Professional Documents

Culture Documents

LFI Tool - PD-HX-REP-003 Rev.01

Uploaded by

Qayyum KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LFI Tool - PD-HX-REP-003 Rev.01

Uploaded by

Qayyum KhanCopyright:

Available Formats

Restricted

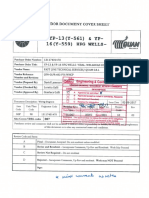

PDO FEED OFFICE

Learnings from Incidents (LFI) Tool

Document No: FEED-HX-REP-003

01 6/17/2019 Issued for Approved UEFH3/SE UEFH/MD UEFH/MD

Rev. Date Description Originator Checker Approver

(Ref.Ind / Std.Initial) (Ref.Ind / Std.Initial) (Ref.Ind / Std.Initial)

Format No:FEED-QM-FOM-023, Rev.06

Learnings from Incidents (LFI) Tool

1. Background:

This Learnings from Incidents (LFI) Tool summarizes all agreed and CFDH endorsed learnings from PDO AIPS incidents

recorded in the AIPS Databook. It consists of incidents that happened between 2012-2017. Each record consists of Incident

reference number for easy referencing in order to search quickly in AIPS Databook and other issued reports

PDO201904100035 (Ref 3) . Furthermore, a short description of the incident is provided as well as the actual and potential

consequence of it. Key are the key learnings of the specific incident and each learning is categorised into 3 types such as

Design Integrity, Technical Integrity and Operation Integrity. Also the key disciplines assigned to each learning in order to

take responsibility to embed it in the project lifecycle.

In total approx. 380 learnings have been derived from about 122 incidents. For 2012, the learnings are coming from 11 Tier

1 incidents; for 2013 from 13 Tier 1, 1 Tier 2 and 2 HiPo incidents; for 2014 from 22 Tier 1 incidents; from 2015 from 11

Tier 1, 7 Tier 2 and 5 HiPo incidents; for 2016 from 8 Tier 1, 8 Tier 2 and 5 HiPo incidents; and for 2017 from 13 Tier 1, 11

Tier 2 and 5 HiPo incidents. More information on the incident, can be found in the AIPS Databook.

This LFI Tool will be continuously updated as and when the incidents for later years learnings are reviewed and endorsed by

the CFDHs.

2. Objective:

The main objective is to incorporate the applicable learnings from the past PDO AIPS incidents into the project life cycle

such that the same incidents shall not reoccur. This to demonstrate one of the statement of fitness element as part of the

AIPSM compliance.

Template No: FEED-HX-REP-003 Rev.01 Page 2 of 26

Learnings from Incidents (LFI) Tool

3. Instructions during Design Stage: Detailed information is provided in PR-2050, however the key instructions are

specified below.

BfD: During this stage each learning related to all categories (Design Integrity, Technical Integrity & Operation Integrity) in

LFI tool to review the applicability to the project considering all phases of the project life cycle (till handover to operations).

Refer to LFI Tool column "Applicable to Project" - Mention "Yes or No" and no need to review the pre-screened "NA"

learnings. At this stage the requirement is to screen the applicable learnings by end of the BfD and ensure any conceptual

or basic design related learnings as applicable are embedded in the design. The LFI screening sheet has to be signed by

relevant TA2s.

FEED: The applicable LFIs shall be reviewed which was done during BfD stage and ensure the screening done during BfD

stage is updated (if required) at the beginning of the FEED and shall be completed on or before HAZID. The compliance

inputs provided during BfD to be updated if any and further inputs has to be provided on or before HAZOP and final

compliance inputs and sign-off to be completed on or before IPF.

FEED+DD/DD: The applicable LFIs shall be reviewed during FEED+DD/DD stage and ensure that the previous screening

done is correct. All the relevant learnings are screened at the beginning of the FEED+DD/DD projects and this shall be

completed on or before HAZID. The compliance inputs provided during previous stages to be verified/updated (including

document numbers) and further inputs has to be provided/updated on or before HAZOP and final compliance inputs and

sign-off to be completed once all learnings are incorporated in "Approved" documents and the status (Open/Closed) to be

updated accordingly for the applicable learnings.

Post DD: The LFIs which are applicable to construction, pre-commissioning and commissioning shall be further update at

this stage by PDO construction and commissioning team along with Project Management Team. The Project Team shall

ensure the completion of LFI tool as part of the preparation of Statement of Fitness.

4. Deviation from Learnings:

As these learnings are from the PDO real incidents, it is very important to review and incorporate all relevant/applicable

learnings in the relevant project phase as part of the AIPSM compliance. However, if the applicable learning is not

incorporated for any reasons, a justification shall be included in the LFI sheet itself to demonstrate why the learning is not

been implemented. The relevant discipline TA2 is accountable to justify the rationale of not incorporating the relevant

learnings in the design.

Template No: FEED-HX-REP-003 Rev.01 Page 3 of 26

Learnings from Incidents (LFI) Tool

5. Notes:

1. Each and every learning is assigned to various disciplines, responsible to provide the compliance demonstration as part

of the LFI standardisation process and which has been agreed with the respective leads.

2. During pre-screening process, those LFIs falls under the following category are screened out by indicating as "Not

Applicable (NA)":

(i) Learnings which are repeated (duplicated learnings);

(ii) Learnings which are completely belongs or can only be demonstrated by non-Project or non-Engineering team (e.g;

Operations)

(iii) Learnings which are already captured in the PDO standards & DEPs which are followed in PDO projects.

