Professional Documents

Culture Documents

Designing of HV Power Substation and Layout PDF

Designing of HV Power Substation and Layout PDF

Uploaded by

Ragavan0 ratings0% found this document useful (0 votes)

13 views6 pagesOriginal Title

Designing of HV Power Substation and Layout.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views6 pagesDesigning of HV Power Substation and Layout PDF

Designing of HV Power Substation and Layout PDF

Uploaded by

RagavanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Designing of HV Power Substation and Layout

In designing the substation, three voltage

have to be considered:

Content 1. Touch Voltage: This is the difference in

potential between the surf ace potential

1. Introduction and the potential at an Earthed

2. Earthing and Bonding equipment whilst a man is standing and

3. Substation Earthing Calculation touching the earthed structure.

Methodology (Earthing Materials) 2. Step Voltage: This is the potential

4. Layout of Substation difference developed when a man

5. Different Layouts for Substations (single bridges a distance of 1m with his Feet

busbar, mesh, 1 1/2 cb) while not touching any other earthed

6. Principle of Substation Layouts (spatial equipment.

separation, maintenance zones) 3. Mesh Voltage: This is the maximum

7. Components of a Substation (cbs, cts, touch voltage that is developed in the

isolators, insulation, transformers etc.) mesh of the earthing grid.

Substation Earthing Calculation

Introduction

Methodology

Substations are the points in the power

network where transmission lines and

Calculations for earth impedances and touch

distribution feeders are connected

and step potentials are based on site

together through circuit breakers or switches

measurements of ground resistivity and

via busbars and transformers. This allows for

system fault levels. A grid layout with

the control of power flows in the network

particular conductors is then analyzed to

and general switching operations for

determine the effective substation earthing

maintenance purposes.

resistance, from which the earthing voltage is

The first step in designing a power substation

calculated. In practice, it is normal to take the

is to design an earthing and bonding system.

highest fault level for substation earth grid

calculation purposes.

Additionally, it is necessary to ensure a

Earthing and Bonding sufficient margin such that expansion of the

system is catered for.

The function of an earthing and bonding

system is to provide an earthing system To determine the earth resistivity, probe

connection to which transformer neutrals or tests are carried out on the site. These tests

earthing impedances may be connected in are best performed in dry weather such that

order to pass the maximum fault current. The conservative resistivity readings are

earthing system also ensures that no thermal obtained.

or mechanical damage occurs on the

equipment within the power substation, Earthing Materials

thereby resulting in safety too peration and

maintenance personnel.

1. Conductors

The earthing system also

Bare copper conductor is usually used for the

guarantees equipotential bonding such that

substation earthing grid. The copper bars

there are no dangerous potential gradients

Themselves usually have a cross-sectional

developed in the substation.

area of 95 square millimeters, and they are

laid at a shallow Depth of 0.25-0.5m, in 3-7m Methods have been adopted to achieve a

squares. compromise between complete security of

In addition to the buried potential earth grid, supply and capital investment.

a separate above ground earthing ring is

usually provided, to which all metallic There are four categories of substation that

substation plant is bonded. give varying securities of supply:

• Category 1 – No outage is necessary

within the substation for either

2. Connections: maintenance or fault conditions.

• Category 2 – Short outage is necessary

Connections to the grid and other earthing

to transfer the load to an alternative

joints should not be soldered because the heat

circuit for maintenance or fault

generated during fault conditions could

conditions.

cause a soldered joint to fail. Joints are

• Category 3 – Loss of a circuit or section

usually bolted and in this case, the face of the

of the substation due to fault or

joints should be tinned.

maintenance.

• Category 4 – Loss of the entire

substation due to fault or maintenance.

3. Earthing Rods

The earthing grid must be supplemented by Different Layouts for Substations

earthing rods to assist in the dissipation of

earth fault currents and further reduce the

overall substation earthing resistance. These

rods are usually made of solid copper, Single Busbar

or copper clad steel.

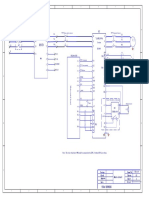

The general schematic for such a substation is

4. Switchyard Fence shown in the figure below.

Earthing: The switchyard fence earthing

practices are possibleand are used by

different utilities.

