Professional Documents

Culture Documents

Global Intrima Bulletin - Fire Protection Maintenance

Uploaded by

wawan0 ratings0% found this document useful (0 votes)

53 views2 pagesFire

Original Title

Global Intrima Bulletin - Fire protection maintenance

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFire

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

53 views2 pagesGlobal Intrima Bulletin - Fire Protection Maintenance

Uploaded by

wawanFire

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

G LOBAL I NTRIMA B ULLETIN

Fire Protection System

Inspection, Testing and

Maintenance Programs

Only regular and thorough inspection, testing and maintenance can

ensure that your initial investment in a fire protection system contin-

ues to pay off through a system that remains viable.

Fire protection system inspection, testing and maintenance program

is needed because :

1. Ensure all fire protection equipment and systems will operate

properly during an emergency and help limit the extent of a loss; a

weak fire inspection program leaves you vulnerable to a crippling

loss incident

Komp. Mega Grosir Cempaka Mas 2. Comply with industry best practices

Blok L No. 5 Jl. Letjend Suprapto,

3. Keep your good fire/property loss history intact, which will help

Jakarta 10640 - Indonesia

ensure competitive and smooth property insurance renewals;

please note that other factors beyond your loss history can impact

insurance renewals

Phone: +62 21 42900128

Fax: +62 21 4290 0129 4. Comply with government legislated fire codes; federal, state, pro-

E-mail: admin@global- vincial and city/municipal fire codes normally mandate minimum

intrima.com requirements for fire protection system inspection, testing and

maintenance programs

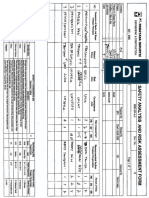

NFPA INSPECTION CHECK LIST

Activity Frequency Description

Sprinkler system

Sprinkler control valves Inspect Weekly If not locked open or electronically supervised – weekly

Inspect Monthly If locked open or electronically supervised – monthly

Maintain Annually Fully close and reopen, lubricate, etc.

Main drain (2 inch drain) Test Annually

Water storage tank Inspect Quarterly Check water level monthly if not alarmed

Water supply evaluation Flow test 5 years

Backflow prevention assemblies Flow test Annually Some quarterly per NFPA 25*

Sprinkler Inspect Annually

Replace Damaged or pre-1920 models

Replace Annually Industrial cooking equipment

Water spray nozzles Inspect Monthly

Heating systems (cold weather) Inspect Daily For tanks, pump houses, dry pipe valve houses, etc.

Antifreeze Test Annually Specific gravity

Dry, Preaction, and Deluge Systems

Trip Test Annually Full flow every 3rd year

Pressure gauges Inspect Weekly Monthly if DPV air pressure supervision, record pressures

Priming water Test Quarterly

Dry Systems

Flushing investigation Test 5 years At 15, 25, and 5 year intervals thereafter

Quick-opening devices Test Quarterly

Alarm Systems

Water flow Test Quarterly Global Intrima advice

Other Test 6 months

Detectors Test Annually Check with OEM or NFPA 25 for specific advice

Batteries Inspect 6 months Check with OEM or NFPA 25 for specific advice

Other audible & visual alarms Test 6 months

Fire Pumps

Automatic start Test Weekly Via pressure drop

Pressure switch set points Inspect/test Weekly Record start pressure

Excessive vibration or noise Inspect/test Weekly

Suction & discharge pressure Inspect/test Weekly Record pressure

Packing temperature & tightness Inspect/test Weekly

Circulation relief valve Inspect/test Weekly

Suction supply & priming Inspect Weekly

Performance test Flow test Annually

Electric Driver (weekly - 10 min.)

Manual start Test Monthly Exercise isolation switch & breaker

Diesel Engine Driver (weekly – 30 min.)