It is expected that the learnings which are already captured in relevant PDO standards & DEPs are to be implemented by

default as the design to be followed as per codes and standards in first place. The learnings belongs or can only be

demonstrate/review by non-project or non-Engineering team (e,g; operations) is not required to demonstrate/review

during design phase and separate demonstration process is manage by those relevant units/departments.

3. The status (Open/Closed) has to be mentioned at the end of DD stage (before post DD) of the project, where the

construction, pre-commissioning and commissioning scope is handled by others. The LFIs related to construction, pre-

commissioning and commissioning scope to kept as open and these LFIs shall be further updated at this stage by PDO

construction and commissioning team along with Project Management Team.

4. Compliance Demonstration Phase in LFI Tool: Post DD indicates pre-commissioning, commissioning, construction phase

etc. till handover to operations. The procurement related LFI shall be considered as part of the DD.

5. In general, the LFI compliance demonstration is part of the AI-PSM Compliance Report and are not required to be

produced as the standalone report in projects. LFI compliance demonstration worksheet is to be place as one of the

appendix of the AI-PSM Compliance Report.

6. At BfD & FEED stage, the sign-off of LFI compliance demonstration can be supported with reference to first revision

(Rev.01) issued documents. However for the FEED+DD/DD projects, the sign-off of the LFI demonstration shall be

completed once all the approved vendor/ owner documents are issued in Assai by the respective disciplines. At

FEED+DD/DD stage, all the documents referenced in the LFI tool for demonstration shall be through final approved

(vendor/owner) documents only.

6. References:

1. AIPSM Incident Databook - http://portal.corp.pdo.om/solutions/LKB/MSE/AIPSM/Pages/HomePage.aspx

2. PR 2050 - FEED Office Demonstration of AI-PSM Compliance Procedure

3. Document No: PDO201904100035 - Learning from Incidents A summary Report of Learnings from PDO AIPS Events

(2012-2017)

Template No: FEED-HX-REP-003 Rev.01 Page 4 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Accountable Discipline 1: Accountable Discipline 1:

Design shall consider new facility Accountable Discipline 2: Accountable Discipline 2:

impact such as process condition

AIPS-201203 and composition (e.g. pressure, End of BfD, FEED

8 No Process Not Applicable

temperature, water, salt) on tie-in as well DD

systems and connected

downstream existing facilities [DI]

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Challenge/review the need for

having a surge relief valve (SRV). If

by design an SRV is required, the

design shall consider the ability of

an operator to respond adequate End of FEED as

14 AIPS-201205 and in time to the demands, e.g. No Process Not Applicable

well DD

have alarms available indicating the

relief valve has lifted (e.g. loss of N2

pressure). The alarm and response

time shall be documented in the

design basis [DI]

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Facilities with the potential for

liquid hammering, such as steam

AIPS-201207 facilities, shall be designed to allow End of FEED as

21 Piping Not Applicable

for effective venting/draining of all well DD

piping and equipment prior to

commissioning and (re-)start [DI]

Template No: FEED-HX-REP-003 Rev.01 Page 5 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Process design review shall include

the impact and effects of inlet lines

AIPS-201208 with multiple feeds in both start-up End of FEED as

24 No Process Not Applicable

and operating scenarios, as well as well DD

and with these lines individually in

shutdown [DI]

Accountable Discipline 1: Accountable Discipline 1:

Process design and facility reviews Accountable Discipline 2: Accountable Discipline 2:

shall evaluate pipe displacement

and movement of equipment due End of FEED as

25 AIPS-201208 to slug or liquid hammering effects, No Piping Not Applicable

well DD

with special attention to piping

supports and possible shearing off

of small bore connections [DI]

Accountable Discipline 1: Accountable Discipline 1:

Design for fire and gas detection Accountable Discipline 2: Accountable Discipline 2:

End of FEED as Control &

29 AIPS-201209 systems at remote, (partially) No Not Applicable

well DD Automation

unmanned stations [DI]

Accountable Discipline 1: Accountable Discipline 1:

For fouling service design for fail Accountable Discipline 2: Accountable Discipline 2:

safe conditions in case of faulty

AIPS-201209 reading of instrumentation and End of FEED as Control &

31 No Not Applicable

consider implementing means to well DD Automation

allow (continuous) flushing of

instrument lead lines [DI]

Template No: FEED-HX-REP-003 Rev.01 Page 6 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Accountable Discipline 1: Accountable Discipline 1:

Provision shall be provided for Accountable Discipline 2: Accountable Discipline 2:

pressure testing of equipment at

the required (design) pressures. End of FEED as

35 AIPS-201210 System design shall allow for No Process Not Applicable

well DD

additional piping configuration to

facilitate this mandated pressure

testing [DI]

Accountable Discipline 1: Accountable Discipline 1:

AIPS-201211 Above Ground GRE piping shall not End of FEED as Accountable Discipline 2: Accountable Discipline 2:

36 No Piping Not Applicable

be installed in fire zones [DI] well DD

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Gaskets for equipment in acid

AIPS-201302 service shall comply with the End of FEED as

45 applicable design specifications and No well DD Piping Not Applicable

vendor recommendations [TI]

Accountable Discipline 1: Accountable Discipline 1:

When designing Utility and non-HC

AIPS-201308 units review the need/requirement End of FEED as Accountable Discipline 2: Accountable Discipline 2:

54 No Technical Safety Not Applicable

for a Fire & Gas Detection System well DD

[DI]

