Professional Documents

Culture Documents

WP5 HDGAS Final-Event Poster MAN

WP5 HDGAS Final-Event Poster MAN

Uploaded by

Dan Rosoiu0 ratings0% found this document useful (0 votes)

8 views1 pageOriginal Title

WP5_HDGAS_Final-Event_Poster_MAN

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views1 pageWP5 HDGAS Final-Event Poster MAN

WP5 HDGAS Final-Event Poster MAN

Uploaded by

Dan RosoiuCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

This project has received funding from the European Union’s Horizon 2020 research and innovation programme

under Grant Agreement no. 653391

MAN LNG Truck with low pressure Dual-Fuel Engine

LNG will become latest 2025 an alternative to diesel in European

long haul transport (time schedule EU-Directive 2014/94/EU).

Dual-Fuel Technology has high potentials to increase GHG/fuel efficiency

compared to state of the art NG-powertrains in the market.

Objectives & Results

• Development Dual-Fuel engine with external mixture (IDIADA)

TGX with Dual-Fuel powertrain • Development LNG Tank with electric low pressure pump (SAG, WP2)

• Truck-integration DF powertrain/LNG storage/fuel quality sensor (MAN)

• Optimization of LNG refilling (MAN, SAG)

• Package investigations finalized (MAN)

• Commissioning LNG low pressure pump finalized (MAN)

• Truck is tested/running in Dual-Fuel mode (MAN)

TGX 18.480 4X2 BLS

Truck Model

GVW 18t (tractor); 40 t (tractor/trailer), wheelbase 3,6 m;

Base Engine D2676 LF25, 353 kW/480 hp, 2300 Nm, Euro VI

Engine

Dual-Fuel Engine Converted to Dual-Fuel operation (NG, Diesel)

(Partner IDIADA) • Methane Oxidation Catalyst MOC

Exhaust

• Selective Catalytic Reduction SCR (same as Diesel)

Aftertreatment

• Diesel Particulate Filter DPF (same as Diesel)

Transmission Model TipMatic 12 (12-speed direct drive, Intarder)

Mileage > 1000 km

Diesel/Urea Tank

LNG Fuel Quality Sensor

Rear Battery System

LNG Tank 850 l (system); 400 kg (net weight)

Methane Oxidation Catalyst MOC

LNG Fuel 550 l; 200 - 230 kg (-140°C / -160°C)

NG 2 - 8 bar (after refueling), 16 bar (tank boil off)

Pressures 12 - 16 bar (ICE supply by LNG-pump)

Diesel/Urea 470 l (diesel), 80 l (urea)

LNG Tank (Partner SAG) Fuel Storage

LNG Filling Tests

FEM

Simulation

www.HDGAS.eu

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Reeds-8 General Engineering Knowledge For Marine Engineers.Document265 pagesReeds-8 General Engineering Knowledge For Marine Engineers.habesha0288% (16)

- Type Rating 738NG ResumeDocument4 pagesType Rating 738NG ResumeAndito MurtiNo ratings yet

- Bma4723 Vehicle Dynamics Chap 22Document35 pagesBma4723 Vehicle Dynamics Chap 22Fu HongNo ratings yet

- Prueba de Inyectores de La Serie 7000Document13 pagesPrueba de Inyectores de La Serie 7000FredySonccoNo ratings yet

- Hydraulic ExcavatorDocument22 pagesHydraulic ExcavatorUjjwal ShresthaNo ratings yet

- Technical Data Sheets Special Vehicles enDocument16 pagesTechnical Data Sheets Special Vehicles enDan RosoiuNo ratings yet

- R1937-JSA-003 Job Safety Analysis For TrenchingDocument5 pagesR1937-JSA-003 Job Safety Analysis For TrenchingVineet AgrawalNo ratings yet

- Pe Renault-2014Document112 pagesPe Renault-2014Dan RosoiuNo ratings yet

- 50TPD Soybean Oil Batch Type Solvent Extraction PlantDocument4 pages50TPD Soybean Oil Batch Type Solvent Extraction PlantKenan KardasNo ratings yet

- MT050 Series Dehydrator User ManualDocument32 pagesMT050 Series Dehydrator User ManualSalvador López Arranz100% (1)

- Catalina 310 Owners Manualv2Document88 pagesCatalina 310 Owners Manualv2Jesse K On SmittyNo ratings yet

- Super ASTMDocument2 pagesSuper ASTMAnbarasan AnandhanNo ratings yet

- Crude Oil Banyu Urip Assay PDF NewDocument1 pageCrude Oil Banyu Urip Assay PDF NewShopstellar id100% (1)

