Professional Documents

Culture Documents

Bita GN62 PDF

Uploaded by

AfzaalUmairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bita GN62 PDF

Uploaded by

AfzaalUmairCopyright:

Available Formats

BRITISH INDUSTRIAL TRUCK ASSOCIATION

GUIDANCE NOTE GN62 Rev 1

MAINTENANCE, INSPECTION AND REPAIR OF FORK

May 2011

ARMS & ATTACHMENTS

Page 1 of 9

IMPORTANT NOTICE

PLEASE READ CAREFULLY

(a) The recommendations and advice contained in this Guidance Note are based on

specifications, procedures and other information which have been collected by the British

Industrial Truck Association Limited (“BITA”) from its members. They represent what is, so far

as BITA is aware, the best available data at the time of publication on the construction and

use of industrial trucks in the general conditions described, and are intended to provide

guidance for such use.

(b) However, there are a wide variety of situations in which industrial trucks may be used,

consequently in all cases the suitability and safety of this Guidance Note must be determined

by the person seeking to apply it on the basis of his own judgement, in the light of the

conditions in which use is envisaged and subject to all relevant statutory requirements.

(c) BITA accepts no responsibility for the recommendations, advice, statements, opinions and

conclusions expressly or by implication set out below and gives no warranty or representation

of assurance in respect of the accuracy or validity of the same.

0. SCOPE

Solid section fork arms and mechanical or hydraulic attachments by their very function are

subject to considerable stress. When abused or incorrectly used and improperly maintained,

they can suffer decreased service life.

Observance of the guidance notes detailed below for maintenance inspections and

examination should eliminate failures in fork arms and attachments when working in normal

conditions and in accordance with approved operating practices and manufacturers operator’s

manual.

Fork arms are referenced in this guidance from section; 2

Attachments are referenced in this guidance from section; 8

1. NOMINAL RATED LOAD (WORKING LOAD)

1.1 When fork arms are used in pairs (the normal arrangement), the nominal rated load of each

fork arm shall be at least half the manufacturer’s rated capacity of the truck, and at the rated

load centre distance shown in Tables 1 to 4, ISO 2328.

1.2 When attachments are used the rating plate on the lift truck should reflect the attachment(s)

fitted. The capacity stated should not exceed the capacity on the attachment rating plate.

2. FORK ARMS

2.1 Maintenance & Inspection

Due to their nature there is no maintenance to be carried out on the fork arms other than

lubrication of positioning locks.

© Published by: BRITISH INDUSTRIAL TRUCK ASSOCIATION

5 - 7 High Street, Sunninghill, Berkshire, SL5 9NQ.

BRITISH INDUSTRIAL TRUCK ASSOCIATION

GUIDANCE NOTE GN62 Rev 1

MAINTENANCE, INSPECTION AND REPAIR OF FORK

May 2011

ARMS & ATTACHMENTS

Page 2 of 9

2.2 The main reason for fork arm wear and damage include incorrect operating practices

generally as follows:-.

Driving along with forks too low causing contact with the ground

Lifting with the tips of the forks causing permanent deformation of the blade.

Impact damage resulting in distortion of the forks

“Sweeping” or lateral pushing of loads causing deformation of the hangers

Insufficient clearance between fork and load, resulting from incorrect fork spacing causing

deformation of the hangers

Overloading by any means

2.3 Illustrations of Definitions/Terms

Top Attachments may be (but not limited Lower Attachments may be (but not limited

to) to)

o ITA Hooks to ISO 2328:2007 o ITA Hooks to ISO 2328:2007

o Square Hooks o Square Hooks

o Tubes for Shaft Mount o Terminal West Style Lower Brackets

o Roller Assemblies o Roller Assemblies

POSITIONING LOCK

TOP ATTACH

SHANK

BLADE BOTTOM ATTACH

TOE HEEL

TAPER

Fig 1: Fork Arm

© Published by: BRITISH INDUSTRIAL TRUCK ASSOCIATION

5 - 7 High Street, Sunninghill, Berkshire, SL5 9NQ.

BRITISH INDUSTRIAL TRUCK ASSOCIATION

GUIDANCE NOTE GN62 Rev 1

MAINTENANCE, INSPECTION AND REPAIR OF FORK

May 2011

ARMS & ATTACHMENTS

Page 3 of 9

3. CLEAN FOR INSPECTION

a) Remove grease and dirt

b) Clean around welds and heel area

4. EXAMINATION FOR DEFECTS AND MEASUREMENT OF WEAR

Competent Persons carrying out examination of fork arms should meet the requirements of

BS EN ISO 17020:2004, be capable of detecting defects or weaknesses for the purpose of

the examination and have sufficient knowledge and experience to assess the importance of

defects or weaknesses and to identify what actions need to be taken in order to rectify them.