Accountable Discipline 1: Accountable Discipline 1:

The maximum discharge pressure Accountable Discipline 2: Accountable Discipline 2:

and trip setting of an Electrical

Submersible Pump (ESP) shall be

AIPS-201315 below the maximum allowable flow End of FEED as

69 No Process Not Applicable

line pressure and shall involve well DD

systems to relief pressure where

excursions above can be expected

[DI]

Template No: FEED-HX-REP-003 Rev.01 Page 7 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Accountable Discipline 1: Accountable Discipline 1:

A steam boiler with a history of Accountable Discipline 2: Accountable Discipline 2:

End of BfD, FEED

89 AIPS-201406 having used hydrogen as a fuel No Process Not Applicable

as well DD

source shall not be re-used [DI]

Accountable Discipline 1: Accountable Discipline 1:

Local control cabins in steam End of FEED as Accountable Discipline 2: Accountable Discipline 2:

90 AIPS-201406 injection facilities shall be located No Piping Not Applicable

well DD

to the side of boiler equipment [DI]

Accountable Discipline 1: Accountable Discipline 1:

Facility layout, including temporary Accountable Discipline 2: Accountable Discipline 2:

AIPS-201406 (hired/leased) equipment shall End of FEED as

91 No Piping Not Applicable

comply with applicable codes and well DD

standards [DI]

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Header tie-in design and

AIPS-201407 configurations shall take flow End of FEED as

95 No Piping Not Applicable

induced corrosion into well DD

consideration [DI]

Template No: FEED-HX-REP-003 Rev.01 Page 8 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Remote facilities should be

identifiable in case of (3rd party)

report of incident at facility, and End of FEED as

102 AIPS-201409 where possible CCTV shall be Technical Safety Telecom

well DD

installed to provide ability to detect

larger leaks and spills at the site

[OI]

Accountable Discipline 1: Accountable Discipline 1:

Design systems to prevent start-up Accountable Discipline 2: Accountable Discipline 2:

against high differential pressure.

Pressure equalization across (large) End of FEED as

108 AIPS-201411 valves shall always be done No Process Not Applicable

well DD

gradually to avoid damage to

piping/equipment due to hammer

effect [DI]

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

The design philosophy of a facility

shall ensure that all inlet wells and

flow lines to the main station/RMS

can be safely closed on process End of FEED as

153 AIPS-201502 upset or power failure, such that no No Process Not Applicable

well DD

pressure exceedance in the system

can develop. Positive identification

of no-flow should be available to

control room operator [DI]

Template No: FEED-HX-REP-003 Rev.01 Page 9 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

The Plant Operating Manual and

the Process Safeguarding

Memorandum shall describe the

AIPS-201502 safeguarding at the interface and Operations in

154 No End of DD Process

should include the description of Design

the wells and how they will be shut

down, e.g. by PMR or other means

(including manual closure) [DI]

Accountable Discipline 1: Accountable Discipline 1:

Remotely located relief valves shall Accountable Discipline 2: Accountable Discipline 2:

have indication to operations that

they have lifted (e.g. through a

AIPS-201502 pressure alarm). For an over- End of FEED as Control &

155 Not Applicable

pressure in an off plot location, well DD Automation

reset shall be local to ensure that a

reset is done after verification at

the location [DI]

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Provide inlet pipe support outside

AIPS-201502 the bund wall to avoid having a End of FEED as

157 No Piping Civil

weak joint that could be vulnerable well DD

to washout [DI]

Template No: FEED-HX-REP-003 Rev.01 Page 10 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Accountable Discipline 1: Accountable Discipline 1:

Remote relief pit shall be equipped End of FEED as Accountable Discipline 2: Accountable Discipline 2:

158 AIPS-201502 with level indicators to prevent No Process Not Applicable

well DD

overfill [DI]

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Design Reviews for Modification

Projects shall include evaluation of

AIPS-201505 “dead-leg” potential, with the End of FEED as

166 No Piping Not Applicable

objective to eliminate dead-legs well DD

where possible, and provide

mitigation when not possible [DI]

Accountable Discipline 1: Accountable Discipline 1:

Facility Blowdown design of gas Accountable Discipline 2: Accountable Discipline 2:

End of FEED as

183 AIPS-201509 facilities shall comply with DEP No Process Not Applicable

well DD

80.45.10.12 (Blowdown) [DI]

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

When material selection specifies

AIPS-201510 CS with weld overlay, all sizes End of FEED as

184 No Piping Not Applicable

smaller than 4” diameter shall be well DD

made of solid CRA material [DI]

Accountable Discipline 1: Accountable Discipline 1:

Flare design, safe blower location Accountable Discipline 2: Accountable Discipline 2:

End of FEED as

244 AIPS-201605 and sterile area shall be part of No Process Technical Safety

well DD

facility design review [DI]

Template No: FEED-HX-REP-003 Rev.01 Page 11 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Ensure piping analysis, near

AIPS-201704 rotating equipment, shall include End of FEED as

296 No Piping Not Applicable

vibration as well as stress analysis well DD

[DI]

Accountable Discipline 1: Coplete hook-up is Accountable Discipline 1:

demolised and there will not be any dead legs

left. Accountable Discipline 2:

Accountable Discipline 2:

Project teams shall ensure that

AIPS-201720 decommissioning scope does not End of FEED as

353 Yes Process Not Applicable

leave dead legs behind in the well DD

process system [DI]

