Professional Documents

Culture Documents

M.bow String Girder-10411-9 PDF

Uploaded by

kesharinareshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

M.bow String Girder-10411-9 PDF

Uploaded by

kesharinareshCopyright:

Available Formats

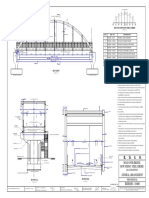

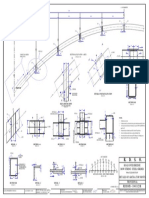

910 800 800 800

A F G

H

B B B

234

234

234

234

C C C C

D D D D

E E E E

900 900 900 900

LONG.-GUIDE BEARING ASSEMBLY LGB TRANS.-GUIDE BEARING ASSEMBLY TGB FREE - BEARING ASSEMBLY FB FIXED - BEARING TGB

(SCALE 1:7.5) (SCALE 1:7.5) (SCALE 1:7.5) (SCALE 1:7.5)

X-SECTIONAL VIEW ACROSS LONGITUDINAL AXIS OF GIRDER (CENTER LINE OF THE GIRDER COINCIDES WITH CENTER LINE OF BEARING SHOWN)

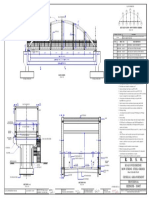

2+2

20

STAINLESS STEEL PLATE

410 85 85

910 6 MM THICK, WELD 3mm 450

35

3 10 DETAIL X

810 ELEVATION

53

(SCALE 1:7.5)

70

5

3

65

50

30

STAINLESS STEEL PLATE

53 40x3x790, WELD 2mm 50 40 720 50

5

900

ELEVATION 800

10

STAINLESS STEEL

(SCALE 1:7.5)

35

700

910

PLATE 35x3x620, ELEVATION

PISTON BASE

DUST SEAL 10x15 ALLROUND

630

620

WELD 2 MM (SCALE 1:7.5)

SURFACE HARDENED TO

50

50 33 53 638 53 33 50

300 BHN MINIMUM

LEGEND SYMBOL

53

PTFE SHEET 5 MM

THICK, DIMPLED OR

MODULAR, PASTED IN ELEVATION HARDENED SURFACE 300 BHN MINIMUM

550 2 MM DEEP RECESS 410 (SCALE 1:7.5)

10

175

DUST SEAL

50

PISTON WALL

450 STAINLESS STEEL PLATE

5

40x3x780 WELD 2mm

POLY TETERA FLUORO ETHYLENE (PTFE)

630 VIEW FROM TOP

HIGH STRENGTH BOLT

53 33

PART C: BRASS RINGS

175

VIEW FROM TOP FOR RETAINING

202

(SCALE 1:7.5) ELASTOMER IN POT 5 5

4

650

800

450 10 (SCALE 1:7.5)

550 NOTE:

45

175

10 1. All dimensions are in MM.

450

40

2. The design is in accordance with IRC- 83 (PART-III)-2002.

40

36

DETAIL Y

203

449

STAINLESS STEEL PLATE

6 MM THK, WELD 3 MM

STAINLESS STEEL ELEVATION 3. The concrete in bed block shall be of min M40 GRADE.

PLATE 35x3x620, (SCALE 1:7.5)

ALL ROUND

SURFACE HARDENED TO ELEVATION WELD 2 MM

4. Bearings shall be provided before concreting of deck slab is taken up.

175

550

606

910

300 BHN MINIMUM (SCALE 1:7.5) (NOT TO BE PROVIDED IN 5. Bearings shall be protected during concreting or providing holding down bolts

FREE BEARING) operations. Any mortar or foreign material contaminating the bearing shall be

completely removed.

