Professional Documents

Culture Documents

Industry LubeOil CrusherLubeTanksGearbox ASIN5094UK

Industry LubeOil CrusherLubeTanksGearbox ASIN5094UK

Uploaded by

Lmf DanielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Industry LubeOil CrusherLubeTanksGearbox ASIN5094UK

Industry LubeOil CrusherLubeTanksGearbox ASIN5094UK

Uploaded by

Lmf DanielCopyright:

Available Formats

Lube Oil

Crusher Lube Tanks, Gearbox

CJC™ Application Study

CUSTOMER

Application Study BHP Billiton Iron Ore, Newman, W.A., Australia

written by:

THE SYSTEM

Mr. Barry Kirkup Crusher Lube Tanks, gearbox, primary and secondary

Mining & Hydraulics Suppliers crusher, at BENE Plant.

West Australia

Primary Crusher Name: Allis Chalmers Gyratory

Oil Type: BP GR-XP ISO 150

Oil Volume: 2000 L

Distributor for: THE PROBLEM

The oil in the crusher lube tank had a high level of con-

Stauff Corporation Pty. Ltd.

tamination due to dirt/dust ingress. Prior to this project,

Authorised Agents for

the ISO cleanliness level of this oil was generally above

C.C.JENSEN A/S

ISO 23/22/21. This relates to above 80,000 particles

in Australia and

larger than 4 micron per mL of oil. This is detrimental to

New Zealand the crusher, as it leads to excessive wear and premature

failure of the lube pumps, bushes and other wear compo-

2007 nents of the crusher. The CJC™ HDU 27/54 P in BENE Lube Room

THE SOLUTION

A CJC™ Fine Filter HDU 27/54 P (pump flow 400 L/

hr) with CJC™ Filer Inserts 2 x B 27/27 was installed

on each crusher to filter the oil and remove harmful con-

taminants.

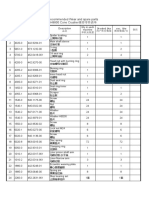

PARTICLE COUNT OVER TIME

THE TEST

The filtration system was installed in January during a 90000

80000 > 4 micron

BENE shut down and commissioned on 1/2/2007. The

oil in the crusher lube tank was also changed out during > 6 micron

No. of Particles per mL

70000

this shut down. The oil was sampled and tested on site >14 micron

60000

in the CM lab every week as per the condition monito-

ring schedule. This allowed the progress of the filtration 50000

system to be closely monitored. 40000

30000

THE RESULT 20000

Data in the table shows a steady decrease in contamina- 10000

tion level during the three months after the CJC™ Fine

0

Filter was installed. Target level was set to 20/17/15.

The ISO cleanliness level during this time dropped from Before 1 month 3 months TARGET

24/22/14 to 18/16/12. This average drop of five ISO filtration after after

cleanliness codes relates to the crusher lube oil being 32

times cleaner than before the installation.

THE RESULT

NB: The complete report is available for BHP Billiton

mines - please contact: BENE PRIMARY CRUSHER

BHP Billiton Iron Ore After 1 After 3

Leanne MacAdams, Reliability Engineer Particles Before TARGET

Month Months

Whaleback Maintenance, BHP Billiton Iron Ore

> 4 micron 82289 32196 2133 10000

e-mail: Leanne.MacAdams@bhpbilliton.com

> 6 micron 21378 5126 497 1300

SUMMARY >14 micron 103 72 27 320

“This project successfully reduced the contamination ISO 24/22/14 22/20/13 18/16/12 20/17/15

level in the crusher to below the target cleanliness level.

This has significant impact on the life of the wear com- No. of Particles per mL

ponents in the crushers.”

ASIN5094-UK C.C.JENSEN A/S

Mining Løvholmen 13 y DK-5700 Svendborg y Denmark

Crushers Phone: +45 6321 2014 y Fax: +45 6222 4615

19.01.2009 filter@cjc.dk y www.cjc.dk

You might also like

- Product 096 PDF Crushing2Document1 pageProduct 096 PDF Crushing2Lmf DanielNo ratings yet

- 5JTANordberg Cone ReplacementDocument32 pages5JTANordberg Cone ReplacementLmf DanielNo ratings yet

- 150 103 Burner Control For Gas and Oil Burners Flame Sensor: D-GF D-LeDocument6 pages150 103 Burner Control For Gas and Oil Burners Flame Sensor: D-GF D-LeLmf DanielNo ratings yet

- sj-9 Hauck BurnerDocument52 pagessj-9 Hauck BurnerLmf DanielNo ratings yet

- Anly Two Digi Timer RelayDocument2 pagesAnly Two Digi Timer RelayLmf DanielNo ratings yet

- QS331 Cone Crusher: Features & BenefitsDocument34 pagesQS331 Cone Crusher: Features & BenefitsLmf DanielNo ratings yet

- Warm Air Heater ManualDocument32 pagesWarm Air Heater ManualLmf DanielNo ratings yet

- cs550 Specification Sheet EnglishDocument5 pagescs550 Specification Sheet EnglishLmf DanielNo ratings yet

- Sandvik Cs550 Cone Crusher: Technical SpecificationDocument8 pagesSandvik Cs550 Cone Crusher: Technical SpecificationLmf DanielNo ratings yet

- CV115-129 01 Interlock S226.037 01Document22 pagesCV115-129 01 Interlock S226.037 01Lmf DanielNo ratings yet

- 708 05 Fenner CouplingsDocument18 pages708 05 Fenner CouplingsLmf Daniel100% (1)

- 800i Connected Cone Crusher Brochure EnglishDocument5 pages800i Connected Cone Crusher Brochure EnglishLmf DanielNo ratings yet