Accountable Discipline 1: Accountable Discipline 1:

Accountable Discipline 2: Accountable Discipline 2:

Effluent treatment sampling system

shall be designed in such a way that End of FEED as

363 AIPS-201724 release and loss of product to the No Process Not Applicable

well DD

environment does not occur when

taking samples [DI]

Template No: FEED-HX-REP-003 Rev.01 Page 12 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Accountable Discipline 1: Accountable Discipline 1:

Verify during design whether an Accountable Discipline 2: Accountable Discipline 2:

AIPS-201729 insulation gasket is required, e.g. End of FEED as

377 No Process Not Applicable

when dissimilar materials are used well DD

[DI]

Accountable Discipline 1: Accountable Discipline 1:

The use of a non-standard gasket End of FEED as Accountable Discipline 2: Accountable Discipline 2:

378 AIPS-201729 requires an MOC and needs to be No Piping Not Applicable

well DD

approved by appropriate CFDH [DI]

Template No: FEED-HX-REP-003 Rev.01 Page 13 of 26

Project ID:

Project Name:

Project Stage:

Document No. & Rev.No:

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

The learnings from Learning from Incidents (LFI) are embedded in the project are endorsed by the following persons as applicable to confirm that they that are suitable, appropriate and robust to manage that the reoccurrence of the potential incidents are

Civil Eng TA2 (Name & Ref ID): Signature: Date:

Control & Automation Eng TA2 (Name & Ref ID): Signature: Date:

Electrical Eng TA2 (Name & Ref ID): Signature: Date:

Materials & Corrosion Eng TA2 (Name & Ref ID): Signature: Date:

Pipelines Eng TA2 (Name & Ref ID): Signature: Date:

Piping Eng TA2 (Name & Ref ID): Signature: Date:

Process Eng TA2 (Name & Ref ID): Signature: Date:

Project Management Eng TA2 (Name & Ref ID): Signature: Date:

Design

Integrity

& Quality Eng TA2 (Name & Ref ID): Signature: Date:

Technical

Integrity

Rotating Eng TA2 (Name & Ref ID): Signature: Date:

Static Eng TA2 (Name & Ref ID): Signature: Date:

Technical Safety Eng TA2 (Name & Ref ID): Signature: Date:

Telecom Eng TA2 (Name & Ref ID): Signature: Date:

Template No: FEED-HX-REP-003 Rev.01 Page 14 of 26

Design

Integrity

Project ID:

& Name:

Project

Technical

Project Stage:

Integrity No. & Rev.No:

Document

Date:

Learning from Incidents (LFI) Tool

Applicable to Compliance Accountable Accountable LFI Compliance Document Evidence for Status

Learning Incident Project (All LFI Compliance Demonstration for

Key Learnings Demonstration Discipline 1 for Discipline 2 for Accountable Discipline 1 & 2 (Closed or

S.No. Reference ID Phases) Accountable Discipline 1 & 2

Phase the Learning the Learning (Document Description & Number) Open)

(Yes or No)

Operations in Design TA2 (Name & Ref ID): Signature: Date:

M&I in Design TA2 (Name & Ref ID): Signature: Date:

Commissioning Eng TA2 (Name & Ref ID): Signature: Date:

Construction TA2 (Name & Ref ID): Signature: Date:

Template No: FEED-HX-REP-003 Rev.01 Page 15 of 26

from Incidents (LFI) Tool

M

Remarks &

I

i

n

D

e

s

i

g

n

The same learning is also

appeared for the Incident

Reference ID: AIPS-201511

Template No: FEED-HX-REP-003 Rev.01 Page 16 of 26

from Incidents (LFI) Tool

Remarks

The startup of the process unit

shall be discussed under the

"Start-up" guide word during

HAZOP and the supports shall be

designed for the inputs provided

in the Line List.

The same learning is also

appeared for the Incident

Reference ID: AIPS-201411

failsafe Design is always

implemented and followed,

instrument flushing by means of

standard mono-flanged

arrangement (SDB & DDB)

Template No: FEED-HX-REP-003 Rev.01 Page 17 of 26

from Incidents (LFI) Tool

Remarks

Template No: FEED-HX-REP-003 Rev.01 Page 18 of 26

from Incidents (LFI) Tool

Remarks

Process: To review the line

velocities as part of line sizing

and to be captutred in line list as

per codes and standards.

Highlight if any higher velocities

cases and to be captured

accordingly in the design.

Piping: To update piping size

based on Process input.

Template No: FEED-HX-REP-003 Rev.01 Page 19 of 26

from Incidents (LFI) Tool

Remarks

Facility identification is

mandatory requirement. This has

to be part of the Safety Sign and

CCTV to be assessment to be

done case to case basis.

This learning is applicable to trip

of wells by PMR based on the

inputs from Ptrocess & C&A to

demonstrate this learning in

projects.

Process Inputs to C&A: The PMR

trip details to be reflected in PEFS

C&A Inputs: The FCS & IPS logic

details to be provided to

Electrical indicating the scheme

how to built the logic to address

this learning.

Template No: FEED-HX-REP-003 Rev.01 Page 20 of 26

from Incidents (LFI) Tool

Remarks

The scope of Hazop to remove

the HIPPS lekage RV only and

existing wells hook-ups are being

replaced by DSS materail.

Template No: FEED-HX-REP-003 Rev.01 Page 21 of 26

from Incidents (LFI) Tool

Remarks

Key Learning shall be considered

to mention that drain/vent plug

threaded portion shall also be

provided with weld overlay when

specified weld overlay for the

valve.