Particular attention should be paid to:

4.1 Examination for Defects

4.1.1 Identification Marking

The rated load and load centre of each fork arm shall be permanently marked on the fork

shank, as specified in ISO 2330.

4.1.2 Forks do not necessarily need to be removed from the carriage for examination unless there

is doubt about their condition.

4.1.3 Forks are manufactured as a single piece through the fork heel and do not always wear to a

consistent pattern so the inspection method should reflect the manufacturing method and

wear pattern.

4.1.4 The fork may wear with lateral taper, for example due to incorrect load chain adjustment or

load wheel wear/inflation, or longitudinal taper, for example, forks being dragged along the

ground with the mast on full back tilt.

4.1.5 Forks with a blade thickness less than the shank are made for specialist operations. In this

case the competent person should establish the nominal blade thickness before making a

judgement of percentage wear/suitability for continued service.

4.1.6 Visually inspect both top and bottom hooks for deformation which can cause excessive lateral

movement and looseness of fit.

4.1.7 Check Positioning Lock Assembly

a) Examine positioning lock assembly, ensuring it is in good working order

b) If faulty, the positioning lock assembly should be replaced

4.1.8 The forks should be visually inspected for cracks at the inner heel radius, top and bottom

hooks and welded joints. No cracks are permissible, if there is any doubt dye penetrant crack

detection media should be used in confirmation.

4.2 Measurement for Wear

During manufacture the extreme edges of the fork heel radius may also result in reduced

thickness at the heel. If this is the case the point of measurement should be moved slightly

forward of the radius.

© Published by: BRITISH INDUSTRIAL TRUCK ASSOCIATION

5 - 7 High Street, Sunninghill, Berkshire, SL5 9NQ.

BRITISH INDUSTRIAL TRUCK ASSOCIATION

GUIDANCE NOTE GN62 Rev 1

MAINTENANCE, INSPECTION AND REPAIR OF FORK

May 2011

ARMS & ATTACHMENTS

Page 4 of 9

4.2.1 If any measurement taken exceeds the wear limit of 10% the fork arm should be scrapped.

Some forks can be manufactured with a thickened heel, in this case, the comparison between

the fork shank and blade heel dimension should still be made. See fig 2.

Some forks are manufactured with extra

material here. Wear of this material is not

included in the 10% limit.

4.2.2 When examining fork arms the criteria for rejection due to excessive heel wear should be

made on the following basis:

Fork Thickness Dimensions

Nominal Thickness Minimum Thickness

mm mm

32 29

35 32

40 36

45 41

50 45

60 54

65 59

70 63

75 68

80 72

90 81

100 90

110 99

120 108

135 122

140 126

150 135

Note: Fork callipers/gauges may be used to measure fork heel wear. If these devices

indicate wear close to the rejection limit the wear shall be confirmed by an accurate

measuring device (e.g. an engineer’s rule or vernier gauge).

© Published by: BRITISH INDUSTRIAL TRUCK ASSOCIATION

5 - 7 High Street, Sunninghill, Berkshire, SL5 9NQ.

BRITISH INDUSTRIAL TRUCK ASSOCIATION

GUIDANCE NOTE GN62 Rev 1

MAINTENANCE, INSPECTION AND REPAIR OF FORK

May 2011

ARMS & ATTACHMENTS

Page 5 of 9

4.2.3 Differences in fork arm tip height should be measured using the following criteria:

A set of fork arms shall be checked for any difference in height when mounted on the fork

carrier. If the difference in tip heights exceeds 3% of the blade length or that

recommended by the manufacturer, the set of fork arms shall be withdrawn from service.

For ease of reference the following fork lengths with a tip height limit deviation of 3% refers:

1000mm length Forks – 3% = 30mm deviation

1200mm length Forks – 3% = 36mm deviation

Note: Irrespective of measured deviation, if height difference impedes proper load

handling, remove from service.

4.2.4 Forks can be manufactured at different angles between the blade and shank, though 90° is

generally the standard. The angle between blade and shank should be checked and the

deviation from manufactured angle should not exceed 1°. If over 1° the forks will require

resetting by the manufacturer and if over 3° the forks should be scrapped.

For ease of reference the deviation from manufactured angle equates to the fork tip height as

follows:

1000mm length Forks – 1 deg = 17mm deviation

1000mm length Forks – 3 deg = 52mm deviation SCRAP

1200mm length Forks – 1 deg = 21mm deviation

1200mm length Forks – 3 deg = 63mm deviation SCRAP

5. REPAIR, MODIFICATION & TESTING

5.1 Repair

a) Fork arms shall only be repaired if the manufacturer or expert of equal competence

authorises it.

b) The repair of cracks and the building up of fork heel wear shall not be permitted.

