Professional Documents

Culture Documents

KASHForm03 Masonry

Uploaded by

jaqvenus0 ratings0% found this document useful (0 votes)

25 views4 pagesThis qualification is designed to equip individuals / trainees with operational skills in performing construction of brick and concrete block structure. It may apply to the following occupational titles: Mason To obtain this qualification, all the following units of competency must be achieved.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis qualification is designed to equip individuals / trainees with operational skills in performing construction of brick and concrete block structure. It may apply to the following occupational titles: Mason To obtain this qualification, all the following units of competency must be achieved.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views4 pagesKASHForm03 Masonry

Uploaded by

jaqvenusThis qualification is designed to equip individuals / trainees with operational skills in performing construction of brick and concrete block structure. It may apply to the following occupational titles: Mason To obtain this qualification, all the following units of competency must be achieved.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 4

KASH form 03

Curriculum Design

Course Title: Masonry

Qualification Level: NC II

Suggested Nominal Training Duration:

Course Description:

This qualification is designed to equip individuals/traineess with operational skills in

performing construction of brick and concrete block structure, installation of pre-cast

balluster/handrail and plastering of concrete wall surface. This qualification may apply to the

following occupational titles:

• Mason

To obtain this qualification, all the following units of competency must be achieved.

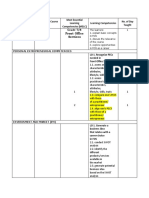

Unit of Nominal Assessment

Learning Outcome Methodology

Competency Duration Approach

1. Prepare LO1.Identify Materials Discussion Demonstration of

construction LO2.Requisition Practical Practical Skills

materials and Materials Exercise

tools LO3. Receive and Demonstration Direct Observation

inspect materials

Questioning

2. Observe LO1. Arrange upper and Direct Demonstration of

procedures, lining components, Observation Practical Skills

specifications stack separately, and

and manuals of position according to Questioning Direct Observation

instruction the flow of operation.

LO2. Mark size and fit of Questioning

upper and lining

components. Written

LO3. Identify and select

marking tools

LO4. Match and align pattern

templates with the

corresponding upper

and lining component.

LO5. Trace pattern for upper

and lining component

and mark with a single

stroke

LO6. Segregate and bundle

marked components

3. Perform LO1. Use required size of Direct Demonstration of

mensurations punchers to punch Observation Practical Skills

and center of eyelet

calculations marking Questioning Direct Observation

LO2. Keep straight array of

punch holes without Question

rough edges, complete

Unit of Nominal Assessment

Learning Outcome Methodology

Competency Duration Approach

and passes through the Written

entire material, without

damaging other

components

LO3. Insert fully the eyelet

into the hole as per

selected in the work

ticket

LO4. Spread inserted eyelet

on the reverse side of

the upper and flange

out evenly

LO5. Fasten the eyelet to the

material and flatten

without sharp edges

and in good shape and

condition

LO6. Use eyeleting tools

safely

4. Maintain tools LO1. Set up and adjust Direct Demonstration of

and equipment stamping machine Observation Practical Skills

dials, foil, temperature

and pressure Questioning Direct Observation

LO2. Receive and check work

bundle with the work Question

ticket and sequence the

flow of operation Written

LO3. Stamp upper and lining

components in

accordance with quality

standard

LO4. Maintain machine

5. Lay brick/ block LO1. Identify and explain

for structure the uses of tools and Lecture • Observation

equipment in and oral

brick/block laying. Demonstration questioning

LO2. Identify and explain

Project-based

the composition,

instruction

• Demonstration

properties, uses and and oral

types of masonry questioning

materials.

LO3. Enumerate and • Written test

explain the various

methods and

processes in

masonry

construction.

LO4. Identify and interpret

drawing symbols and

plans.

LO5. Perform trade

mathematics and

mensuration.

LO6. Perform 5S.

LO7. Identify and describe

safework practices

and first aid

regulations.