These are:

1. Extend the substation earth grid 0.5m-

1.5m beyond the fence perimeter. The

fence is then bonded to the grid at

regular intervals.

2. Place the fence beyond the perimeter of

the switchyard earthing grid and bond

Single- busbar substation layout

the fence to its own earthing rod system.

This earthing rod system is not coupled

With this design, there is an ease of operation

to the main substation earthing grid.

of the substation. This design also places

minimum reliance on signaling for

satisfactory operation of protection.

Additionally there is the facility to support

Layout of Substation the economical operation of future feeder

bays.

The layout of the substation is very important Such a substation has the following

since there should be a security of supply. characteristics:

In an ideal substation all circuits and 1. Each circuit is protected by its own circuit

equipment would be duplicated such that breaker and hence plant outage does not

following a fault, or during maintenance, a necessarily result in loss of supply.

connection remains available. Practically this 2. A fault on the feeder or transformer

is not feasible since the cost of circuit breaker causes loss of the

implementing such a design is very high. transformer and feeder circuit, one of

which may be restored after isolating the The layout of a 1 1/2 circuit breaker

faulty circuit breaker. substation is shown in the schematic below.

3. A fault on the bus section circuit breaker

causes complete shutdown of the

substation. All circuits may be restored

after isolating the faulty circuit breaker.

A busbar fault causes loss of one

transformer and one feeder.

4. Maintenance of one busbar section or

isolator will cause the temporary outage

of two circuits.

5. Maintenance of a feeder or transformer

circuit breaker involves loss of the circuit.

6. Introduction of bypass isolators between One and a half Circuit Breaker layout

busbar and circuit isolator allows circuit

breaker maintenance facilities without The reason that such a layout is known as a 1

loss of that circuit. 1/2 circuit breaker is due to the fact that in

the design, there are 9 circuit breakers that

Mesh Substation are used to protect the 6 feeders. Thus, 1 1/2

circuit breakers protect 1 feeder.

The general layout for a full mesh substation

is shown in the schematic below. Some characteristics of this design are:

1. There is the additional cost of the circuit

Full mesh substation layout breakers together with the complex

arrangement.

2. It is possible to operate any one pair of

circuits, or groups of pairs of circuits.

3. There is a very high security against the

loss of supply.

Principle of Substation Layouts

Substation layout consists essentially in

The characteristics of such a substation are as arranging a number of switchgear

follows. Operation of two circuit breakers is components in an ordered pattern governed

required to connect or disconnect a circuit, by their function and rules of spatial

and disconnection involves opening of a separation.

mesh. Circuit breakers may be maintained

without loss of supply or protection, and no

additional bypass facilities are required.

Busbar faults will only cause the loss of one Spatial Separation

circuit breaker. Breaker faults will involve the

loss of a maximum of two circuits. generally, 1. Earth Clearance – this is the clearance

not more than twice as many outgoing between live parts and earthed

circuits as in feeds are used in order to structures, walls, screens and ground.

rationalize circuit equipment load capabilities 2. Phase Clearance – this is the clearance

and ratings. between live parts of different phases.

3. Isolating Distance – this is the clearance

between the terminals of an isolator and

the connections There to.

One and a half Circuit Breaker layout

4. Section Clearance – this is the clearance

between live parts and the terminals of a

work section. The limits of this work

section, or maintenance zone, may be the

ground or a platform from which There are at least three such electrical

the man works. separations per phase that are needed in a

circuit:

Separation of Maintenance Zones 1. Between the terminals of the bus bar

isolator and their connections.

2. Between the terminals of the circuit

Two methods are available for separating

breaker and their connections.

equipment in a maintenance zone that has

3. Between the terminals of the feeder

been isolated and made dead:

isolator and their connections.

1. The provision of a section clearance

2. Use of an intervening earthed barrier Components of a Substation

The choice between the two methods

depends on the voltage and whether The substation components will only be

horizontal or vertical clearances are considered to the extent where they influence

involved. A section clearance is composed of substation layout.

a the reach of a man, taken as 8 feet, plus an

earth clearance. For the voltage at which the

earth clearance is 8 feet, the space required Circuit Breakers

will be the same whether a section clearance

or an earthed barrier is used.