6. MODIFICATIONS

6.1 Modifications (including welding of brackets, spacers or drilling of holes) other than fork blade

shortening should be referred to the manufacturer for authorisation.

7. TESTING

7.1 After any repair other than that to the fork latch the fork arm should be retested in accordance

with ISO 2330 & ISO 5057 and fully certificated before return to service.

8. ATTACHMENTS

8.1 Attachments are available in a wide variety of designs and capacities to suit specific

applications and can vary from simple mechanical units with no moving parts to complex

multi-function designs with hydraulic, electrical and electronic components.

8.2 Because of this, these guidelines can only be of a general nature and specific information

should always be obtained from the manufacturer’s handbook.

8.3 NOTE: Attachments shall not be used for purposes other than that for which they were

designed .

© Published by: BRITISH INDUSTRIAL TRUCK ASSOCIATION

5 - 7 High Street, Sunninghill, Berkshire, SL5 9NQ.

BRITISH INDUSTRIAL TRUCK ASSOCIATION

GUIDANCE NOTE GN62 Rev 1

MAINTENANCE, INSPECTION AND REPAIR OF FORK

May 2011

ARMS & ATTACHMENTS

Page 6 of 9

9. MAINTENANCE

9.1 Clean the attachment before starting work. Particularly around high stress areas, e.g.

mountings, bases of carrying rams, clamp arms etc. Try not to wash lubricants from bearings

and bushes. Lack of lubrication is one of the main reasons for premature wear of attachment

bushes and bearings so ensure that all bushes and bearings are checked for adequate

lubrication before returning to service.

9.2 Maintenance will consist mainly of lubricating moving parts and cleaning out accumulations of

debris which is often present on equipment used in arduous applications. Increased

frequency of cleaning and re-lubrication may be necessary to prevent premature bearing

replacement particularly in arduous applications. Ensure that the correct lubricant is used and

note that some attachments use a Teflon lubricant applied by spray which should not be

mixed with normal grease.

9.3 Adjustment to flow valves may be required to maintain arm synchronisation or correct speed

of movement. (Refer to manufacturer’s operating manuals).

10. EXTRAS

10.1 Many attachments are supplied with extras such as 5th hydraulic kits, camera, multi-stage

valves; these also should be checked and maintained correctly.

11. INSPECTION AND EXAMINATION

11.1 Full operation of all of the attachment functions and a visual check will often highlight an area

which might require further attention.

11.2 Check that the attachment rating plate is present and legible.

12. FASTENERS

12.1 Check the security and tightness of all fasteners paying particular attention to the mountings,

arm fixings and rotation bearings. If necessary tighten to the torque recommended by the

manufacturer. NOTE! Not all socket fasteners are 12.9 grade which is normal in the UK. Do

not replace with stronger fasteners without first checking with the manufacturer.

12.2 Many fasteners are secured with either some kind of applied thread lock or thread lock insert.

Some manufacturers recommend replacing fasteners at regular intervals or if the fasteners

have been removed. Check the manufacturers hand books for details.

13. BEARINGS AND BUSHES

13.1 Check for excess wear and clearances in bearings and bushes. Check for play in rotation

bearings both around the axis and axially. Excess arm carrier bush wear may negate arm toe

in and cause dropped loads. Replace as necessary. On old or heavily used attachments

check that the housings or mating surfaces are themselves not worn. Excess wear here may

require replacement of major components.

13.2 Note manufacturers hand books for tolerance of arm play, toe in/out, arm alignment.

© Published by: BRITISH INDUSTRIAL TRUCK ASSOCIATION

5 - 7 High Street, Sunninghill, Berkshire, SL5 9NQ.

BRITISH INDUSTRIAL TRUCK ASSOCIATION

GUIDANCE NOTE GN62 Rev 1

MAINTENANCE, INSPECTION AND REPAIR OF FORK

May 2011

ARMS & ATTACHMENTS

Page 7 of 9

14. DAMAGE AND ABUSE

14.1 Look for obvious signs of impact damage, deformation due to overloading or abrasion wear on

components due to poor operator practice.

14.2 Be aware that impact damage can transfer to other parts of the attachment.

14.3 Mishandling of loads can also cause damage. Look for signs of mishandling such as paint

worn off the inside of arms of Paper Roll clamps, “cuddling” of paper reels can cause internal

stresses and failure of welds. Marks on the outside of arms can be caused by loads being

pushed. This again may result in undue stresses into the attachment parts and could cause

eventual failure or damage.

15. SACRIFICAL WEAR PARTS

15.1 In some attachment operations it is difficult to avoid parts being rubbed against the ground.

To this end sacrificial wear plates may be fitted.

15.2 These may be on the bottom of clamp arms and bodies, or the outside of the short arm of

rotating paper roll clamps. Replace before they are fully worn away.