Fuel supply Inspect Weekly

Engine oil level Inspect/test Weekly Record temperature, pressure

Ventilation Inspect/test Weekly

Batteries & charging system Inspect/test Weekly

Cooling system Inspect/test Weekly Record temperature

Speed governor Inspect/test Weekly Record rpm

Overpressure relief valve Inspect/test Weekly

Fire Door and Dampers

Fire doors Inspect Monthly

Test Annually

Fire dampers and shutters Test Annually

Manual Fire Fighting

Extinguishers Inspect Monthly

Recharge 1-5 years Recharge, refer to NFPA 25 or OEM

Hydrostatic 5-12 years Refer to NFPA 25 or OEM

Standpipe Test 5 years Flow test on wet, hydrostatic on dry

Hose Inspect Quarterly Check condition

Test 3 years After first 5 years

Hydrant Inspect Monthly

Maintenance Annually Flush

*NFPA 25 is the National Fire Protection Association standard on Inspection, Testing, and Maintenance of Water-Based Extinguishing Systems.

**OEM stands for Original Equipment Manufacturer.

• For most clients, comprehensive annual servicing by a third party is recommended for Pumps; Diesel Drivers; Tanks; Preaction Valves; Foam Systems; Gaseous, Dry and Wet

Chemical, or Water Mist Extinguishing Systems; and Fire Alarm Systems.

• Consult the OEM and/or NFPA 25 for detailed inspection, maintenance and testing requirements concerning all fire protection equipment.

You might also like

- Maintenance Schedule for Campus EquipmentDocument7 pagesMaintenance Schedule for Campus EquipmentHtet Linn Aung100% (2)

- Fire Sprinkler Checklist NFPA StandardsDocument2 pagesFire Sprinkler Checklist NFPA StandardsKevin Pagayaman100% (2)

- Sprinkler Report NFPA 25 03.27.13Document8 pagesSprinkler Report NFPA 25 03.27.13redbire100% (1)

- 2017-NIFSAB SprinklerInspection PocketGuide-WebDocument16 pages2017-NIFSAB SprinklerInspection PocketGuide-WebManav GaneshNo ratings yet

- Chiller ChecklistDocument18 pagesChiller Checklistavinash rathod100% (1)

- Inspection Testing Maint Fire Protection Equipment Frequency MatrixDocument1 pageInspection Testing Maint Fire Protection Equipment Frequency Matrixمحمد ارشاد شاہNo ratings yet

- NFPA 25 Maintenance and Service KitsDocument1 pageNFPA 25 Maintenance and Service KitsNaing Win TunNo ratings yet

- PropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USDocument9 pagesPropertyRiskEngineering GAPS FireProtection InspectionMaintFrequency Chart XL Catlin USSteve VelardeNo ratings yet

- Equipment Calibration/Maintenance: APPENDIX D - USFWS QA Program (5/04)Document5 pagesEquipment Calibration/Maintenance: APPENDIX D - USFWS QA Program (5/04)Defry Farhandinata100% (1)

- Sprinkler Maintenance Schedule RefferenceDocument1 pageSprinkler Maintenance Schedule RefferenceFardin ShawonNo ratings yet

- Pump PPM ChecklistDocument4 pagesPump PPM ChecklistAjay VarmaNo ratings yet

- Fire Protection SystemsDocument5 pagesFire Protection SystemsRizalNo ratings yet

- Examples of Safety Critical Devices and Associated TestDocument3 pagesExamples of Safety Critical Devices and Associated TestGTMNo ratings yet

- ATTACH 3 LOG SHEET UpdatedDocument12 pagesATTACH 3 LOG SHEET UpdatedHedi Ben MohamedNo ratings yet

- RMS - Boiler Maintenance & Periodic Testing ChecklistDocument5 pagesRMS - Boiler Maintenance & Periodic Testing ChecklistERplant RefinersNo ratings yet

- Appendix - Fire Protection Preventive Maintenance ScheduleDocument5 pagesAppendix - Fire Protection Preventive Maintenance Schedulemohamed attiaNo ratings yet

- Table 7.19: Criteria For Determining The Availability of Corrosion InhibitorsDocument2 pagesTable 7.19: Criteria For Determining The Availability of Corrosion InhibitorsshadowprimitiveNo ratings yet

- Fire Protection Inspection Checklist en PDFDocument4 pagesFire Protection Inspection Checklist en PDFFarid Sedeky100% (1)