There are two forms of open circuit breakers:

1. Dead Tank – circuit breaker compartment

HENCE: is at earth potential.

Separation by earthed barrier = Earth 2. Live Tank – circuit breaker compartment

Clearance + 50mm for barrier + Earth is at line potential.

Clearance The form of circuit breaker influences the

Separation by section clearance = 2.44m + way in which the circuit breaker is

Earth clearance accommodated. This may be one of four

For vertical clearances it is necessary to take ways.

into account the space occupied by the

equipment and the need for an access

platform at higher voltages. The height of the 1. Ground Mounting and Plinth Mounting

platform is taken as 1.37m below the highest

point of work. The main advantages of this type of

mounting are its simplicity, ease of erection,

ease of maintenance and elimination of

Establishing Maintenance Zones support structures. An added advantage is

that in indoor substations, there is the

reduction in the height of the building. A

Some maintenance zones are easily defined

disadvantage however is that to prevent

and the need for them is self evident as is the

danger to personnel, the circuit breaker has to

case of a circuit breaker. There should be a

be surrounded by an earthed barrier, which

means of isolation on each side of the circuit

increases the area required.

breaker, and to separate it from adjacent live

parts, when isolated, either by section Retractable Circuit Breakers

clearances or earth barriers.

These have the advantage of being space

Electrical Separations saving due to the fact that isolators can be

accommodated in the same area of clearance

Together with maintenance zoning, the that has to be allowed between the retractable

separation, by isolating distance and phase circuit breaker and the live fixed contacts.

clearances, of the substation components and Another advantage is that there is the ease

of the conductors interconnecting them and safety of maintenance. Additionally such

constitute the main basis of substation a mounting is economical since at least two

layouts. insulators per phase are still needed to

support the fixed circuit breaker plug • Insulation Security

contacts. • Standardization

• Ease of Maintenance

• Cost

Suspended Circuit Breakers Some types of isolators include:

• Horizontal Isolation types

At higher voltages tension insulators are • Vertical Isolation types

cheaper than post or pedestal insulators.

• Moving Bushing types

With this type of mounting the live tank

circuit breaker is suspended by tension

insulators from overhead structures, and held Conductor Systems

in a stable position by similar insulators

tensioned to the ground. There is the claimed An ideal conductor should fulfil the

advantage of reduced costs and simplified following requirements:

foundations, and the structures used to • Should be capable of carrying the

suspend the circuit breakers may be used for specified load currents and short time

other purposes. currents.

• Should be able to withstand forces on

it due to its situation. These forces

comprise self weight, and

• Weight of other conductors and

equipment, short circuit forces and

Current Transformers

atmospheric forces such as wind and

ice loading.

CT’s may be accommodated in one of six • Should be corona free at rated voltage.

manners: • Should have the minimum number of

1. Over Circuit Breaker bushings or in joints.

pedestals.

• Should need the minimum number of

2. In separate post type housings.

supporting insulators.

3. Over moving bushings of some types of

• Should be economical.

insulators.

The most suitable material for the conductor

4. Over power transformers of reactor

system is copper or aluminium. Steel may be

bushings.

used but has limitations of poor conductivity

5. Over wall or roof bushings.

and high susceptibility to corrosion. In an

6. Over cables.

effort to make the conductor ideal, three

In all except the second of the list, the CT’s

different types have been utilized, and these

occupy incidental space and do not affect the

include:

size of the layout. The CT’s become more

• Flat surfaced Conductors

remote from the circuit breaker in the order

• Stranded Conductors

listed above. Accommodation of CT’s over

• Tubular Conductors

isolator bushings, or bushings through walls

or roofs, is usually confined to

indoor substations. Insulation

Insulation security has been rated very highly

among the aims of good substation design.

Isolators

Extensive research is done on improving

These are essentially off load devices

flashover characteristics as well as combating

although they are capable of dealing with

pollution. Increased creepage length,

small charging currents of busbars and

resistance glazing, insulation greasing and

connections. The design of isolators is closely

line washing have been used with varying

related to the design of substations.

degrees of success.

Isolator design is considered in the following

aspects:

• Space Factor Power Transformers

EHV power transformers are usually oil

immersed with all three phases in one tank.

