Professional Documents

Culture Documents

AWP - (H&V) - Installation Guide - AWP - AU PDF

AWP - (H&V) - Installation Guide - AWP - AU PDF

Uploaded by

JL AOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AWP - (H&V) - Installation Guide - AWP - AU PDF

AWP - (H&V) - Installation Guide - AWP - AU PDF

Uploaded by

JL ACopyright:

Available Formats

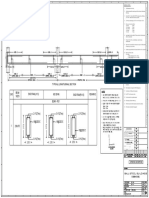

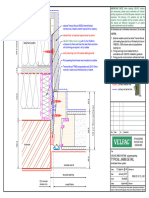

Insulated Roof Installation Note: Ensure steelwork is suitable for panels and is within tolerance e f Min 50mm

& Wall Panels Guide Min. bearing face for vertical joint steelwork is 140mm Install main Note: Some installations Install 2 main

Min. bearing face for intermediate support is 50mm fasteners through may require additional fasteners at

the male joint at

b each panel end into

fasteners depending on

wind loadings/

intermediate

support position

Fit panel bearers, located maximum vertical rail location specification. Check (minimum)

150mm from panel ends and at project specific details

maximum 1500mm centres. Ensure

that bearers are

accurately lined

and levelled

h

Lower the next panel (P2) into position

2 P1 ensuring that the factory applied weather

seal is compressed and that the AWP

1 filler remains in position. Install main

fasteners as per item

e and f

d P2

a c Locate first panel (P1) on

panel bearers ensuring panel

A VJ2 EPDM bubble gasket is required at each is evenly spaced and

Line, level and fix drip flashing vertical panel joint to provide an air seal. Apply gasket correctly positioned between

using low profile fasteners. Joints

March 2014

to the vertical steel member, ensure that it overlaps vertical joint centres

KS1000 AWP Wall in the drip flashing to incorporate the vertical leg of the drip flashing. Ensure the vertical

Horizontally Laid Continuous run

of 6 x 4mm

butyl or gun

150mm overlap or butt straps

sealed with two runs of

steel face is continuous, cover flashings required 3 P1

where gap is greater than 20mm

grade sealant gun-grade sealant

k g

Lower the preformed corner panel (C2) into Fit AWP filler at panel

l position ensuring that the factory applied ends, and run a

weather seal is compressed and that the gun-grade air seal

The gap between the panel ends

AWP filler remains in position. Install main across male joint

is to be filled with PIR insulation

fasteners through the male joint

Note: Panels can be installed in either a tiered or coursed board to a depth to suit the top

sequence. A number of base details are available, see hat section, ensure that continuity

Kingspan standard construction details. Visually check of insulation is achieved by filling

Components internal liner joint to ensure panels are joined fully. Check

panel cover width module as works progress to ensure

any gaps with fire rated canister

applied insulation

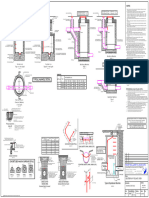

p Run a gun-grade

air seal across

male joint

KS1000 AWP Wall Panel

“creep” does not occur, particularly important when Incorporate a butt

windows are incorporated into the elevation P2 strap into the top Factory

AWP filler at

every horizontal

hat joint, sealing applied panel joint

Primary / 6x4mm Galvanised Top Top Hat weather seal

Main Fastener Butyl Angle Hat Insert with two runs of

Sealant Ledger gun-grade sealant

C2

5 P1

P2

o

Butt Strap

C1 Place the top hat in to the vertical joint,

aligned to the bottom of the panel. Fix through

the insulation infill to the vertical steel member at max.

