-

druck auf das Kalibrierergebnis von Anemometern, Bachelorarbeit, WindGuard

Wind Tunnel Services GmbH, 2017

Anemometer calibration at different air temperatures and air pressures Page 16 of 16

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Spacecraft Structures: Tetsuo Yasaka Junjiro OnodaDocument13 pagesSpacecraft Structures: Tetsuo Yasaka Junjiro OnodaBig FloresNo ratings yet

- MGT657-Top Glove CorporationDocument14 pagesMGT657-Top Glove CorporationreSTART StudioNo ratings yet

- Makino Milling Machine Libraries (MML) Mccomm - Ocx Reference ManualDocument28 pagesMakino Milling Machine Libraries (MML) Mccomm - Ocx Reference ManualErich KreisederNo ratings yet

- Book 3 PDFDocument15 pagesBook 3 PDFBig FloresNo ratings yet

- Flow Visualisation Experiments On Sports BallsDocument7 pagesFlow Visualisation Experiments On Sports BallsBig FloresNo ratings yet

- Topic 7 Lecture SlidesDocument61 pagesTopic 7 Lecture SlidesBig FloresNo ratings yet

- 2D CFD Analysis of Racing Car For Studen PDFDocument3 pages2D CFD Analysis of Racing Car For Studen PDFBig FloresNo ratings yet

- Machines: Calculation of The Incompressible Viscous Fluid Flow in Piston Seals of Piston Hybrid Power MachinesDocument28 pagesMachines: Calculation of The Incompressible Viscous Fluid Flow in Piston Seals of Piston Hybrid Power MachinesBig FloresNo ratings yet

- Mary Hays's Biography of María de Estrada, A Spanish Woman in The American ConquestDocument15 pagesMary Hays's Biography of María de Estrada, A Spanish Woman in The American ConquestBig FloresNo ratings yet

- CFD Analysis of Diffuser in A Car For DoDocument7 pagesCFD Analysis of Diffuser in A Car For DoBig Flores100% (1)

- NDT and E International: SciencedirectDocument12 pagesNDT and E International: SciencedirectBig FloresNo ratings yet

- Aerodynamics Wind Tunnel Laboratory Test: Szymon Borowski SRN: 14037348Document6 pagesAerodynamics Wind Tunnel Laboratory Test: Szymon Borowski SRN: 14037348Big FloresNo ratings yet

- Racecar Engineering - January 2020Document102 pagesRacecar Engineering - January 2020Big Flores100% (1)

- Design of Formula One Racing Car: International Journal of Engineering and Technical Research April 2015Document8 pagesDesign of Formula One Racing Car: International Journal of Engineering and Technical Research April 2015Big FloresNo ratings yet

- Koenigsegg Magazine 2017 20170126 WEBDocument39 pagesKoenigsegg Magazine 2017 20170126 WEBBig FloresNo ratings yet

- Fix Fix Soal Pat Bahasa Dan Sastra Inggris Kelas X Ipa 1, X Ips 1-4Document30 pagesFix Fix Soal Pat Bahasa Dan Sastra Inggris Kelas X Ipa 1, X Ips 1-4Eka MurniatiNo ratings yet

- Meduri - Bharata NatyamDocument23 pagesMeduri - Bharata NatyamTariq Omar AliNo ratings yet

- Chapter 15Document12 pagesChapter 15IsisahNo ratings yet

- OceanofPDF - Com Learning To Love Myself - Alex AubreyDocument143 pagesOceanofPDF - Com Learning To Love Myself - Alex AubreyJeshvanthNo ratings yet

- Cybermind 3Document8 pagesCybermind 3Adam FredrikssonNo ratings yet

- G.R. No. 244828Document10 pagesG.R. No. 244828Faux LexieNo ratings yet

- Intersection A Curve and A LineDocument16 pagesIntersection A Curve and A LineIr HeriawanNo ratings yet

- Socio-Demographic Characteristics of Male Contraceptive Use in IndonesiaDocument6 pagesSocio-Demographic Characteristics of Male Contraceptive Use in IndonesiaBella ValensiaNo ratings yet

- Skimming Texts on GED RLADocument13 pagesSkimming Texts on GED RLAadkmelii06No ratings yet

- Longer Confession and Extant Fragments Final 10-27-2015Document17 pagesLonger Confession and Extant Fragments Final 10-27-2015André Galvão SoaresNo ratings yet

- Sample StoryDocument2 pagesSample StoryLara Mae Gonzales100% (1)

- July 3 2011Document6 pagesJuly 3 2011stalbertthegreatNo ratings yet

- MTU16V4000DS2000 2000kW StandbyDocument4 pagesMTU16V4000DS2000 2000kW Standbyalfan nashNo ratings yet

- PDS-Mosalinker PC30 (V1.0) enDocument2 pagesPDS-Mosalinker PC30 (V1.0) enLIM YE HENGNo ratings yet

- Opito International GuidelinesDocument65 pagesOpito International GuidelinesKleine SterNo ratings yet

- Sciencedirect: Fabian Dillinger, Olivia Bernhard, Gunther Reinhart Fabian Dillinger, Olivia Bernhard, Gunther ReinhartDocument6 pagesSciencedirect: Fabian Dillinger, Olivia Bernhard, Gunther Reinhart Fabian Dillinger, Olivia Bernhard, Gunther ReinhartAnita SetyastutiNo ratings yet

- Cell 7Document6 pagesCell 7XI-A Vishal BishnoiNo ratings yet

- Schematic Diagram: MODEL: 32WL66A / 32WL66E / 32WL66R / 32WL66TDocument38 pagesSchematic Diagram: MODEL: 32WL66A / 32WL66E / 32WL66R / 32WL66TSasha HesenliNo ratings yet

- Geopolitics in Contemporary World PDFDocument30 pagesGeopolitics in Contemporary World PDFHabib EjazNo ratings yet

- Flowcharts PPT CADocument14 pagesFlowcharts PPT CAHarpreet KaurNo ratings yet

- Countdown To The End of TimeDocument56 pagesCountdown To The End of Timelelandmary7322314No ratings yet

- 5 Steps To Avoid TemptationDocument1 page5 Steps To Avoid TemptationKENNETH IFEOSAMENo ratings yet

- Double Reeds: The OboeDocument1 pageDouble Reeds: The OboeTom HartNo ratings yet

- RCoE - Training Book - Id-63-87Document25 pagesRCoE - Training Book - Id-63-87PILAR TIARA LELEPADANGNo ratings yet

- Risk Assessment-Concrete Casting by Using PumpsDocument3 pagesRisk Assessment-Concrete Casting by Using PumpsSarfraz Randhawa100% (2)

- AOPA Membership Application GuidelinesDocument23 pagesAOPA Membership Application GuidelinesphenixousNo ratings yet

- Mathworksheets4 22Document9 pagesMathworksheets4 22api-233717707No ratings yet

- Holden Trailblazer 284082Document9 pagesHolden Trailblazer 284082Luke AustinNo ratings yet