Auto transformers can offer advantage of

smaller physical size and reduced losses.

The different classes of power transformers

are:

• o.n.: Oil immersed, natural cooling

• o.b.: Oil immersed, air blast cooling

• o.f.n.: Oil immersed, oil circulation

forced

• o.f.b.: Oil immersed, oil circulation

forced, air blast cooling

Power transformers are usually the largest

single item in a substation. For economy of

service roads, transformers are located on one

side of a substation, and the connection to

switchgear is by bare conductors. Because of

the large quantity of oil, it is essential to take

precaution against the spread of fire.

Hence, the transformer is usually located

around a sump used to collect the excess oil.

Transformers that are located and a cell

should be enclosed in a blast proof room.

Overhead Line Terminations

Two methods are used to terminate overhead

lines at a substation.

1. Tensioning conductors to substation

structures or buildings

2. Tensioning conductors to ground

winches.

The choice is influenced by the height of

towers and the proximity to the

substation. The following clearances should

be observed:

Voltage Level Minimum Ground

Clearance

Less than 66kV 6.1 m

66kV – 110kV 6.4 m

110kV – 165kV 6.7 m

Greater 7.0 m

than 165kV

You might also like

- Ieee C37.20.1-1987Document36 pagesIeee C37.20.1-1987Febry Aryanto100% (1)

- Fuji Yida Plano Electrico Yaskawa H1000Document14 pagesFuji Yida Plano Electrico Yaskawa H1000oro plata100% (2)

- Worksheet 28 PDFDocument2 pagesWorksheet 28 PDFVijay Bhaskar100% (3)

- Earthing and Bonding: The First Step in Designing A Substation Is To Design An Earthing and Bonding SystemDocument10 pagesEarthing and Bonding: The First Step in Designing A Substation Is To Design An Earthing and Bonding Systempiyush_ppNo ratings yet

- Designing of HV Power Substation and LayoutDocument11 pagesDesigning of HV Power Substation and LayoutSuresh UmadiNo ratings yet

- Seminar Report On SDMADocument13 pagesSeminar Report On SDMAdarpansinghalNo ratings yet

- Substation LayoutDocument9 pagesSubstation LayoutReynan Gabriel BugayongNo ratings yet

- Specification For Power System Analysis SoftwareDocument4 pagesSpecification For Power System Analysis SoftwareTaniguevelane DjenarthananeNo ratings yet

- Hy Hydromatrix en Data PDFDocument16 pagesHy Hydromatrix en Data PDFJuanNo ratings yet

- Spare GuidelinesDocument81 pagesSpare GuidelinesPradeep SinghNo ratings yet

- Brochures PDFDocument11 pagesBrochures PDFFiroDjinsoNanoNo ratings yet

- Exploring The IEEE C37.234 Guide For Protective Relay Application To Power System BusesDocument10 pagesExploring The IEEE C37.234 Guide For Protective Relay Application To Power System BusesJawadNo ratings yet

- Sec.5-230 KV Control-Protection PakseDocument117 pagesSec.5-230 KV Control-Protection PakseLove Buddha's WordsNo ratings yet

- A Review Paper On Technical Data of Present HVDC Links in IndiaDocument7 pagesA Review Paper On Technical Data of Present HVDC Links in IndiaEditor IJRITCCNo ratings yet

- NSD 50&mcdDocument25 pagesNSD 50&mcdkrishnamanikandanNo ratings yet

- Backup To Busbar Protection With Numerical Distance ProtectionDocument4 pagesBackup To Busbar Protection With Numerical Distance ProtectionTran Cong ThanhNo ratings yet

- Energy Audit of A 400-220 KV Substation - A Case Study PDFDocument8 pagesEnergy Audit of A 400-220 KV Substation - A Case Study PDFRajuNo ratings yet

- KP PPTDocument22 pagesKP PPTSaurabh AgarwalNo ratings yet

- Sandeep Dixit: Understanding Load Dispatch-Abt-Grid Code-Standards InterplayDocument50 pagesSandeep Dixit: Understanding Load Dispatch-Abt-Grid Code-Standards Interplayvikas_nptiNo ratings yet