AWP Panel

Low Profile PIR Filler Bearer 500mm centres, ensuring top hat is pulled tightly against panel to

Fastener Insulation P1

Fire-rated

Canister

4 ensure effective weather seal. Care must be taken not to overdrive

Foam

Base

m n

Channel

Recessed C1 Apply 6 x 4mm butyl sealant to

Washer Prior to installation of the

Gun-grade sealant internal legs of top hat (or to panel)

type - Selleys top hat apply gun-grade Note: When using WV (Wave)

Permasil 626 or sealant to horizontal

equivalent profile, use 9 x 6mm PVC

panel joint at panel ends,

VJ2 EPDM Bubble Gasket

i 140mm Air seal - VJ2

EPDM bubble in line with AWP filler

foam tape

This installation guide should be read in conjunction Locate the preformed gasket 95 x 10mm

with the ‘project specific’ design drawings and

method statements.

corner panel (C1) on

panel bearers and

j AWP filler 6

Gun-grade

Although this ‘installation guide’ is deemed to be install main fasteners Install air seal sealant

correct at the time of publication, Kingspan reserve through the male joint. and AWP Min 140mm Air seal -

the right to amend the information at any time in the The maximum filler at panel Air seal - gun-grade

gun-grade Air seal - VJ2

future. Installation Guides are available for the full unsupported leg is ends as EPDM bubble sealant to

sealant to male joint

range of Kingspan Insulated Roof, Wall and Facade 1000mm previous male joint gasket 95 x

Systems.

Please call Kingspan on: 40mm

q 10mm

AUS: +61 2 8889 3000 Push top hat AWP filler

NZ: +64 3 358 7536 insert into position

SEA: +65 6832 5021

6 x 4mm Site

butyl sealant applied PIR

Top hat and insert insulation

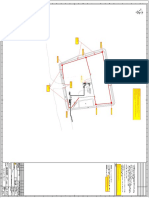

Insulated Roof Installation Note: Ensure steelwork is suitable for panels and is within tolerance ‘Z’ flashing with

continuous runs

& Wall Panels Guide Min. bearing face for intermediate support is 50mm of 6x4mm butyl