Remark: The flare design only

considers normal liquid carry

over and hence not designed for

bulk liquid.

Template No: FEED-HX-REP-003 Rev.01 Page 22 of 26

from Incidents (LFI) Tool

Remarks

It is covered in DEP-31.38.11.01

and GU-706 for Stress analysis

If the MOC of the dead leg which

will be created due to demolition

is CRA than there is no issue.

However if the MOC which will

be created due to demolition is

Carbon Steel than the same

needs to be discussed with Asset

to whether the demoliton of the

dead leg shall also be part of the

project scope or will be taken by

the Asset separately.

Template No: FEED-HX-REP-003 Rev.01 Page 23 of 26

from Incidents (LFI) Tool

Remarks

Template No: FEED-HX-REP-003 Rev.01 Page 24 of 26

from Incidents (LFI) Tool

Remarks

able to confirm that they that are suitable, appropriate and robust to manage that the reoccurrence of the potential incidents are eliminated.

Date:

Date:

Date:

Date:

Date:

Date:

Date:

Date:

Date:

Date:

Date:

Date:

Date:

Template No: FEED-HX-REP-003 Rev.01 Page 25 of 26

from Incidents (LFI) Tool

Remarks

Date:

Date:

Date:

Date:

Template No: FEED-HX-REP-003 Rev.01 Page 26 of 26

You might also like

- 220801dist13009 Exde03 43 PDFDocument43 pages220801dist13009 Exde03 43 PDFBayu JatmikoNo ratings yet

- Papua LNG Upstream Project: Instrumentation Control and Safeguarding Systems Design BasisDocument46 pagesPapua LNG Upstream Project: Instrumentation Control and Safeguarding Systems Design BasisSangaranNo ratings yet

- KG98 2 ONT OMF in 7861 DS 150 R3 Level Transmitter Code 1Document31 pagesKG98 2 ONT OMF in 7861 DS 150 R3 Level Transmitter Code 1Madheswaran DharmapuriNo ratings yet

- Aogc 036 Sa DSC 001 (B1)Document9 pagesAogc 036 Sa DSC 001 (B1)amini_mohiNo ratings yet

- GNC TPEF GEN in 7771 00015 A03 FG Systems SpecificationDocument60 pagesGNC TPEF GEN in 7771 00015 A03 FG Systems SpecificationOkoro KennethNo ratings yet

- SNBP-EPC-00-INS-DBS-001 Rev.B - Instrument Telecomunication Design BasisDocument19 pagesSNBP-EPC-00-INS-DBS-001 Rev.B - Instrument Telecomunication Design Basissugeng wahyudiNo ratings yet

- 305.icm-Ou-11.07 Programmable Logic ControllerDocument28 pages305.icm-Ou-11.07 Programmable Logic ControllerTpNo ratings yet

- PP in Ii 001Document15 pagesPP in Ii 001Dav EipNo ratings yet

- AR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFDocument6 pagesAR1810.00-PRO-LST-002 Rev00 CAUSE & EFFECT DIAGRAM OF TARFA#2 PDFYaakoubi FethiNo ratings yet

- SIL Methodology: A Methodology For SIL Verification in Accordance With IEC 61508 and IEC 61511 RequirementsDocument24 pagesSIL Methodology: A Methodology For SIL Verification in Accordance With IEC 61508 and IEC 61511 Requirementsmdfaheem786No ratings yet

- GFDP COM 52 TEL SP GE 006 Specification For PublicDocument24 pagesGFDP COM 52 TEL SP GE 006 Specification For PublicHaider HassanNo ratings yet

- B 125674001 PaDocument18 pagesB 125674001 Pazizu1234No ratings yet

- Amnit in 300 Wir 1003 Ded C Junction Box Schedule AppDocument46 pagesAmnit in 300 Wir 1003 Ded C Junction Box Schedule Appzaraki kenpachiNo ratings yet

- SPD0055ERN: Process Design Manual Alarp Procedure (As Low As Reasonably Practicable)Document16 pagesSPD0055ERN: Process Design Manual Alarp Procedure (As Low As Reasonably Practicable)chuntao fengNo ratings yet

- Radar Level Transmitter Instrument Data SheetDocument46 pagesRadar Level Transmitter Instrument Data Sheetono_czeNo ratings yet

- Site Acceptance Test Procedure for Oily Water Treatment Package OptimizedDocument14 pagesSite Acceptance Test Procedure for Oily Water Treatment Package OptimizedSachin PatilNo ratings yet

- 05-1 - EPC-GE-AEI-P-XR-00001 Process Emergency Shutdown Logic Diagram, Hierachy - Rev D4 PDFDocument2 pages05-1 - EPC-GE-AEI-P-XR-00001 Process Emergency Shutdown Logic Diagram, Hierachy - Rev D4 PDFCường Đặng ViếtNo ratings yet

- Shell Backup Power InstallationDocument13 pagesShell Backup Power InstallationAzeta RobertNo ratings yet

- Project One - Ecr Epcm Services Contract: Level Instruments DatasheetsDocument105 pagesProject One - Ecr Epcm Services Contract: Level Instruments DatasheetsKhan Akhtar HusainNo ratings yet

- ECA-00-PCS-PHI-0002 - Rev3-PLC PACKAGE SYSTEMS ROTATING MACHINERY PHILOSOPHYDocument13 pagesECA-00-PCS-PHI-0002 - Rev3-PLC PACKAGE SYSTEMS ROTATING MACHINERY PHILOSOPHYhcsharma1967No ratings yet