203

ELASTOMERIC PAD 6. Manufacture & finishing of bearings shall be as per para 927.2 & 927.3 of IRC 83

5

STAINLESS STEEL PLATE Part III

3 STAINLESS STEEL PLATE

33x3x790 WELD 2 mm

5

50

6 MM THICK, WELD 3 MM 7. Manufacturing tolerances shall be as per para 927.1 of IRC 83 Part III

ALL ROUND

SURFACE HARDENED VIEW FROM TOP 5 8. Acceptance of bearing shall be as per para 928 of IRC 83 Part III.

VIEW FROM BOTTOM TO 300 BHN MINIMUM PART E: POT FOR BEARINGS

202

9. Material to be used for pot, piston and top plate including all guides, lugs etc shall

PART A: TOP PLATE FOR LONG. GUIDE (SCALE 1:7.5) be of cast steel to IS 1030:1989 grade 340-570W.

33 53

(SCALE 1:7.5)

630

3

10. All the flame cut, sawn or planed edges of the plates should be machined. All

sheared corners shall be rounded off with 2 MM radius.

50

410 11. For welding stainless steel sheet, M1 electrode type with stainless steel core wire as

50 700 50 per IRS: M-28-2012 shall be used.

450

800 12. PTFE sheet shall be pure poly tetra fluoro ethylene, and shall be 4.5 mm thick,

having either dimples (hot pressed or moulded) or modules as per IRC 83 Part III.

VIEW FROM TOP VIEW FROM BOTTOM These shall be pasted in recess 2.5 MM deep in the bearing and the peel strength of

PISTON

449 PART D: ELASTOMER PART F: TOP PLATE FOR TRANSVERSE GUIDE

glue to be used shall not be less than 4 N/MM.

PAD FOR BEARINGS (SCALE 1:7.5) 13. Material to be used for wiper seal and dust seal shall be of microcellular

polychloroprene rubber or polythene foam & it's adhesion to metal shall be with

3 630 3 (SCALE 1:7.5)

800 10 polychloroprene rubber based adhesive dunlop S-758, dendrite PC-65 or any other

50 700 50 50 700 50 equivalent brands.

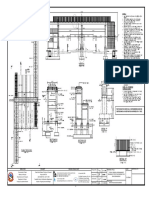

R5

VIEW FROM BOTTOM 14. All non-working surfaces shall be given protective coating comprising of 2 coats

R230 of epoxy primer enriched with metallic zinc, one intermediate coat of high build

PART B: PISTON FOR

88

epoxy paint reinforced with mio (micaceous iron oxide) & one coat of high

AFTER 15 MM

FREE/SLIDING BEARINGS performance epoxy finish paint as per para 39.2.2 of IRS B1.

15

650

CURVE

(SCALE 1:7.5)

35

15. All bearings shall be sent by manufacturer duly set. Marked with center line of

AFTER 40 MM

DETAIL Y

ELEVATION SURFACE HARDENED TO bearing along the girder and across it, along with the shipping mark of the bearing

15

449

CURVE

300 BHN MINIMUM

40

50

(SCALE 1:7.5) and fitted with transportation clamps. It is prohibited to open transportation clamps

40

ELEVATION

50

before final assembly of the bearing on the girder without the presence of bearing

(SCALE 1:7.5) R230 manufacturer representative.

16. After the girders are properly leveled/ aligned and bearings tied to the girder using

DETAIL X DETAIL Y Class 8.8 bolts, transportation clamps shall be opened and all expansion type

(SCALE 1:5) (SCALE 1:5) bearing shall be set properly as per ambient temperature. Thereafter holes in

175

SURFACE HARDENED 175 substructure already provided (shall be drilled at this stage if not already provided),

TO 300 BHN MINIMUM shall be filled with holding down bolts and quickly grouted.

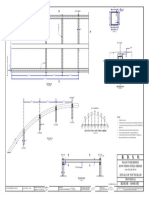

OF BOTTOM LONG. BEAM

OF SYMMETRY 17. Anchor bolts shall be provided in holes (max. dia 40 MM) made in pier top/

NUT

600

pedestals.