sealant

1

Run of gun-grade

air seal across

3

male joint

f

b Install min. 1 main fastener

through the male joint at the

Apply 6x4mm

butyl sealant or

top and bottom, and min. 2 at

intermediate locations

i

gun grade AWP filler at top of Fill gaps

sealant Note: Some installations may with FR

panel only, run a Galv cleader

require additional fasteners foam filler

gun-grade air seal angle by steel

depending on wind loadings/ 0.5mm coil contractor

across male joint

specification. Check project coated verge

ensuring it meets

specific details flashing with

previously installed air 150mm sealed

seal overlap or

Note: Position of AWP butt-straps

a 2

filler at top of panel

Line, level and fix drip

flashing using low c P2

profile fasteners. Joints Install internal P1

in the drip flashing to

incorporate 150mm

corner flashing

with low profile

k

overlap or butt straps fasteners Repeat processes

sealed with two runs of h to j to complete

gun-grade sealant elevation

d

March 2014

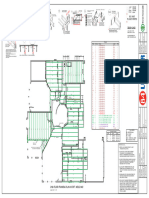

KS600/900/1000 AWP Wall Apply 6x4mm

Vertically Laid butyl sealant or

gun grade sealant

Direc

tion

of lay j

P1 Locate next panel (P2) into position

h ensuring that the factory applied

e Run a gun-grade air seal across

weather seal is compressed and

that the AWP filler remains in

male joint ensuring it meets position. Ensure panel is lined and

Locate first panel

Continuous base previously installed air seal levelled correctly in line with

(P1) ensuring it

support angle Do not apply AWP filler block adjacent panel and fix as per item f

Continuous run is correctly

of 6x4mm butyl positioned lined

Components sealant and levelled

KS1000 AWP Wall Panel Continuous

ledger angle

Pef rod sealed with Run of gun-grade air

silicone sealant seal across male joint

0.5mm coil coated

Primary / Low Profile 6x4mm Galvanised

base drip flashing

g

Main Fastener Fastener Butyl Angle At corner positions through

Sealant Ledger

fix min. 2 No. fasteners

of lay

tion into female panel joint at each

Direc

AWP Filler 4

horizontal rail location

Note: Fasteners to be suitably

5

located to ensure they are

covered by external corner

flashing

Fire-rated

Canister Panel Stack Joint

Secondary / PIR Foam

Stitching Insulation Continuous

Screw Cut end cover ledger angle

flashing

Gun-grade sealant

type - Selleys Permasil

l Continuous

galv support

626 or equivalent 0.5mm coil coated

Locate panel (P4) drip flashing sealed angle

in to position to face of panel

ensuring factory with 6x4mm butyl PIR block

applied weather

seal is compressed

sealant

KS1000 AWP

n

and AWP filler AWP joint filler and panel vertically laid Fix external corner

This installation guide should be read in conjunction P4 P3 remains in position silicone sealant to

male joint

flashing with stitching

with the ‘project specific’ design drawings and P2 screws at max. 450mm

method statements. P1 centres. Joints in the

corner flashing to

Although this ‘installation guide’ is deemed to be

0.5mm coil coated incorporate butt straps

correct at the time of publication, Kingspan reserve Fill gaps with corner flashing with sealed with two runs of

the right to amend the information at any time in FR foam filler 150mm sealed overlap gun-grade sealant

the future. Installation Guides are available for the or butt-straps. Sealed

with continuous run of

full range of Kingspan Insulated Roof, Wall and

Facade Systems. m 6x4mm butyl sealant

Please call Kingspan on:

AUS: +61 2 8889 3000 Di

re

ct

NZ: +64 3 358 7536 Di Internal flashing with

io

n

re of

SEA: +65 6832 5021 ct lay

io

n 150mm sealed overlap

of or butt-straps. Sealed of lay

lay lay tion

tion

of KS1000 with continuous run of Direc

Direc AWP panel 6x4mm butyl sealant

vertically laid

You might also like

- 18 SarthakPatel PortalFrameDocument1 page18 SarthakPatel PortalFramesarthak patel100% (1)

- MDC Patoq0202Document75 pagesMDC Patoq0202Ezekiel Dela Paz Bueno0% (1)

- Heijunka 29.3.19Document27 pagesHeijunka 29.3.19rohitNo ratings yet

- HDB SOR - Jul 2013Document260 pagesHDB SOR - Jul 2013kokuei100% (1)

- AWP Fold Out, Horz Vert FinalDocument2 pagesAWP Fold Out, Horz Vert FinalSrdjan KosoricNo ratings yet

- Kingspan Trapezoidal Roof KS1000 RW Installation Guide 012016 NZ enDocument2 pagesKingspan Trapezoidal Roof KS1000 RW Installation Guide 012016 NZ envincent_devine777dNo ratings yet

- AC Ducting Sky Air R32 STD - PCSID1913ADocument3 pagesAC Ducting Sky Air R32 STD - PCSID1913ARhani Dwi AnizarNo ratings yet

- BR124-04A Construction Section & SpecificationsDocument1 pageBR124-04A Construction Section & SpecificationsLaurentiu NaeNo ratings yet

- 3-Y12 (Thro) 2-Y12 (Thro) Y8@200C/C 2-Y12 (Thro) : End Span (L.H.S) Mid Span End Span (R.H.S) Remarks Beam Sizes S.NoDocument1 page3-Y12 (Thro) 2-Y12 (Thro) Y8@200C/C 2-Y12 (Thro) : End Span (L.H.S) Mid Span End Span (R.H.S) Remarks Beam Sizes S.NoParamesWaranNo ratings yet

- Do Not Scale, If in Doubt Please Contact Urban Glass For ClarityDocument1 pageDo Not Scale, If in Doubt Please Contact Urban Glass For ClarityErnie ErnieNo ratings yet

- Entrance of VIP: Service Path TarmacDocument5 pagesEntrance of VIP: Service Path TarmacfebousNo ratings yet

- Chi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsDocument1 pageChi Ti T D2/ D2 Details Chi Ti T Seno D1/ Seno D1 DetailsPhanLạcKhanhNo ratings yet

