Professional Documents

Culture Documents

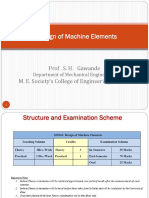

Profile Projector: A Guide to Measurement and Inspection

Uploaded by

Shyam SenthilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Profile Projector: A Guide to Measurement and Inspection

Uploaded by

Shyam SenthilCopyright:

Available Formats

Profile Projector

Profile Projector (or optical comparator) is a device that applies the principles of optics to

the inspection of manufactured parts. Using this instrument enlarged images of small shapes

under test can be obtained that can the used for comparing shapes or profiles of relatively

small engineering components with an accurate standard or enlarged drawing.

Fig. Profile Projector

Fig. Profile projector

Fig. Profile Projector

Fig. Workpiece measurement using Profile projector

Types of Optical Systems

Simple optics: It incorporates a light source, a magnification lens, a main reflecting mirror

and a screen. Machines with this design display images that are both upside-down and

reversed.

Corrected optics: This system uses two internal mirrors to flip the image so that it's

displayed right-side-up, but it's reversed on the horizontal axis.

Fully corrected system: which displays images that are both erect and unreversed.

Types of measurements:

Measurement by motion: worktables are incorporated into the optical competitors to track

parts' positions as they move.

Features:

Medium-sized model that featured high versatility and easy operation.

Digital readout protractor screen facilitates angle measurement.

Screen glass carries the chart clips.

Easy-to-read digital XY-coordinate counters are located near the projection screen to

minimize eye-movement.

Floating-type table (X- direction only) for speedy measurement.

Stepwise Procedure

Switch on the optical profile projector.

Place the clean work piece on the glass of the table.

Focus it properly by moving focusing wheel and moving the work table to obtain correct

magnified image of the object.

Horizontal (x axis) measurement can be taken by right hand side micrometer and the

vertical measurement can be taken from front side micrometer.

Applications of profile projectors

Profile Projector can reveal imperfections such as burrs, scratches, indentations or

undesirable chamfers which both micrometers or calipers can’t reveal.

They are used to measure, gauge, test, inspect or examine parts for complaints with

specifications.

In addition, the comparator screen can be simultaneously viewed by more than one

person and provide for a medium for discussion.

They’re able to measure in 2-D space. Unlike micrometers and calipers, which

measure one dimension at a time, where comparators measure length and width

simultaneously.

Uses of an optical projector:

Using optical projectors, it is possible to measure those components which are difficult to

be measured by other methods due to typical size, material composition and dimensional

characteristics.

It displays the magnified images of the objects located by some holding device or staging

fixture on an appropriate viewing screen.

The magnified images serves as an aid to more precise determination of dimension, form,

etc.

Cost savings:

Optical comparators save time. Ease-of-use factors and ergonomic designs reduce the

inspection time, retraining costs and operator fatigue, all while increasing throughput.

Custom hard gages are subject to wear and need frequent recertification, which takes

them out of service and adds an additional cost.

Disadvantages

The limitation of using profile projector as a fixed device forms a disadvantage of it, while

instruments such micrometer or calipers can be used to reach for measuring far and joint

accessible components and it is large and bulky and usually require a cart to transport from

place to place, also the device requires power for operation.

You might also like

- (Nelson Newman) Raspberry Pi 4 Projects User Guide PDFDocument143 pages(Nelson Newman) Raspberry Pi 4 Projects User Guide PDFluigui20100% (3)

- DrainageDocument42 pagesDrainagekingjames90100% (3)

- 172R Wiring Diagram ManualDocument488 pages172R Wiring Diagram ManualmidunNo ratings yet

- Warehouse Space Rental OpportunitiesDocument6 pagesWarehouse Space Rental OpportunitiesAnonymous 5JrxY4No ratings yet

- The Physics of The Trumpet (Bostjan Berkopec)Document12 pagesThe Physics of The Trumpet (Bostjan Berkopec)carmechanicNo ratings yet

- Updating Program Felcom18-19.Document2 pagesUpdating Program Felcom18-19.Ivo CastroNo ratings yet

- 20 Safety Rules for Working with Electrical EquipmentDocument23 pages20 Safety Rules for Working with Electrical EquipmentJoshua Ignatius EyanaNo ratings yet