FIXED BEARING BOTTOM LONG. BEAM LONG. GUIDE BEARING 18. Anchor bolts and nuts shall be hot dip galvanized 100 micron thick, as per IS:

175

90

4759.

175

800

KNURLING TOOL OR CHISELLING

32

ROUND WASHER FOR 32 DIA. BOLT

BOTTOM CROSS BEAM

800

R. D. S. O.

ISOMETRIC THREAD

DIA.

MIN EMBEDDED LENGTH 330

175

SURFACE ROUGHENED BY

175

12000

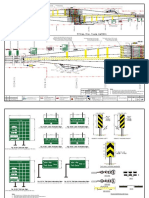

DIRECTION OF TRAFFIC ROAD OVER BRIDGE

OF BOTTOM LONG. BEAM

BOW STRING STEEL GIRDER

175

PISTON

175

60m CLEAR SPAN

50

WELD 2 MM ALL ROUND

50

50 700 50

800 50 700 50 62000 DETAILS OF PTFE POT BEARING

600

800 TRANS. GUIDE BEARING FREE BEARING

VIEW FROM BOTTOM ANCHOR BOLT ARRANGEMENT OF POT PTFE BEARINGS PROVISIONAL

(SCALE 1:5)

PART G: TOP PLATE FOR VIEW FROM BOTTOM (SCALE 1:200)

FREE BEARING

(SCALE 1:7.5)

PART H: PISTON FOR FIXED BEARING

(SCALE 1:7.5)

(PAPER SIZE A1) RDSO/B - 10411/9

DRAWN BY: M/S Abhinav Associates DESIGNED BY: SCRUTINIZED & CHECKED BY: APPROVED BY:

"THIS DRAWING IS THE PROPERTY OF RESEARCH DESIGN AND STANDARD ORGANIZATION ( MINISTRY

CALCULATION REGISTER NO. DD/2014/20 AutoCAD FILE NO.: B-10411 OF RAILWAY ), LUCKNOW-226011, INDIA, AND SHALL NOT BE USED, COPIED OR REPRODUCED IN PART

CHECKED BY: V. K. PANDEY (SSE) VIVEK KUMAR (XEN/NCR/B&S/RDSO) SRIJAN TRIPATHI (DBS /SB-I) A. K. DADARYA (EDBS) OR WHOLE, WITHOUT PRIOR CONSENT IN WRITING."

You might also like

- Fabrication Inspection of Bow String GirdersDocument46 pagesFabrication Inspection of Bow String GirdersHabib Ur Rahman100% (1)

- All RDSO Bow String Girder of Span 60-72 MDocument9 pagesAll RDSO Bow String Girder of Span 60-72 MAjay Sinha60% (5)

- 48m BowStringDocument1 page48m BowStringgoutammand100% (2)

- RDSO Drawing ListDocument42 pagesRDSO Drawing Listkaushik96040% (5)

- Welding Duplex Stainless Steels - A Review of Currernt RecommendationsDocument12 pagesWelding Duplex Stainless Steels - A Review of Currernt RecommendationsTrushar Parmar100% (1)

- 60 M.bow String Girder 10411 1 RDocument1 page60 M.bow String Girder 10411 1 RkesharinareshNo ratings yet

- 60 M.bow String Girder 10411 3 RDocument1 page60 M.bow String Girder 10411 3 RkesharinareshNo ratings yet

- RCC Encasing Pipe CulvertDocument40 pagesRCC Encasing Pipe CulvertVM&CO VM&CO0% (1)

- 36m BowString PDFDocument1 page36m BowString PDFgoutammand67% (3)

- Bow String Girder QuantityDocument3 pagesBow String Girder Quantityvsballa25% (4)

- 42 M Bow String Girder-10408-R PDFDocument1 page42 M Bow String Girder-10408-R PDFPhanindra MajetiNo ratings yet

- Design of PSC Box 45.0 M Span PDFDocument89 pagesDesign of PSC Box 45.0 M Span PDFsiddharth yadavNo ratings yet