LO8. Perform safe work

practices and

respond to

Unit of Nominal Assessment

Learning Outcome Methodology

Competency Duration Approach

emergency

situations.

LO9. Install/dismantle

scaffold.

LO10. Install and mark

batterboards.

LO11. Install reinforcing

bar/dowel.

LO12. Lay brick/block.

LO13. Check for

plumbness/

squareness.

LO14. Construct/cast-in

place concrete

structures.

LO15. Check all

brick/block and

concrete works for

quality.

LO16. Clean work site and

maintain tools and

equipment.

6. Plaster LO1. Identify and explain

concrete/ the uses of tools and Lecture • Observation

masonry equipment in and oral

surface plastering concrete Demonstration questioning

surface.

Project-based

LO2. Identify and explain

instruction

• Demonstration

the materials used in and oral

plastering questioning

LO3. Identify and explain

the use of masonry • Written test

anchors, ties and

reinforcements.

LO4. Identify and interpret

drawing symbols and

plans.

LO5. Perform trade

mathematics and

mensuration.

LO6. Perform 5S.

LO7. Identify and describe

safety practices and

first aid regulations in

plastering.

LO8. Perform safe work

practices and

respond to

emergency

situations.

LO9. Install/dismantle

scaffold.

LO10. Establish plumbness

and squareness of

surface.

LO11. Plaster wall.

LO12. Check all plastered

wall/s.

Unit of Nominal Assessment

Learning Outcome Methodology

Competency Duration Approach

LO13. Clean work site and

maintain tools and

equipment.

7. Install pre-cast LO1. Identify and explain

baluster and the uses of tools and Lecture • Observation

handrails equipment in and oral

installing pre-cast Demonstration questioning

baluster/handrails.

Project-based

LO2. Identify and explain

instruction

• Demonstration

the materials used in and oral

installing pre-cast questioning

baluster/handrails.

LO3. Enumerate the • Written test

methods of installing

pre-cast baluster and

handrails.

LO4. Identify and interpret

drawing symbols and

plans.

LO5. Perform trade

mathematics and

mensuration.

LO6. Perform 5S.

LO7. Identify and describe

safe work practices

and first aid

regulations in

installing pre-cast

baluster and

handrails.

LO8. Perform safework

practices and respond

to emergency

situation.

LO9. Lay out and mark the

location of pre-cast

baluster/handrails.

LO10. Install baluster/

handrails.

LO11. Check all installed

baluster/handrails.

LO12. Clean work site and

maintain tools and

equipment.

You might also like

- Recruitment ProposalDocument5 pagesRecruitment Proposalanqutza50% (2)

- Trainees Rcord BookDocument22 pagesTrainees Rcord BookStephanie Joy Sablon100% (1)

- Competency Based CurriculumDocument17 pagesCompetency Based CurriculumMarc Gelacio100% (1)

- Leaders Standard WorkDocument28 pagesLeaders Standard WorknklawNo ratings yet

- Grade 11 SMAW - q2 w7Document6 pagesGrade 11 SMAW - q2 w7Jhon Vernie Reponte GambitoNo ratings yet

- CBC Eim NC IiDocument25 pagesCBC Eim NC IiChe Morales100% (2)

- Tile Setting - CBCDocument47 pagesTile Setting - CBCrommel patorito100% (3)

- Falcon Trading Guidance Mindset Blog Post PDFDocument4 pagesFalcon Trading Guidance Mindset Blog Post PDFMạnhCườngNo ratings yet

- Grade 11 SMAW - q2 w5Document7 pagesGrade 11 SMAW - q2 w5Jhon Vernie Reponte GambitoNo ratings yet

- CBC BPPDocument67 pagesCBC BPPglobal citi college100% (3)

- Agri Crops NC II MODULES OF INSTRUCTIONDocument39 pagesAgri Crops NC II MODULES OF INSTRUCTIONAndrea Pabalinas80% (10)

- Scheme of Work Construction Studies 5th YearDocument7 pagesScheme of Work Construction Studies 5th Yearapi-401919939No ratings yet