- Guidelines For The Installation of Cable in Cable Trays PDFDocument7 pagesGuidelines For The Installation of Cable in Cable Trays PDFStefanos DiamantisNo ratings yet

- 3 Distribution System DesignDocument15 pages3 Distribution System DesignAHMED YOUSEFNo ratings yet

- Bushing TestingDocument8 pagesBushing TestingjoseNo ratings yet

- Kishenpur Grid Station CompleteDocument39 pagesKishenpur Grid Station CompletepunitkapoorNo ratings yet

- Introduction To Harmonic Analysis Basics - R2Document46 pagesIntroduction To Harmonic Analysis Basics - R2salemg82No ratings yet

- PGCIL ET Salary in Hand, Structure & Allowances - OlxamDocument3 pagesPGCIL ET Salary in Hand, Structure & Allowances - OlxamAravindanNo ratings yet

- Transformers ConnectionsDocument6 pagesTransformers Connectionsgeorgel1980No ratings yet

- Component of HVDC Transmission NetworkDocument5 pagesComponent of HVDC Transmission NetworkIqbalilah RamdaniNo ratings yet

- Micom Agile P841: Grid SolutionsDocument8 pagesMicom Agile P841: Grid SolutionsTaQuangDucNo ratings yet

- Summary Paper For For C37 243 IEEE Guide For Application of Digital Line Current Differential Relays PSRC Sept 2016 v5Document20 pagesSummary Paper For For C37 243 IEEE Guide For Application of Digital Line Current Differential Relays PSRC Sept 2016 v5Debayan BhattacharyaNo ratings yet

- On-Line Estimation of Transmission Line Parameters, Temperature and Sag Using PMU MeasurementsDocument7 pagesOn-Line Estimation of Transmission Line Parameters, Temperature and Sag Using PMU Measurementswvargas926No ratings yet

- RM6 ManualDocument56 pagesRM6 ManualMuhammed DemirNo ratings yet

- Fast Methods For Transient Stability Prediction in Power SystemsDocument20 pagesFast Methods For Transient Stability Prediction in Power SystemslisusedNo ratings yet

- Components: Citation NeededDocument2 pagesComponents: Citation Neededarundas16No ratings yet

- Adaptive Protection Scheme For Smart GridsDocument6 pagesAdaptive Protection Scheme For Smart GridsMiguel QuispeNo ratings yet

- Small EPABX Systems Configuaration: Schedule 1Document24 pagesSmall EPABX Systems Configuaration: Schedule 1rads2012No ratings yet

- Prospects of Bulk Power EHV and UHV Transmission (PDFDrive)Document20 pagesProspects of Bulk Power EHV and UHV Transmission (PDFDrive)Prashant TrivediNo ratings yet

- Bus Bar TEST REPORTDocument17 pagesBus Bar TEST REPORTAmmu KuttiyNo ratings yet

- Advanced Event Analysis Tutorial: Part 1: QuestionsDocument5 pagesAdvanced Event Analysis Tutorial: Part 1: QuestionsDanilo Poma MuñozNo ratings yet

- OHL AmpacityDocument8 pagesOHL AmpacityJayabalan R KNo ratings yet

- HVDC TransmissionDocument16 pagesHVDC TransmissionAritra ChatterjeeNo ratings yet

- Introduction of Electric Power SystemDocument17 pagesIntroduction of Electric Power SystemsohaibNo ratings yet

- 6 RTU Specifications III A 2216Document10 pages6 RTU Specifications III A 2216rasim_m1146No ratings yet

- UPFC Detailed Model MATLAB and SimulinkDocument3 pagesUPFC Detailed Model MATLAB and SimulinkEdilberto MJNo ratings yet

- HVDC TransmissionDocument14 pagesHVDC TransmissionAxay ShahNo ratings yet

- Xr-Ee-Es 2009 007Document109 pagesXr-Ee-Es 2009 007Kumail Hasan NaqviNo ratings yet

- Diesel Generator Information SheetDocument4 pagesDiesel Generator Information Sheetmauricio_rodrigues09No ratings yet

- GE B90 PresentationDocument71 pagesGE B90 PresentationIsuru WijewardeneNo ratings yet