15.3 Fork arms on attachments such as fork clamps and double pallet handlers can also suffer

from abuse and wear in the same way as normal fork arms. However, some of these are also

fitted with sacrificial wear plates in locations most likely to be affected, e.g. at fork heels. It is

acceptable to replace these when worn providing the manufacturer’s instructions are followed.

As with normal forks the wear limit of the basic fork blade is 10% and wear strips should not

be seen as a way of recovering forks worn to or past this limit. NOTE: with normal forks the

original blade thickness can be obtained from the shank thickness but this may not be the

case with some attachments. If in doubt consult the manufacturer.

15.4 In all cases use the correct grade of steel or else they will be short lived. Do not add wear

pads without the authorisation of the manufacturer.

15.5 Check the condition, i.e. for wear or damage of contact pad surfaces and their security on the

base material.

16. CYLINDERS

16.1 Attachment hydraulic cylinders are used for positioning or clamping the load and should be

checked for oil leaks around the cylinder head and inlet/outlet fittings. Also check the cylinder

barrel for damage and the base welds for cracks, these should either be repaired by a

competent welder or the barrel replaced with new. Check the cylinder rod for wear and more

especially indentations or marks which could damage the internal parts of the cylinder and

cause leakages.

16.2 Many attachments may have more than one cylinder to perform a function, therefore check

correct cylinder stroke lengths and adjust if required.

16.3 Cylinders end fastenings may require setting up to specific torques, also many cylinders

require “end float”. In all cases ensure all cylinders are fastened according to the

manufacturers instructions (refer to hand book).

© Published by: BRITISH INDUSTRIAL TRUCK ASSOCIATION

5 - 7 High Street, Sunninghill, Berkshire, SL5 9NQ.

BRITISH INDUSTRIAL TRUCK ASSOCIATION

GUIDANCE NOTE GN62 Rev 1

MAINTENANCE, INSPECTION AND REPAIR OF FORK

May 2011

ARMS & ATTACHMENTS

Page 8 of 9

17. HOSES

17.1 Check all hydraulic hoses for oil leaks, security and damage.

17.2 Note: because there is often limited space between the attachment and fork truck it is easy

for hoses to become snagged or chafed.

18. SETUP AND OPERATION

18.1 Check the toe in of clamp arms or tines against the manufacturers’ specification.

18.2 Check the correct operation of the clamp pressure relief valve and the correct operation of the

clamp check valve. The best way to do this is using a clamp test cylinder used in a safe

manner according to the manufacturer’s recommendations.

18.3 Check security and operation of return or positioning spring and stops, e.g. pad positioning

springs.

18.4 Check correct operation of gas struts.

18.5 Operate all the attachment functions to check for full and smooth movement. Note that some

rotating attachments that have restricted movement, i.e. are not continuous 360 degrees in

both directions, will have some form of stop and or slow down valve cushioning device, check

that this is functional.

18.6 Check for synchronisation of arm movement.

18.7 Adjust flow valves where necessary to correct arm synchronisation or to restrict operational

speed. Refer to manufacturer’s operating manuals.

18.8 Check for correct operation and adjustment of any switches or sensors which might be used

to control part of an operation sequence or provide indication means to the operator.

18.9 Where electrical valves are employed to split hydraulic functions ensure that they work

correctly and consistently.

19. CRACKS

19.1 Check for cracks at highly stressed areas and in particular at the base of carrying rams,

carriage mountings, and clamp arm attachment points. If in doubt use a dye penetrant test in

the first instance. Magnetic particle inspection should only be carried out by trained and

experienced operators.

© Published by: BRITISH INDUSTRIAL TRUCK ASSOCIATION

5 - 7 High Street, Sunninghill, Berkshire, SL5 9NQ.

BRITISH INDUSTRIAL TRUCK ASSOCIATION

GUIDANCE NOTE GN62 Rev 1

MAINTENANCE, INSPECTION AND REPAIR OF FORK

May 2011

ARMS & ATTACHMENTS

Page 9 of 9

20. REPAIR AND MODIFICATION

20.1 Attachments should not be modified without the permission of the manufacturer. Even the

shortening of the forks will render the attachment identification plate inaccurate.

20.2 Repairs should only be carried out using original spares or warranties may be invalidated.

20.3 Re-facing of contact pads may require special preparation and adhesives. Follow the

manufacturer’s instructions.

20.4 Structural repairs should only be carried out with the advice of the manufacturer or an expert

of equal competence.

20.5 If retesting is required this should be carried out with a test load 1.33 times the attachment

rated capacity.