- Day 04 Maintenance of LPG SystemDocument11 pagesDay 04 Maintenance of LPG Systemkmas1612No ratings yet

- Fire Protection Equipment Performance Tests: GAP.1.12.0.FDocument1 pageFire Protection Equipment Performance Tests: GAP.1.12.0.Fmakasad26No ratings yet

- Generic Maintenance Plan SummaryDocument7 pagesGeneric Maintenance Plan SummaryTafadzwa MurwiraNo ratings yet

- Maintenance PlanDocument7 pagesMaintenance PlanTafadzwa MurwiraNo ratings yet

- Preventive Maintenance Checklist: Monthly TasksDocument2 pagesPreventive Maintenance Checklist: Monthly TasksmhafizanNo ratings yet

- Fire Pumps - Inspection, Testing and MaintenanceDocument2 pagesFire Pumps - Inspection, Testing and Maintenancesunilarora9999No ratings yet

- ARC Property Inspection Maintenance FPEDocument7 pagesARC Property Inspection Maintenance FPEsanaNo ratings yet

- Into Plane Fuel ChecklistDocument5 pagesInto Plane Fuel ChecklistHusam FNo ratings yet

- MANTENIMIENTODocument5 pagesMANTENIMIENTOalextlv1996cvNo ratings yet

- Visual Inspections Fire Protection SystemDocument4 pagesVisual Inspections Fire Protection SystemArben MontellanoNo ratings yet

- Boiler Checklist A4Document1 pageBoiler Checklist A4Yudha KurniawanNo ratings yet

- Boiler, Electrical, Burner Checklists for Plant MaintenanceDocument1 pageBoiler, Electrical, Burner Checklists for Plant Maintenanceحمودي معزNo ratings yet

- Fire Protection MaintenanceDocument4 pagesFire Protection MaintenanceFridaytenAprilSalinasNo ratings yet

- Maintenance Schedule for Water Distribution SystemsDocument1 pageMaintenance Schedule for Water Distribution SystemsGaurav JhaNo ratings yet

- PM ProgramDocument29 pagesPM Programemad youssefNo ratings yet

- Fire Safety Log Book: Address of PremisesDocument15 pagesFire Safety Log Book: Address of PremisesAlan_Wild100% (1)

- Fire Sprinkler and Standpipe System ChecklistDocument12 pagesFire Sprinkler and Standpipe System ChecklistHasan100% (1)

- Document 007 26.10.19Document38 pagesDocument 007 26.10.19Lucky GouseNo ratings yet

- Guide to inspecting and maintaining environmental test chambersDocument16 pagesGuide to inspecting and maintaining environmental test chambersГоран ГорановNo ratings yet

- Standpipe System ChecklistDocument3 pagesStandpipe System ChecklistMd. Sujaur RahmanNo ratings yet

- Development of Emission Factors From API 622 - 624 Test Data - Buzz Harris - Bronson PateDocument23 pagesDevelopment of Emission Factors From API 622 - 624 Test Data - Buzz Harris - Bronson PateratnakarpatilNo ratings yet

- 5.7.3 Diesel Elctrical Firefighting Pump InspectionDocument2 pages5.7.3 Diesel Elctrical Firefighting Pump Inspectionloay.shemeisNo ratings yet

- Inspect & Test Fire Sprinkler Flow & Tamper Switches Every 6 MonthsDocument8 pagesInspect & Test Fire Sprinkler Flow & Tamper Switches Every 6 Monthsm.sofiqur rahmanNo ratings yet

- NFPA Inspection Requirements for Fire SystemsDocument28 pagesNFPA Inspection Requirements for Fire SystemssechooNo ratings yet

- O&M Guidelines NPDocument6 pagesO&M Guidelines NPPaldexNo ratings yet

- Maintenance of Absorption Column and Stripping ColumnsDocument2 pagesMaintenance of Absorption Column and Stripping ColumnsJoseph OrjiNo ratings yet

- Equipment O&M ChecklistsDocument11 pagesEquipment O&M ChecklistsAsebaho BadrNo ratings yet

- Why It Pays To Maintain Your BoilerDocument2 pagesWhy It Pays To Maintain Your BoilerOmar KhaledNo ratings yet

