Professional Documents

Culture Documents

Solvent Deasphalting Plants With PRO PDF

Solvent Deasphalting Plants With PRO PDF

Uploaded by

Guillaume MontarnalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solvent Deasphalting Plants With PRO PDF

Solvent Deasphalting Plants With PRO PDF

Uploaded by

Guillaume MontarnalCopyright:

Available Formats

EDL Anlagenbau Gesellschaft mbH

Process Simulation of Solvent Deasphalting Plants

with PRO/II based on Thermodynamic Equilibrium Data

"VLE K -Values - Fill Options"

Moscow, 28-30 March 2012

EDL Anlagenbau Gesellschaft mbH

Introduction

SDA, the Solvent Deasphalting technology is actually one of the

most interesting „Bottom to Barrel“ technology for heavy residues

in modern refineries

?

• Large price differences between light sweet crudes and heavy sour crudes

created strong incentives for bottom processing tecchnologies

• Old fashion technology SDA in the lube oil refinery

will be more and more also applied in fuel oil refineries, too

• The SDA technology is the lowest investment cost variant compared to

Gasification, Visbreaker, Hydrocracker, Coker et al

• In the best case both products DAO as well as Pitch can be converted in

further process steps to valuble products, no further residues will be available

2EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Integration of SDA in modern Refinery

Lube Oil Refinery Bright Stock

FCC -Plant

Crude Fuel Oil Refinery

ADU Hydrocracker

DAO

AR

VDU

SDA

Asphalt (Pitch)

Bitumen plant

ADU…Atmospheric Distillation Unit VR

VDU…Vacuum Distillation Unit

SDA…Solvent Deasphalting

AR…..Atmospheric Residue

VR…..Vacuum Residue

3EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Typical SDA

a typical SDA plant is a PDA, e.g.

- Propane Deasphalting Plant -

The plant normally consists of the following parts:

• Propane Extraction

• DAO Train

• Asphalt Train

• Propane Condensation and Recovery

• Pressure Relieve -, Slop - and Flushing system

4EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

SDA simulation and design

The simulation and design of a SDA , especially the

liquid –liqud extraction process is a challenging task !

?

• the feed, Vacuum Residue can only be simulated with pseudo

components e.g. it is impossible to use components from the data base

with a defined structure

• the pseudo components have no structure to produce BIPs from the

UNIFAC –Model to build activity coefficients between the components

• the liquid –liquid extraction process for the SDA is based on the different

solubilities between the solvent and the hydrocarbons

• BIPs are necessary to calculate the equilibria in the two liquid phases,

the DAO and the Asphalt phase

BIP… Binary Interaction Parameters

5EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Model Basis: „Chueh and Prausnitz“

The BIPs can be calculated based on a publication from Chueh and Prausnitz

(1967) for an EOS (Equation of State) via the partial molar volumes of the

multicomponent liquid mixture:

Equation of State:

RT a

P 0.5

b T ( b)

Partial differentiation of EOS:

2( xi aki ) abk /( b)

RT bk

(1 ) i

P 2P k

b b ( b)T 1/ 2

( )T 0 and ( 2 )T 0

c

c RT a 2 b

( b) 2 T 1/ 2 2 ( b) 2

with the mixing rules for a mixture and used for a 0.4278 and b 0.0867

a, b, aii , bi , aij ........ f ( xi , i ,ci , Pci , Tci , ai , bi )

6EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Model Basis: „Chueh and Prausnitz“

applying the pseudocritical rules to the critical region: TR 0,93

T 'CM TCM (TCT TCM ) D(TR )

'CM CM (CT CM ) D(TR )

Further, with adjustments to SRK and PR applied in PRO/II we get

the BIP„s between the components:

n

' 1/ 3 ' 1/ 3

kij 1 ' 1/ 3

CMi CMj

( CMi CMj ) / 2

' 1/ 3

n3 (the best fit with experimental data)

7EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Notation

a, b.......constants in Redlich Kwong EOS

D(TR )...correction function to the critical region

k ij .........BIP's for interaction parameters

P...........total pressure

T...........temperature

TR ..........reduced temperature

V......... ..total volume of liquid mixture

............molar vo lume of liquid or liquid mixture

k ..........partial molar volu me of component k in liquid phase

CM ........pseudocritical volume of mixture

'CM .......corrected pseudocritical volume of mixture

CT .........true critical volume of mixture

x......... ....mole ffraction in liquid phase

a , b ....dimensionl ess parameter in Redlich Kwong EOS

............acentric factor

8EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

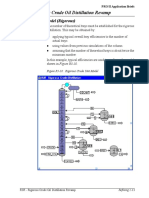

PRO/II PFD- one stage

Typical one stage liquid –liquid extraction unit:

9EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Pseudo component feed Vacuum Residue (VR)

d15 0.9669 kg/kg

10EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Pseudo component properties

11EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

PRO/II- K-value –Fill Options

12EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

EOS for „Fill –Options“

The following EOS are awailable for the „Fill –Option“:

- Modified Chueh Prausnitz Hydrocarbon Fill -

• Soave Redlich Kwong

• SRK –Panagiotopoulos-Reid

• SRK –Modified Panagiotopoulos-Reid

• SRK –SIMSCI

• Peng –Robinson

• PR –Panagiotopoulos-Reid

• PR –Modified Panagiotopoulos-Reid

• Predictive Peng Robinson 78

• Tacite

The best fit with practical results we achieved with the

SRK –Modified Panagiotopoulos Reid thermodynamic !

13EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

BIPs calculation

BIPs calculated from the output report:

14EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Stream list

DAO: 28.5 %, Asphalt : 71.5 %

15EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

VR-DAO-Asphalt TBP

16EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

VR-DAO-Asphalt distribution

17EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Property list

As shown in the property list special data as S, V, Ni, Fe, N and CCR

can be controlled in the DAO, Asphalt via a distribution in the feed (VR):

18EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Bench scale tests

The theoretical results were compared to bench scale tests in a autoclave:

Autoclave

Conditions: subcritical pressure from 30 to 35 bar and

temperature about 50°C

Solvent: Propane (100%)

19EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

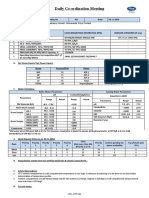

Bench scale tests

Results: DAO and Asphalt from the bench scale unit

Asphalt DAO

DAO…..Deasphalted oil

AS……..Asphalt (Pitch)

*…SRK -Mod Panag. -Reid

**…PR -Mod Panag. -Reid

The SRK Modified Panagiotopoulos -Reid method gives the best fit to the practical results !

20EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Study of thermodynamic models

21EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Solvent impact

Crude Oil

Amospheric Residue

Vacuum Residue

Propane Precipitate

Oils

Pentane Precipitate

Heptane Precipitate

Resins

Asphaltenes

The choise of the solvent or solvent mixture is very important !

22EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Simulation studies of Solvent mixtures

23EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Ternary plots -Temperature influence-

Binodal curves

Ternary plot from literature:

Solvent to Feed ratio

(tie lines):

1…0,5

2…3,0

3…8,0

1

2 3

24EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Ternary plot – Pressure influence -

Binodal curves

Solvent to Feed ratio

(tie lines):

1…0,5

2…3,0

3…8,0

1 2 3

25EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

PRO/II simulation of multiple stage extraction

Heater on stage 1 to precipitate Asphalt

Controller for precipitation

26EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Ternary plot – Pressure influence -

The number of trays are not so important !

For the design the

HTU, NTU concept

must be applied !

HTU…Height of Transfer Unit

NTU…Number of Transfer Unit

27EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Summary

The Solvent Deasphalting (SDA) is a key technology processing heavy

residues to valuable oils (DAO, Deasphalted Oil) and asphalt (Pitch) for the

Bitumen production. The process will be more and more interesting also in

fuel oil refineries as a “Bottom to Barrel” technology with low costs.

The calculation of the extraction process with NPB components is difficult

because of the lack of BIPs between the components. Other ways to build

up the data from the UNIFAC model are not applicable.

The model from CHUEH and PAUSNITZ, published in the AIChE Houston

Meeting in 1967 is applicable to estimate the BIPs between the NBP

components and the solvents, finally to calculate the extraction of the SDA

for high pressure.

28EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

Summary

The model application in the PRO/II simulation program under the

Equation of State (EOS) with the VLE K values –“Fill Option” is the basis

for the complete process simulation of the whole SDA process.

Experimental results have shown that the model can be applied to design

the SDA process with different solvents (Propane, Butane etc.) and

solvent mixtures for the sub- and supercritical extraction processes.

Further investigation should be done to apply the model also to other

extraction technologies e.g. solvent extraction with furfural or NMP.

Thank you for your attention !