Bibliography

ISO 2330:2002 Fork-Lift Trucks – Fork Arms – Technical Characteristics and Testing

ISO 5057:1993 Industrial Trucks – Inspection and Repair of Fork Arms in Service on

Fork Lift Trucks

ISO 2328:2007 Fork Lift Trucks – Hook on Type Fork Arms and Fork Arm Carriages –

Mounting Dimensions

© Published by: BRITISH INDUSTRIAL TRUCK ASSOCIATION

5 - 7 High Street, Sunninghill, Berkshire, SL5 9NQ.

You might also like

- Installing and Maintaining Drill LinesDocument1 pageInstalling and Maintaining Drill LineslacariaNo ratings yet

- Hazardous Area MotorsDocument8 pagesHazardous Area MotorsRamanathan AthappaNo ratings yet

- How To Effectively Implement ISA 99 / IEC 62443Document24 pagesHow To Effectively Implement ISA 99 / IEC 62443AmmarGhazaliNo ratings yet

- Ewcat PDFDocument22 pagesEwcat PDFMohsen YavariNo ratings yet

- Pre-Read Well Control CourseDocument20 pagesPre-Read Well Control CourseWilliamNo ratings yet

- Equipment Numbering Code - 16 Jun 13Document136 pagesEquipment Numbering Code - 16 Jun 13krishnsgkNo ratings yet

- Introduction To Esp Cable: Modular Design Many OptionsDocument12 pagesIntroduction To Esp Cable: Modular Design Many OptionsAnthony SiuNo ratings yet

- Hoist Inspection - SOWDocument10 pagesHoist Inspection - SOWAbdallah AbdelrehimNo ratings yet

- 07 CBM RigsDocument5 pages07 CBM RigsRahesa Wahyu NalendraNo ratings yet

- Glamox - Techninca Lighting 2013 NewDocument216 pagesGlamox - Techninca Lighting 2013 NewmyothantamtNo ratings yet

- Manual 752 RB3 PartDocument10 pagesManual 752 RB3 PartLee NaidooNo ratings yet

- ABB Motors for Hazardous AreasDocument65 pagesABB Motors for Hazardous Areaslaem269No ratings yet

- Rite Naming Convention PDFDocument6 pagesRite Naming Convention PDFKamelFaizeenAbdullahNo ratings yet

- ABS Drops Guide E-Sept17Document85 pagesABS Drops Guide E-Sept17Max BeeksNo ratings yet

- Acceleration Levels of Dropped Objects PDFDocument7 pagesAcceleration Levels of Dropped Objects PDFnotonectal100% (1)

- Daily Drilling Report: The Gold DiggersDocument3 pagesDaily Drilling Report: The Gold DiggerscodigocarnetNo ratings yet

- Norshore Atlantic SpecificationsDocument4 pagesNorshore Atlantic SpecificationsWawan Nur CahyoNo ratings yet

- SPE 128477 MS P 20ksi Bop StackDocument4 pagesSPE 128477 MS P 20ksi Bop Stacknjava1978No ratings yet

- Dhirubhai Deepwater KG2 Storage CapacitiesDocument2 pagesDhirubhai Deepwater KG2 Storage CapacitiesTim ClarkeNo ratings yet

- Safety-Alert-Crown Saver Function Testing PDFDocument2 pagesSafety-Alert-Crown Saver Function Testing PDF孔超No ratings yet

- Operating Instructions: User Manual No.: T4854-Z-Ma-001, Rev. 0 Equipment: Hydraracker X-Y 1 of 89Document89 pagesOperating Instructions: User Manual No.: T4854-Z-Ma-001, Rev. 0 Equipment: Hydraracker X-Y 1 of 89ayhamNo ratings yet

- TR Design BookDocument9 pagesTR Design BookMohammed JassimNo ratings yet

- TD MPI Inspection StandardDocument97 pagesTD MPI Inspection StandardMohamed BadranNo ratings yet

- 1.8.1.1.11.2.3 Titan C Service Manual (NEW)Document70 pages1.8.1.1.11.2.3 Titan C Service Manual (NEW)WayneNo ratings yet

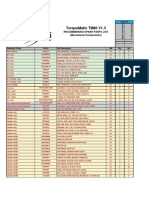

- TM80 V1.3 Recommended Spare Parts ListDocument2 pagesTM80 V1.3 Recommended Spare Parts ListAlejandra Noguera GiraldoNo ratings yet

- Drilling MotorsDocument6 pagesDrilling MotorsBassim Hato100% (2)

- CREW: Department of Defense: Department of The Air Force: Regarding Perchlorate: Scanned Perchlorate October 2008 YDocument200 pagesCREW: Department of Defense: Department of The Air Force: Regarding Perchlorate: Scanned Perchlorate October 2008 YCREWNo ratings yet

- RIN PartC 2014-11 PDFDocument220 pagesRIN PartC 2014-11 PDFJuniorJavier Olivo FarreraNo ratings yet