- Daily Lesson PlanDocument3 pagesDaily Lesson PlanKemArconadaNo ratings yet

- A Practical Guide to a Task-based Curriculum: Planning, Grammar Teaching and AssessmentFrom EverandA Practical Guide to a Task-based Curriculum: Planning, Grammar Teaching and AssessmentNo ratings yet

- Lesson 5 Freedom of The Human PersonDocument8 pagesLesson 5 Freedom of The Human PersonTotep Reyes75% (4)

- Oral-COm WK 1Document3 pagesOral-COm WK 1bernadette domoloanNo ratings yet

- DLL in Commercial Cooking 7-Week3Document4 pagesDLL in Commercial Cooking 7-Week3JeeNha Bonjoure100% (5)

- CBC Smaw NC IDocument71 pagesCBC Smaw NC Iglobal citi collegeNo ratings yet

- Annex A: Learning Outcomes Learning ResourcesDocument5 pagesAnnex A: Learning Outcomes Learning ResourcesAileen LigmayoNo ratings yet

- Ia - Smaw CGDocument4 pagesIa - Smaw CGArlyn AgustinNo ratings yet

- CC 103 - Computer Programming 2Document6 pagesCC 103 - Computer Programming 2jaspermallari1995No ratings yet

- Course Design and Module of Instruction Automotive Servicing NC IDocument40 pagesCourse Design and Module of Instruction Automotive Servicing NC IFe Marie JisonNo ratings yet

- Electricity CBCDocument101 pagesElectricity CBClipNo ratings yet

- KASHForm03 PainterDocument2 pagesKASHForm03 PainterjaqvenusNo ratings yet

- Grade 7 Shielded Metal Arc Welding (SMAW) Competency-Based CurriculumDocument38 pagesGrade 7 Shielded Metal Arc Welding (SMAW) Competency-Based CurriculumLorenzo InofreNo ratings yet

- Self Assessment InstrumentsDocument5 pagesSelf Assessment InstrumentsVicente NegreNo ratings yet

- Dressmaking VDocument31 pagesDressmaking VCamille EscolanoNo ratings yet

- Department Major Course Name Course Code Prerequisites Credit Hours CRH Course DescriptionDocument44 pagesDepartment Major Course Name Course Code Prerequisites Credit Hours CRH Course DescriptionSara Al-asmaryNo ratings yet

- CBC HRD NC IiDocument82 pagesCBC HRD NC Iiglobal citi collegeNo ratings yet

- Syllabus For Drawing 1 (Mechanical Drafting)Document6 pagesSyllabus For Drawing 1 (Mechanical Drafting)Sangguniang Barangay Malinao IlayaNo ratings yet

- Lab Report - Electric MachinesDocument10 pagesLab Report - Electric MachinesLUQMAN AMMARNo ratings yet

- Welding CBCDocument77 pagesWelding CBCpolly agkisNo ratings yet

- Agri Crops NC II Modules of InstructiondocxDocument40 pagesAgri Crops NC II Modules of InstructiondocxSalahudin KulnitaNo ratings yet

- October 09-13, 2023 (G11)Document3 pagesOctober 09-13, 2023 (G11)MJ Lim FalcisNo ratings yet

- Tle 7 - 8 - FisheryDocument17 pagesTle 7 - 8 - FisheryRey JavierNo ratings yet

- Scheme MTW 1st y STDocument18 pagesScheme MTW 1st y STapi-425678385No ratings yet

- CG - Electrical Installation and MaintenanceDocument10 pagesCG - Electrical Installation and MaintenanceEl G. Se ChengNo ratings yet

- Final Fos Exploratory 7 8Document6 pagesFinal Fos Exploratory 7 8Marilyn Lamigo BristolNo ratings yet

- Basic Six 1st Term I.C.T. Curriculum ( (In Progress)Document10 pagesBasic Six 1st Term I.C.T. Curriculum ( (In Progress)Owen OsagieNo ratings yet