- Abap Dynamic TableDocument8 pagesAbap Dynamic TablevenkatNo ratings yet

- LLM User Guide 10 2Document547 pagesLLM User Guide 10 2seenuyarasiNo ratings yet

- Research Paper On Cyber Security & CryptographyDocument2 pagesResearch Paper On Cyber Security & CryptographyInternational Journal of Innovative Science and Research Technology100% (1)

- Design of Shaft PDFDocument5 pagesDesign of Shaft PDFAnonymous oTrMzaNo ratings yet

- Mechatronics Unit III and IV Question and AnswersDocument6 pagesMechatronics Unit III and IV Question and AnswersSaravanan MathiNo ratings yet

- Top 100 IT Companies Rank ListDocument3 pagesTop 100 IT Companies Rank ListSomesh100% (2)

- Profile ProjectorDocument17 pagesProfile ProjectorMukeshChoudhry100% (2)

- ACX5 Brochure enDocument44 pagesACX5 Brochure enrnkmip100% (3)

- MET 414 Quality Management: Dr.J.Hussain Professor/Mechanical MEA Engineering College PerinthalmannanDocument56 pagesMET 414 Quality Management: Dr.J.Hussain Professor/Mechanical MEA Engineering College PerinthalmannanDr. J.HussainNo ratings yet

- Refrigeration and Air Conditioning Course OverviewDocument9 pagesRefrigeration and Air Conditioning Course OverviewAsif jabarNo ratings yet

- RacDocument26 pagesRacgurunakhale123No ratings yet

- c4 Tutorial TurbineDocument2 pagesc4 Tutorial TurbinehahahaNo ratings yet

- Unit I DME I 13 09 2021Document68 pagesUnit I DME I 13 09 2021Vaibhav JainNo ratings yet

- Unit-1 Vehicle Frame and SuspensionDocument41 pagesUnit-1 Vehicle Frame and SuspensionKrishna 1996No ratings yet

- RAC Tutorial Sheet 2Document3 pagesRAC Tutorial Sheet 2Ankur Sachdeva0% (1)

- Damped Free VibrationDocument6 pagesDamped Free Vibrationraffiq85No ratings yet

- Lec 3. Centfg - Compressor ExDocument30 pagesLec 3. Centfg - Compressor ExmichaelNo ratings yet

- Load Estimation: Types of LoadsDocument5 pagesLoad Estimation: Types of Loadsanupnaskar naskarNo ratings yet

- Air Conditioning System ExperimentDocument3 pagesAir Conditioning System ExperimentBoJassim100% (1)

- Transformations and Data StorageDocument82 pagesTransformations and Data StorageAnmolNo ratings yet

- Internship PresentationDocument26 pagesInternship PresentationKarthik NayakNo ratings yet

- Experiment No - 1: AIM: Study of Various Types of Gear Boxes Such As Industrial Gear Box, SynchromeshDocument3 pagesExperiment No - 1: AIM: Study of Various Types of Gear Boxes Such As Industrial Gear Box, SynchromeshParas KumbalwarNo ratings yet

- Mechanism Design: Quick Return, Timing ChartsDocument6 pagesMechanism Design: Quick Return, Timing ChartsAsim AshrafNo ratings yet

- Design of Machine Elements II: Curved BeamsDocument255 pagesDesign of Machine Elements II: Curved BeamsAjayNo ratings yet

- Heat & Mass Transfer: Theory & ApplicationDocument40 pagesHeat & Mass Transfer: Theory & ApplicationSyed Ahmed Raza100% (1)

- Design, Fabrication and Testing of Human Powered Water PurifierDocument8 pagesDesign, Fabrication and Testing of Human Powered Water PurifierIJRASETPublicationsNo ratings yet

- Dynamic Force Analysis on Slider Crank MechanismDocument39 pagesDynamic Force Analysis on Slider Crank MechanismSAI PRAMOD RAVADANo ratings yet

- Assignment 2Document1 pageAssignment 2dhrumilNo ratings yet

- MD ShaftDocument18 pagesMD Shaftiftikhar ahmedNo ratings yet

- Cash Flow and Equivalence PDFDocument6 pagesCash Flow and Equivalence PDFIscandar Pacasum DisamburunNo ratings yet

- Measure Taper Angle with Sine BarDocument5 pagesMeasure Taper Angle with Sine Barঅর্ঘ্য রায়No ratings yet