- Second DetailDocument1 pageSecond DetailAyad GamalNo ratings yet

- Manhole and Septic TankDocument1 pageManhole and Septic TankkevoroyalprinzNo ratings yet

- FootingDocument1 pageFootingSanjeev VermaNo ratings yet

- Kingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKDocument1 pageKingspan - Kingzip - Roof - KS500 1000 ZIP IP Installation Guide - 032017 - UKGeorgios PNo ratings yet

- Design Multistory Buildings Maxi - of It of - , ConDocument1 pageDesign Multistory Buildings Maxi - of It of - , ConjosNo ratings yet

- Do Not Scale, If in Doubt Please Contact Urban Glass For ClarityDocument1 pageDo Not Scale, If in Doubt Please Contact Urban Glass For ClarityErnie ErnieNo ratings yet

- Inclined Tower Level Unita - Block Wall SectionDocument1 pageInclined Tower Level Unita - Block Wall SectionHirushan MenukaNo ratings yet

- FT-BS EN-F-0604b Intubatt 3 Slab Edge Horizontal SealDocument1 pageFT-BS EN-F-0604b Intubatt 3 Slab Edge Horizontal SealTung ThanhNo ratings yet

- Mitsubishi VRF Interior Mascat Tavan Pefy P Vma E3Document3 pagesMitsubishi VRF Interior Mascat Tavan Pefy P Vma E3Ilie-valentinGanciarovNo ratings yet

- DIN-rail Mounted Fieldbus TerminatorsDocument4 pagesDIN-rail Mounted Fieldbus Terminatorsravi_fdNo ratings yet

- Dia. 13mm CWSP: R.C Wall/Block Wall Dia. 50mm Vent PipeDocument1 pageDia. 13mm CWSP: R.C Wall/Block Wall Dia. 50mm Vent PipeAmadi HenryNo ratings yet

- New House PlanDocument1 pageNew House PlanSsebowa AmosNo ratings yet

- 1.0 Air Conditioning and VRF DetailsDocument2 pages1.0 Air Conditioning and VRF DetailsfebousNo ratings yet

- Advanced Dual Pump Controller 3PHDocument16 pagesAdvanced Dual Pump Controller 3PHandrewNo ratings yet

- Sloping Side Elevation: Base Slab PlanDocument1 pageSloping Side Elevation: Base Slab PlanMwesigwa DaniNo ratings yet

- A Underground Distribution: Original Issue ApprovedDocument1 pageA Underground Distribution: Original Issue ApprovedP.R. CoatingsNo ratings yet

- Boundary Wall DrawingDocument1 pageBoundary Wall Drawingsandip wankhadeNo ratings yet

- Stairiser SR DatasheetsDocument2 pagesStairiser SR DatasheetsMuaad El AlamiNo ratings yet

- Typical Drainage DetailsDocument1 pageTypical Drainage DetailssuhailNo ratings yet

- Drainage Details Sheet 1Document1 pageDrainage Details Sheet 1Mohamed AdelNo ratings yet

- 250603DEDLD0130 EXDE00 01-With CommentsDocument1 page250603DEDLD0130 EXDE00 01-With CommentsMohammed HijaziNo ratings yet

- Roof and TrussesDocument1 pageRoof and TrussesAllan Orimba OdondiNo ratings yet

- General Notes:: DIVISION 4: Masonry DIVISION 7: Thermal & Moisture DIVISION 9: FinishesDocument5 pagesGeneral Notes:: DIVISION 4: Masonry DIVISION 7: Thermal & Moisture DIVISION 9: FinishesKarim TarekNo ratings yet

- T Proc Notices Notices 040 K Notice Doc 38357 961081229Document13 pagesT Proc Notices Notices 040 K Notice Doc 38357 961081229jweremaNo ratings yet

- H3AC3 English Installation GuideDocument1 pageH3AC3 English Installation Guidejmom18_647241209No ratings yet