- II - Technical Specification CRP - Thapagundu PDFDocument98 pagesII - Technical Specification CRP - Thapagundu PDFSumukh MahekarNo ratings yet

- 765kV Layout Rev - 3Document2 pages765kV Layout Rev - 3400KVNo ratings yet

- SIP5 APN 037 - Selection of SIPROTEC5 Device With PMU Functionality PDFDocument18 pagesSIP5 APN 037 - Selection of SIPROTEC5 Device With PMU Functionality PDFChintanPandyaNo ratings yet

- Module 4: Substation Equipment's Details and Operations: July 2021Document14 pagesModule 4: Substation Equipment's Details and Operations: July 2021Gundeboyina GopiNo ratings yet

- Optimal Capacitor Placement Using EtapDocument8 pagesOptimal Capacitor Placement Using Etapjoydeep_d3232No ratings yet

- Material List CivilDocument7 pagesMaterial List CivilRhuss SalazarNo ratings yet

- Midway Report: Project Semester: Study of 220KV Substation and SLDCDocument15 pagesMidway Report: Project Semester: Study of 220KV Substation and SLDCdamanpreet singhNo ratings yet

- Lecture 6 Synchronous Machine ModelingDocument57 pagesLecture 6 Synchronous Machine ModelingManuelNo ratings yet

- MK Giridharan Latest EditionDocument2 pagesMK Giridharan Latest EditionBenadict JoshuaNo ratings yet

- Reactive Power Compensation Using Capacitor BanksDocument164 pagesReactive Power Compensation Using Capacitor BanksjujuNo ratings yet

- Integration of Green and Renewable Energy in Electric Power SystemsFrom EverandIntegration of Green and Renewable Energy in Electric Power SystemsNo ratings yet

- The Void in ManDocument1 pageThe Void in ManRagavanNo ratings yet

- Ÿ Váèwáè Ô - S ÷B Ôôd ÷ Ô - SLB - Ô - S Gı - 2019Á21 ( Luæÿ/Va: T )Document20 pagesŸ Váèwáè Ô - S ÷B Ôôd ÷ Ô - SLB - Ô - S Gı - 2019Á21 ( Luæÿ/Va: T )RagavanNo ratings yet

- துனைநூற்பட்டியல்Document11 pagesதுனைநூற்பட்டியல்RagavanNo ratings yet

- Ocs SopDocument6 pagesOcs SopRagavan0% (1)

- State Wise Length Nhs IndiaDocument21 pagesState Wise Length Nhs IndiaRagavanNo ratings yet

- 765kV - Bornagar SS DetailsDocument24 pages765kV - Bornagar SS DetailsRagavanNo ratings yet

- Designing of HV Power Substation and LayoutDocument6 pagesDesigning of HV Power Substation and LayoutRagavanNo ratings yet

- Monthly Progress Report of Critical Transmission Projects Under Central, State and Private SectorDocument32 pagesMonthly Progress Report of Critical Transmission Projects Under Central, State and Private SectorRagavanNo ratings yet

- Exe Summary Ss-12Document1 pageExe Summary Ss-12RagavanNo ratings yet

- Construction TX 12Document91 pagesConstruction TX 12RagavanNo ratings yet

- Ats 12Document53 pagesAts 12RagavanNo ratings yet

- Construction Ss 12Document87 pagesConstruction Ss 12RagavanNo ratings yet

- Competitive 11Document80 pagesCompetitive 11RagavanNo ratings yet

- Competitive 11Document144 pagesCompetitive 11RagavanNo ratings yet

- Transmission Lines Completed During - 2016-2017Document9 pagesTransmission Lines Completed During - 2016-2017RagavanNo ratings yet

- Biodiversity Conservation in Western Ghats, India: Capacity Building in Harnessing Geospatial Data ManagementDocument20 pagesBiodiversity Conservation in Western Ghats, India: Capacity Building in Harnessing Geospatial Data ManagementRagavanNo ratings yet

- Development of Standard Interoperable Database For Local Level Planning-NRDMS ApproachDocument24 pagesDevelopment of Standard Interoperable Database For Local Level Planning-NRDMS ApproachRagavanNo ratings yet