- Belt Drives and Chain DrivesDocument39 pagesBelt Drives and Chain DrivesSeparatorNo ratings yet

- (Lab No. 1) Determination of Viscosity of A Given Liquid Using Viscometer.Document15 pages(Lab No. 1) Determination of Viscosity of A Given Liquid Using Viscometer.Haider AliNo ratings yet

- Kinematics of Cams: Cams With Different Follower MotionDocument76 pagesKinematics of Cams: Cams With Different Follower MotionMPee Finance SumerpurNo ratings yet

- Calibrate Vernier Caliper Using Slip GaugesDocument3 pagesCalibrate Vernier Caliper Using Slip GaugesVikram BillalNo ratings yet

- Assignment 1: Turbo MachinesDocument2 pagesAssignment 1: Turbo MachineskookoNo ratings yet

- Expert Systems Applications in Manufacturing PDFDocument2 pagesExpert Systems Applications in Manufacturing PDFMalikNo ratings yet

- Practice Exercise 1: Suppose You Wish To Build A Model That Will Help Determine IfDocument4 pagesPractice Exercise 1: Suppose You Wish To Build A Model That Will Help Determine IfFakhar Un Nisa0% (1)

- Problems Paired T-TestDocument14 pagesProblems Paired T-TestArghya BoseNo ratings yet

- 2 Marks MMDocument5 pages2 Marks MMPappujiNo ratings yet

- DOM - Governor NotesDocument17 pagesDOM - Governor NotesEssKay0% (1)

- 1.1 Background of The StudyDocument12 pages1.1 Background of The StudyStephen DuamorNo ratings yet

- Inverted PendulumDocument9 pagesInverted PendulumMahmoud Samir MahmoudNo ratings yet

- Assignment: A and A Wheel WeighingDocument1 pageAssignment: A and A Wheel WeighingIshfaqurNo ratings yet

- 7 Centrifugal Compressors FanDocument23 pages7 Centrifugal Compressors FanhuynhnhuNo ratings yet

- Engineering-Curves 1Document17 pagesEngineering-Curves 1api-327264533No ratings yet

- Gyroscopic CoupleDocument10 pagesGyroscopic CoupleAnandha RamanNo ratings yet

- MeshingDocument35 pagesMeshingNilambar BarihaNo ratings yet

- ME450 Winter2009 Final Report - Project 24 - Bicycle Hydraulic Regenerative Braking System PDFDocument107 pagesME450 Winter2009 Final Report - Project 24 - Bicycle Hydraulic Regenerative Braking System PDFKeerthi Tom RajanNo ratings yet

- Lab 2 Analog Encoder PWM R9Document5 pagesLab 2 Analog Encoder PWM R9subairiNo ratings yet

- Brayton CycleDocument5 pagesBrayton CycleDanang Wahdiat Aulia IshaqNo ratings yet

- Measurement of Length, Height & Diameter by Vernier Calipers, MicrometerDocument2 pagesMeasurement of Length, Height & Diameter by Vernier Calipers, MicrometerSarath TejaNo ratings yet

- Ref Lec-2 (CH 4-5) PDFDocument45 pagesRef Lec-2 (CH 4-5) PDFمحمد متوليNo ratings yet

- ME432 Power Plant Engineering May Jun 2007 PDFDocument3 pagesME432 Power Plant Engineering May Jun 2007 PDFBala MuruganNo ratings yet

- Assignment 8Document1 pageAssignment 8Ayush NarayanNo ratings yet

- Classification of CNC MachinesDocument10 pagesClassification of CNC Machinesparth solankiNo ratings yet

- Self Generating SensorsDocument23 pagesSelf Generating SensorsVhan DarshNo ratings yet

- CS71 - Computer Graphics 2 MarksDocument23 pagesCS71 - Computer Graphics 2 MarkspeyartheriyathuNo ratings yet

- Profile ProjectorDocument25 pagesProfile Projectorrummanomar0% (2)

- Profile Projector: Prepared and Presented byDocument24 pagesProfile Projector: Prepared and Presented bytechnical tjNo ratings yet

- Profile Projector: Prepared and Presented byDocument25 pagesProfile Projector: Prepared and Presented byMuhammad FaridNo ratings yet

- Profile Projector 10052016Document24 pagesProfile Projector 10052016S MurthyNo ratings yet