- Escoramento de ValasDocument1 pageEscoramento de ValasPablo OliveiraNo ratings yet

- FLOOR 2AACAsdcfdfefwaswe2dcdcedDocument1 pageFLOOR 2AACAsdcfdfefwaswe2dcdcedKanak YadavNo ratings yet

- Manhole DetailsDocument1 pageManhole DetailsZacharul ShahNo ratings yet

- 10 - Staircase Reinforcement DetailsDocument1 page10 - Staircase Reinforcement DetailsJoseph DamianNo ratings yet

- 401-BD-T-02-20-5.14D-TW-SD-001 (L2.0-Sector-5.14d For Ref)Document1 page401-BD-T-02-20-5.14D-TW-SD-001 (L2.0-Sector-5.14d For Ref)Ravikiran SeshapuNo ratings yet

- Front Elevation 1:100 West Elevation 1:100: E E D D C C B B A ADocument1 pageFront Elevation 1:100 West Elevation 1:100: E E D D C C B B A AKamagara Roland AndrewNo ratings yet

- Leake Lane DDocument1 pageLeake Lane DJuan Carlos OlivasNo ratings yet

- 9946Z - 0657-SP-SL-DE-C-G77-450-P3 - Private Construction Details (Sheet 1 of 2)Document1 page9946Z - 0657-SP-SL-DE-C-G77-450-P3 - Private Construction Details (Sheet 1 of 2)jmdavies.isNo ratings yet

- Typical Enphase SLD 3ph ResiDocument1 pageTypical Enphase SLD 3ph Resielectromec technologyNo ratings yet

- 1036 22 Dryer PB 211 1 R1 PDFDocument1 page1036 22 Dryer PB 211 1 R1 PDFghansaNo ratings yet

- Installation Guide: Subject To Wind LoadingsDocument2 pagesInstallation Guide: Subject To Wind LoadingsGabi DanutNo ratings yet

- 2104-20 Manhole DetailsDocument1 page2104-20 Manhole DetailsJULIEN GEORGES NGUELE BALLANo ratings yet

- Yard Staircase: A C D E F I B G HDocument6 pagesYard Staircase: A C D E F I B G HJohn ObilloNo ratings yet

- UntitledDocument1 pageUntitledSteven SahaniNo ratings yet

- Plate 1Document1 pagePlate 1vivek mrNo ratings yet

- 7.2 Roof Plan 2Document1 page7.2 Roof Plan 2Peter ValentineNo ratings yet

- DTF Structural DrawingsDocument35 pagesDTF Structural Drawings宋海波No ratings yet

- Muloho A3 Page SizeDocument1 pageMuloho A3 Page SizeanzaniNo ratings yet

- C.H. - 0+465.5 Section No5Document1 pageC.H. - 0+465.5 Section No5Fran LuqueNo ratings yet

- MVTD GL 1600kg 1100mm 2PSide 1400x2400 Single EntryDocument1 pageMVTD GL 1600kg 1100mm 2PSide 1400x2400 Single Entryarticle searchNo ratings yet

- Clivet Fcu DC MotorDocument9 pagesClivet Fcu DC MotorMichael NguyễnNo ratings yet

- Door JambDocument1 pageDoor JambBasiaNo ratings yet

- C1866-101 - Drainage DetailsDocument1 pageC1866-101 - Drainage DetailsPaqui MorentNo ratings yet

- K 2882T InstallDocument1 pageK 2882T InstallGagaHarsawanNo ratings yet

- Cascade - Encapsulation Collar - MuffDocument1 pageCascade - Encapsulation Collar - Muffjohn3791No ratings yet

- Commercial Building Construction Gantt ChartDocument1 pageCommercial Building Construction Gantt Chartteck yu100% (2)

- Greater Hyderabad Municipal Corporation: Building Permit Order Town Planning SectionDocument4 pagesGreater Hyderabad Municipal Corporation: Building Permit Order Town Planning SectionMadhusudan MadhuNo ratings yet