- Hydraulic Flushing ProcedureDocument6 pagesHydraulic Flushing ProcedureIsaalexNo ratings yet

- Vendor Data Book For Helideck Fixed Foam System (ABS Approved)Document53 pagesVendor Data Book For Helideck Fixed Foam System (ABS Approved)VAN VIET NGONo ratings yet

- BL-22-IG-262 - 0 - Alarm Protective Equipment ManagementDocument12 pagesBL-22-IG-262 - 0 - Alarm Protective Equipment ManagementAanantharaj LourdesamyNo ratings yet

- Bahregan Crude Oil Storage Tanks DCS SpecificationDocument29 pagesBahregan Crude Oil Storage Tanks DCS SpecificationFatholla SalehiNo ratings yet

- Control ValvesDocument2 pagesControl ValvesJuan Pablo MarvalNo ratings yet

- Org Arw Imt SPR 00001 - 4.0 - 1Document22 pagesOrg Arw Imt SPR 00001 - 4.0 - 1abha singhNo ratings yet

- Instrument Support and Installation DetailsDocument44 pagesInstrument Support and Installation Detailsanil pkNo ratings yet

- DWG RegisterDocument7 pagesDWG RegisterPrasadNo ratings yet

- C-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterDocument50 pagesC-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterMidha NeerNo ratings yet

- Security Level 2 Annexure(1) TEG1-1135-002Sheet 2 of 15Document15 pagesSecurity Level 2 Annexure(1) TEG1-1135-002Sheet 2 of 15sushilNo ratings yet

- TW Sizing Guide PDFDocument19 pagesTW Sizing Guide PDFSreejesh SundaresanNo ratings yet

- Hassi Messaoud Peripheral Fields Development Front End Engineering and Design (Feed)Document14 pagesHassi Messaoud Peripheral Fields Development Front End Engineering and Design (Feed)toudja sidaliNo ratings yet

- MKP-05-En-IC-SPC-005 Specification For Fire & Gas DetectorDocument12 pagesMKP-05-En-IC-SPC-005 Specification For Fire & Gas Detectorsugeng wahyudiNo ratings yet

- Pc12002-393-03-Sp-003, Rev 1 Specification For F&G DetectorsDocument34 pagesPc12002-393-03-Sp-003, Rev 1 Specification For F&G DetectorsHamza ShujaNo ratings yet

- NPT10111-PE-V-GA-621101-004 PLC Panel General Arrangement Drawings (ETP Area) Rev-01 PDFDocument4 pagesNPT10111-PE-V-GA-621101-004 PLC Panel General Arrangement Drawings (ETP Area) Rev-01 PDFkkumar_717405No ratings yet

- GMS-SPT-013 Pneumatic On-Off Valve and Motor Operated Valve Specification - Rev 1Document20 pagesGMS-SPT-013 Pneumatic On-Off Valve and Motor Operated Valve Specification - Rev 1prihartono_diasNo ratings yet

- Electrical Tray InstallationDocument4 pagesElectrical Tray InstallationClinton OlivierNo ratings yet

- BAP-00-80-PE-0203-R R.2 Review and Approval Procedure - ASF 18.03.14Document12 pagesBAP-00-80-PE-0203-R R.2 Review and Approval Procedure - ASF 18.03.14Jan Richardo GultomNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument13 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNo ratings yet

- National Oil Corporation Instrument Cable SpecDocument29 pagesNational Oil Corporation Instrument Cable SpecRochdi SahliNo ratings yet

- 01 Mono Flange ValvesDocument6 pages01 Mono Flange ValvesShwet KumarNo ratings yet

- National Oil Corporation: Rev Date Description Checked ApprovedDocument22 pagesNational Oil Corporation: Rev Date Description Checked ApprovedRochdi Sahli100% (1)

- Fire Gas Detection Philosophy 1641849168Document44 pagesFire Gas Detection Philosophy 1641849168f5crdfwhg9No ratings yet

- Npe VD Mhe Dia Axjk001 0001 r6 Cause & Effect Diagram APDocument7 pagesNpe VD Mhe Dia Axjk001 0001 r6 Cause & Effect Diagram APJan Richardo GultomNo ratings yet

- 7650-8550-DS-500-6211 DoneDocument11 pages7650-8550-DS-500-6211 DoneKhan Akhtar HusainNo ratings yet

- Control Loop Diagram PDFDocument227 pagesControl Loop Diagram PDFAhmad RabieNo ratings yet

- IPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ADocument3 pagesIPS-MBD21907-In-516B-Data Sheet of On Off Valve-Flush Bottom (Y Type) - ANikhil KarkeraNo ratings yet

- s10332300-3008 - 0 Tank Gauging SystemsDocument23 pagess10332300-3008 - 0 Tank Gauging Systemsappril26No ratings yet

- CCTV PDFDocument29 pagesCCTV PDFIovi DanielNo ratings yet

- SNBP-EPC-00-INS-RFQ-012 - RFQ For Flow Transmitter DP TypeDocument20 pagesSNBP-EPC-00-INS-RFQ-012 - RFQ For Flow Transmitter DP Typesugeng wahyudiNo ratings yet

- F&G Cause and Effect Matrix for Salalah Methanol ProjectDocument6 pagesF&G Cause and Effect Matrix for Salalah Methanol ProjectpavanNo ratings yet