- IRC 83-4.2014 - Amendment No. 2 - Dec 2019 PDFDocument4 pagesIRC 83-4.2014 - Amendment No. 2 - Dec 2019 PDFJayantNo ratings yet

- RoB Cost Estimates For Alt - 1, 63m Bowstringer GirderDocument10 pagesRoB Cost Estimates For Alt - 1, 63m Bowstringer GirderHegdeVenugopal100% (1)

- IRC 24-2010 Ammendment (Nov-17)Document3 pagesIRC 24-2010 Ammendment (Nov-17)avisek_basuNo ratings yet

- Dynamic Prestress Technical Guidelines PDFDocument8 pagesDynamic Prestress Technical Guidelines PDFdhopat kalpesh100% (1)

- Slab Culvert IRC 21 IRC 112Document5 pagesSlab Culvert IRC 21 IRC 112Ashish Bhoi100% (1)

- Drawing Title: Employer Project Design Consultant: HouseDocument5 pagesDrawing Title: Employer Project Design Consultant: HouseRoshan KejariwalNo ratings yet

- 60 M.bow String Girder-10411-7-RDocument1 page60 M.bow String Girder-10411-7-RkesharinareshNo ratings yet

- Pleuger Electrical Submersible Pumps and Water-Filled MotorsDocument12 pagesPleuger Electrical Submersible Pumps and Water-Filled MotorsGabrielMachado100% (1)

- BSR - NH - Circle - Jaipur - 2019 Final PDFDocument109 pagesBSR - NH - Circle - Jaipur - 2019 Final PDFRohit Bali100% (1)

- Cost Estimate - Package 1Document78 pagesCost Estimate - Package 1dheeraj sehgalNo ratings yet

- Amendment IRC-6 Oct 2019Document5 pagesAmendment IRC-6 Oct 2019Aayush Aggarwal0% (1)

- 60 M.bow String Girder-10411-RDocument1 page60 M.bow String Girder-10411-Rkesharinaresh80% (5)

- 42 M Bow String Girder-10408-1-RDocument1 page42 M Bow String Girder-10408-1-RPhanindra MajetiNo ratings yet

- 54 M.bow String Girder-10410-9Document1 page54 M.bow String Girder-10410-9SANJEEV VERMANo ratings yet

- Typical Design Calculations of PierDocument40 pagesTypical Design Calculations of PierAjayvidyanand Sharma100% (1)

- Bs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Document57 pagesBs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Vvs RayuduNo ratings yet

- IRC - SP Well Foundation by Balwant Rao PDFDocument133 pagesIRC - SP Well Foundation by Balwant Rao PDFAnoopNo ratings yet

- Welding ParametersDocument87 pagesWelding ParametersDhanish Kumar100% (3)

- Staging DesignDocument8 pagesStaging DesignAbhinandan Jasrotia0% (1)

- Dynamic Prestress HDPE Pipe Brochure PDFDocument4 pagesDynamic Prestress HDPE Pipe Brochure PDFdhopat kalpeshNo ratings yet

- 42m BowStringDocument1 page42m BowStringsorowareNo ratings yet

- 30 M Bow String Girder-10409-7rDocument1 page30 M Bow String Girder-10409-7rprejithNo ratings yet

- RDSO B 11754 4R1 (Mod)Document1 pageRDSO B 11754 4R1 (Mod)shibnath lahiriNo ratings yet

- 42 M Bow String Girder-10408-8-R1 PDFDocument1 page42 M Bow String Girder-10408-8-R1 PDFPhanindra MajetiNo ratings yet

- B6 Preparation of Bridge GAD BKK 220322Document43 pagesB6 Preparation of Bridge GAD BKK 220322Ali_nauman429458No ratings yet

- Fermenter Design PDFDocument41 pagesFermenter Design PDFAngel Mah Xin Yee100% (1)