- 6000 Spa PDFDocument51 pages6000 Spa PDFLmf DanielNo ratings yet

- Recommended Wear and spare parts H8800 Cone Crusher推荐零件清单Document3 pagesRecommended Wear and spare parts H8800 Cone Crusher推荐零件清单Lmf DanielNo ratings yet

- S226.027.en - Vibration SwitchDocument6 pagesS226.027.en - Vibration SwitchLmf DanielNo ratings yet

- S226-049.00 Daily Log - enDocument10 pagesS226-049.00 Daily Log - enLmf DanielNo ratings yet

- Filter-Insert-Replacement HDU1525 CJCDocument1 pageFilter-Insert-Replacement HDU1525 CJCLmf Daniel100% (1)

- Hydrocone Manual - S223.360.01.en PDFDocument291 pagesHydrocone Manual - S223.360.01.en PDFLmf Daniel100% (2)

- Article Cleaner Oil With CJC Oil Filters Sandvik Stenkoll March 2017-UKDocument2 pagesArticle Cleaner Oil With CJC Oil Filters Sandvik Stenkoll March 2017-UKLmf DanielNo ratings yet

- Washing Equipment Product Handbook - WEB - 06 2016Document52 pagesWashing Equipment Product Handbook - WEB - 06 2016Lmf DanielNo ratings yet

- PXF Operation Manual For PXF PDFDocument199 pagesPXF Operation Manual For PXF PDFLmf DanielNo ratings yet

- LG1525 Psst1102ukDocument2 pagesLG1525 Psst1102ukLmf DanielNo ratings yet

- TFDocument2 pagesTFLmf DanielNo ratings yet

- 2300-AFS Auxiliary Filtration System PDFDocument8 pages2300-AFS Auxiliary Filtration System PDFLmf DanielNo ratings yet

- Hdu1525 Psst1000ukDocument2 pagesHdu1525 Psst1000ukLmf DanielNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- CLDR Sample ExamDocument28 pagesCLDR Sample ExamYoussefNo ratings yet

- Introduction To Coiled TubingDocument131 pagesIntroduction To Coiled TubingAmin Dehghani100% (2)

- Atlas Copco Xrvs 476 Manual PDFDocument104 pagesAtlas Copco Xrvs 476 Manual PDFpowermanagerNo ratings yet

- ADAU1592Document25 pagesADAU1592Aniket SinghNo ratings yet

- BQDocument136 pagesBQfateenhananeyNo ratings yet

- EY Accounting Policy ManualDocument4 pagesEY Accounting Policy ManualInzamum Ul-Haque67% (3)

- Examen Ingles B1Document2 pagesExamen Ingles B1Raquel trheNo ratings yet

- 20 X 70Document102 pages20 X 70MatAlengNo ratings yet

- Blog 04 04 2012Document415 pagesBlog 04 04 2012Sumesh ThandanNo ratings yet

- ITS Webinar - Tantangan Pada Pelaksanaan (01.10.2022)Document23 pagesITS Webinar - Tantangan Pada Pelaksanaan (01.10.2022)Destra Dwi Falah SetyamaNo ratings yet

- Check List of Cable Tray ErectionDocument1 pageCheck List of Cable Tray ErectionUtku Can Kılıç0% (2)

- Parking Brake SystemDocument6 pagesParking Brake Systemnipuna22No ratings yet

- ERPDocument7 pagesERPaartikalaniNo ratings yet

- H99936801 - SMMSi Owners Manual HT5 60HzDocument21 pagesH99936801 - SMMSi Owners Manual HT5 60HzRoberto FloresNo ratings yet

- Summer Internship Report - Docx123Document87 pagesSummer Internship Report - Docx123Preksha JainNo ratings yet

- Director Marketing Communications in Salt Lake City UT Resume Stephen AuberyDocument2 pagesDirector Marketing Communications in Salt Lake City UT Resume Stephen AuberyStephenAuberyNo ratings yet

- Characteristics, Processes and Ethics of ResearchDocument3 pagesCharacteristics, Processes and Ethics of ResearchJanelle Ilao CabinganNo ratings yet

- Leadership As An Essential Skill in Human's Life: A. IntroductionDocument3 pagesLeadership As An Essential Skill in Human's Life: A. Introductionkevin0% (1)

- BYPASS PANEL DrawingDocument10 pagesBYPASS PANEL DrawingNiranjan KumarNo ratings yet

- Half-Wave Flower Pot Antenna - VK2ZOIDocument9 pagesHalf-Wave Flower Pot Antenna - VK2ZOIEiber Eloy Azuaje MejíasNo ratings yet

- Welding Consumables CH-16Document40 pagesWelding Consumables CH-16Qaisir MehmoodNo ratings yet

- Voyage Planner: Installation & Operation InstructionsDocument32 pagesVoyage Planner: Installation & Operation Instructionskullanici2010No ratings yet

- User Manual TMS 300 Rayos X PortatilDocument37 pagesUser Manual TMS 300 Rayos X Portatilpablo50% (2)

- Puri InvDocument5 pagesPuri Invwoki hojNo ratings yet

- Red Hat LinuxDocument12 pagesRed Hat LinuxJendral CannavaroNo ratings yet

- Solved Computer MCQs For UDC/LDC MS OFFICEDocument40 pagesSolved Computer MCQs For UDC/LDC MS OFFICErashid33% (3)

- IFly 744 TutorialDocument84 pagesIFly 744 Tutorialleopolman100% (1)

- LRTC - Light Rail Transit ConsultantsDocument25 pagesLRTC - Light Rail Transit Consultantsgautam anandNo ratings yet

- Part List - Piston & Rod Group PDFDocument2 pagesPart List - Piston & Rod Group PDFRahulNo ratings yet

- PPAP Part Submission Warrant.Document4 pagesPPAP Part Submission Warrant.aperezpi26606No ratings yet