- PWA IAN 100 Rev 0 - Amendments To Section 6 Parts 4 5 6 8 of QCS 2014Document24 pagesPWA IAN 100 Rev 0 - Amendments To Section 6 Parts 4 5 6 8 of QCS 2014VJ QatarNo ratings yet

- Construction: Cubic Consultant &Document18 pagesConstruction: Cubic Consultant &Uthayakumar NitharsanNo ratings yet

- BPS-UTI-501-R.C.C.Road DetailDocument1 pageBPS-UTI-501-R.C.C.Road Detailsri projectssNo ratings yet

- A Comparative Study of BNBC 1993 and 2017 Provisions For The Design of Multistoried Steel Buildings in High Wind and High Seismic ZoneDocument7 pagesA Comparative Study of BNBC 1993 and 2017 Provisions For The Design of Multistoried Steel Buildings in High Wind and High Seismic ZoneTahmidur RahmanNo ratings yet

- Part 4Document143 pagesPart 4Shoaib Ul HassanNo ratings yet

- Amc Ssi PDFDocument308 pagesAmc Ssi PDFRinoy R BhagoraNo ratings yet

- Design Using Structural Fire Standards - SteelConstruction - InfoDocument7 pagesDesign Using Structural Fire Standards - SteelConstruction - InfooscavierNo ratings yet

- PMP Application Roles DescriptionDocument2 pagesPMP Application Roles DescriptionyasserosmanNo ratings yet

- Louis KahnDocument2 pagesLouis KahnadityaNo ratings yet

- SAFE'n'SOUND Fire and Soundproofing Insulation - TechdataDocument2 pagesSAFE'n'SOUND Fire and Soundproofing Insulation - TechdataMario MendozaNo ratings yet

- Autos Rejection Formate NazakatDocument4 pagesAutos Rejection Formate NazakatM ALI RajaNo ratings yet

- Design of Cantilever Slab As Per IS 456 2000Document2 pagesDesign of Cantilever Slab As Per IS 456 2000Ram LangheNo ratings yet

- Kindergarten in Guastalla / Mario Cucinella ArchitectsDocument13 pagesKindergarten in Guastalla / Mario Cucinella ArchitectsSaveanu RazvanNo ratings yet

- Earthen Buildings: Arthen UildingsDocument18 pagesEarthen Buildings: Arthen Uildingsbasabi12No ratings yet

- Brochure Offsite MMC Brochure 2020 DigitalDocument36 pagesBrochure Offsite MMC Brochure 2020 DigitalNeven Ahmed HassanNo ratings yet

- 13 - Chakravarthi and All 2019Document8 pages13 - Chakravarthi and All 2019Sahnoune Ben sahnouneNo ratings yet

- Typical Longitudinal Section of BeamDocument1 pageTypical Longitudinal Section of Beammanh hung leNo ratings yet

- Compression Members ProblemsDocument23 pagesCompression Members ProblemsReyNo ratings yet

- Glass Balustrade StaadDocument6 pagesGlass Balustrade StaadArya GopakumarNo ratings yet

- Ce 2352 - Design of Steel Structures: Department of Civil Engineering Sixth SemesterDocument13 pagesCe 2352 - Design of Steel Structures: Department of Civil Engineering Sixth SemesterRaguram pNo ratings yet

- Surface MiningDocument3 pagesSurface MiningDillan MasendaNo ratings yet

- Architecture (AR) III YearDocument17 pagesArchitecture (AR) III YearFiroj AnsariNo ratings yet

- Rapid Casting Solutions - A ReviewDocument24 pagesRapid Casting Solutions - A ReviewAlex BurdeNo ratings yet

- ARC 3513, Module No.4.4 Steel Structures, Flexural Steel MembersDocument107 pagesARC 3513, Module No.4.4 Steel Structures, Flexural Steel MembersShaikhaNo ratings yet