- 9 Sacrificial - Shuttering-1 by RMDocument18 pages9 Sacrificial - Shuttering-1 by RMASHISANo ratings yet

- 60 M.bow String Girder 10411 2 RDocument1 page60 M.bow String Girder 10411 2 Rkesharinaresh100% (1)

- NDT - Cladding TechnologyDocument59 pagesNDT - Cladding TechnologySurajit Singha100% (4)

- Drawings For Culvert at 293+538 PDFDocument3 pagesDrawings For Culvert at 293+538 PDFSurya GowthamNo ratings yet

- Design of Pot Ptfe Bearing (Fixed Bearing) As Per Irc 83:2002 (Part 3)Document7 pagesDesign of Pot Ptfe Bearing (Fixed Bearing) As Per Irc 83:2002 (Part 3)DPJAIN INFRASTRUCTURE100% (1)

- 42 M Bow String Girder-10408-3-R PDFDocument1 page42 M Bow String Girder-10408-3-R PDFPhanindra MajetiNo ratings yet

- BR - No - Staging - Solid SlabDocument6 pagesBR - No - Staging - Solid Slabmohana tNo ratings yet

- HI-SI Toll Plaza Marking R2-23-01-2020 Final PDFDocument4 pagesHI-SI Toll Plaza Marking R2-23-01-2020 Final PDFRamBhuvan SonkarNo ratings yet

- M Bow String Girder-10409-9Document1 pageM Bow String Girder-10409-9prejithNo ratings yet

- M Bow String Girder-10408-9-R PDFDocument1 pageM Bow String Girder-10408-9-R PDFPhanindra MajetiNo ratings yet

- PipeDocument30 pagesPipepudumai100% (1)

- Arch Bridge Code - RDSO, IRDocument8 pagesArch Bridge Code - RDSO, IRJogesh S SondhiNo ratings yet

- Kompedium FrosioDocument126 pagesKompedium Frosioprotein100% (5)

- IRC 6-2017 Ammendment (Nov-17)Document9 pagesIRC 6-2017 Ammendment (Nov-17)avisek_basuNo ratings yet

- Rdso B-11753 5R1Document1 pageRdso B-11753 5R1shibnath lahiriNo ratings yet

- Link Road DRGSDocument8 pagesLink Road DRGSBasava Sowmya100% (2)

- Amendment To IRC 24 - 2010Document6 pagesAmendment To IRC 24 - 2010mrraee4729100% (1)

- Toe Wall-GantryDocument1 pageToe Wall-GantrySumant kumarNo ratings yet

- 3.0 Effective Width of Tyres and Load Distribution For IRC Class Special Vehicle 385 T (SV Class)Document2 pages3.0 Effective Width of Tyres and Load Distribution For IRC Class Special Vehicle 385 T (SV Class)vivekNo ratings yet

- 40 M COMPOSITE GIRDER New-ModelDocument1 page40 M COMPOSITE GIRDER New-Modelabhijeet sahuNo ratings yet

- Hume Pipe Culvert Drawing PDFDocument1 pageHume Pipe Culvert Drawing PDFDrainage Division CHIRALA0% (2)

- Thulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Document4 pagesThulo Neti Khola Bridge - Abutment Design: Fig: Abutment (All Dimensions in Metres)Himal KafleNo ratings yet

- Illustrative Worked Examples: Commentary of Irc: 6-2017Document4 pagesIllustrative Worked Examples: Commentary of Irc: 6-2017jatin singla100% (1)

- Ground Floor Plan: Fire Exit Stair (See Attached File For Details)Document1 pageGround Floor Plan: Fire Exit Stair (See Attached File For Details)Mark Kristoffer HilarionNo ratings yet

- Floor PlanDocument1 pageFloor PlanNusaybah Mohamed ShafeeqNo ratings yet

- Scci - Udh Baguio Topographic Map - 092321Document1 pageScci - Udh Baguio Topographic Map - 092321Staff05 GMTSNo ratings yet