- Temporary Liquid Mud PlantDocument117 pagesTemporary Liquid Mud PlantAhmedNo ratings yet

- DNV, TIFF TIN For Case-Hardened GearsDocument6 pagesDNV, TIFF TIN For Case-Hardened GearsPeter Carden100% (1)

- Wellsite Gas Watch - Wireless Portable Monitor 100Document50 pagesWellsite Gas Watch - Wireless Portable Monitor 100YoshizatoNo ratings yet

- Puntos Debiles Actualizados 25 Junio2018Document261 pagesPuntos Debiles Actualizados 25 Junio2018Jose Antonio AcostaNo ratings yet

- WT3553 MsdsDocument17 pagesWT3553 Msdspitrer123100% (1)

- BS en 1089-3 - 2011Document20 pagesBS en 1089-3 - 2011Luís Silva100% (1)

- Pages From PS 21 NOVDocument1 pagePages From PS 21 NOVHanyNo ratings yet

- Spare Parts and Life Cycle CostsDocument6 pagesSpare Parts and Life Cycle CostsorlandoduranNo ratings yet

- HiSIDE Inline Mixing Unit Manual PDFDocument28 pagesHiSIDE Inline Mixing Unit Manual PDFbruce lianNo ratings yet

- Depreciation Drilling Rigs Esv2008Document108 pagesDepreciation Drilling Rigs Esv2008corsini999No ratings yet

- Case Study VR Lubricator ToolDocument2 pagesCase Study VR Lubricator ToolVictorNo ratings yet

- Modu Code 2009Document128 pagesModu Code 2009RAZORMWNo ratings yet

- Har-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Document12 pagesHar-Bach Marketing, Inc. Padeye Evaluation Safety Warnings/Instructions Project 21721Damar Budi LaksonoNo ratings yet

- Silo Weigh PDFDocument7 pagesSilo Weigh PDFOleg AndrisanNo ratings yet

- Pad EyesDocument2 pagesPad Eyesberry habNo ratings yet

- Welldata/Real Time (RT) 18: Operator ManualDocument140 pagesWelldata/Real Time (RT) 18: Operator ManualMaulik MakwanaNo ratings yet

- OTC-28011-MS - WSOG and Emergency DisconnectDocument19 pagesOTC-28011-MS - WSOG and Emergency Disconnectwpechie_66286825No ratings yet

- SLP STD 28 CHIKSANDocument20 pagesSLP STD 28 CHIKSANmashanghNo ratings yet

- Fac RuleDocument240 pagesFac RulematheusNo ratings yet

- General Piping - Process and Utility Field Pressure TestingDocument20 pagesGeneral Piping - Process and Utility Field Pressure TestingJanuar GhifaryNo ratings yet

- NOV Anson - M95 Plug ValvesDocument23 pagesNOV Anson - M95 Plug ValvesRafael Perez100% (1)

- Dimension Transport Skid For 13 58 BOPDocument2 pagesDimension Transport Skid For 13 58 BOPAdhie WaelacxhNo ratings yet

- Brass Shear Screws Data PDFDocument2 pagesBrass Shear Screws Data PDFBella cedricNo ratings yet

- Intervention/decommissioningDocument15 pagesIntervention/decommissioningAnonymous ZO1piE3VNo ratings yet

- D392004720 MKT 001 PDFDocument28 pagesD392004720 MKT 001 PDFsorangel_123No ratings yet

- Encoder: Technical Manual 222115-001 40223723-SeriesDocument34 pagesEncoder: Technical Manual 222115-001 40223723-SeriesAndres NavarroNo ratings yet

- 091 Preventing Crown CollisionsDocument5 pages091 Preventing Crown CollisionsalduwaikiNo ratings yet

- PB DDM 026Document3 pagesPB DDM 026Jim SharpNo ratings yet

- Supplementary Specification To API 17D Subsea Trees: DecemberDocument42 pagesSupplementary Specification To API 17D Subsea Trees: DecemberAlejandro Sánchez LópezNo ratings yet

- HPT Stage 1 Blades and Duct SegmentsDocument28 pagesHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekNo ratings yet

- 407-19-23 July 2019Document9 pages407-19-23 July 2019turboshaftNo ratings yet

- 206-19-42 July 2019Document9 pages206-19-42 July 2019turboshaftNo ratings yet

- Cargo Handling TechnologiesDocument147 pagesCargo Handling Technologiesjess jeruster100% (1)

- Weekly Racking Inspection Checklist: N/A Yes No CommentsDocument1 pageWeekly Racking Inspection Checklist: N/A Yes No CommentsAfzaalUmairNo ratings yet

- BPC ProductCatalogDocument14 pagesBPC ProductCatalogwahyu sinawangNo ratings yet