- B224-125-16-51-VDR-7207 Vendor Data Requirements For InstrumentationDocument4 pagesB224-125-16-51-VDR-7207 Vendor Data Requirements For InstrumentationmanuneedhiNo ratings yet

- TRHT SP Te 86 Oo 203 - 0Document28 pagesTRHT SP Te 86 Oo 203 - 0belhaska100% (1)

- Fdocuments - in - Hook Up Flow Aramco PDFDocument14 pagesFdocuments - in - Hook Up Flow Aramco PDFjosejohn1No ratings yet

- Hook Ups PDFDocument8 pagesHook Ups PDFAnonymous d7Jde8No ratings yet

- Ictict517 Ae Pro 1of3Document18 pagesIctict517 Ae Pro 1of3Ashutosh MaharajNo ratings yet

- Ictict517 Ae Pro 2of3Document19 pagesIctict517 Ae Pro 2of3Ashutosh MaharajNo ratings yet

- Fundamentals of Software Development CourseDocument8 pagesFundamentals of Software Development CourseSocialNo ratings yet

- Introduction to Software Engineering Course CodeDocument9 pagesIntroduction to Software Engineering Course CodeZaidali Burmawala0% (1)

- Example Ato Operations ManualDocument12 pagesExample Ato Operations ManualChleyde Danguilan100% (1)

- Heat Tran BuriedDocument3 pagesHeat Tran BuriedQayyum KhanNo ratings yet

- ColumnDocument10 pagesColumnQayyum KhanNo ratings yet

- Al Huwaisah GGP Pipeline Project Hydraulic Report: RevisionDocument49 pagesAl Huwaisah GGP Pipeline Project Hydraulic Report: RevisionQayyum KhanNo ratings yet

- BN-DG-C01J Plant Layout - Storage Tanks: Home Services Software Library ContactDocument17 pagesBN-DG-C01J Plant Layout - Storage Tanks: Home Services Software Library ContactQayyum KhanNo ratings yet

- Qayyum CoverDocument1 pageQayyum CoverQayyum KhanNo ratings yet

- Appendix - III STATEMENT OF FITNESSDocument9 pagesAppendix - III STATEMENT OF FITNESSQayyum KhanNo ratings yet

- ASBUILT - Rev.04 - Scehmatic & Operating Diagram For YP-13&YP-16Document5 pagesASBUILT - Rev.04 - Scehmatic & Operating Diagram For YP-13&YP-16Qayyum KhanNo ratings yet

- Attachment - A3 - Ver - 2 4-21wellDocument1 pageAttachment - A3 - Ver - 2 4-21wellQayyum KhanNo ratings yet

- Flow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Document1 pageFlow Line and Well Hook-Up Authorisation (GD) : (Well SRS - V48A)Qayyum KhanNo ratings yet

- Fakhr-9 (A3)Document11 pagesFakhr-9 (A3)Qayyum KhanNo ratings yet

- Attachment - A3 - Ver - 2 4-21wellDocument1 pageAttachment - A3 - Ver - 2 4-21wellQayyum KhanNo ratings yet

- Forcast-09.02.20 To13.02.20 Process DepartmentDocument4 pagesForcast-09.02.20 To13.02.20 Process DepartmentQayyum KhanNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentQayyum KhanNo ratings yet

- Sizing CalcDocument7 pagesSizing CalcQayyum KhanNo ratings yet

- C&E-Yibal WHCPDocument2 pagesC&E-Yibal WHCPQayyum KhanNo ratings yet

- Pump in ParellDocument2 pagesPump in ParellQayyum KhanNo ratings yet

- ASBUILT - Rev.04 - Scehmatic & Operating Diagram For YP-13&YP-16Document5 pagesASBUILT - Rev.04 - Scehmatic & Operating Diagram For YP-13&YP-16Qayyum KhanNo ratings yet

- Han 13 Pdfeed PX 2365 00001 0004 Noy000hn0130 03Document1 pageHan 13 Pdfeed PX 2365 00001 0004 Noy000hn0130 03Qayyum KhanNo ratings yet

- Forcast-12.01.20 To 16.01.20 - Process DepartmentDocument4 pagesForcast-12.01.20 To 16.01.20 - Process DepartmentQayyum KhanNo ratings yet

- Compostion 90% 22gorDocument1 pageCompostion 90% 22gorQayyum KhanNo ratings yet

- NitrogenDocument1 pageNitrogenQayyum KhanNo ratings yet

- Accumulators: Functions & Effects Accumulator Volume Calculation 1 2Document30 pagesAccumulators: Functions & Effects Accumulator Volume Calculation 1 2Carlos LlanquiNo ratings yet

- NitrogenDocument1 pageNitrogenQayyum KhanNo ratings yet

- Relief and Flare Sytem Design (Autosaved)Document51 pagesRelief and Flare Sytem Design (Autosaved)Qayyum KhanNo ratings yet

- SafetyDocument9 pagesSafetyQayyum KhanNo ratings yet

- PDO Discipline-Document Type MatrixDocument10 pagesPDO Discipline-Document Type MatrixQayyum KhanNo ratings yet

- Production TrunklineDocument5 pagesProduction TrunklineQayyum KhanNo ratings yet

- On Hore and Off ShoreDocument7 pagesOn Hore and Off ShoreQayyum KhanNo ratings yet

- Relief and Flare Sytem Design (Autosaved)Document51 pagesRelief and Flare Sytem Design (Autosaved)Qayyum KhanNo ratings yet