- CDH1MP5 125 90 150A30X B11CAUAW DimsheetDocument1 pageCDH1MP5 125 90 150A30X B11CAUAW Dimsheetashfaq shaikhNo ratings yet

- 5100045016-Basic Cradle HC160-HC170 - ADocument2 pages5100045016-Basic Cradle HC160-HC170 - ArolandNo ratings yet

- Flexospan 07 42 13fleDocument23 pagesFlexospan 07 42 13fleAashish MuraliNo ratings yet

- Hi Master Index - 2011Document60 pagesHi Master Index - 2011mehdiNo ratings yet

- Curtain Wall Manual - Section 6 Material Properties: Approved Via Ballot #808-15 Out For Ballot (16-1006)Document12 pagesCurtain Wall Manual - Section 6 Material Properties: Approved Via Ballot #808-15 Out For Ballot (16-1006)philipNo ratings yet

- Range of Fermentation ProcessesDocument43 pagesRange of Fermentation ProcessesBharath wajNo ratings yet

- Liquid Level Relay PDFDocument5 pagesLiquid Level Relay PDFMansor MuamatNo ratings yet

- Company Profile: Pt. Prondt Indo UtamaDocument26 pagesCompany Profile: Pt. Prondt Indo UtamaAndy AhmadNo ratings yet

- MaterialsDocument3 pagesMaterialsFajar RamadhanNo ratings yet

- Hisaka Instruction ManualDocument48 pagesHisaka Instruction ManualCONG THANH DOANNo ratings yet

- Miscellaneous TopicsDocument6 pagesMiscellaneous TopicsNyoman RakaNo ratings yet

- Mock 8Document27 pagesMock 8Otob NitroNo ratings yet

- Sa 193Document16 pagesSa 193ArpitNo ratings yet

- Astm A744-A744m 2010Document6 pagesAstm A744-A744m 2010Júlio RosaNo ratings yet

- H12 M-10 H12 MV-10: Data SheetDocument4 pagesH12 M-10 H12 MV-10: Data SheetDirceu ValadaresNo ratings yet

- Magnetic Level Gauges & Level Transmitters: FeaturesDocument3 pagesMagnetic Level Gauges & Level Transmitters: Featuressunshine dreamNo ratings yet

- Material Data Sheet Stainless Steel Sheet Aisi 301Document2 pagesMaterial Data Sheet Stainless Steel Sheet Aisi 301Andrea MartinezNo ratings yet

- BS en 1011-5Document14 pagesBS en 1011-5Peter TvardzíkNo ratings yet

- Metals: - Ferrous Metals - Non-Ferrous MetalsDocument4 pagesMetals: - Ferrous Metals - Non-Ferrous MetalsRavi Kumar SinghNo ratings yet

- Austenitic Alloy Hardness ConversionDocument1 pageAustenitic Alloy Hardness ConversiongoggerNo ratings yet

- Micro-Line Straight Handpiece-Angled Handpiece (TA-Nr. 012581) (03-13)Document6 pagesMicro-Line Straight Handpiece-Angled Handpiece (TA-Nr. 012581) (03-13)Renata NataNo ratings yet

- Fig-4970-4970G-NEW DESIGNDocument1 pageFig-4970-4970G-NEW DESIGNAsmaaNo ratings yet

- LR Approved Manufacturers of Steel Castings 100104 PDFDocument41 pagesLR Approved Manufacturers of Steel Castings 100104 PDFmaxwell onyekachukwuNo ratings yet

- Relief Valve DimensionsDocument12 pagesRelief Valve DimensionsPTC Phils.100% (1)

- A 50RO BG Hydronic Heating and Plumbing Products BrochureDocument40 pagesA 50RO BG Hydronic Heating and Plumbing Products Brochuresasan49100% (1)

- Coriolis-Micro Motion - EB-20005377Document66 pagesCoriolis-Micro Motion - EB-20005377Juan Dela CruzNo ratings yet