- What Is ASME B30.30, and How Does It Apply To Wire Rope InspectionDocument22 pagesWhat Is ASME B30.30, and How Does It Apply To Wire Rope InspectionAfzaalUmairNo ratings yet

- Rig Components: Well DrillingDocument129 pagesRig Components: Well DrillingAfzaalUmairNo ratings yet

- Iso 4306-3-2016Document20 pagesIso 4306-3-2016AfzaalUmair100% (2)

- Overhead Bridge Crane Operating SpeedsDocument3 pagesOverhead Bridge Crane Operating SpeedsMontoya SantiagoNo ratings yet

- Rig Component: Guide To Oil Well DrillingDocument181 pagesRig Component: Guide To Oil Well DrillingAfzaalUmairNo ratings yet

- ISO 10245-4-2004 Cor1-2006Document1 pageISO 10245-4-2004 Cor1-2006AfzaalUmairNo ratings yet

- Pad Eyes Procedure Rev 0Document7 pagesPad Eyes Procedure Rev 0AfzaalUmair100% (2)

- Iso 10972-4 - 2007Document10 pagesIso 10972-4 - 2007AfzaalUmairNo ratings yet

- Engineering Encyclopedia: Classifying Compressors by TypeDocument45 pagesEngineering Encyclopedia: Classifying Compressors by TypeAfzaalUmair100% (1)

- 44 172 Boom (Power Pinned Fly) : Ft. - FTDocument4 pages44 172 Boom (Power Pinned Fly) : Ft. - FTAfzaalUmairNo ratings yet

- Yalelift - YLITG ATEX Operating and Maintenance Manual 13Document1 pageYalelift - YLITG ATEX Operating and Maintenance Manual 13AfzaalUmairNo ratings yet

- T 500 Series: Truck CraneDocument14 pagesT 500 Series: Truck CraneAfzaalUmairNo ratings yet

- Guide to safe cranesDocument17 pagesGuide to safe cranesThupten Gedun Kelvin Ong100% (1)

- Crane Safety and Awareness: Internal Use OnlyDocument99 pagesCrane Safety and Awareness: Internal Use Onlydsn_sarmaNo ratings yet

- Engineering Encyclopedia: Compressor Performance CharacteristicsDocument60 pagesEngineering Encyclopedia: Compressor Performance CharacteristicsAfzaalUmair100% (1)

- Leaf Chain Pre InstallationDocument4 pagesLeaf Chain Pre InstallationAfzaalUmairNo ratings yet

- ANSI AWP Whitepaper (Skyjack)Document6 pagesANSI AWP Whitepaper (Skyjack)j24maybe5963No ratings yet

- Material For HEDocument36 pagesMaterial For HEMohd Idris MohiuddinNo ratings yet

- Engineering Encyclopedia: Fabrication, Inspection, and Testing of Heat ExchangersDocument31 pagesEngineering Encyclopedia: Fabrication, Inspection, and Testing of Heat ExchangersAfzaalUmair100% (1)

- Engineering Encyclopedia: Evaluating The Material Requirements of Compressor Mechanical ComponentsDocument126 pagesEngineering Encyclopedia: Evaluating The Material Requirements of Compressor Mechanical ComponentsAfzaalUmair100% (1)

- Crane Girder CamberDocument6 pagesCrane Girder CamberGary J. Davis, P. E.100% (1)

- Engineering Encyclopedia: Maintenance and Repair of Heat ExchangersDocument69 pagesEngineering Encyclopedia: Maintenance and Repair of Heat ExchangersAfzaalUmairNo ratings yet

- Engr Encyclopedia AramcoHeatExchangers PDFDocument51 pagesEngr Encyclopedia AramcoHeatExchangers PDFhelden50229881100% (4)

- Engineering Encyclopedia: Completing Safety Instruction Sheets For Storage TanksDocument6 pagesEngineering Encyclopedia: Completing Safety Instruction Sheets For Storage TanksAfzaalUmairNo ratings yet

- Maintenance and Repair of Pressure VesselsDocument81 pagesMaintenance and Repair of Pressure Vesselsjishnunelliparambil100% (3)

- Specifying Design Requirements For Heat Ex ChangersDocument89 pagesSpecifying Design Requirements For Heat Ex Changersrahul11129100% (4)

- Engineering Encyclopedia: Determining Acceptability of Materials For Storage TanksDocument25 pagesEngineering Encyclopedia: Determining Acceptability of Materials For Storage TanksAfzaalUmairNo ratings yet

- Duty of Care Breaches in ASIC v Vines 2006Document8 pagesDuty of Care Breaches in ASIC v Vines 2006sawani mendisNo ratings yet

- Seismic Performance of Large RC Circular Hollow Columns: Giulio RANZO and M J N PriestleyDocument8 pagesSeismic Performance of Large RC Circular Hollow Columns: Giulio RANZO and M J N PriestleyAnonymous 66uWhphVNo ratings yet