- Traing PlanDocument3 pagesTraing PlanOrlando NajeraNo ratings yet

- Smaw DLP - DivisionDocument37 pagesSmaw DLP - DivisionJoel SoreñoNo ratings yet

- Supervise FinalDocument22 pagesSupervise FinalJkevin John Capada DardoNo ratings yet

- Me 323Document6 pagesMe 323pogipogNo ratings yet

- Session Plan Grade 11Document7 pagesSession Plan Grade 11franceearl.claron.studentNo ratings yet

- Aug.27 - 30,2019 - DLL NatoDocument3 pagesAug.27 - 30,2019 - DLL NatoJoanne CabangilNo ratings yet

- f1 Self Assessment Checklist DolienteDocument4 pagesf1 Self Assessment Checklist DolienteDoliente Valenzuela VivianNo ratings yet

- Afc SyllabusDocument23 pagesAfc SyllabusSaAd KhanNo ratings yet

- UntitledDocument56 pagesUntitledMICHELLE BITALASNo ratings yet

- Lab Report - Building TransportationDocument28 pagesLab Report - Building TransportationLUQMAN AMMARNo ratings yet

- ITE 292 OBE Syllabus (Edited)Document5 pagesITE 292 OBE Syllabus (Edited)MC CapsNo ratings yet

- College of Engineering, Computer Studies and Technology General Engineering Department San Sebastian College-Recoletos de CaviteDocument5 pagesCollege of Engineering, Computer Studies and Technology General Engineering Department San Sebastian College-Recoletos de CaviteMartin SantonilNo ratings yet

- Form 1.3 Summaries of Current Competencies Versus Required CompetenciesDocument5 pagesForm 1.3 Summaries of Current Competencies Versus Required CompetenciesRamir SalengaNo ratings yet

- CBC For ACP NCIIDocument63 pagesCBC For ACP NCIIjaspermallari1995No ratings yet

- Fernandez WHLP Week 1 - Tech DraftDocument3 pagesFernandez WHLP Week 1 - Tech DraftShan FernandezNo ratings yet

- COOKERYDocument146 pagesCOOKERYsafc.santoaugustinNo ratings yet

- General Surveying 1 SyllabusDocument5 pagesGeneral Surveying 1 SyllabusBin-najir DilangalenNo ratings yet

- Install and ConfigureDocument14 pagesInstall and ConfigureJeru MacNo ratings yet

- Structural Enginering LaboratoryDocument21 pagesStructural Enginering LaboratorysaifulsabdinNo ratings yet

- PW2 - Type of Fiber and Stripping Process SESI 1 2022 - 2023Document12 pagesPW2 - Type of Fiber and Stripping Process SESI 1 2022 - 2023Hari VarashanNo ratings yet

- Supervicing F1Document21 pagesSupervicing F1Jkevin John Capada DardoNo ratings yet

- Syllabus CSI104 Summer 2020Document12 pagesSyllabus CSI104 Summer 2020Chi TuyếtNo ratings yet

- Ia - Rac CGDocument3 pagesIa - Rac CGArlyn AgustinNo ratings yet

- Identify The Common Electrical Wire Splices An Joints in Their Uses Electrical Wire Splices An Joints in Their Uses Realize The Importance of Knowing These FormsDocument2 pagesIdentify The Common Electrical Wire Splices An Joints in Their Uses Electrical Wire Splices An Joints in Their Uses Realize The Importance of Knowing These FormsJudelyn Wabinga - SismarNo ratings yet

- Evolutionary Topology Optimization of Continuum Structures: Methods and ApplicationsFrom EverandEvolutionary Topology Optimization of Continuum Structures: Methods and ApplicationsNo ratings yet

- Semantic Web Technologies: Trends and Research in Ontology-based SystemsFrom EverandSemantic Web Technologies: Trends and Research in Ontology-based SystemsRating: 5 out of 5 stars5/5 (1)