- Trisomy 21 An Understanding of The DiseaseDocument28 pagesTrisomy 21 An Understanding of The DiseaseHannahjane YbanezNo ratings yet

- Assessment Cover Sheet: BSB52415 Diploma of Marketing and Communication Student NameDocument11 pagesAssessment Cover Sheet: BSB52415 Diploma of Marketing and Communication Student NameChun Jiang0% (1)

- Binh Dien Fertilizer Joint Stock CompanyDocument11 pagesBinh Dien Fertilizer Joint Stock CompanyHuynh Minh Quan B2014431No ratings yet

- PW 160-Taliban Fragmentation Fact Fiction and Future-PwDocument28 pagesPW 160-Taliban Fragmentation Fact Fiction and Future-Pwrickyricardo1922No ratings yet

- OYO Case Study SolutionDocument4 pagesOYO Case Study SolutionVIKASH GARGNo ratings yet

- Analisis Kinerja Turbin Uap Unit 3 BerdasarkanDocument12 pagesAnalisis Kinerja Turbin Uap Unit 3 BerdasarkanfebriansyahNo ratings yet

- Nursing Care Plans for ChildrenDocument4 pagesNursing Care Plans for ChildrenAlexander Rodriguez OlipasNo ratings yet

- COSMETOLOGY-9 Q1 W3 Mod2Document15 pagesCOSMETOLOGY-9 Q1 W3 Mod2Christian Elliot DuatinNo ratings yet

- Quality Control and Quality AssuranceDocument7 pagesQuality Control and Quality AssuranceMoeen Khan Risaldar100% (1)

- Articulos 2022-2Document11 pagesArticulos 2022-2Nilser Enrique Valle HernandezNo ratings yet

- Families of Carbon Compounds: Functional Groups, Intermolecular Forces, & Infrared (IR) SpectrosDocument79 pagesFamilies of Carbon Compounds: Functional Groups, Intermolecular Forces, & Infrared (IR) SpectrosRuryKharismaMuzaqieNo ratings yet

- Examining The Structural Relationships of Destination Image, Tourist Satisfaction PDFDocument13 pagesExamining The Structural Relationships of Destination Image, Tourist Satisfaction PDFAndreea JecuNo ratings yet

- Cell Organelles 11Document32 pagesCell Organelles 11Mamalumpong NnekaNo ratings yet

- Nord Stage Factory Patches v3 v4 v5Document18 pagesNord Stage Factory Patches v3 v4 v5Danilo Giuliani DobermannNo ratings yet

- F 83179Document6 pagesF 83179pcmfilhoNo ratings yet

- Yingli CS Centrale-Poggiorsini EN 062011-1 PDFDocument2 pagesYingli CS Centrale-Poggiorsini EN 062011-1 PDFZvonko Trajkov100% (1)

- James M. Buchanan - Why I, Too, Am Not A Conservative PDFDocument121 pagesJames M. Buchanan - Why I, Too, Am Not A Conservative PDFHeitor Berbigier Bandas100% (2)

- Chapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Document80 pagesChapter (3) Simple Stresses in Machine Parts: Design of Machine Elements I (ME-41031)Dr. Aung Ko LattNo ratings yet

- (Culture and History of The Ancient Near East 65) Leslie Anne Warden - Pottery and Economy in Old Kingdom Egypt-Brill Academic Publishers (2014)Document343 pages(Culture and History of The Ancient Near East 65) Leslie Anne Warden - Pottery and Economy in Old Kingdom Egypt-Brill Academic Publishers (2014)HugoBotello100% (1)

- Goethe Zertifikat b1 HorenDocument2 pagesGoethe Zertifikat b1 HorenLevent75% (4)

- IM PS Fashion-Business-Digital-Communication-And-Media 3Y Course Pathway MI 04Document7 pagesIM PS Fashion-Business-Digital-Communication-And-Media 3Y Course Pathway MI 04oliwia bujalskaNo ratings yet

- Labconco-3905503 Rev e Purifier Hepa Filtered and Class I Filtered Enclosures User ManualDocument77 pagesLabconco-3905503 Rev e Purifier Hepa Filtered and Class I Filtered Enclosures User ManualCalixto GrajalesNo ratings yet

- Carbon Emission and Battery Monitoring SystemDocument17 pagesCarbon Emission and Battery Monitoring SystemIJRASETPublicationsNo ratings yet

- The Historical Foundations of Law. Harold BermanDocument13 pagesThe Historical Foundations of Law. Harold BermanespinasdorsalesNo ratings yet

- Remote Control Panel (RCP) User'S GuideDocument13 pagesRemote Control Panel (RCP) User'S GuideAdrian PuscasNo ratings yet

- Powerful and Durable JCB JS200 Tracked ExcavatorDocument6 pagesPowerful and Durable JCB JS200 Tracked ExcavatorMB Viorel100% (1)

- Basic Electronic ComponentsDocument28 pagesBasic Electronic ComponentsJafar ShaikhNo ratings yet

- Analysis On Forgery Patterns For GPS Civil Spoofing SignalsDocument4 pagesAnalysis On Forgery Patterns For GPS Civil Spoofing SignalsMadhu KrishnaNo ratings yet

- Manjit Thapp ResearchDocument24 pagesManjit Thapp ResearchDough RodasNo ratings yet

- Pediatrics Study ScheduleDocument2 pagesPediatrics Study ScheduleNatnaelNo ratings yet