- Free-Range Chicken Farming PDFDocument138 pagesFree-Range Chicken Farming PDFDennis MacedoNo ratings yet

- Daily Lesson Plan Year 4 Subject Year Day / Date Time DurationDocument4 pagesDaily Lesson Plan Year 4 Subject Year Day / Date Time DurationINDRA DEVI A/P MANIAM MoeNo ratings yet

- Comparative ResearchDocument22 pagesComparative Researchtshiringtmg7No ratings yet

- Archaeology - The Telltale ArtDocument15 pagesArchaeology - The Telltale ArtShubha PujariNo ratings yet

- English Proficiency TrainingDocument21 pagesEnglish Proficiency TrainingDayang GNo ratings yet

- Document listing students' names, student IDs and contact detailsDocument12 pagesDocument listing students' names, student IDs and contact detailsTholut 188No ratings yet

- Final Merit List of FCPS II Subspecialty Med Allied and Surgery Allied Induction January 2024 1Document5 pagesFinal Merit List of FCPS II Subspecialty Med Allied and Surgery Allied Induction January 2024 1javedkakajNo ratings yet

- Restrict Group Access in QV 9 Using ADDocument7 pagesRestrict Group Access in QV 9 Using ADBea BoocNo ratings yet

- A. Two Subsequences: Codeforces Round #751 (Div. 2)Document4 pagesA. Two Subsequences: Codeforces Round #751 (Div. 2)Trần Nhật KhánhNo ratings yet

- Vegetarian and Vegan Diets in Type 2 Diabetes ManagementDocument3 pagesVegetarian and Vegan Diets in Type 2 Diabetes Managementapi-259343531No ratings yet

- 100 Awesome Chess Moves by Eric Schiller PDFDocument290 pages100 Awesome Chess Moves by Eric Schiller PDFAbhilasha0% (1)

- Paragraph WritingDocument22 pagesParagraph WritingarvindranganathanNo ratings yet

- Chapter 2Document16 pagesChapter 2ChuYumNo ratings yet

- The Brothers KaramazovDocument8 pagesThe Brothers KaramazovAnonymous sao1siUbNo ratings yet

- 9696 Geography Example Candidate Responses 2011 WEBDocument313 pages9696 Geography Example Candidate Responses 2011 WEBAsma Merchant67% (3)

- Blooms Taxonomy and Costas Level of QuestioningDocument6 pagesBlooms Taxonomy and Costas Level of QuestioningChris Tine100% (1)

- De Onde Eu Te VejoDocument2 pagesDe Onde Eu Te VejoBianca Oliveira CoelhoNo ratings yet

- How To Answer A Problematic Question??? Key Points: Topic + I R A C 1) Topic / Scope of DiscussionDocument5 pagesHow To Answer A Problematic Question??? Key Points: Topic + I R A C 1) Topic / Scope of Discussionsyahiir syauqii100% (2)

- Tu Cuerpo Habla Enric CorberaDocument70 pagesTu Cuerpo Habla Enric CorberaJohn Freddy Villa CastroNo ratings yet

- 206841Document1 page206841VinceOnikaa PerryGermanottaNo ratings yet

- Experimental and Numerical Investigation of Rotating Bladed Disk Forced Response Using Under-Platform Friction DampersDocument11 pagesExperimental and Numerical Investigation of Rotating Bladed Disk Forced Response Using Under-Platform Friction DamperssenthilNo ratings yet

- Arts 7 Lesson PlanDocument10 pagesArts 7 Lesson PlanShamaica SurigaoNo ratings yet

- Assessing ViolenceDocument6 pagesAssessing ViolenceKarlo Jose Dao-ayanNo ratings yet

- Tañada v. Angara Case DigestDocument12 pagesTañada v. Angara Case DigestKatrina PerezNo ratings yet

- 3 Affect Regulation, Mentalization, and The Development of The Self (Peter Fonagy, Gyorgy Gergely, Elliot L. Jurist Etc.) - 211-259Document49 pages3 Affect Regulation, Mentalization, and The Development of The Self (Peter Fonagy, Gyorgy Gergely, Elliot L. Jurist Etc.) - 211-259Sergio Andres Rico AvendanoNo ratings yet

- Rasa Theory and Its Application in TranslationDocument36 pagesRasa Theory and Its Application in TranslationKamal JajoriyaNo ratings yet

- EN22307194-Ranathunga R.A.S.S-Tensile Testing of Metals.Document16 pagesEN22307194-Ranathunga R.A.S.S-Tensile Testing of Metals.Nipun DinushaNo ratings yet

- Theater and Visual Arts ElementsDocument62 pagesTheater and Visual Arts ElementsLab LabNo ratings yet