- Profile Projector Inspection GuideDocument25 pagesProfile Projector Inspection GuideMuhammad FarhanNo ratings yet

- Profile ProjectorDocument25 pagesProfile ProjectorMohd Sayyid Mu'ammarNo ratings yet

- 1st Sum - Composite Cylinder - 31.12.19Document2 pages1st Sum - Composite Cylinder - 31.12.19Shyam SenthilNo ratings yet

- BCD 2020 Registration Form PDFDocument2 pagesBCD 2020 Registration Form PDFShyam SenthilNo ratings yet

- Vernier and MicrometerDocument4 pagesVernier and MicrometerShyam SenthilNo ratings yet

- Tool Maker MicroscopeDocument4 pagesTool Maker MicroscopeShyam SenthilNo ratings yet

- Zeiss Ultra OptimeterDocument3 pagesZeiss Ultra OptimeterShyam SenthilNo ratings yet

- Measurement of Surface Finish QuantitativelyDocument12 pagesMeasurement of Surface Finish QuantitativelyShyam SenthilNo ratings yet

- Profile Projector: A Guide to Measurement and InspectionDocument4 pagesProfile Projector: A Guide to Measurement and InspectionShyam SenthilNo ratings yet

- Unit 1 IntroductionDocument11 pagesUnit 1 IntroductionShyam SenthilNo ratings yet

- Script AlexithymiaDocument5 pagesScript AlexithymiaShyam SenthilNo ratings yet

- A Generic DMM Test and CalibrationDocument11 pagesA Generic DMM Test and CalibrationrobertNo ratings yet

- Brochure The Prestige City - PDF Download - E-BrochureDocument31 pagesBrochure The Prestige City - PDF Download - E-Brochureprestige sarjapur city bangaloreNo ratings yet

- ENSA Questions AnswersDocument18 pagesENSA Questions AnswersNurul ShakirahNo ratings yet

- Analysis of Intake and Exhaust Air System of GEVO for bsfc ReductionDocument54 pagesAnalysis of Intake and Exhaust Air System of GEVO for bsfc Reductionrakesh sNo ratings yet

- Map Reduce ExamplesDocument16 pagesMap Reduce Examplesicecream-likeyNo ratings yet

- BZU Multan Semester Results BSc Electrical Engineering Power SpecializationDocument3 pagesBZU Multan Semester Results BSc Electrical Engineering Power SpecializationHusnain NaqviNo ratings yet

- Bread SpreadDocument7 pagesBread SpreadChetanBansalNo ratings yet

- SMB PRO MULTI BMS Supports LFP, LI Ion, LTO & LIPO CellsDocument6 pagesSMB PRO MULTI BMS Supports LFP, LI Ion, LTO & LIPO CellsGustavo R GorNo ratings yet

- Cessna 185 Familiarisation CourseDocument5 pagesCessna 185 Familiarisation CourseAmmar A. AlliNo ratings yet

- Education Officer Maternity Cover Rzss - Edinburgh Zoo BiazaDocument1 pageEducation Officer Maternity Cover Rzss - Edinburgh Zoo Biazaapi-392902267No ratings yet

- NRLM Skills PresentationDocument23 pagesNRLM Skills PresentationVinod Kumar NooluNo ratings yet

- Comp ConDocument2 pagesComp ConUmbrellamonNo ratings yet

- Frequently Asked Questions (F.A.Q) : Regarding Digsilent PowerfactoryDocument7 pagesFrequently Asked Questions (F.A.Q) : Regarding Digsilent PowerfactoryClaudio0914No ratings yet

- Rose Petal Paper ProductsDocument3 pagesRose Petal Paper ProductsHardesh Kumar HiraNo ratings yet

- OPEN BANK ACCOUNT FORMDocument5 pagesOPEN BANK ACCOUNT FORMaribandikNo ratings yet

- Omron E5 JDocument69 pagesOmron E5 JVoneisisoNo ratings yet

- Plant-Microbial Fuel Cell Generates Electricity from Living PlantsDocument3 pagesPlant-Microbial Fuel Cell Generates Electricity from Living PlantsDani MuliawanNo ratings yet

- Low Pressure Switch Technical SpecsDocument10 pagesLow Pressure Switch Technical Specsdcf67myNo ratings yet