- MFM Consolidated Preventive Maintenance Ver 2 - 3132017Document201 pagesMFM Consolidated Preventive Maintenance Ver 2 - 3132017Paul CansinoNo ratings yet

- Hydraulic System Inspection SOPDocument6 pagesHydraulic System Inspection SOPZev ZekNo ratings yet

- SOP: Optimize Hydraulic System PerformanceDocument6 pagesSOP: Optimize Hydraulic System PerformanceGovinda RaiNo ratings yet

- NFPA 25 2011 Sprinkler Inspection TableDocument2 pagesNFPA 25 2011 Sprinkler Inspection TableHermes VacaNo ratings yet

- PM PlanDocument56 pagesPM PlanAdrian Christopher Moldez100% (1)

- Maintenance Schedule 1Document1 pageMaintenance Schedule 1puwe qiheNo ratings yet

- Ram GearboxDocument2 pagesRam GearboxTALHA AHMADNo ratings yet

- Role of The Consulting Engineer in The Application of Water Mist SystemsDocument23 pagesRole of The Consulting Engineer in The Application of Water Mist Systemsershad7404No ratings yet

- Ust Monitoring PlanDocument5 pagesUst Monitoring PlanAhmedA.HassanNo ratings yet

- LMP Wet Pipe SystemsDocument4 pagesLMP Wet Pipe SystemsAob AprilNo ratings yet

- PDA TR #26 Update: Sterilizing Filtration of Liquids Meeting Validation RequirementsDocument36 pagesPDA TR #26 Update: Sterilizing Filtration of Liquids Meeting Validation Requirementskalpesh baldaniya100% (1)

- Laboratory Equipment Maintenance LogDocument28 pagesLaboratory Equipment Maintenance LogmzaimNo ratings yet

- Statement of Testing and Maintenance Page 1Document1 pageStatement of Testing and Maintenance Page 1Vench VoizNo ratings yet

- Mohan 2019Document106 pagesMohan 2019Ruben Van Coile100% (1)

- Global Intrima Bulletin - Fire Protection MaintenanceDocument2 pagesGlobal Intrima Bulletin - Fire Protection MaintenancewawanNo ratings yet

- Arc FlashDocument15 pagesArc FlashramlijavierNo ratings yet

- Surat Pneumonia DisnakerDocument2 pagesSurat Pneumonia DisnakerwawanNo ratings yet

- Arc FlashDocument15 pagesArc FlashramlijavierNo ratings yet

- JSA Fencing CV. Naya TirtaDocument1 pageJSA Fencing CV. Naya TirtawawanNo ratings yet

- C - 6 Crane & Lifting Equipment StandartDocument4 pagesC - 6 Crane & Lifting Equipment StandartwawanNo ratings yet

- DASR SMS Gap Analysis ToolDocument37 pagesDASR SMS Gap Analysis Toolwawan100% (1)

- NCR FormsDocument1 pageNCR FormswawanNo ratings yet

- Comparison of Chemical AgentsDocument1 pageComparison of Chemical AgentswawanNo ratings yet

- NCR FormsDocument1 pageNCR FormswawanNo ratings yet

- Gas Test Record: Permit To WorkDocument1 pageGas Test Record: Permit To WorkwawanNo ratings yet

- BV Technical Guide Iso 14001 2015Document12 pagesBV Technical Guide Iso 14001 2015Takis RappasNo ratings yet

- Associated Training Corp. Richardson TX. 972-889-9075 Fax 972-889-9135Document17 pagesAssociated Training Corp. Richardson TX. 972-889-9075 Fax 972-889-9135wawanNo ratings yet

- Associated Training Corp. Richardson TX. 972-889-9075 Fax 972-889-9135Document17 pagesAssociated Training Corp. Richardson TX. 972-889-9075 Fax 972-889-9135wawanNo ratings yet

- The Effect of Collector Aspect Ratio On The Collector Efficiency of Flat-Plate Solar Air HeatersDocument7 pagesThe Effect of Collector Aspect Ratio On The Collector Efficiency of Flat-Plate Solar Air Heatersaxel_oscNo ratings yet