- KASHForm03 PainterDocument2 pagesKASHForm03 PainterjaqvenusNo ratings yet

- KASHForm03 PainterDocument2 pagesKASHForm03 PainterjaqvenusNo ratings yet

- MicrosoftDocument12 pagesMicrosoftjaqvenusNo ratings yet

- Career Entry For Software Development - JavaDocument8 pagesCareer Entry For Software Development - JavajosefalarkaNo ratings yet

- Black+Box+Thinking+-+Matthew+SyedDocument16 pagesBlack+Box+Thinking+-+Matthew+Syedjasmine19jhsNo ratings yet

- The Matrix of Four Steps To Raising ConsciousnessDocument3 pagesThe Matrix of Four Steps To Raising ConsciousnessNolodichoNo ratings yet

- Item Analysis and ValidityDocument49 pagesItem Analysis and Validitygianr_6No ratings yet

- Research-G2-12-Gas-C-Chapter 1-3Document24 pagesResearch-G2-12-Gas-C-Chapter 1-3Nicole Ann BaroniaNo ratings yet

- Performance Rating BLANKDocument22 pagesPerformance Rating BLANKJanine Eunice dela CruzNo ratings yet

- RebuildYourVision PDFDocument5 pagesRebuildYourVision PDFjohnbyheartNo ratings yet

- Kuesioner EnglishDocument2 pagesKuesioner Englishels elisaaaNo ratings yet

- Perfect FashionDocument28 pagesPerfect FashionAsad Saimon100% (1)

- Hypodermic Needle TheoryDocument2 pagesHypodermic Needle TheoryAnonymous PSybP1Rq9No ratings yet

- Classification of Sources: Primary or Secondary: InstructionsDocument5 pagesClassification of Sources: Primary or Secondary: InstructionsEvone Mariz Tan AzagraNo ratings yet

- Synopsis Fides Et Ratio - JP II PDFDocument1 pageSynopsis Fides Et Ratio - JP II PDFJosh A.No ratings yet

- Imperialism Lesson PlanDocument3 pagesImperialism Lesson Planapi-229326247No ratings yet

- Part 1 ResearchDocument9 pagesPart 1 ResearchShania ImperialNo ratings yet

- Materi Bahasa Inggris XI WritingDocument2 pagesMateri Bahasa Inggris XI Writingarya sutaNo ratings yet

- 50 Ways To Bore, Irritate, or Confuse A Man - CollegeHumor PostDocument15 pages50 Ways To Bore, Irritate, or Confuse A Man - CollegeHumor PostdvtherionNo ratings yet

- Perdev Q2 Week 3 Las 1Document4 pagesPerdev Q2 Week 3 Las 1Demuel Tenio LumpaanNo ratings yet

- Tesl752 Siop FinalDocument7 pagesTesl752 Siop Finalapi-325199921No ratings yet

- Writing A Strong Tear ParagraphDocument2 pagesWriting A Strong Tear Paragraphapi-341009360No ratings yet

- Tara Westrate: 6100 Plainfield Avenue Kalamazoo, Mi 49048Document3 pagesTara Westrate: 6100 Plainfield Avenue Kalamazoo, Mi 49048api-253874188No ratings yet

- Levels of Government AssignmentDocument1 pageLevels of Government Assignmentapi-339133165No ratings yet

- Tee Ball Unit Using Sepep SampleDocument17 pagesTee Ball Unit Using Sepep Sampleapi-443558457No ratings yet

- Reading Skills - IIDocument37 pagesReading Skills - IIits me RaviNo ratings yet

- Person Based StructureDocument19 pagesPerson Based StructureAnisha ThakkarNo ratings yet

- Personality Development Reviewer PDFDocument6 pagesPersonality Development Reviewer PDFMikka RoqueNo ratings yet

- Assessment (Subjective / Objective Data) Nursing Diagnosis Planning Interventions RationaleDocument2 pagesAssessment (Subjective / Objective Data) Nursing Diagnosis Planning Interventions RationaleMaria Lourdes CruzNo ratings yet