- Performance Analysis of Transmission Facilities - Technical Information - ANEELDocument1 pagePerformance Analysis of Transmission Facilities - Technical Information - ANEELRagavanNo ratings yet

- Jurnal MenDocument6 pagesJurnal MenIka YuliyaniNo ratings yet

- Manual UPS New N 1 3kVA en SaDocument40 pagesManual UPS New N 1 3kVA en SaRonald Yucra Cadena100% (1)

- HV Winding Phase Overcurrent ProtectionDocument5 pagesHV Winding Phase Overcurrent Protection386No ratings yet

- Datasheet Energy Meters Selection Guide enDocument2 pagesDatasheet Energy Meters Selection Guide enMarc HeideNo ratings yet

- 7UM62xx Catalog SIP-2006 enDocument39 pages7UM62xx Catalog SIP-2006 ensidthuNo ratings yet

- Selection of Neutral Grounding Reactor For Line To Ground FaultDocument4 pagesSelection of Neutral Grounding Reactor For Line To Ground FaultjlcegarraNo ratings yet

- NTPC Anta ElectricalDocument35 pagesNTPC Anta ElectricalVikas RawalNo ratings yet

- PST Unit 2Document12 pagesPST Unit 2Karthick Sivakumar ChellamuthuNo ratings yet

- ConradDocument3 pagesConradboopelectraNo ratings yet

- Presentation On Electric CarDocument20 pagesPresentation On Electric Carnirmalkr100% (1)

- Switchyard Protections: By-Priyank ShahDocument38 pagesSwitchyard Protections: By-Priyank ShahSrikanth ReddyNo ratings yet

- An Integrated Battery Charger-Discharger With PF CorrectionDocument7 pagesAn Integrated Battery Charger-Discharger With PF Correctiongaganmeena1994No ratings yet

- Mitigation of Voltage Swells by Static Series Compensator: MemberDocument7 pagesMitigation of Voltage Swells by Static Series Compensator: MemberKevin MacancelaNo ratings yet

- MCCB WiNbreak1Document16 pagesMCCB WiNbreak1ceracalNo ratings yet

- Control PanelsDocument40 pagesControl PanelsMYSTERIOOOOUSNo ratings yet

- 15P0056B1 - Ams90 - 1 - en - R03 - Half-Controlled Acdc Single-Phase DriveDocument20 pages15P0056B1 - Ams90 - 1 - en - R03 - Half-Controlled Acdc Single-Phase DriveKhaled RabeaNo ratings yet

- Indrivetec EmsDocument2 pagesIndrivetec EmshermantoNo ratings yet

- Eocr Total enDocument38 pagesEocr Total enArturo SanchezNo ratings yet

- Department of Medical, Health & Family Welfare and NHM Government of Rajasthan, JaipurDocument2 pagesDepartment of Medical, Health & Family Welfare and NHM Government of Rajasthan, JaipurAnmol SinghNo ratings yet

- APPA A18 Clamp Multi MeterDocument4 pagesAPPA A18 Clamp Multi MeterLalo LeloNo ratings yet

- POWER ELECTRONICS 2015 Note For VTU Electrical and Electronics Semester 4Document265 pagesPOWER ELECTRONICS 2015 Note For VTU Electrical and Electronics Semester 4Karthik VNo ratings yet

- Camarines Norte - AlbayaldeDocument56 pagesCamarines Norte - AlbayaldeJChris EsguerraNo ratings yet

- Engineering Economic Analysis CHPDocument72 pagesEngineering Economic Analysis CHPMike Emmerton100% (1)

- FCRO2100 Product GuideDocument2 pagesFCRO2100 Product GuideChenaker HamzaNo ratings yet

- 1-Axis CNC Motor DriverDocument11 pages1-Axis CNC Motor DriverMarlon PerinNo ratings yet

- Automatic Energy Meter Reading Using Smart Energy MeterDocument6 pagesAutomatic Energy Meter Reading Using Smart Energy MeterKarl Martin AlduesoNo ratings yet

- Implementation of High Step-Up Solar Power Optimizer For DC Micro Grid ApplicationDocument5 pagesImplementation of High Step-Up Solar Power Optimizer For DC Micro Grid ApplicationMeral MeralNo ratings yet