- PickupDocument1 pagePickupDan RosoiuNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalDan RosoiuNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalDan RosoiuNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalDan RosoiuNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalDan RosoiuNo ratings yet

- TrooperDocument1 pageTrooperDan RosoiuNo ratings yet

- электрикаDocument72 pagesэлектрикаDan RosoiuNo ratings yet

- Pe Sae-Gigant-2015Document36 pagesPe Sae-Gigant-2015Dan RosoiuNo ratings yet

- Каталог ADocument1,460 pagesКаталог ADan RosoiuNo ratings yet

- Data Book: Automotive TechnicalDocument1 pageData Book: Automotive TechnicalDan RosoiuNo ratings yet

- Pe Meritor-Ror-2015Document60 pagesPe Meritor-Ror-2015Dan RosoiuNo ratings yet

- Pe Actros - 2015Document86 pagesPe Actros - 2015Dan RosoiuNo ratings yet

- Pe Kaessbohrer-Setra-2015Document76 pagesPe Kaessbohrer-Setra-2015Dan RosoiuNo ratings yet

- Pe Scania-2014Document220 pagesPe Scania-2014Dan RosoiuNo ratings yet

- Pe Mercedes - Benz-2015Document550 pagesPe Mercedes - Benz-2015Dan RosoiuNo ratings yet

- Pe Man - Tga-2014 PDFDocument162 pagesPe Man - Tga-2014 PDFDan RosoiuNo ratings yet

- Pe Iveco-2011Document158 pagesPe Iveco-2011Dan RosoiuNo ratings yet

- Pe Daf-2014Document218 pagesPe Daf-2014Dan RosoiuNo ratings yet

- Pe Man-2015Document376 pagesPe Man-2015Dan RosoiuNo ratings yet

- Emoss Ever Leaflet WebDocument2 pagesEmoss Ever Leaflet WebDan RosoiuNo ratings yet

- Epcdh6m11d0003 en GeneralDocument127 pagesEpcdh6m11d0003 en GeneralDan RosoiuNo ratings yet

- P445PTDocument141 pagesP445PTRafael ArandaNo ratings yet

- "Production of Hydrogen Gas Using Gasification From BiomassDocument40 pages"Production of Hydrogen Gas Using Gasification From BiomassFaizNo ratings yet

- Practical 3: Aim: Perform Various Tests Applied To Insulating OilDocument2 pagesPractical 3: Aim: Perform Various Tests Applied To Insulating OilDINESHNo ratings yet

- Paper On StoichometryDocument6 pagesPaper On StoichometryanupzodNo ratings yet

- CS Aluska Barry, Electrical EngineerDocument2 pagesCS Aluska Barry, Electrical EngineerLuis Alfonzo RodríguezNo ratings yet

- GX200 2-4 Service ManualDocument14 pagesGX200 2-4 Service ManualEliana CristinaNo ratings yet

- Ameron FRP Fittings 7000MDocument8 pagesAmeron FRP Fittings 7000MNatchimuthu Durai BalanNo ratings yet

- Emra Report 2021Document185 pagesEmra Report 2021Emir ArvasNo ratings yet

- Buttsworth D.R. - Spark Ignition Internal Combustion Engine Modelling Using MatlabDocument42 pagesButtsworth D.R. - Spark Ignition Internal Combustion Engine Modelling Using Matlabsuperhunter007No ratings yet

- 07 UltraClassic Maintenance InformationDocument12 pages07 UltraClassic Maintenance Informationmdavis1008No ratings yet

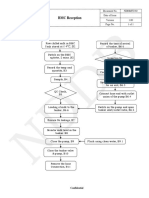

- NDDB Flow Chart BMC Milk ReceptionDocument3 pagesNDDB Flow Chart BMC Milk ReceptionUmesh Poudel JoJoNo ratings yet

- 1.1 About Areca Nut: Chapter-1Document34 pages1.1 About Areca Nut: Chapter-1Nehal PintoNo ratings yet

- SchuF Group - SpecialValve PDFDocument6 pagesSchuF Group - SpecialValve PDFkresimir.mikoc9765No ratings yet

- Methodology For Micro ConcrteDocument2 pagesMethodology For Micro ConcrteLokeswara Reddy75% (4)

- B&S 479cc Vanguard Engine ManualDocument13 pagesB&S 479cc Vanguard Engine ManualspaytNo ratings yet

- API vs. Asme-AnsiDocument2 pagesAPI vs. Asme-Ansinaruto256No ratings yet

- Spec 223 2Document1 pageSpec 223 2antvilaNo ratings yet

- Volvo ManualDocument141 pagesVolvo Manualrichieg7777No ratings yet

- Marine Books ShopDocument6 pagesMarine Books ShopsmithworkNo ratings yet