29EDL_SDA_PRO/II_Fill-Options EDL Anlagenbau

You might also like

- Process Simulation of Solvent Deasphalting Plants With PROIIDocument29 pagesProcess Simulation of Solvent Deasphalting Plants With PROIIstudyendless100% (2)

- Pocket Manual HGU Rev01-HmelDocument103 pagesPocket Manual HGU Rev01-HmelSandeep kumar sonkarNo ratings yet

- Basics of OIl RefineryDocument28 pagesBasics of OIl RefineryDebasis Kumar Saha50% (2)

- Rev-Updated Final Report - Conceptual Design AssessmentDocument45 pagesRev-Updated Final Report - Conceptual Design AssessmentLisbeth Roos RoosNo ratings yet

- Rice Based EthanolDocument296 pagesRice Based EthanolMihir WarkhadeNo ratings yet

- Damper System For Gas Turbine Exhaust Gas SystemDocument2 pagesDamper System For Gas Turbine Exhaust Gas Systemjkhan_724384No ratings yet

- RFCC1Document35 pagesRFCC1alexHuy88No ratings yet

- Daily Coordination Meeting 29-10-20.dcoxDocument4 pagesDaily Coordination Meeting 29-10-20.dcoxabhaymehta67No ratings yet

- BPCL PuneDocument9 pagesBPCL PuneDeependra SinghNo ratings yet

- Economical and Environmental Evaluation of Double Acting TankerDocument18 pagesEconomical and Environmental Evaluation of Double Acting Tankergreatenick.nbNo ratings yet

- Capex & Opex9834865Document32 pagesCapex & Opex9834865Farrah Taha AbdullahNo ratings yet

- AHD-PP-E-RD-27001 Design Basis Memorandum (DBM) ElectricalDocument39 pagesAHD-PP-E-RD-27001 Design Basis Memorandum (DBM) ElectricalMohammed K. HayderNo ratings yet

- Shift LogDocument4 pagesShift LogRohith kumarNo ratings yet

- Date:6/10/2017 Weekend & Holiday Report: TOPPING UNITS (10&110) Item Old NewDocument3 pagesDate:6/10/2017 Weekend & Holiday Report: TOPPING UNITS (10&110) Item Old NewrawadNo ratings yet

- Naptha Cracking Plant OperationDocument173 pagesNaptha Cracking Plant OperationSiva KumarNo ratings yet

- Copeland Scroll Compressors Specifications AC Models Only PDFDocument32 pagesCopeland Scroll Compressors Specifications AC Models Only PDFDang Anh Tuan100% (1)

- Air Conditioning (R22) Copeland Scroll™ Specifications: Quick Reference GuideDocument32 pagesAir Conditioning (R22) Copeland Scroll™ Specifications: Quick Reference GuideDASIHER2111No ratings yet

- Copeland Scroll Compressors Specifications AC Models Only PDFDocument32 pagesCopeland Scroll Compressors Specifications AC Models Only PDFabhe prasetyaNo ratings yet

- 9591-102-102-PVM-U-004-04 Duct Design DataDocument14 pages9591-102-102-PVM-U-004-04 Duct Design DataVijay PalNo ratings yet

- United States Patent (10) Patent No.: US 6,458,856 B1: Peng Et Al. (45) Date of Patent: Oct. 1, 2002Document12 pagesUnited States Patent (10) Patent No.: US 6,458,856 B1: Peng Et Al. (45) Date of Patent: Oct. 1, 2002Luigi RussoNo ratings yet

- Commercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryDocument15 pagesCommercial Experience in The Operation of Ards Units in Kuwait National Petroleum Company at Mina Al-Ahmadi RefineryOwais AhmedNo ratings yet

- Process Design Basis FOR Unit 05 - Kerosene Hydrodesulphurization UnitDocument18 pagesProcess Design Basis FOR Unit 05 - Kerosene Hydrodesulphurization Unitdhiaa mohammedNo ratings yet

- JI2048-977-MS-DAT-0041 - Rev002 (T-1020)Document9 pagesJI2048-977-MS-DAT-0041 - Rev002 (T-1020)Tech DesignNo ratings yet

- Co-Gen BidDocument556 pagesCo-Gen BidManish ThakurNo ratings yet

- R6 - Sour Water Stripper: Process DataDocument8 pagesR6 - Sour Water Stripper: Process Datanico123456789No ratings yet

- DM001 o Acw Vom Om DCC 819228 A2Document205 pagesDM001 o Acw Vom Om DCC 819228 A2Jama 'Figo' MustafaNo ratings yet

- Condensate Stab 2013 AIChE 91a Paper292728Document14 pagesCondensate Stab 2013 AIChE 91a Paper292728Samaneh HajipourNo ratings yet

- Ie 2019245Document12 pagesIe 2019245AhmadNo ratings yet

- R3R - Rigorous Crude Oil Distillation RevampDocument20 pagesR3R - Rigorous Crude Oil Distillation Revampnico123456789No ratings yet