- Diagramatic Plumbing Layout PDFDocument1 pageDiagramatic Plumbing Layout PDFdkdesign consultantNo ratings yet

- Eurocode 3: Design of Steel StructuresDocument11 pagesEurocode 3: Design of Steel Structuresتنكو احمد رمضانNo ratings yet

- Deluge Valve - SD-DVH2Document16 pagesDeluge Valve - SD-DVH2Vijay Gaikwad0% (1)

- Ficha Técnica 610P BabyPlastDocument4 pagesFicha Técnica 610P BabyPlastSergiogoloNo ratings yet

- Building Technology ReviewerDocument117 pagesBuilding Technology ReviewerJess AndanNo ratings yet

- Chemrite - 520Document2 pagesChemrite - 520ICPL-RWPNo ratings yet

- Az p4620 PhotoresistDocument14 pagesAz p4620 Photoresist刘钢No ratings yet

- Separation of Cations by Paper ChromatographyDocument4 pagesSeparation of Cations by Paper Chromatographyapi-281104735100% (1)

- Chevron Richmond Refinery Pipe Rupture and Fire PDFDocument7 pagesChevron Richmond Refinery Pipe Rupture and Fire PDFReynald De VeraNo ratings yet

- Phil2008 AtienzaDocument25 pagesPhil2008 Atienza1sabellNo ratings yet

- Yeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Document8 pagesYeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Mohammed AsherNo ratings yet

- Radiographic Film Interpretation of WeldsDocument193 pagesRadiographic Film Interpretation of WeldskenNo ratings yet

- Bill of Quantities-Amai Pakpak Medical Center: General RequirementsDocument8 pagesBill of Quantities-Amai Pakpak Medical Center: General RequirementsreynoldNo ratings yet

- Salt Light Lamp ReportDocument7 pagesSalt Light Lamp Reportammal naqviNo ratings yet

- Ferrous and Non-Ferrous Alloys GuideDocument22 pagesFerrous and Non-Ferrous Alloys GuideHarsh V Ashok0% (1)

- Metallurgy and Machinability PDFDocument34 pagesMetallurgy and Machinability PDFromanosky11No ratings yet

- Local, Distortional, and Euler Buckling of Thin-Walled ColumnsDocument17 pagesLocal, Distortional, and Euler Buckling of Thin-Walled ColumnsReaditReaditNo ratings yet

- Sambeiro Close Revised Plumbing Bill 2Document7 pagesSambeiro Close Revised Plumbing Bill 2Dapo AlimiNo ratings yet

- Hutama - Waskita, Kso: Job Mix Design ConcreteDocument4 pagesHutama - Waskita, Kso: Job Mix Design ConcreteLanny SuakNo ratings yet

- CENTRIFUGATIONDocument29 pagesCENTRIFUGATIONvaniagiraldiNo ratings yet

- 1A - 11kV HT PanelDocument10 pages1A - 11kV HT PanelPraveen KumarNo ratings yet

- Soil Improvement-Sand DrainDocument4 pagesSoil Improvement-Sand DrainP.Sang-Geo100% (1)

- Metal CastingDocument69 pagesMetal CastingMohd Mansoor HasanNo ratings yet

- Converting Tribology Based Condition Monitoring Into Measurable Maintenance ResultsDocument12 pagesConverting Tribology Based Condition Monitoring Into Measurable Maintenance ResultsddadaraNo ratings yet

- Chem 503 - Activity 2Document6 pagesChem 503 - Activity 2Aries Jay ReyesNo ratings yet

- Design Basis: M/S Space Combine Kind Attn: Mr. Arun VishwakarmaDocument6 pagesDesign Basis: M/S Space Combine Kind Attn: Mr. Arun Vishwakarmabyajaytyagi2266No ratings yet

- BSD104DV H3axDocument21 pagesBSD104DV H3axTiborNo ratings yet

- Sample ODS Record BookDocument9 pagesSample ODS Record BookcaptanupamNo ratings yet

- ParkerStore Corp001 UkDocument516 pagesParkerStore Corp001 UkMarcelo Partes de Oliveira100% (1)