- Naptha Cracking Plant Operation PDFDocument172 pagesNaptha Cracking Plant Operation PDFChetal Bhole100% (4)

- Optimal Management of Topside Diluent Injection For A Heavy Oil FieldDocument23 pagesOptimal Management of Topside Diluent Injection For A Heavy Oil FieldTimur RegarNo ratings yet

- Advertisement For Incubation of TechnologyDocument4 pagesAdvertisement For Incubation of TechnologyAman AgarwalNo ratings yet

- USB LED Lamp CircuitDocument11 pagesUSB LED Lamp Circuitbelacheweshetu222No ratings yet

- CompressorDocument27 pagesCompressorsoxal100% (1)

- sc8b05757 Si 001Document6 pagessc8b05757 Si 001wiharto hernowoNo ratings yet

- STAGE II, UNIT # 2 (1X600MW) : ProjectDocument14 pagesSTAGE II, UNIT # 2 (1X600MW) : ProjectRukma Goud ShakkariNo ratings yet

- Off-Line Energy Optimization ModelDocument6 pagesOff-Line Energy Optimization ModelSata AjjamNo ratings yet

- Analysis of A 10 MW Recompression Supercritical Carbon Dioxide Cycle For Tropical Climatic Conditions Sathish Et AlDocument14 pagesAnalysis of A 10 MW Recompression Supercritical Carbon Dioxide Cycle For Tropical Climatic Conditions Sathish Et AlTanatswa MoyoNo ratings yet

- Revamping of Vapor Recovery Unit-22, Cairo Oil Refining Company - Mostrod Refinery Plant For Maximization of LPG ProductionDocument115 pagesRevamping of Vapor Recovery Unit-22, Cairo Oil Refining Company - Mostrod Refinery Plant For Maximization of LPG ProductionMohamed HamedNo ratings yet

- Karbala Refinary Project: Preparing Fatima Ali MahdiDocument28 pagesKarbala Refinary Project: Preparing Fatima Ali Mahdiضياء محمدNo ratings yet

- Process Design Basis FOR Unit 06 - Diesel Hydrodesulphurization UnitDocument24 pagesProcess Design Basis FOR Unit 06 - Diesel Hydrodesulphurization Unitdhiaa mohammedNo ratings yet

- OverviewDocument41 pagesOverviewSumitAggarwalNo ratings yet

- Daily Co-Ordination Meeting: HPL, CPP SiteDocument3 pagesDaily Co-Ordination Meeting: HPL, CPP Siteabhaymehta67No ratings yet

- 15-501-EP-DS-001 (Metering Skid Data Sheet), Rev.1Document2 pages15-501-EP-DS-001 (Metering Skid Data Sheet), Rev.1Umair A. KhanNo ratings yet

- Power Plant Engineering QP 1Document2 pagesPower Plant Engineering QP 1JAI GANESH RNo ratings yet

- PHILIPS - 42PFL4506H Chassis TPM7.1E LA PDFDocument83 pagesPHILIPS - 42PFL4506H Chassis TPM7.1E LA PDFTestrooteNo ratings yet

- Double Suction Centrifugal PumpDocument8 pagesDouble Suction Centrifugal PumpBilal WaseemNo ratings yet

- Applied Energy: SciencedirectDocument26 pagesApplied Energy: SciencedirectLéo SilvaNo ratings yet

- Daharki Combined Cycle Power PlantDocument77 pagesDaharki Combined Cycle Power Plantmuhammad abdulrehmanNo ratings yet

- CHEMCAD 5 1 3 Example Book PrintableDocument36 pagesCHEMCAD 5 1 3 Example Book PrintableOliver RomeroNo ratings yet

- Chiller Technical Datasheet - Aircooled Screw Chiller Tech Data - DC IIIDocument3 pagesChiller Technical Datasheet - Aircooled Screw Chiller Tech Data - DC IIIVenu GopalNo ratings yet

- Data Sheet & SLDDocument22 pagesData Sheet & SLDvaithy2011100% (1)

- Equation Calculator For Leed-Nc V2.2 Eac40Document8 pagesEquation Calculator For Leed-Nc V2.2 Eac40anas_pmNo ratings yet

- 04 NGLFractionationTrainDocument20 pages04 NGLFractionationTraingerbasio100% (1)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to DisplaysNo ratings yet

- Deactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingFrom EverandDeactivation of Heavy Oil Hydroprocessing Catalysts: Fundamentals and ModelingNo ratings yet

- Printed Batteries: Materials, Technologies and ApplicationsFrom EverandPrinted Batteries: Materials, Technologies and ApplicationsSenentxu Lanceros-MéndezNo ratings yet